Product Screenshots

Frequently Asked Questions

How does your testing engine works?

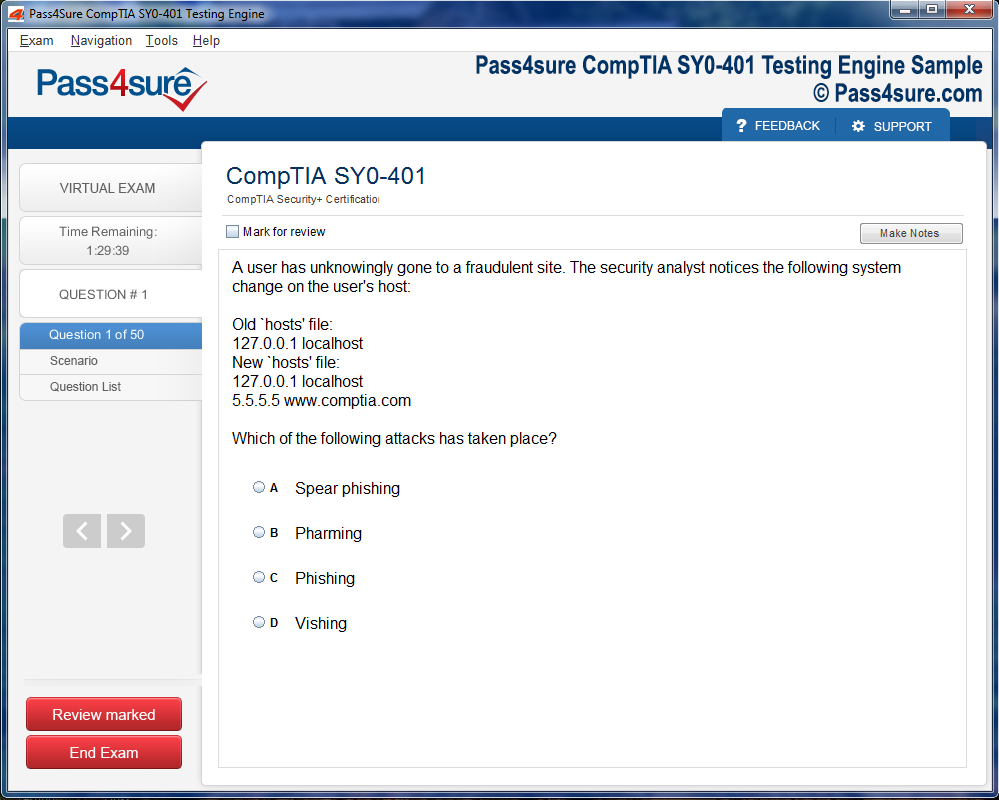

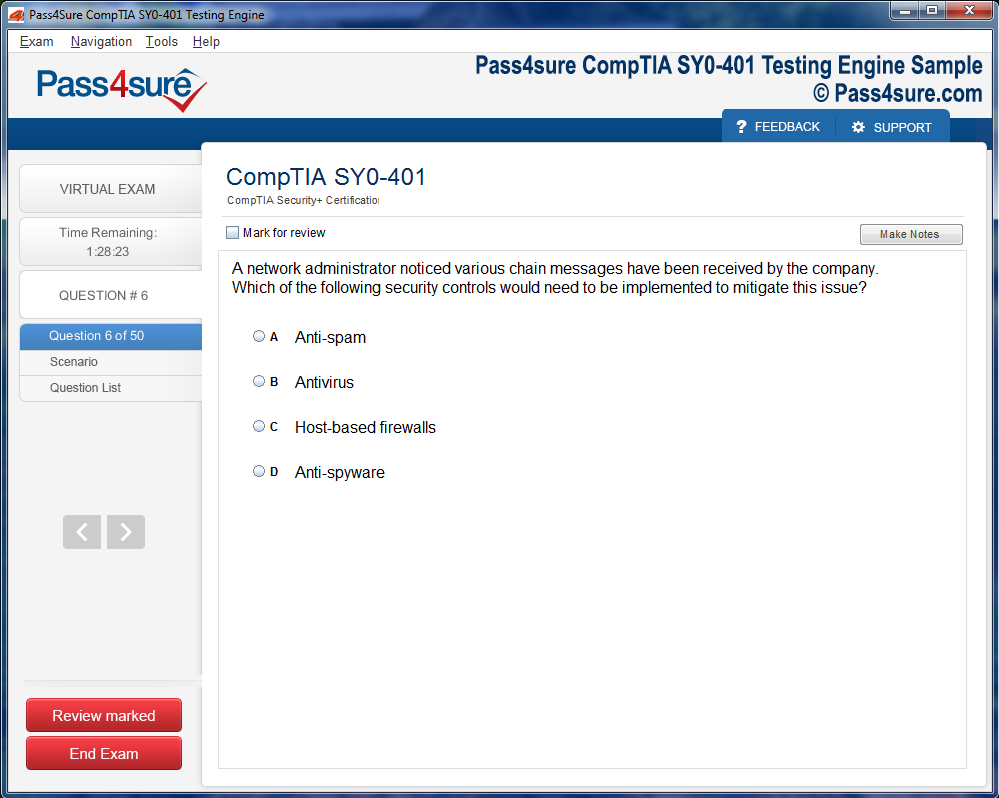

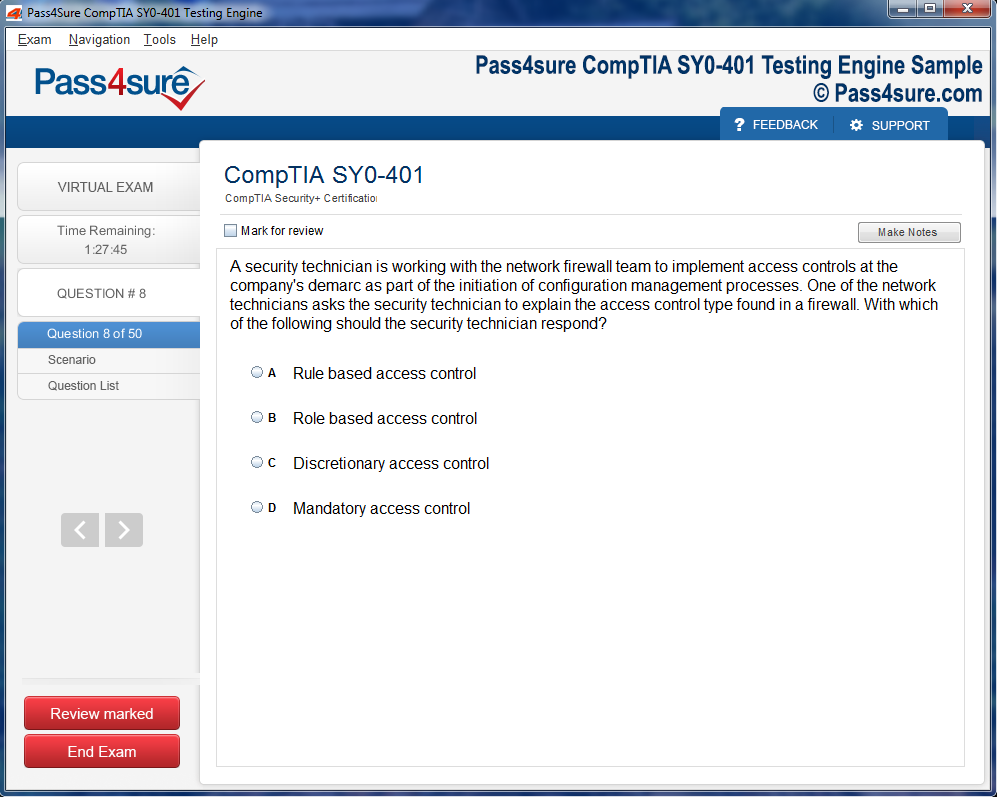

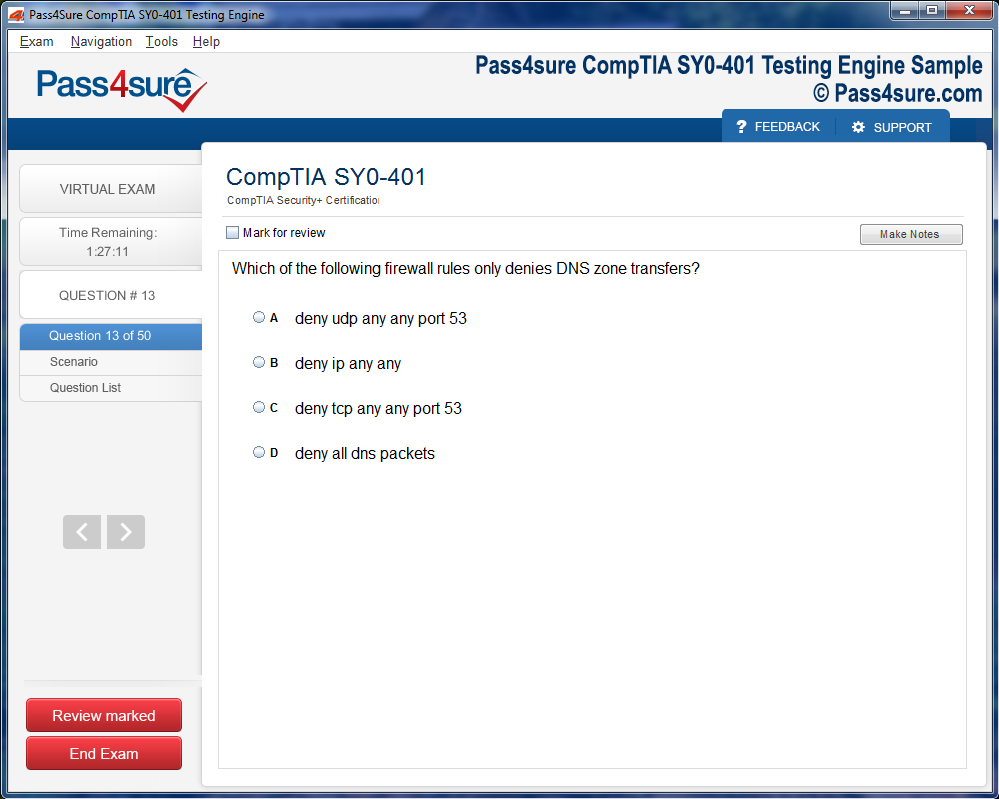

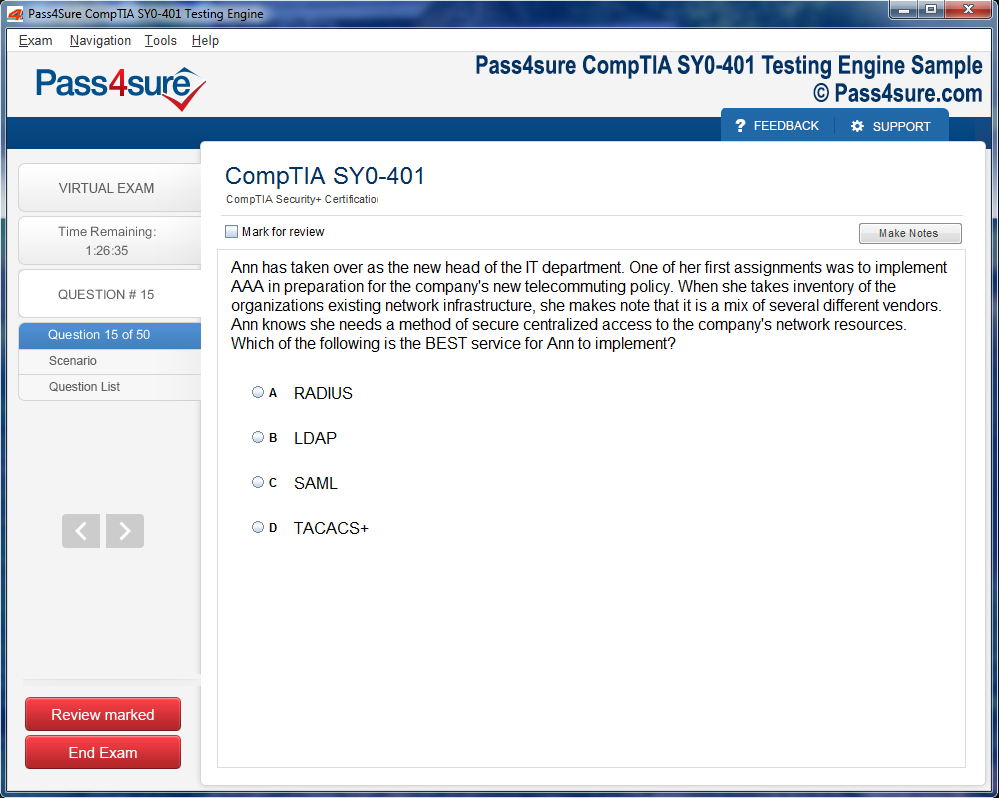

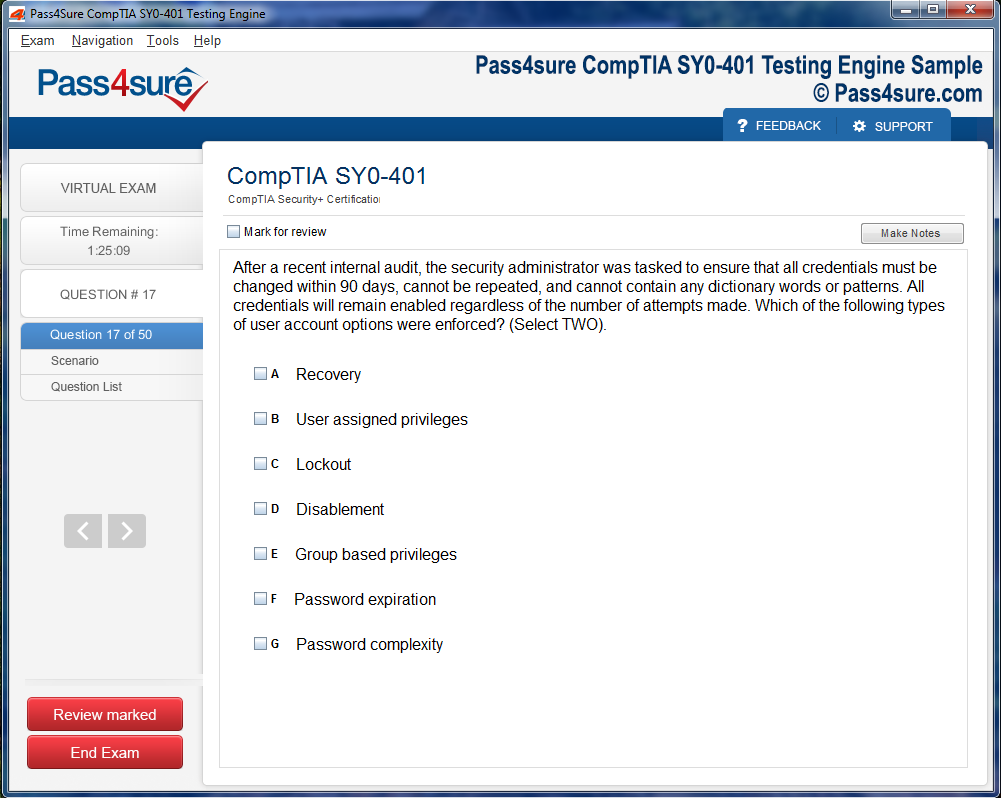

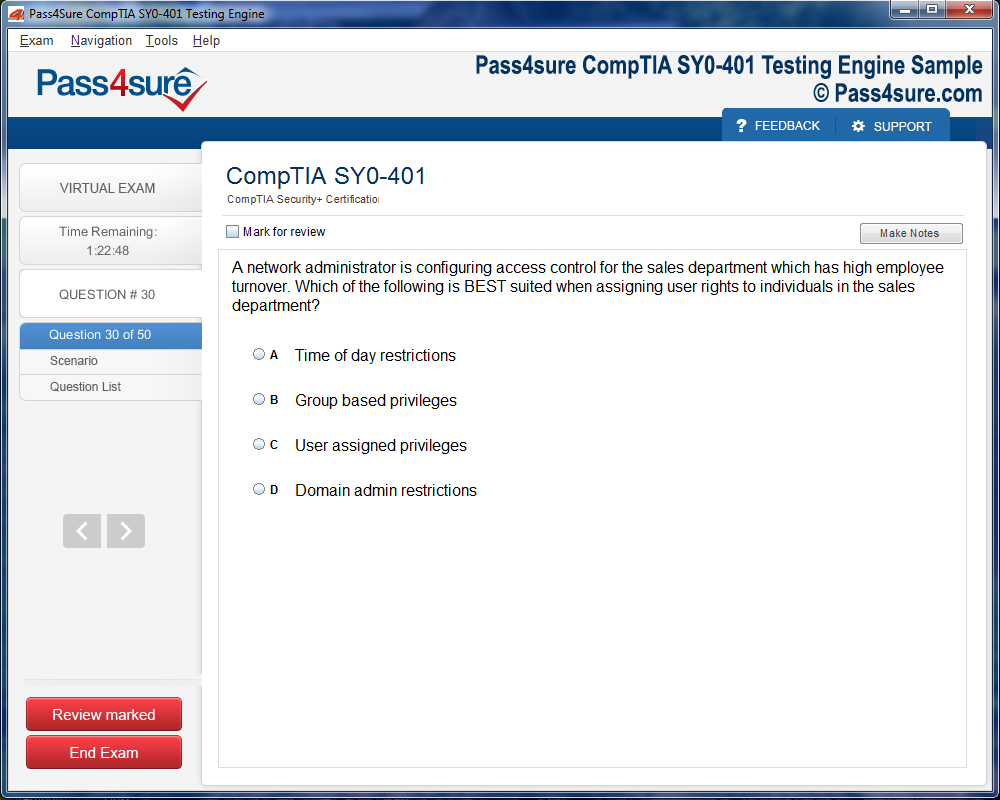

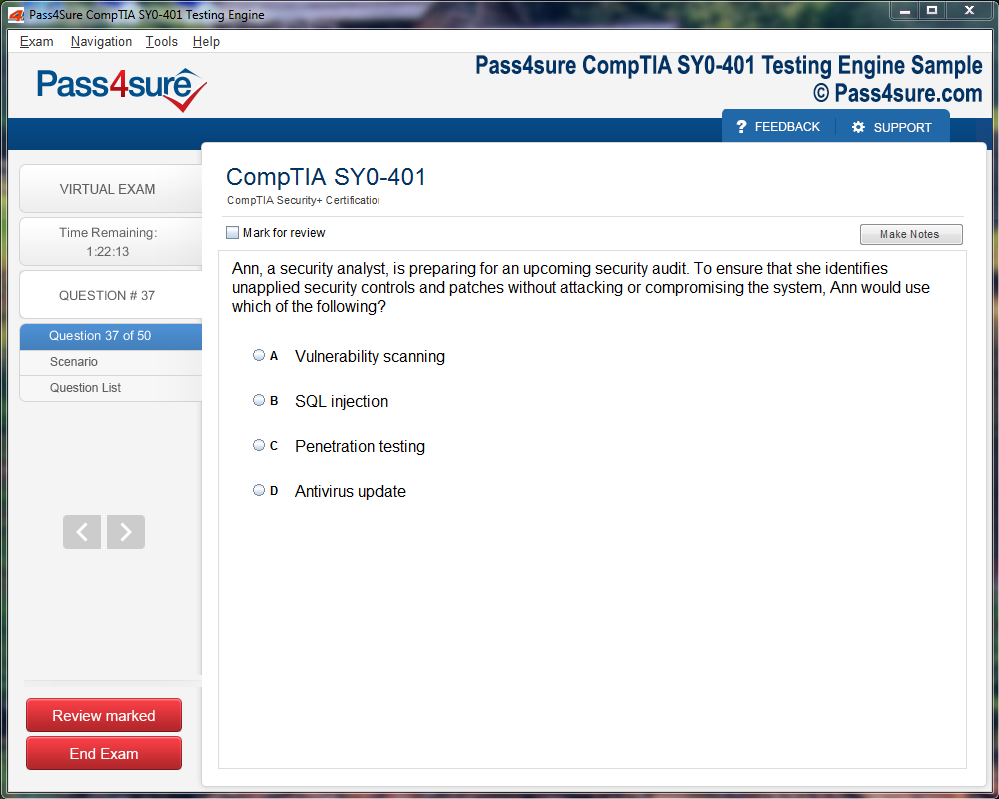

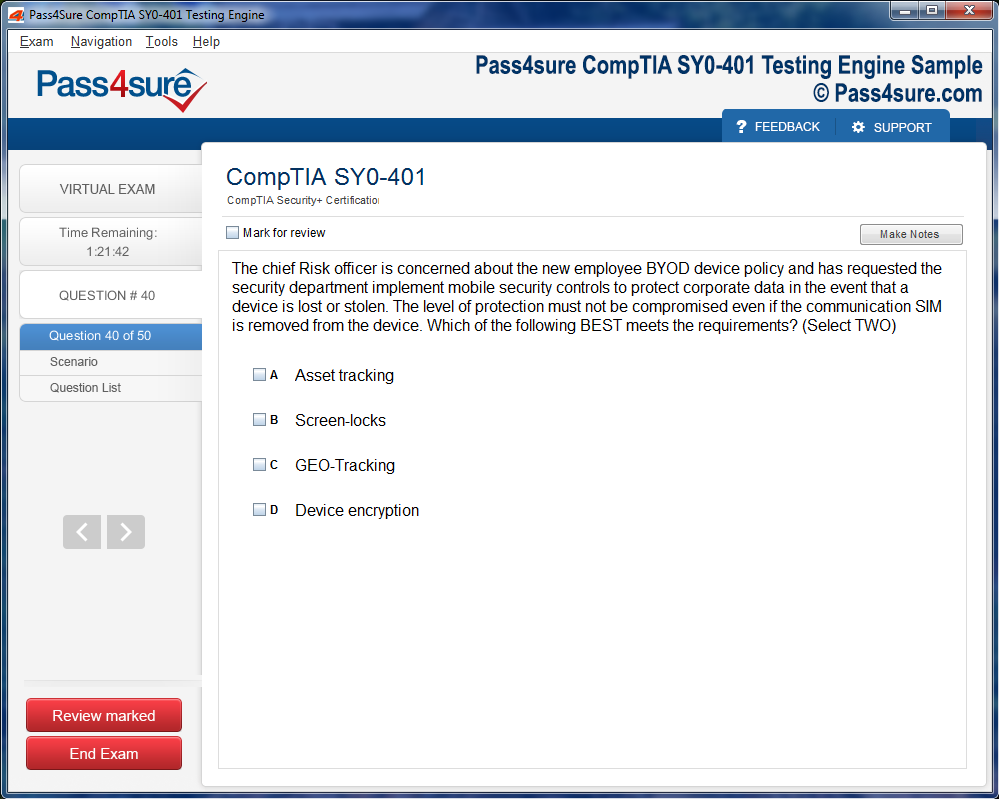

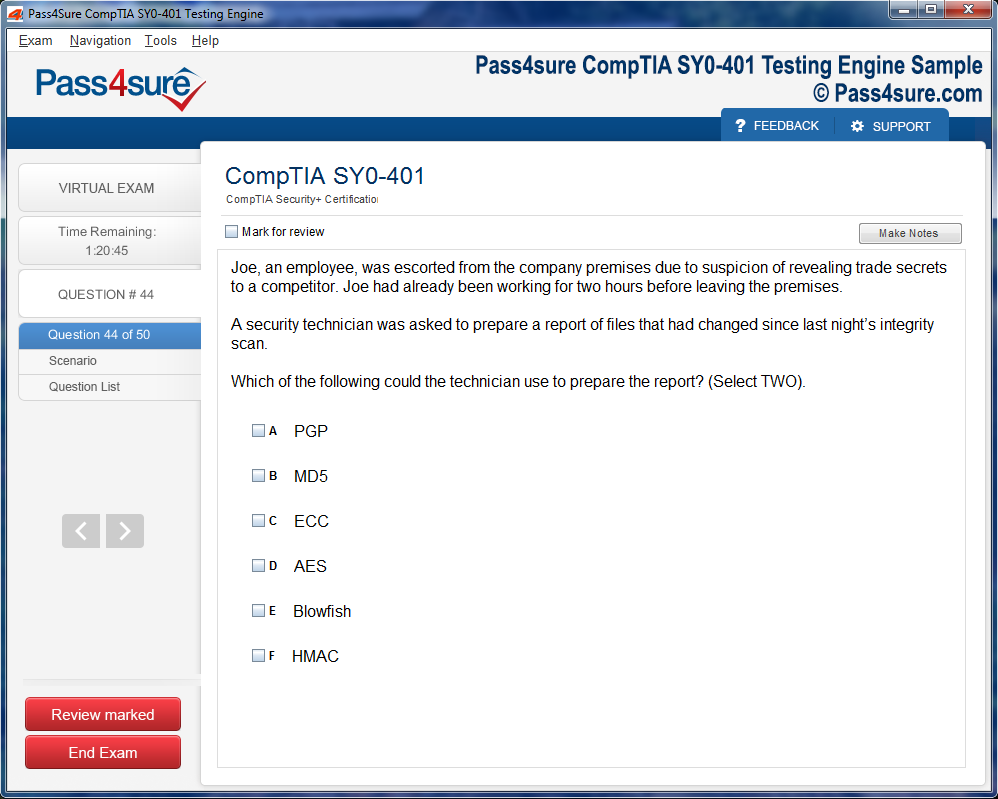

Once download and installed on your PC, you can practise test questions, review your questions & answers using two different options 'practice exam' and 'virtual exam'. Virtual Exam - test yourself with exam questions with a time limit, as if you are taking exams in the Prometric or VUE testing centre. Practice exam - review exam questions one by one, see correct answers and explanations.

How can I get the products after purchase?

All products are available for download immediately from your Member's Area. Once you have made the payment, you will be transferred to Member's Area where you can login and download the products you have purchased to your computer.

How long can I use my product? Will it be valid forever?

Pass4sure products have a validity of 90 days from the date of purchase. This means that any updates to the products, including but not limited to new questions, or updates and changes by our editing team, will be automatically downloaded on to computer to make sure that you get latest exam prep materials during those 90 days.

Can I renew my product if when it's expired?

Yes, when the 90 days of your product validity are over, you have the option of renewing your expired products with a 30% discount. This can be done in your Member's Area.

Please note that you will not be able to use the product after it has expired if you don't renew it.

How often are the questions updated?

We always try to provide the latest pool of questions, Updates in the questions depend on the changes in actual pool of questions by different vendors. As soon as we know about the change in the exam question pool we try our best to update the products as fast as possible.

How many computers I can download Pass4sure software on?

You can download the Pass4sure products on the maximum number of 2 (two) computers or devices. If you need to use the software on more than two machines, you can purchase this option separately. Please email sales@pass4sure.com if you need to use more than 5 (five) computers.

What are the system requirements?

Minimum System Requirements:

- Windows XP or newer operating system

- Java Version 8 or newer

- 1+ GHz processor

- 1 GB Ram

- 50 MB available hard disk typically (products may vary)

What operating systems are supported by your Testing Engine software?

Our testing engine is supported by Windows. Andriod and IOS software is currently under development.

A Step-by-Step Guide to INFOR M3-123

