Exam Code: CLSSBB

Exam Name: Certified Lean Six Sigma Black Belt

Certification Provider: GAQM

Corresponding Certification: CLSSBB

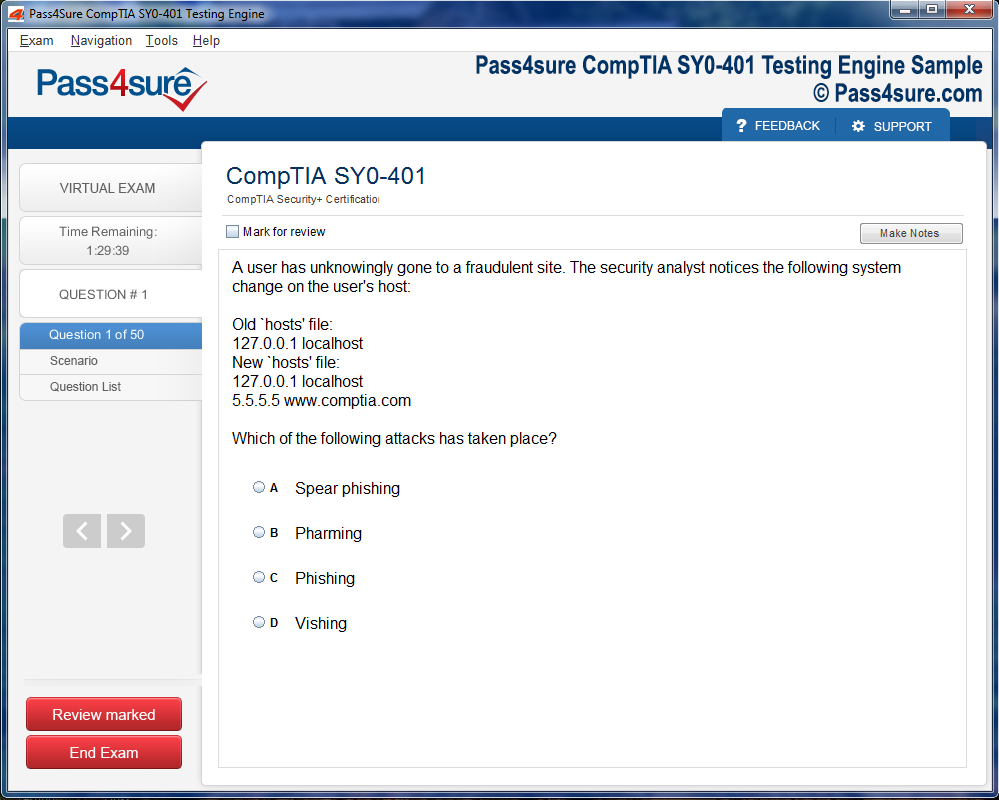

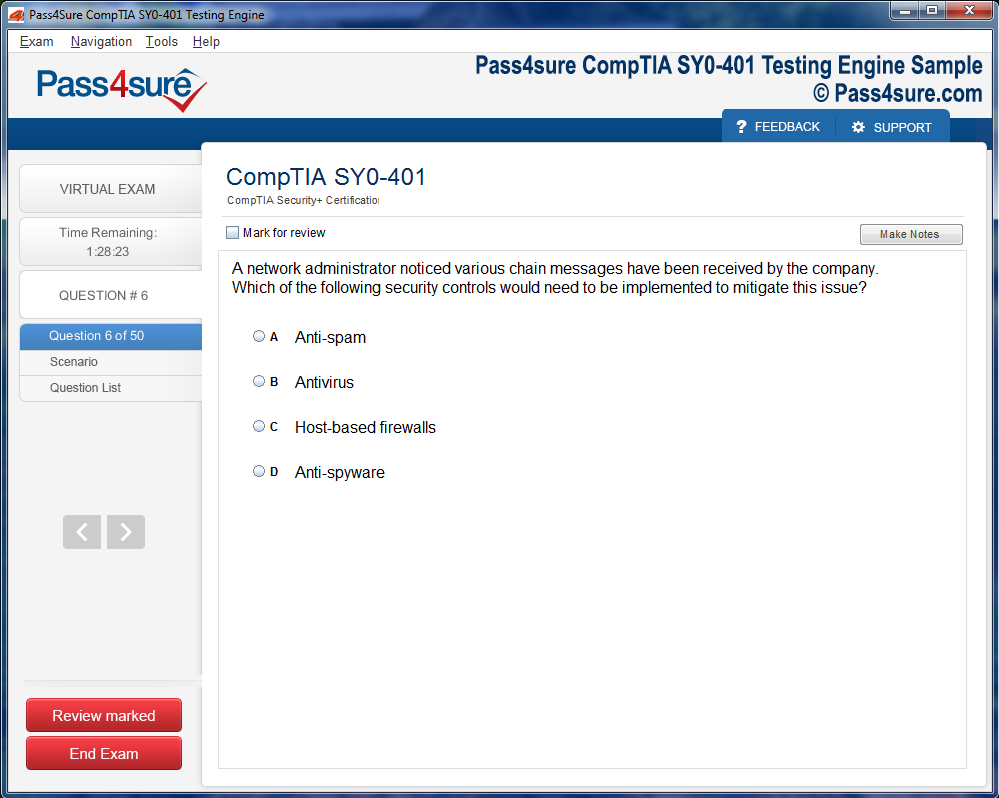

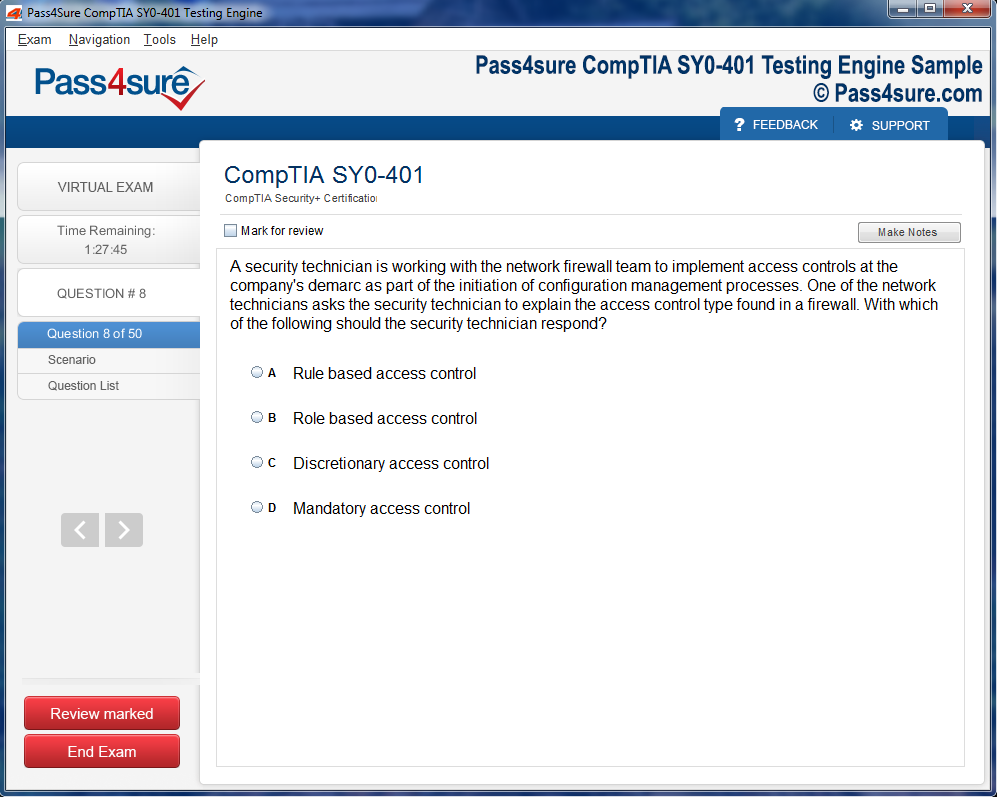

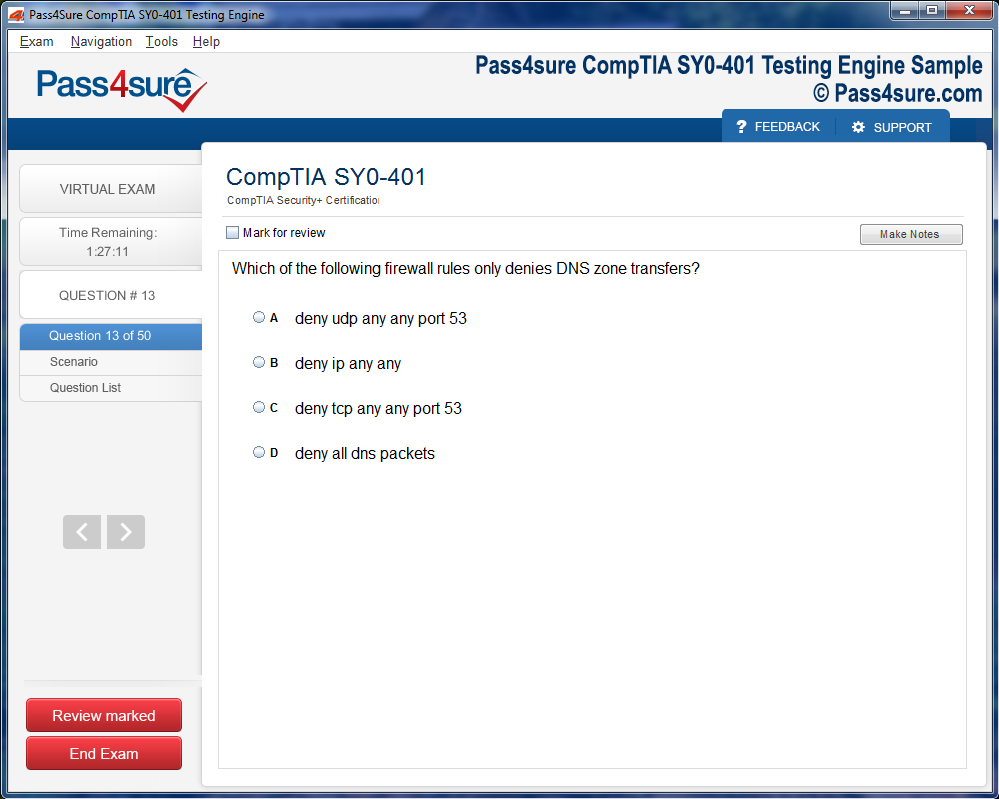

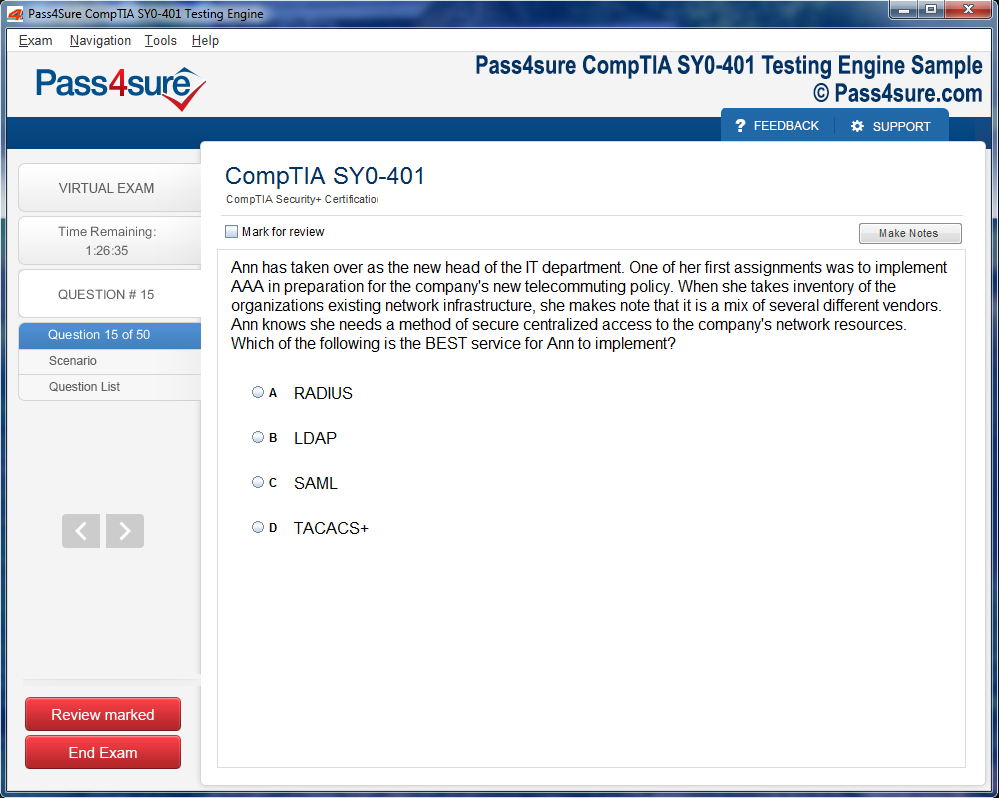

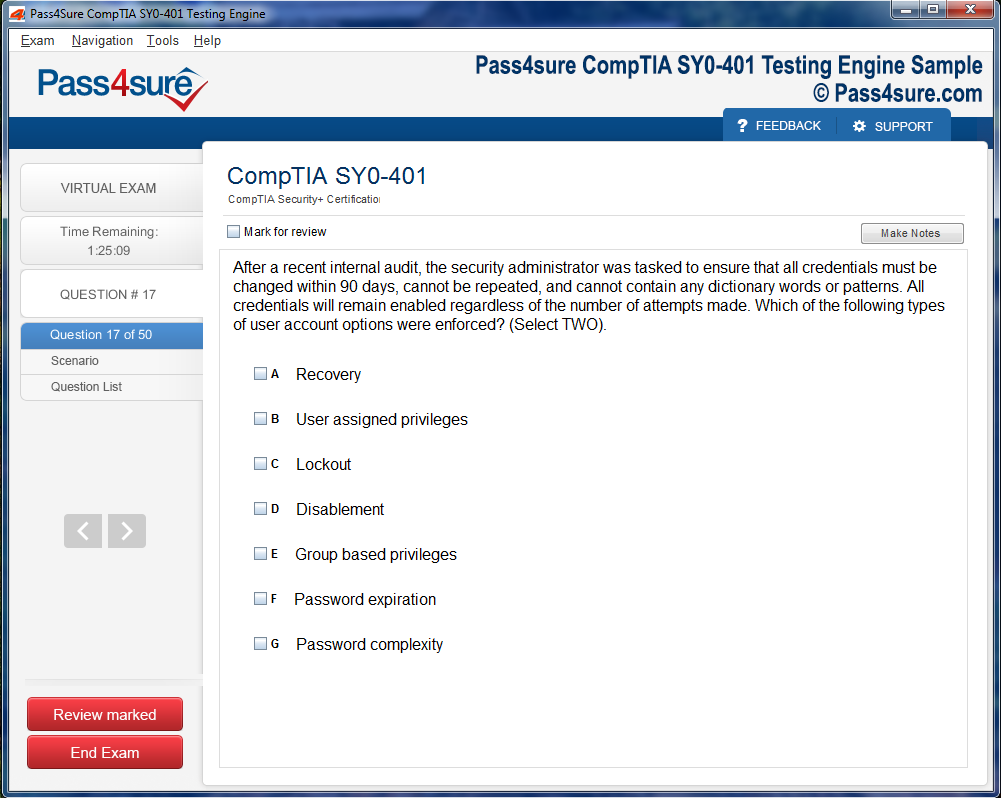

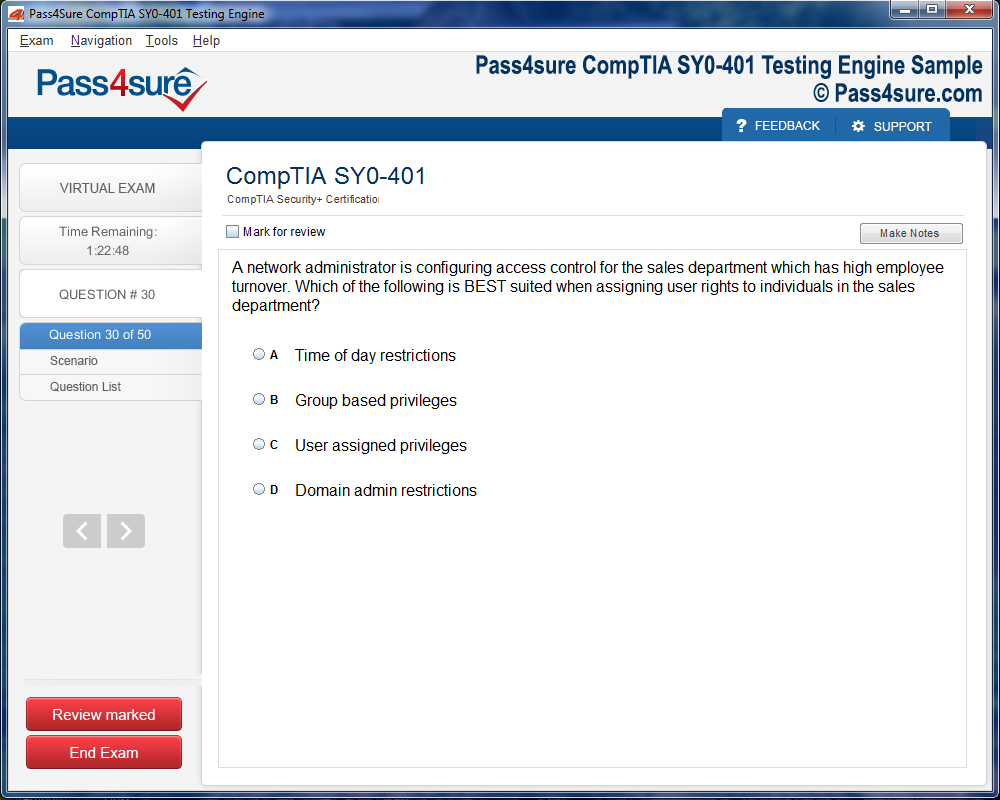

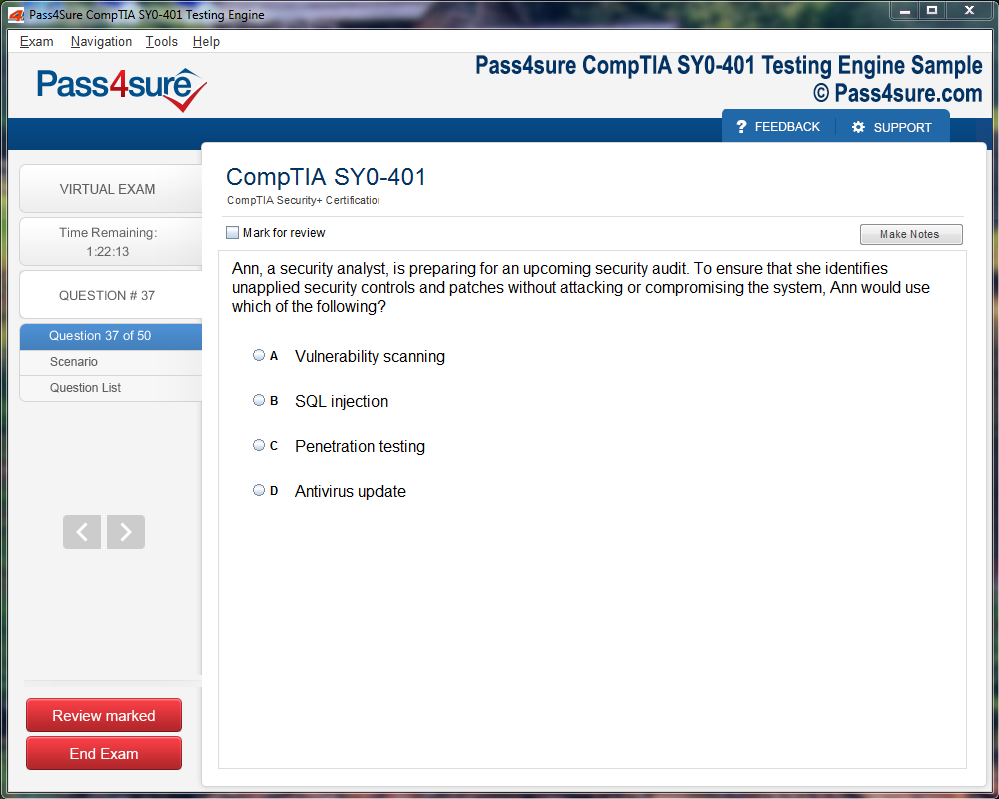