INFOR M3-123 thrives in environments demanding multifaceted operational coordination. Beyond foundational functions, its advanced modules orchestrate a symphony of interdependent processes. For instance, the production planning module does not merely allocate resources; it leverages prognostic algorithms to anticipate bottlenecks and dynamically adjust schedules. Such predictive dexterity transforms reactive management into a preemptive strategy, allowing enterprises to circumvent delays, optimize throughput, and conserve capital.

The interconnectivity of modules enables a phenomenon akin to operational synesthesia. Procurement data cascades seamlessly into inventory metrics, which then inform production cadence. Sales insights feedback into resource allocation, generating a continuous loop of adaptive intelligence. This interconnected lattice fosters not just efficiency, but a lucid awareness of enterprise dynamics, allowing executives to act with deliberation rather than conjecture.

Customization at this level becomes both granular and strategic. Users can define conditional triggers, automate cross-module notifications, and configure dashboards that translate complex datasets into visually comprehensible narratives. Such adaptive visualization ensures decision-makers remain cognizant of emergent patterns, mitigating risk while enhancing operational acuity. The modular synergy exemplifies a design philosophy where complexity is made navigable through structured intuitiveness.

Data Stratification and Analytical Exegesis

Data within INFOR M3-123 is not merely recorded; it undergoes rigorous stratification and exegesis. Each data point, whether it pertains to inventory fluctuations, supplier reliability, or consumer behavior, is embedded within a multilayered schema. The system’s analytical tools facilitate both macro and micro examination, allowing stakeholders to identify latent trends, detect anomalies, and derive actionable intelligence.

Advanced reporting functionalities employ multidimensional pivoting, temporal slicing, and correlation matrices. Such capabilities empower analysts to interrogate datasets from unconventional angles, uncovering insights previously obscured by linear reporting paradigms. For example, temporal slicing may reveal seasonal supplier inconsistencies, enabling preemptive adjustments in procurement strategies. The language of data transforms into a narrative of causality, fostering an operational mindset that is both investigative and anticipatory.

Integration with external intelligence streams amplifies the system’s analytical potency. By ingesting market indicators, logistical feeds, and regulatory updates, INFOR M3-123 situates internal data within a broader ecosystem. This contextual awareness catalyzes strategic foresight, equipping enterprises with the cognitive scaffolding necessary to navigate volatile commercial landscapes.

Workflow Orchestration and Cognitive Automation

A hallmark of INFOR M3-123 lies in its workflow orchestration capabilities. Workflows transcend rudimentary automation; they encapsulate decision logic, conditional routing, and exception management. By encoding operational heuristics into digital conduits, businesses reduce reliance on manual oversight while preserving procedural fidelity.

Cognitive automation augments these workflows through adaptive algorithms that learn from historical patterns. Routine exceptions are handled autonomously, and deviations prompt intelligent alerts that guide human intervention precisely where it is needed. This calibration of automation with human judgment epitomizes an advanced equilibrium between mechanistic efficiency and strategic oversight.

The orchestration framework extends beyond task completion; it nurtures operational cognition. Employees interfacing with these workflows gain insight into systemic interdependencies, developing a meta-awareness of process interrelations. Such understanding fosters agility, allowing teams to respond to emergent challenges with informed precision rather than rote reaction.

Resource Allocation and Adaptive Logistics

Resource management within INFOR M3-123 transcends conventional inventory oversight. The system’s architecture enables adaptive allocation, continuously recalibrating human, material, and financial resources based on real-time demands. This dynamism ensures that bottlenecks are mitigated before they crystallize, while surplus assets are redeployed efficiently, minimizing waste and optimizing cost structures.

Logistical orchestration incorporates both predictive and prescriptive dimensions. Predictive analytics forecast demand surges, potential supply chain disruptions, and labor constraints, while prescriptive modules recommend optimized resource redistribution strategies. The resulting ecosystem is both anticipatory and prescriptive, allowing enterprises to operate with a strategic clairvoyance that blends foresight with actionable guidance.

Global enterprises benefit from multi-locale configuration capabilities. Currency volatility, cross-border taxation, and region-specific regulations are seamlessly integrated into operational planning. This global awareness ensures that resource allocation is contextually grounded, avoiding inefficiencies born from a homogenized approach to diverse operational theaters.

Core Functionalities and Navigation

Building upon foundational acumen, INFOR M3-123 manifests as a symphonic orchestration of interwoven enterprise processes. Its architectural ethos revolves around coherence, minimizing operational entropy while magnifying transparency. Users are immersed in an interface meticulously designed to balance cognitive load with operational potency. Command panels segregate high-frequency tasks from auxiliary functions, facilitating a harmonious interaction between immediacy and depth.