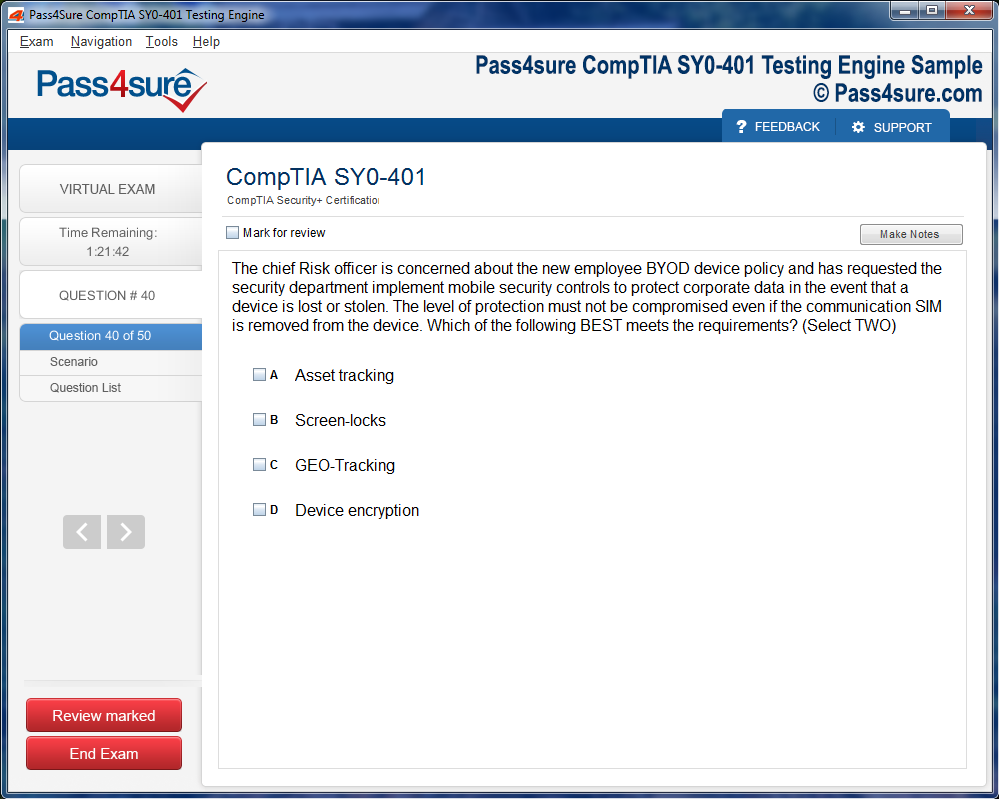

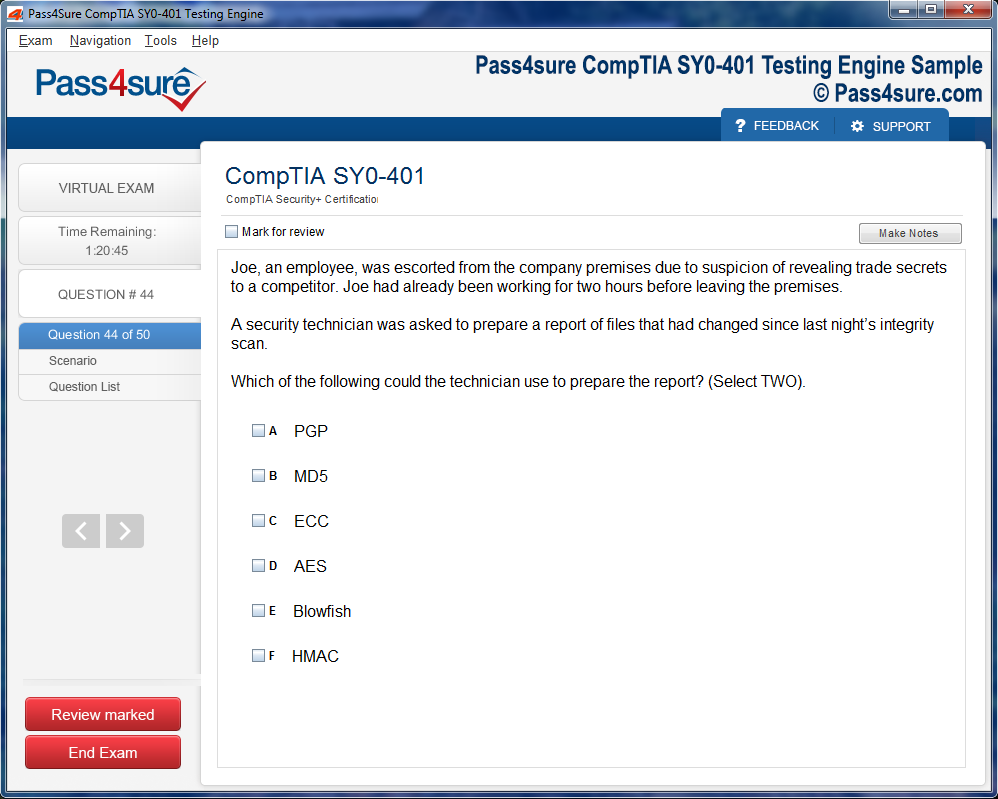

Product Screenshots

Frequently Asked Questions

How does your testing engine works?

Once download and installed on your PC, you can practise test questions, review your questions & answers using two different options 'practice exam' and 'virtual exam'. Virtual Exam - test yourself with exam questions with a time limit, as if you are taking exams in the Prometric or VUE testing centre. Practice exam - review exam questions one by one, see correct answers and explanations.

How can I get the products after purchase?

All products are available for download immediately from your Member's Area. Once you have made the payment, you will be transferred to Member's Area where you can login and download the products you have purchased to your computer.

How long can I use my product? Will it be valid forever?

Pass4sure products have a validity of 90 days from the date of purchase. This means that any updates to the products, including but not limited to new questions, or updates and changes by our editing team, will be automatically downloaded on to computer to make sure that you get latest exam prep materials during those 90 days.

Can I renew my product if when it's expired?

Yes, when the 90 days of your product validity are over, you have the option of renewing your expired products with a 30% discount. This can be done in your Member's Area.

Please note that you will not be able to use the product after it has expired if you don't renew it.

How often are the questions updated?

We always try to provide the latest pool of questions, Updates in the questions depend on the changes in actual pool of questions by different vendors. As soon as we know about the change in the exam question pool we try our best to update the products as fast as possible.

How many computers I can download Pass4sure software on?

You can download the Pass4sure products on the maximum number of 2 (two) computers or devices. If you need to use the software on more than two machines, you can purchase this option separately. Please email sales@pass4sure.com if you need to use more than 5 (five) computers.

What are the system requirements?

Minimum System Requirements:

- Windows XP or newer operating system

- Java Version 8 or newer

- 1+ GHz processor

- 1 GB Ram

- 50 MB available hard disk typically (products may vary)

What operating systems are supported by your Testing Engine software?

Our testing engine is supported by Windows. Andriod and IOS software is currently under development.

CLSSBB Certification Explained: What You Need to Know

In the contemporary tapestry of business operations, efficiency and innovation reign supreme. Organizations incessantly endeavor to harmonize quality, productivity, and customer satisfaction. Within this landscape, the Certified Lean Six Sigma Black Belt (CLSSBB) certification emerges as a beacon of professional excellence. More than a credential, this certification signifies mastery over transformative methodologies that drive tangible organizational advancements. It equips professionals with the acumen to spearhead initiatives that eradicate inefficiencies, optimize processes, and cultivate a culture of continuous improvement.

The CLSSBB is not merely a title; it embodies strategic insight, analytical prowess, and leadership finesse. Individuals who attain this credential become catalysts for change, capable of navigating complex operational challenges with dexterity and foresight. Organizations that invest in CLSSBB-certified professionals often witness measurable enhancements in process performance, cost reduction, and stakeholder satisfaction, making this certification a vital asset in the modern business arsenal.

The Essence of CLSSBB

At its core, the CLSSBB certification represents advanced proficiency in Lean Six Sigma, an integrated methodology that marries Lean principles with Six Sigma rigor. Lean methodology concentrates on streamlining workflows, eliminating redundant processes, and maximizing value generation. Six Sigma, conversely, emphasizes statistical rigor, process standardization, and minimizing defects through data-driven decision-making. Together, they constitute a robust, symbiotic framework for operational excellence.

Professionals armed with CLSSBB credentials are adept at deploying sophisticated tools such as Failure Mode and Effects Analysis (FMEA), Design of Experiments (DOE), and statistical process control. Their skill set enables them to unravel process bottlenecks, design innovative solutions, and implement sustainable operational improvements. Across sectors—from manufacturing floors to service industries—these individuals champion initiatives that translate into enhanced quality, accelerated timelines, and cost efficiency, creating a ripple effect of organizational advancement.

Strategic Advantages of CLSSBB Certification

Possessing the CLSSBB certification confers multifaceted advantages. Firstly, career progression becomes significantly accelerated. Certified professionals are frequently considered for roles such as Process Improvement Manager, Quality Assurance Leader, or Operations Director. The certification conveys credibility, illustrating a profound understanding of process optimization and a commitment to operational excellence.

Secondly, the organizational impact is profound. CLSSBB-certified professionals identify latent inefficiencies, streamline operations, and institute evidence-based solutions that yield measurable improvements. These contributions often manifest in enhanced customer satisfaction, reduced waste, and augmented profitability, thereby establishing certified individuals as indispensable assets.

Thirdly, global recognition is a substantial benefit. As enterprises increasingly operate in transnational markets, the CLSSBB certification provides a competitive edge, signaling the holder’s capability to apply standardized methodologies across diverse environments. This universality fosters adaptability, enabling professionals to navigate cultural, operational, and regulatory differences with confidence and competence.

Finally, personal growth is an inherent advantage. The rigorous journey to certification hones analytical thinking, problem-solving dexterity, and leadership acumen. Professionals refine their ability to manage complex projects, mentor emerging talent, and drive strategic initiatives, cultivating an enduring trajectory of personal and professional enrichment.

Prerequisites for Pursuing CLSSBB

Securing a CLSSBB certification necessitates a foundation of prior knowledge, experience, and practical engagement. A critical prerequisite is a Lean Six Sigma Green Belt certification, which establishes fundamental comprehension of methodologies, tools, and applications. The Green Belt serves as a stepping stone, preparing candidates for the advanced concepts encountered at the Black Belt level.

Equally important is professional experience. Candidates should typically possess a minimum of three years in roles demanding process improvement, quality management, or operational leadership. This experiential background ensures practical familiarity with process dynamics, statistical analysis, and project management—elements vital for successfully leading complex improvement initiatives.

Educational background, while flexible, is advantageous. Degrees in engineering, business administration, or related fields provide a robust framework for understanding operational and analytical principles. Moreover, proficiency in statistical tools, data analytics, and process mapping enhances the candidate’s ability to interpret, evaluate, and optimize workflows.

Project experience constitutes another pivotal prerequisite. Candidates are often expected to have participated in or led at least one Six Sigma project, demonstrating the practical application of DMAIC methodology. This hands-on exposure reinforces theoretical knowledge, enabling candidates to translate analytical insight into tangible organizational improvements.