Navigation transcends conventional menus, embracing intuitive search algorithms and contextual queries. Keyboard accelerators, malleable to user predilections, enable rapid transit through voluminous datasets. Order orchestration is a central pillar; complex configurations including multi-item consignments, recurrent requisitions, and contingent backorders are seamlessly accommodated. Integration with live inventory data ensures equilibrium between availability and demand, mitigating capital inefficiencies.

Inventory management within the system exhibits granular precision. Items are monitored through batch specificity, locational identifiers, and status differentiation. Automated alert mechanisms serve as sentinel guardians, preempting stock depletion, obsolescence, or anomaly detection. Multi-dimensional search parameters afford stakeholders the capability to filter inventories by supplier provenance, categorical taxonomy, or chronological production markers.

Role-based access management fortifies operational sanctity. Permissions and hierarchies govern visibility and modification rights, safeguarding sensitive fiscal and procedural data. Multi-tiered approval workflows instill procedural rigor, fostering accountability while minimizing inadvertent discrepancies.

Analytical instrumentation converts data into strategic intelligence. Pre-configured templates and customizable reports allow multifaceted scrutiny. Visualizations such as trend trajectories, density heatmaps, and temporal graphs facilitate immediate comprehension of intricate datasets, catalyzing optimization of inventory flow, supplier appraisal, and financial prognostication.

Integration with external ecosystems exemplifies interoperability. INFOR M3-123 synchronizes with commerce platforms, supplier portals, and financial suites, ensuring coherence across digital touchpoints. APIs and connectors enable these linkages, streamlining deployment with minimal technical overhead.

Customization remains a leitmotif. Dashboards are sculpted to individual metrics, while automated alerts and task orchestration reduce cognitive fatigue. Users are thus liberated to engage in higher-order decision-making, transforming transactional engagement into strategic insight.

Inventory and Supply Chain Management

Inventory and supply chain management form the circulatory system of contemporary enterprises, and INFOR M3-123 excels as a sentient framework in these spheres. Precision tracking of raw materials, finished goods, and ancillary components occurs across multifarious facilities, with real-time visibility supplanting antiquated static reports.

Batch and lot governance underpins this meticulous oversight. Unique identifiers enable end-to-end traceability, essential for quality assurance, compliance adherence, and recall mitigation. Dynamic allocation heuristics optimize distribution across warehouses, reducing storage redundancies and accelerating fulfillment cadence.

Supply chain orchestration is augmented through predictive analytics. Historical patterns, cyclical trends, and probabilistic algorithms inform procurement strategies, enabling anticipatory inventory decisions. Supplier evaluation metrics, encompassing punctuality, quality fidelity, and regulatory adherence, transform procurement from reactive negotiation into data-driven strategy.

Logistical flexibility is intrinsic to the system. Centralized hubs, drop-shipping networks, or multi-echelon distribution models are accommodated seamlessly. Transportation planning optimizes routing, scheduling, and modal selection, reducing expenditure while ensuring delivery precision. Disruption alerts empower proactive mitigation, preventing minor perturbations from escalating into operational crises.

Automation permeates recurring functions. Stock replenishment, order validation, and periodic reporting can execute autonomously, liberating personnel for strategic initiatives and exception oversight. Analytical depth provides visibility into turnover velocities, obsolescence trajectories, and capital allocation efficacy. Heatmaps and scenario simulations allow predictive exploration of operational adjustments, transforming supply chain management from reactive intervention to proactive optimization.

Interdepartmental synergy is fostered through shared data transparency. Sales, manufacturing, and procurement align seamlessly, ensuring that operational decisions are cohesive, informed, and strategically congruent.

Inventory and Supply Chain Symbiosis

Inventory and supply chain orchestration forms the quintessence of operational vitality for contemporary enterprises. INFOR M3-123 manifests a sophisticated lattice for navigating the labyrinthine flows of raw materials, semi-finished assemblies, and finished goods across dispersed nodes. By harnessing instantaneous data revelation, decision-makers are liberated from reliance on stale documentation, enabling nimble and prescient inventory governance.

Batch Traceability and Lot Cognition

At the fulcrum of inventory stewardship lies batch and lot cognition. Each unit is suffused with distinctive identifiers, engendering traceability from procurement to production to distribution. This meticulous surveillance is indispensable for quality fidelity, regulatory adherence, and recall contingencies. Dynamic allocation algorithms further orchestrate stock dispersal, minimizing hoarding costs while ensuring demand fulfillment with judicious alacrity.

Predictive Supply Chain Forethought

The foresight embedded in supply chain planning elevates operational acumen. INFOR M3-123 capitalizes on historical matrices, cyclical oscillations, and prognostic algorithms to render demand forecasting perspicuous. Procurement teams thereby anticipate scarcities, negotiate superior supplier terms, and calibrate order quantities with unparalleled precision. Supplier performance metrics—tracking punctuality, product fidelity, and statutory compliance—imbue managerial decisions with empirical gravitas.

Logistical Flexibility and Distribution Dexterity

Enterprise logistical modalities vary, yet INFOR M3-123 exhibits remarkable adaptability. Whether a firm adheres to centralized distribution, embraces drop-shipping, or navigates multi-tiered networks, the system contorts fluidly to exigencies. Transportation orchestration tools optimize routing, scheduling, and shipping modalities, diminishing expenditure while amplifying delivery veracity. Alert mechanisms preemptively flag potential perturbations, transmuting minor disruptions into manageable anomalies.

Automated Replenishment and Cognitive Efficiency

Recurrent operational tasks are rendered seamless through automation. Stock replenishment cycles, order adjudications, and reporting sequences may be orchestrated autonomously, mitigating human intervention. Consequently, personnel are emancipated to pursue strategic foresight and exception triage, rather than mundane clerical execution. This cognitive liberation enhances decision velocity and operational dexterity.

Analytical Cartography of Inventory

Inventory analytics within INFOR M3-123 unveil profound operational insights. Metrics encompassing turnover cadence, stock senescence, and carrying overhead illuminate latent inefficiencies. Spatial heatmaps delineate warehouse utilization, while scenario simulations prognosticate the ramifications of prospective adjustments. Such analytical rigor transmutes supply chain stewardship from reactive remediations into proactive optimization.

Interdepartmental Synchrony

The system cultivates interdepartmental transparency, fostering cohesion across sales, manufacturing, and procurement. Sales entities gain real-time visibility into inventory reservoirs, manufacturing aligns production temporality with demand oscillations, and procurement monitors supplier fidelity. This panoramic perspective ensures that strategic maneuvers are informed, synchronized, and harmonious with overarching corporate trajectories.

Operational Resilience Through Mastery

Mastery of inventory and supply chain modules within INFOR M3-123 begets formidable operational resilience. Organizations leveraging these tools experience diminished waste proliferation, optimized cost structures, and heightened client gratification through meticulous, punctual order fulfillment. The system’s integration of analytics, automation, and traceability coalesces into a formidable strategic advantage, rendering supply chains not merely functional but astutely responsive and anticipatory.

Financial Synapses in INFOR M3-123

Financial orchestration within INFOR M3-123 operates as a latticework of precision and strategic perspicacity. Rather than merely aggregating numerical inputs, the system actuates a real-time reflection of corporate kinetic energy, transmuting operational activity into fiscal lucidity. This confluence negates the archaic necessity of manual reconciliation, mitigating errors that historically plague financial stewardship. In this ecosystem, data becomes not just information but actionable foresight, allowing executives to maneuver with anticipatory acumen.

Ledger Architecture and Multicurrency Dexterity

At the heart of financial administration lies the ledger—a nexus where transactional chronologies converge. INFOR M3-123 imbues ledger management with polymorphic capabilities, enabling entities to traverse multi-subsidiary landscapes and heterogeneous currency matrices. This flexibility extends beyond mere numerical accommodation; it permits a nuanced audit of cross-border operations, incorporating fluctuating exchange dynamics and tax idiosyncrasies. By automating repetitive entries and sanction workflows, the system minimizes human intervention while maximizing fidelity, transforming quotidian accounting routines into orchestrated financial choreography.

Automated Compliance and Regulatory Vigilance

Compliance is not an adjunct but an integral pillar within INFOR M3-123. Automated mechanisms continuously surveil transactional landscapes, ensuring adherence to regulatory strictures. Every entry carries a biometric-like trace: timestamp, user identification, and procedural metadata, engendering unparalleled auditability. Alerts for discrepancies, deviations, or anomalous patterns act as proactive guardians, preempting potential regulatory infractions. Tax obligations, often convoluted and mutable, are deftly navigated through algorithmic calculation, transforming statutory adherence from a procedural encumbrance into an operationally embedded reflex.

Financial Reporting as Strategic Lens

Reporting within INFOR M3-123 transcends passive number compilation. The system metamorphoses raw financial detritus into strategically potent insights. Preconfigured templates—ranging from profit and loss syntheses to cash flow exegeses—can be meticulously tailored to departmental vectors, temporal slices, or fiscal strata. Visualization tools imbue these reports with cognitive accessibility, converting abstract metrics into perceptual clarity. Executives, liberated from the arcane labyrinth of spreadsheets, can discern financial trajectories, pivot strategies, and allocate resources with judicious alacrity.

Budgeting, Forecasting, and Scenario Cognition

Dynamic forecasting is the quintessence of anticipatory fiscal management. INFOR M3-123 harnesses historical datasets, emergent market vectors, and planned initiatives to architect predictive models of financial evolution. Scenario analysis provides an intellectual sandbox where decision-makers can simulate strategic gambits, exploring ramifications without incurring tangible risk. Budgetary foresight, therefore, is not static; it becomes a living, adaptive construct, responsive to exogenous perturbations and endogenous recalibrations alike.

Integration of Operational and Financial Modalities

The platform’s genius resides in its holistic integration. Inventory flux, procurement cadence, and sales trajectories are seamlessly married to fiscal metrics, yielding a panoramic view of capital allocation. Managers discern liquidity bottlenecks, cost center efficacy, and revenue optimization opportunities through a confluence of operational and financial intelligence. This symbiosis transforms data from discrete silos into an interwoven narrative of enterprise performance.

Interactive Financial Dashboards

Visual cognition is leveraged through interactive dashboards, wherein intricate ratios, cost variances, and revenue oscillations are graphically elucidated. Alerts serve as sentinels, signaling cash flow perturbations, overdue settlements, or budgetary transgressions. By democratizing access to complex financial metrics, INFOR M3-123 empowers non-specialists to participate in fiscal stewardship, fostering organizational literacy and proactive intervention.

Audit Trails and Transactional Provenance

Transparency within financial operations is ensured via immutable audit trails. Each financial move, from inception to completion, is cataloged with forensic precision. This provenance is invaluable not merely for regulatory compliance but for internal governance, risk mitigation, and the cultivation of institutional trust. The system’s capacity to retroactively reconstruct transactional pathways offers both reassurance and strategic insight, revealing patterns that inform policy and operational refinement.

Capital Allocation and Strategic Acumen

The cumulative effect of INFOR M3-123’s financial functionalities is a refinement of capital allocation. By interlacing predictive analytics, compliance mechanisms, and operational integration, the system enables organizations to marshal resources with unparalleled efficiency. Strategic decision-making is elevated from reactive problem-solving to proactive orchestration, where every financial maneuver is informed by comprehensive intelligence and anticipatory modeling.

Predictive Metrics and Performance Projections

In the realm of financial prognostication, INFOR M3-123 wields a panoply of predictive metrics. Historical performance vectors, trend extrapolations, and market sentiment analytics converge to form dynamic, scenario-sensitive forecasts. Managers are equipped not only to project fiscal outcomes but to interrogate underlying assumptions, stress-test strategies, and refine operational tactics in response to simulated contingencies. This predictive capability transforms uncertainty into a navigable landscape of informed probability.

Decision-Enhanced Reporting

The reporting module functions as an interpretive lens, distilling data complexity into actionable intelligence. It offers granular insights at departmental, regional, and enterprise-wide levels, enabling precision-targeted interventions. Visualizations, trend indicators, and interactive reporting modules facilitate a cognitive synthesis that allows decision-makers to apprehend macro and micro-level financial phenomena simultaneously.

Workflow Automation and Operational Orchestration

INFOR M3-123 manifests its prowess through a panoply of automation capabilities that transcend mere task execution. Mundane operations such as order approvals, inventory replenishment, and periodic report generation are transmuted into self-propelling processes. Conditional algorithms act as sentinels, detecting anomalies or exceptions that require human intervention, thereby creating an equilibrium between autonomy and oversight. The resulting operational cadence alleviates employee monotony, fostering a workforce attuned to higher-value cognitive engagement rather than repetitive chores.

Interface Configurability and Cognitive Ergonomics

The user interface of INFOR M3-123 epitomizes configurational sophistication. Dashboards, navigational schemas, and notification matrices can be meticulously tailored to reflect the informational priorities of individual roles or departmental exigencies. This interface malleability cultivates a cognitively ergonomic environment, ensuring that users encounter only salient data while peripheral distractions recede. Global operatives benefit from multi-lingual and multi-currency functionality, engendering seamless collaboration across geopolitical boundaries without compromising systemic integrity.

Ecosystem Integration and Data Synergy

The platform’s interoperability constitutes a keystone of its strategic utility. Through robust API frameworks, INFOR M3-123 integrates effortlessly with e-commerce conduits, vendor management systems, and external analytical engines. This interconnection orchestrates a symphonic flow of data, diminishing the need for manual transcriptions and ensuring that information remains uncorrupted as it traverses disparate systems. The result is an operational tapestry in which insights propagate swiftly, enabling instantaneous reactions to emergent contingencies.

Predictive Analytics and Prescriptive Insight

Advanced analytics serve as the cerebral cortex of INFOR M3-123, processing historical patterns to illuminate probable futures. Machine learning heuristics forecast demand fluxes, detect anomalous behaviors, and recommend optimal allocation of finite resources. Scenario simulation tools allow decision-makers to probe hypothetical conditions, juxtaposing potential strategies against multifactorial outcomes. This prescriptive intelligence transforms intuition into evidence-based precision, allowing organizations to navigate uncertainty with calculated foresight.

Security Stratagems and Regulatory Adherence

The platform’s security architecture functions as both bulwark and compass. Role-based access control, multi-factor authentication, and cryptographic safeguards collectively fortify sensitive data against intrusion. Automated compliance mechanisms continuously audit operational practices, ensuring conformity to local, regional, and international statutory frameworks. This dual emphasis on protection and adherence not only mitigates risk but also instills confidence in organizational continuity amidst regulatory flux.

Reporting Customization and Decision Facilitation

Reporting within INFOR M3-123 is metamorphic rather than static. Users may construct intricate queries, architect bespoke visual representations, and implement timed report dissemination. This bespoke reporting ecosystem guarantees that stakeholders receive insights not as generic data dumps but as actionable intelligence calibrated to their decision-making vectors. The flexibility to manipulate and visualize information enhances situational awareness, enabling swift and informed operational judgments.

Strategic Transformation Through Feature Leverage

The amalgamation of automation, configurability, integration, analytics, security, and reporting elevates INFOR M3-123 beyond transactional functionality. Organizations that harness these capabilities metamorphose routine operations into strategically potent processes. Operational agility, profound analytical acuity, and nuanced control over intricate workflows become attainable, positioning enterprises to thrive amidst dynamic and unpredictable markets.

Structured Training for Proficient Engagement

Effective utilization of INFOR M3-123 demands meticulous induction protocols. Organizations must cultivate a pedagogical scaffold that integrates immersive tutorials, sandbox experimentation, and scenario-based simulations. Through iterative exposure to controlled operational environments, employees internalize procedural nuances and fortify cognitive agility. Scenario-driven exercises, particularly those simulating transactional anomalies or system contingencies, cultivate problem-solving dexterity, ensuring personnel are prepared for live-system exigencies without succumbing to procedural inertia.

The efficacy of structured training hinges upon stratified learning trajectories. Novices engage with foundational modules emphasizing interface navigation, data input validation, and elementary reporting. Intermediate cohorts progress to cross-functional simulations, involving inventory orchestration, financial consolidations, and production scheduling. Advanced users engage with predictive analytics, process automations, and optimization matrices. This hierarchical progression fosters mastery while minimizing cognitive overload and accelerates institutional knowledge acquisition.

The Imperative of Data Hygiene

Data hygiene transcends mere clerical diligence—it constitutes the backbone of operational veracity. Inconsistent or corrupt data erodes forecasting accuracy, impedes decision-making, and exacerbates resource misallocation. Systematic audits, standardized nomenclature conventions, and regimented record-keeping are indispensable. By implementing automated validation scripts and exception reporting mechanisms, organizations ensure data remains pristine and actionable.

High-integrity data facilitates advanced functionalities within INFOR M3-123. Predictive forecasting modules, dynamic inventory simulations, and scenario analyses rely on unblemished datasets. Organizations that neglect this foundational tenet often encounter latent inefficiencies, misaligned procurement schedules, and impaired strategic insight. Embedding data hygiene within organizational culture transforms the system from a transactional utility to a strategic lever.

Process Standardization and Operational Cadence

Process standardization is the linchpin of operational efficiency. By codifying repeatable workflows, organizations mitigate error proliferation, minimize latency, and streamline onboarding procedures. Standardization also facilitates the deployment of automated alerts, approval chains, and exception handling protocols. These mechanisms safeguard procedural fidelity while maintaining the flexibility necessary to accommodate atypical operational scenarios.

Integrating process standardization with continuous feedback loops cultivates organizational resilience. Employees contribute insights regarding workflow friction points, system bottlenecks, and latent inefficiencies. By iteratively refining procedures based on real-world feedback, organizations construct adaptive operational frameworks capable of responding to fluctuating market dynamics without compromising systemic integrity.

Real-World Applications Across Sectors

The versatility of INFOR M3-123 manifests vividly across industrial, retail, and financial sectors. Manufacturing entities leverage its production planning modules to harmonize labor allocation, reduce material wastage, and synchronize supply chain operations. By integrating predictive analytics, firms anticipate demand fluctuations, adjust production cadence, and optimize inventory positioning, mitigating both surplus and scarcity.

Retail enterprises benefit from centralized stock management across multiple locations. Real-time tracking, automated reorder triggers, and trend-responsive allocation empower retailers to respond to dynamic market conditions. Sophisticated reporting facilitates pricing strategies, promotional efficacy analysis, and customer engagement metrics, transforming operational data into actionable intelligence.

Financial institutions utilize the system for transaction consolidation, liquidity monitoring, and regulatory compliance enforcement. By harnessing automated reconciliations, anomaly detection, and audit-ready reporting, organizations safeguard financial integrity while reducing human error. Strategic dashboards provide executives with holistic visibility into operational health, enabling informed decision-making and proactive risk mitigation.

Continuous Improvement as a Strategic Imperative

Operational excellence is unattainable without a culture of continuous improvement. Organizations must periodically reassess workflow efficacy, dashboard configurations, and reporting structures to identify latent inefficiencies. Bottlenecks, redundant procedures, and underutilized modules must be systematically addressed. Employee feedback serves as a critical vector for refinement, bridging the gap between theoretical process design and pragmatic execution.

Scenario simulations provide an invaluable instrument for continuous enhancement. By modeling hypothetical contingencies—supply chain disruptions, demand surges, or financial stressors—organizations can preemptively adjust procedures, allocate resources, and develop contingency protocols. This proactive stance transforms the system from a reactive operational tool into a strategic forecasting instrument.

Strategic Leveraging of Analytics

The analytical capacities of INFOR M3-123 extend beyond descriptive reporting. Predictive models inform procurement strategies, sales projections, and marketing campaigns. Machine-learning-driven trend analyses uncover latent correlations between consumer behavior, inventory flow, and production schedules, enabling organizations to capitalize on emergent opportunities.

Decision-making is further enhanced through scenario-based simulation. Executives can project outcomes of investment decisions, operational adjustments, or market entry strategies, quantifying risk exposure and resource allocation trade-offs. By integrating analytics within operational workflows, organizations achieve a synergistic alignment between strategy formulation and execution.

Augmenting Workforce Competence

Human capital remains a pivotal determinant of system efficacy. Continuous skill development, gamified learning modules, and competency tracking fortify the workforce’s ability to exploit INFOR M3-123’s full potential. By embedding iterative learning loops and incentivizing skill progression, organizations cultivate a cadre of highly capable operators who transcend mere procedural adherence to proactive problem-solving.

Knowledge transfer mechanisms, including mentorship programs and collaborative forums, disseminate tacit expertise, ensuring that critical operational insights persist beyond individual tenure. This collective intelligence accelerates organizational learning and fortifies resilience against systemic disruption.

Optimization Through Automation

Automation within INFOR M3-123 catalyzes operational agility. Repetitive workflows, transactional validations, and reporting sequences can be configured to execute autonomously, reducing manual labor while increasing accuracy. Intelligent triggers, exception handling routines, and workflow orchestration modules allow organizations to balance automation with necessary human oversight, maintaining operational integrity while maximizing efficiency.

Automation also facilitates scalability. As organizational demands expand, automated procedures ensure consistency and fidelity without proportional increases in labor or error exposure. Strategic deployment of these capabilities transforms the system into a multiplier of organizational capacity, driving competitive advantage in rapidly evolving markets.

Scenario-Driven Decision Frameworks

Scenario-driven decision-making constitutes an advanced utilization of INFOR M3-123. By simulating multiple operational contingencies—ranging from supply chain disruptions to financial volatility—organizations gain foresight into potential risks and opportunities. These simulations generate probabilistic outcome matrices, guiding resource allocation, investment prioritization, and tactical adjustments.

Scenario frameworks also inform strategic planning. By testing hypotheses in virtualized environments, decision-makers evaluate the efficacy of policy adjustments, marketing campaigns, and production modifications before incurring real-world costs. This iterative exploration reduces risk, optimizes capital deployment, and reinforces organizational adaptability.

Integrative Supply Chain Orchestration

INFOR M3-123 excels in synchronizing multifaceted supply chain operations. Inventory management, procurement planning, and logistics coordination converge within a unified framework, enabling end-to-end visibility. Organizations achieve reduced lead times, minimized stockouts, and optimized resource utilization. Predictive replenishment algorithms anticipate demand variability, while exception alerts enable rapid remediation of potential disruptions.

The integrative architecture also facilitates vendor collaboration. Real-time data sharing, automated communication protocols, and performance monitoring metrics enhance supplier responsiveness, improving contractual compliance and mitigating operational risk. By unifying internal and external supply chain touchpoints, organizations achieve fluid, resilient, and adaptive logistics networks.

Supplier Ecosystem Optimization and Strategic Partnerships

INFOR M3-123 transforms supplier management from a transactional function into a strategic ecosystem. Traditional procurement paradigms often reduce suppliers to cost centers; this system reconceptualizes them as nodes within a dynamic network of interdependencies. Supplier profiles are enriched with multifarious attributes—delivery punctuality, quality indices, compliance histories, and even environmental footprints. By quantifying these variables, businesses gain a granular understanding of each supplier’s operational temperament and potential volatility.

The platform employs advanced scoring algorithms that evaluate supplier performance holistically. These algorithms transcend static metrics, integrating temporal trends, situational anomalies, and cross-supplier interactions. The result is a predictive portrait of supplier reliability, allowing procurement managers to preemptively mitigate risks associated with late deliveries or substandard quality. This predictive scaffolding transforms supplier engagement into a proactive, data-driven dialogue rather than reactive problem-solving.

Contract management within this ecosystem is equally sophisticated. Automated contract lifecycle tools track key dates, monitor performance clauses, and flag compliance breaches. Moreover, the system’s integration with real-time market data allows for dynamic renegotiation triggers, ensuring that procurement strategies remain aligned with fluctuating market conditions. The result is a supplier network that is not merely operational but strategically calibrated, fostering resilience, adaptability, and mutual value creation.

Predictive Maintenance and Asset Longevity

Operational continuity hinges on the robustness of critical assets. INFOR M3-123 embeds predictive maintenance functionalities that extend beyond mere scheduling into anticipatory diagnostics. Sensors, IoT integrations, and historical performance datasets converge within the system to generate prognostic insights on asset health. These insights identify subtle deviations in performance—vibrations, thermal anomalies, or efficiency degradation—before they escalate into failures.

Maintenance workflows are intelligently prioritized based on risk, impact, and operational criticality. The system dynamically allocates maintenance crews, spare parts, and scheduling windows to ensure minimal disruption to production. This predictive approach is both cost-efficient and temporally strategic, reducing emergency interventions while prolonging asset lifespans. The result is a maintenance culture that is proactive rather than reactive, minimizing downtime and safeguarding operational continuity.

Furthermore, analytics derived from maintenance patterns inform capital expenditure strategies. Equipment with recurrent anomalies may trigger preemptive replacements or process redesigns, while consistently reliable assets inform replication and scaling decisions. Through this lens, asset management evolves from a custodial responsibility into a strategic lever for operational optimization and financial prudence.

Risk Mitigation and Contingency Frameworks

Enterprise operations are inherently exposed to multidimensional risks—supply chain volatility, regulatory shifts, market disruptions, and technological failures. INFOR M3-123 integrates risk mitigation as a core functionality, embedding probabilistic models, scenario simulations, and decision-support matrices directly within operational workflows. Risks are not merely cataloged; they are quantified, contextualized, and actively managed.

Scenario simulations allow enterprises to test operational resilience under hypothetical stressors. Supply chain disruptions, labor shortages, and sudden demand surges can be modeled to understand cascading effects across interdependent modules. The system generates actionable insights—alternative sourcing strategies, inventory buffers, and production rescheduling—that transform theoretical risks into tangible contingency plans. This level of preparedness cultivates organizational confidence, enabling decision-makers to navigate uncertainty with strategic agility.

Compliance management further reinforces risk mitigation. Regulatory constraints—ranging from environmental mandates to financial reporting standards—are embedded into operational rules. Automated alerts, audit trails, and exception reporting ensure that deviations are immediately addressed, safeguarding the enterprise from legal and reputational repercussions. The system’s holistic approach to risk is both preventive and corrective, integrating operational, strategic, and compliance dimensions into a unified framework.

Operational Intelligence and Decision Augmentation

INFOR M3-123 transcends conventional ERP functionality by serving as an incubator for operational intelligence. Data streams from production, procurement, sales, and maintenance converge to form an analytic lattice, revealing latent correlations and emergent patterns. Through advanced visualization techniques, these insights are transformed into cognitive artifacts that guide executive decisions with precision and foresight.

Decision augmentation tools utilize a combination of machine learning, historical trend analysis, and scenario modeling. For example, predictive demand models not only forecast future sales but also recommend production schedules, raw material acquisitions, and workforce deployment strategies. The system thus acts as a cognitive partner, augmenting human decision-making rather than supplanting it.

Additionally, anomaly detection algorithms continuously scan operational parameters to identify deviations from expected performance. Whether it is an unexplained dip in output efficiency or an unusual spike in resource consumption, the system flags irregularities and contextualizes them within historical and industry-wide data. This proactive intelligence enables interventions that are informed, timely, and surgically targeted, preserving operational integrity and enhancing strategic responsiveness.

Adaptive Learning and Employee Empowerment

The sophistication of INFOR M3-123 is matched by its capacity to cultivate human expertise. Interactive tutorials, sandbox simulations, and contextual guidance modules enable employees to engage with complex workflows in a risk-free environment. By iteratively experimenting with module functionalities, users internalize operational logic, gaining both competence and confidence.

Adaptive learning algorithms personalize training pathways based on individual performance metrics. Users who excel in certain domains may be advanced to more complex workflows, while others receive targeted reinforcement in areas of difficulty. This individualized approach optimizes knowledge acquisition, reducing the temporal and cognitive burden of system mastery.

Moreover, the system fosters cross-functional awareness. Employees gain insight into the interconnectivity of operational modules, understanding how procurement decisions impact production efficiency or how maintenance schedules influence sales commitments. This holistic perspective transforms operational participation from task execution into strategic engagement, empowering personnel to contribute proactively to enterprise objectives.

Environmental and Sustainability Analytics

INFOR M3-123 incorporates environmental stewardship into operational planning, offering analytics that measure ecological impact across processes. Resource consumption, carbon footprint, and waste generation are quantified and visualized, enabling enterprises to identify sustainability opportunities. Procurement decisions, production workflows, and logistics strategies can then be calibrated to minimize environmental externalities without compromising efficiency.

Sustainability analytics are integrated with cost-benefit modeling, allowing decision-makers to evaluate eco-friendly interventions alongside financial implications. Renewable energy adoption, waste reduction strategies, and eco-compliant supply chains can be planned with both ecological prudence and fiscal responsibility. By embedding sustainability into operational intelligence, the system positions enterprises to meet regulatory mandates and market expectations while fostering long-term resilience.

Holistic Resource Allocation

Effective resource allocation within INFOR M3-123 transcends simple distribution of labor and materials. Advanced modules enable organizations to dynamically apportion assets according to predictive demand curves, operational priorities, and emergent contingencies. By integrating real-time metrics with historical performance data, managers calibrate resource deployment to minimize idle capacity while averting overextension. This dynamic allocation fosters an equilibrium between cost efficiency and operational responsiveness, ensuring optimal throughput even under fluctuating market conditions.

Resource orchestration also incorporates human capital considerations. Scheduling algorithms accommodate workforce skill matrices, availability constraints, and compliance mandates, yielding harmonious alignment between task complexity and personnel aptitude. Organizations that leverage such granular orchestration achieve heightened productivity while simultaneously cultivating employee satisfaction and reducing burnout.

Adaptive Workflow Engineering

Workflow engineering within INFOR M3-123 is most potent when approached adaptively rather than rigidly. While standardized procedures form the operational backbone, adaptive workflows accommodate deviations triggered by exceptional circumstances, market volatility, or emergent customer demands. By embedding conditional pathways and automated exception protocols, businesses maintain operational continuity without compromising procedural rigor.

Adaptive workflows further facilitate cross-departmental collaboration. For instance, inventory fluctuations trigger real-time notifications to procurement, production, and sales teams, ensuring synchronous responses across the enterprise. The capacity to flexibly route tasks, approvals, and alerts mitigates bottlenecks and enables faster organizational learning. Over time, this approach cultivates a self-correcting operational environment where the system evolves in tandem with business exigencies.

Predictive Maintenance and Equipment Optimization

Manufacturing organizations derive substantial value from predictive maintenance capabilities embedded within INFOR M3-123. Machine-learning models analyze operational telemetry, historical maintenance logs, and environmental variables to forecast equipment wear and anticipate potential failures. By preemptively scheduling maintenance interventions, organizations reduce unplanned downtime, extend asset longevity, and optimize maintenance expenditures.

Equipment optimization also benefits from simulation-driven insights. Operational scenarios, such as production scaling or shift pattern alterations, can be tested virtually to determine ideal machine utilization rates and resource allocations. Integrating predictive maintenance with production planning generates a synergistic effect, allowing organizations to synchronize maintenance schedules with operational cadence, thereby minimizing disruption while maximizing output.

Multi-Dimensional Reporting

INFOR M3-123 offers sophisticated multi-dimensional reporting capabilities that transcend conventional tabular outputs. Organizations can configure dashboards to visualize key performance indicators across temporal, spatial, and operational dimensions. For instance, inventory turnover can be tracked across multiple warehouses, segmented by SKU, supplier, and sales region, yielding granular insight into supply chain efficiency.

Beyond descriptive reporting, the system supports variance analysis, trend projection, and anomaly detection. Executives can identify deviations from expected performance, trace causal factors, and implement corrective interventions with precision. These reporting capabilities transform raw data into strategic intelligence, equipping organizations to proactively navigate competitive landscapes and mitigate operational risks.

Strategic Inventory Harmonization

Inventory harmonization encompasses both stock equilibrium and strategic positioning. INFOR M3-123 allows organizations to optimize inventory levels not merely for immediate demand but in anticipation of seasonal trends, promotional campaigns, and supply chain contingencies. Sophisticated replenishment algorithms integrate lead time variability, vendor reliability metrics, and historical consumption patterns to ensure robust stock availability without incurring excessive holding costs.

Strategic inventory positioning further enables regional responsiveness. By mapping stock levels to geographic demand hotspots, organizations can reduce shipping latency, enhance customer satisfaction, and leverage logistical economies of scale. This approach requires a nuanced understanding of market dynamics, supplier performance, and operational constraints, which the system facilitates through integrated analytics and scenario modeling.

Cross-Functional Collaboration Enhancements

INFOR M3-123 fosters cross-functional collaboration by providing unified operational visibility. Sales, production, procurement, finance, and logistics converge on a shared platform, enabling synchronous communication and joint decision-making. Automated alerts, shared dashboards, and interdepartmental workflows reduce information silos, ensuring that operational decisions reflect holistic enterprise insight rather than fragmented perspectives.

Collaboration extends to external stakeholders as well. Vendors, distributors, and partners can access controlled modules for real-time visibility into procurement requirements, order status, and compliance documentation. This transparency enhances trust, accelerates response times, and strengthens the resilience of supply chain ecosystems.

Real-Time Scenario Simulation

The ability to simulate operational scenarios in real-time distinguishes INFOR M3-123 as a strategic tool rather than a passive transactional system. Organizations can model demand surges, supply chain disruptions, or labor shortages, observing downstream effects on production, inventory, and financial metrics. Such simulations enable risk mitigation, contingency planning, and resource reallocation before disruptions materialize in reality.

Scenario simulation also informs strategic investment decisions. By projecting the operational impact of capital expenditures—such as machinery upgrades, facility expansion, or software enhancements—executives gain empirical insights into cost-benefit ratios, ROI, and risk exposure. This capability transforms data-driven speculation into actionable foresight, enhancing the strategic acumen of decision-makers.

Advanced Compliance and Auditability

Regulatory compliance and auditability are increasingly critical in modern enterprises. INFOR M3-123 provides automated compliance checks, audit trails, and exception reporting, ensuring that operational activities adhere to internal standards and external regulations. By centralizing compliance documentation and integrating it with real-time workflows, organizations reduce administrative overhead and minimize the risk of regulatory breaches.

Advanced auditability also facilitates continuous improvement. Historical audit data can be analyzed to identify recurrent process deviations, training deficiencies, or procedural bottlenecks. This feedback loop enables proactive remediation and reinforces a culture of accountability, transparency, and operational integrity.

Integrating Machine Learning for Enhanced Insights

Machine learning integration amplifies the strategic value of INFOR M3-123. Predictive algorithms detect subtle patterns within operational data, offering foresight into demand fluctuations, production bottlenecks, and financial anomalies. These insights enable preemptive action, resource optimization, and market-responsive agility.

Further, reinforcement learning techniques can iteratively refine operational parameters. By evaluating historical performance against predicted outcomes, the system continuously adapts optimization models, enhancing decision accuracy over time. Organizations that embrace machine learning within their operational framework achieve a compounding advantage in efficiency, foresight, and resilience.

Agile Production Planning

Agile production planning is a critical differentiator in industries where demand volatility is high. INFOR M3-123 enables dynamic production scheduling, integrating real-time inventory levels, labor availability, and supply chain constraints. By continuously adjusting production sequences, organizations reduce lead times, minimize resource waste, and respond swiftly to market changes.

Agile planning also supports mixed-mode production strategies. For enterprises producing multiple product lines, the system facilitates prioritization based on profitability, strategic importance, and customer demand. By balancing capacity utilization across product lines, organizations maintain operational flexibility while maximizing overall output and revenue potential.

Data-Driven Decision Loops

The system supports iterative, data-driven decision loops that refine operational strategies in real time. Continuous monitoring of key metrics—such as throughput, cycle times, and customer satisfaction—enables organizations to adjust processes promptly. By coupling these metrics with predictive modeling and scenario analysis, decision loops transition from reactive troubleshooting to proactive optimization.

Employee engagement is critical within these loops. By providing operational transparency and decision-making dashboards, personnel gain insight into the impact of their actions, fostering a culture of accountability and continuous improvement. This participatory approach enhances both morale and operational efficacy.

Dynamic Vendor Performance Evaluation

Supplier reliability directly influences operational efficiency. INFOR M3-123 facilitates dynamic vendor evaluation by tracking delivery timelines, quality metrics, and compliance adherence. Organizations can rank suppliers, forecast potential disruptions, and adjust procurement strategies accordingly. This proactive vendor management reduces supply chain risk and reinforces strategic partnerships.

Performance evaluation data also informs negotiation and contractual decisions. Suppliers demonstrating consistent reliability can be incentivized through volume commitments or preferential terms, while underperforming partners can be guided toward corrective action. The system transforms vendor relationships from transactional exchanges to strategic collaborations.

Predictive Market Adaptation

INFOR M3-123 empowers organizations to anticipate market fluctuations through predictive analytics. By correlating historical sales, macroeconomic indicators, and consumer sentiment data, enterprises can forecast demand shifts, inventory requirements, and promotional efficacy. This foresight enables preemptive adjustments in production, marketing, and procurement strategies, reducing exposure to volatility and enhancing competitiveness.

Predictive market adaptation also informs strategic product development. Insights derived from trend analysis, customer behavior, and regional demand patterns guide innovation priorities, feature enhancements, and pricing strategies. Organizations can thus align their offerings with evolving market expectations, creating a cycle of continuous relevance and growth.

Advanced Analytics and Insight Generation

Within INFOR M3-123, analytics transcend superficial enumeration, transforming voluminous transactional data into a stratified repository of actionable intelligence. The system’s analytical apparatus leverages multidimensional interrogation, where variables such as inventory velocity, supplier reliability, and financial flux are interlaced into cohesive insight matrices. This empowers decision-makers to navigate operational complexity with sagacity rather than conjecture.

Pre-configured analytical schemas expedite conventional reporting, yet customization remains paramount. Users can delineate bespoke metrics, integrating temporal, categorical, and spatial dimensions to unravel latent inefficiencies. Heatmaps, trend vectors, and anomaly detection visualizations function as cognitive accelerants, permitting instantaneous comprehension of otherwise arcane patterns. For instance, identifying latent bottlenecks in procurement or uncovering systemic inventory stagnation becomes an almost instantaneous exercise, rather than a protracted analytical endeavor.

Predictive modeling is a salient facet. Machine-assisted algorithms extrapolate future demand scenarios from historical cadence, seasonal fluctuations, and market perturbations. These projections inform procurement schedules, inventory allocations, and production planning. By simulating hypothetical disruptions, such as supplier delays or sudden spikes in demand, enterprises can formulate contingency strategies that mitigate risk while preserving operational fluidity.

Performance metrics are meticulously tracked across departments. Manufacturing throughput, order fulfillment latency, and financial variances converge in holistic dashboards, fostering cross-functional cognizance. This integrative approach engenders a culture of accountability and continuous improvement, as data-driven insights become the fulcrum of strategic decisions.

Customization and Workflow Personalization

The latitude for customization in INFOR M3-123 extends beyond superficial interface adjustments, permeating core operational workflows. Dashboards, notifications, and user interfaces are sculpted according to the unique operational rhythms and cognitive preferences of individual employees. This personalizability is not mere aesthetic indulgence; it materially accelerates task execution by aligning system behavior with user cognition.

Automated task orchestration is particularly impactful. Routine processes, from order approvals to stock replenishment, can be programmed with conditional logic that responds dynamically to operational circumstances. For example, low-stock alerts can trigger tiered procurement approvals, concurrently notifying finance for budgetary compliance. This orchestration reduces human error and ensures operational continuity, even in high-volume environments.

Moreover, customization extends to data visualization. Users can construct interactive dashboards that juxtapose key performance indicators with predictive analytics, facilitating a synoptic understanding of organizational health. Alerts and reminders, strategically timed and contextually relevant, function as cognitive scaffolds, allowing employees to focus on strategic problem-solving rather than repetitive administration.

Role-specific interfaces reinforce this personalization. Sales personnel encounter real-time inventory availability and customer order history, procurement teams are furnished with supplier performance dashboards, and production managers access machine utilization metrics and scheduling projections. This targeted information dissemination ensures that the right data reaches the right stakeholder at the right moment, enhancing decision-making efficacy.

Integration with Enterprise Ecosystems

INFOR M3-123 is architected for interoperability, seamlessly interfacing with a spectrum of external systems. E-commerce platforms, supplier portals, logistics networks, and financial software can synchronize with the M3 framework, ensuring that information flow remains unbroken across enterprise ecosystems. This integration reduces redundant data entry, minimizes errors, and creates a coherent digital environment where every operational touchpoint is interconnected.

APIs and modular connectors form the backbone of this interoperability. Their deployment is designed to be accessible, often requiring minimal technical intervention, yet they are robust enough to handle complex transactional exchanges. Data standardization protocols ensure that disparate systems communicate without loss of fidelity, preserving both the integrity and timeliness of operational data.

Furthermore, integration facilitates a holistic view of enterprise performance. By consolidating information from sales, manufacturing, procurement, and logistics, INFOR M3-123 enables comprehensive end-to-end monitoring. Organizations can trace the lifecycle of an order from inception to fulfillment, examine supplier performance in real time, and correlate operational metrics with financial outcomes. This interconnectedness transforms isolated operational insights into enterprise-wide strategic intelligence.

Strategic Supply Chain Optimization

Beyond day-to-day management, INFOR M3-123 empowers enterprises to engage in strategic supply chain optimization. By leveraging advanced analytics, predictive modeling, and real-time data, organizations can anticipate market shifts, adjust inventory levels, and fine-tune supplier engagements with unprecedented agility.

Dynamic allocation algorithms play a pivotal role. These algorithms evaluate inventory distribution across multiple warehouses, aligning stock levels with anticipated demand while minimizing storage costs. In practice, this reduces obsolescence, prevents stockouts, and ensures rapid fulfillment, even in the face of volatile market conditions.

Transportation and logistics are similarly optimized. Route planning, shipment consolidation, and mode selection are governed by intelligent algorithms that balance cost-efficiency with delivery reliability. Disruption alerts, such as weather delays or carrier bottlenecks, trigger proactive interventions, enabling logistics teams to reroute shipments and maintain service levels without manual oversight.

Supplier collaboration is enhanced through integrated performance tracking. Metrics such as on-time delivery, defect rates, and compliance adherence inform contract negotiations and procurement strategies. By identifying high-performing suppliers and addressing underperformers, enterprises can reduce operational risk, improve product quality, and fortify relationships that underpin long-term strategic advantage.

Risk Management and Compliance Assurance

In contemporary enterprises, regulatory adherence and operational risk mitigation are non-negotiable imperatives. INFOR M3-123 incorporates a suite of features designed to fortify compliance and preempt operational hazards. Audit trails, permission hierarchies, and multi-tier approval workflows collectively establish a robust governance framework. Every change, from inventory adjustment to financial transaction, is logged with precision, ensuring traceability and accountability.

Compliance monitoring is augmented by automated alerts and periodic reporting. For instance, batch tracking mechanisms facilitate adherence to quality standards and regulatory mandates, while expiration monitoring ensures that products meet safety and usability requirements. These systems reduce the likelihood of compliance breaches, mitigate financial exposure, and reinforce operational integrity.

Risk management extends beyond compliance. Predictive analytics identify potential supply chain vulnerabilities, such as single-source dependencies or seasonal demand fluctuations. By modeling various risk scenarios, enterprises can develop contingency plans that minimize disruption, optimize resource allocation, and maintain operational resilience even under adverse conditions.

Real-Time Collaboration and Operational Synergy

INFOR M3-123 fosters a culture of collaboration through its real-time data accessibility. Multiple departments—procurement, manufacturing, sales, and logistics—can simultaneously access synchronized information, ensuring alignment across operational silos. This cohesion reduces miscommunication, accelerates decision-making, and promotes a unified approach to problem-solving.

Collaborative features extend to workflow management. Shared dashboards, integrated notifications, and real-time alerts allow teams to coordinate actions efficiently. For example, a sudden spike in customer orders triggers notifications to production and procurement simultaneously, enabling rapid response without manual coordination. This synchronicity enhances throughput, reduces latency, and amplifies overall organizational responsiveness.

Transparency also strengthens accountability. By making performance metrics and operational data visible to relevant stakeholders, INFOR M3-123 ensures that responsibilities are clearly delineated and that deviations from expected performance are promptly addressed. This level of operational clarity fosters a proactive organizational culture where issues are anticipated and mitigated before they escalate.

Scalability and Enterprise Adaptability

INFOR M3-123 is designed to scale alongside organizational growth. Whether managing a single facility or an international network of warehouses, the system adapts fluidly to increasing operational complexity. Its modular architecture allows enterprises to incrementally activate new functionalities as needed, avoiding the pitfalls of rigid, monolithic software.

Resource allocation is dynamically optimized. As transaction volumes increase, the system adjusts computational prioritization, ensuring that performance remains consistent. Cloud-based and hybrid deployment options further enhance scalability, enabling organizations to expand infrastructure without disruptive overhauls.

Enterprise adaptability extends to process configuration. Organizations can modify workflows, integrate emerging technologies, and redefine operational hierarchies without extensive system redevelopment. This flexibility ensures that INFOR M3-123 remains a future-proof platform, capable of accommodating evolving business models and market exigencies.

Workflow Automation and Operational Orchestration

INFOR M3-123’s automation transcends conventional procedural efficiency, evolving into a quasi-autonomous operational intelligence. Beyond the execution of mundane tasks, the platform orchestrates multi-step processes with a temporal and logical sophistication that mimics human reasoning. Conditional triggers operate as vigilant custodians, parsing transactional inputs and flagging anomalies with surgical precision. For instance, an order that deviates from pre-defined thresholds can be rerouted to a managerial queue, while standard replenishments proceed unfettered. This duality of autonomy and oversight not only mitigates human error but also liberates cognitive bandwidth for strategic contemplation.

In addition, the system’s event-driven architecture allows real-time responsiveness. Stock depletion, for example, can activate a cascade of automated procedures: supplier notifications, internal inventory updates, and predictive restocking alerts. Organizations thus cultivate a rhythm of operations in which continuity is maintained even amidst unpredictability. Routine interventions become exception-based, enabling personnel to focus on value-intensive engagements such as process refinement and risk mitigation. The platform’s automated orchestration therefore acts as a silent executive, preserving operational momentum while ensuring judicious human oversight.

Interface Configurability and Cognitive Ergonomics

The user interface of INFOR M3-123 is not merely a visual façade but a dynamic cognitive scaffold. Dashboards can be sculpted to reflect the operational priorities of departments, roles, or even individual users. Critical data points emerge prominently while extraneous elements recede into background layers, fostering an environment of cognitive clarity. Menu hierarchies are malleable, allowing navigational pathways to be optimized according to workflow frequency and complexity. Notifications are programmable with thresholds, ensuring that attention is drawn only when necessary, thereby preventing alert fatigue and enhancing decision acuity.

The system also accommodates a globalized workforce through multi-lingual and multi-currency capabilities. Teams dispersed across continents can operate within a cohesive ecosystem, free from the frictions of localized formats or incompatible numeric conventions. This global interface adaptability enhances cross-functional collaboration, enabling synchronized operational execution across time zones. By harmonizing human cognition with data presentation, INFOR M3-123 transforms the user experience into a medium of strategic clarity rather than mere task execution.

Ecosystem Integration and Data Synergy

Interoperability is a linchpin in INFOR M3-123’s architecture, positioning the platform as the nexus of organizational data ecosystems. Through robust API frameworks, it establishes bi-directional communication channels with e-commerce interfaces, supplier networks, and external analytical engines. Data becomes a living, malleable entity, traversing systems without loss of fidelity or contextual nuance.

Consider the case of inventory management integrated with supplier logistics. As inventory levels fluctuate, the system autonomously communicates with supplier platforms to initiate restocking, while concurrently updating internal dashboards and predictive analytics modules. This seamless information flow obviates redundant data entry and accelerates decision-making cycles. Similarly, integration with analytical engines allows for real-time pattern recognition, anomaly detection, and resource optimization, transforming disparate data points into a cohesive strategic panorama. The platform’s integrative capacity ensures that organizations operate not as isolated silos but as a synaptic network, responsive and anticipatory in equal measure.

Predictive Analytics and Prescriptive Insight

The analytical suite within INFOR M3-123 functions as a cognitive amplifier, converting historical data into forward-looking intelligence. Machine learning algorithms parse extensive datasets to identify latent patterns, forecast operational trends, and propose resource allocation strategies optimized for both efficiency and profitability.

For example, demand forecasting modules analyze seasonal fluctuations, regional sales patterns, and market signals to produce probabilistic projections. Simultaneously, anomaly detection tools flag aberrant transactions that might signify supply chain disruption, fraud, or operational inefficiency. The prescriptive dimension takes these insights further: by simulating multiple strategic scenarios, managers can evaluate the ramifications of divergent operational decisions before committing resources. The fusion of predictive and prescriptive analytics transforms the organization into a proactive entity, capable of navigating uncertainty with scientific precision rather than reactive conjecture.

Scenario modeling is particularly transformative. By adjusting variables such as supply lead times, promotional campaigns, or labor availability, managers can simulate potential outcomes and stress-test operational strategies. This capability fosters a culture of anticipatory problem-solving, wherein decisions are grounded in empirical foresight rather than historical inertia. The analytical rigor embedded within INFOR M3-123 thus functions as both compass and telescope, guiding immediate operational choices while illuminating future opportunities and threats.

Security Stratagems and Regulatory Adherence

INFOR M3-123’s security paradigm is both comprehensive and adaptive, integrating preventive, detective, and corrective measures. Role-based access control ensures that each user interacts only with information germane to their responsibilities, minimizing exposure of sensitive data. Multi-factor authentication fortifies entry points, while encryption safeguards data at rest and in transit, ensuring confidentiality and integrity.

Compliance automation extends this protective envelope by continuously auditing operational activities against statutory mandates. Organizations operating across multiple jurisdictions benefit from real-time monitoring of regulatory adherence, reducing the risk of inadvertent infractions. For instance, automated checks may flag transactions that contravene local tax regulations or international trade restrictions. By embedding compliance into operational workflows, INFOR M3-123 minimizes both regulatory exposure and operational friction, allowing organizations to focus on strategic execution rather than procedural oversight.

Reporting Customization and Decision Facilitation

The reporting ecosystem within INFOR M3-123 is designed to be both malleable and incisive. Users can construct elaborate queries spanning multiple data dimensions, and subsequently visualize insights in forms that best facilitate comprehension and decision-making. Timed report distribution ensures that stakeholders receive relevant intelligence at the optimal juncture, aligning operational awareness with decision-making rhythms.

Bespoke visualization capabilities empower managers to discern patterns and correlations that might otherwise remain obscured. Heatmaps, trend graphs, and scenario overlays provide multi-layered perspectives, transforming raw data into narrative insight. By enabling granular control over what information is surfaced, when, and to whom, the system ensures that intelligence is actionable rather than overwhelming. The platform thereby converts reporting from a retrospective exercise into a forward-looking instrument of strategic agility.

Strategic Transformation Through Feature Leverage

The convergence of automation, interface configurability, integration, analytics, security, and reporting catalyzes a fundamental transformation of organizational operations. INFOR M3-123 is not merely a transactional platform; it becomes an operational lodestar, guiding enterprises through the complexities of modern commerce. Organizations leveraging its full capabilities gain unprecedented agility, allowing them to anticipate market shifts, optimize resource allocation, and sustain operational coherence under fluctuating conditions.

By embedding intelligence into workflows, organizations elevate routine processes into strategic levers. Decision-making evolves from reactive management to proactive orchestration, informed by predictive insights and scenario simulations. The amalgamation of operational foresight, cognitive clarity, and systemic resilience positions enterprises to not merely survive but thrive in competitive and volatile environments.

Conclusion

INFOR M3-123 stands as a comprehensive, adaptable, and powerful enterprise solution that harmonizes operations across industries. From foundational navigation and core functionalities to advanced analytics, workflow automation, and financial management, the system equips organizations with the tools to operate efficiently, make informed decisions, and maintain strategic agility.

Mastering INFOR M3-123 requires both patience and hands-on engagement. By starting with basic modules, exploring inventory and supply chain management, leveraging financial insights, and customizing advanced features, users transform the software into a strategic asset rather than just a transactional tool. Consistent training, data hygiene, and process standardization ensure accuracy, efficiency, and long-term operational resilience.

Real-world applications demonstrate that businesses—from manufacturing to retail to finance—benefit from integrated operations, predictive insights, and proactive decision-making. By embracing the system’s capabilities and best practices, organizations reduce errors, optimize resources, and respond rapidly to evolving market demands.

Ultimately, INFOR M3-123 is not just software; it is a framework for operational excellence. Organizations that invest in learning, customizing, and strategically applying the system unlock its full potential, achieving efficiency, transparency, and sustainable growth.