Preparing for the CLSSBB Examination

Preparation for the CLSSBB examination demands a comprehensive strategy that integrates structured learning, self-directed study, and practical application. Formal training programs delivered by accredited institutions form the backbone of preparation. These courses delve into advanced topics, including statistical process control, regression analysis, hypothesis testing, and Lean process architecture, equipping candidates with the requisite technical and strategic knowledge.

Complementing formal training is dedicated self-study. Candidates utilize reference texts, practice examinations, and online learning modules to reinforce key concepts. Engaging with interactive forums and study groups can provide alternative perspectives, clarify doubts, and foster collaborative problem-solving, all of which augment comprehension and retention.

Equally indispensable is the practical application of Lean Six Sigma principles. Implementing methodologies in real-world projects allows candidates to confront operational challenges, analyze complex datasets, and apply solutions under dynamic conditions. This experiential learning not only deepens understanding but also cultivates the decision-making confidence required for exam success and professional efficacy.

Leadership and Strategic Thinking Through CLSSBB

Achieving the CLSSBB certification transcends technical mastery; it fosters leadership and strategic thinking. Certified professionals are trained to evaluate operational systems holistically, identify critical improvement opportunities, and prioritize interventions that maximize value. They develop the acumen to balance risk, resource allocation, and stakeholder interests, ensuring initiatives are both effective and sustainable.

Leadership development is embedded within the certification journey. Candidates learn to mentor Green Belts, guide cross-functional teams, and cultivate an organizational culture receptive to continuous improvement. The ability to inspire collaboration, communicate insights effectively, and navigate organizational dynamics distinguishes CLSSBB-certified professionals as transformative leaders rather than mere process specialists.

Moreover, strategic thinking is reinforced through exposure to complex, data-intensive scenarios. Candidates refine their capacity to anticipate process bottlenecks, predict operational outcomes, and make evidence-based decisions. This synthesis of analytical rigor and strategic foresight positions certified professionals to drive systemic change, ultimately elevating organizational performance to unprecedented levels.

Implementing CLSSBB Principles in Organizational Contexts

The practical implications of CLSSBB certification extend far beyond individual accomplishment. Organizations benefit from the systematic application of Lean Six Sigma principles, which enhance operational efficiency, improve quality, and reduce costs. Certified professionals serve as architects of improvement initiatives, translating analytical insights into actionable strategies that deliver measurable results.

Key organizational applications include process mapping, waste elimination, and statistical analysis for performance optimization. Certified professionals employ techniques such as value stream mapping, root cause analysis, and process simulation to identify inefficiencies and design solutions that enhance throughput and customer satisfaction. These interventions often yield compounded benefits, as streamlined processes improve resource utilization, reduce errors, and accelerate delivery timelines.

Furthermore, CLSSBB-certified individuals are instrumental in cultivating a culture of continuous improvement. By mentoring teams, standardizing best practices, and fostering data-driven decision-making, they instill a mindset that prioritizes innovation, efficiency, and quality at every operational level. This cultural transformation ensures that improvements are sustainable, scalable, and aligned with long-term organizational objectives.

Achieving the Certified Lean Six Sigma Black Belt credential demands more than memorization; it requires a holistic understanding of process improvement, statistical methods, and strategic implementation. Candidates who excel often combine structured instruction, deliberate practice, and real-world application to internalize concepts deeply. Lean Six Sigma Black Belt is not merely a title but a manifestation of disciplined analytical thinking and systematic problem-solving. For aspirants, embracing a learning journey with deliberate structure enhances comprehension, fosters confidence, and ensures readiness for both examination and professional deployment.

Structured approaches to learning provide a solid foundation. They allow candidates to navigate the complex landscape of Six Sigma tools, project management principles, and statistical methodologies. Without a structured plan, even the most intelligent learner may encounter gaps that hinder success. The essence lies in integrating theory with actionable techniques, ensuring that knowledge is not only understood but also operationalized. Consistency in learning, coupled with deliberate engagement with materials, fosters mastery over time.

Comprehensive Training Programs

Formalized training programs form the backbone of successful preparation. These programs, often led by experienced instructors, offer a guided pathway through intricate Lean Six Sigma principles. Through meticulously designed modules, learners encounter both conceptual and applied elements in a harmonious blend. Workshops provide interactive environments where participants practice with peers, discuss scenarios, and simulate project management challenges. Such environments are invaluable for translating abstract theory into practical insight.

Project-based simulations enhance comprehension further. These exercises emulate real-world scenarios, allowing candidates to apply DMAIC methodologies, statistical tools, and process analysis techniques. For instance, participants may examine a manufacturing bottleneck or analyze service workflow inefficiencies. Through iterative evaluation, they not only apply tools but also learn to interpret results, propose solutions, and quantify improvements. The experiential learning component is a critical differentiator between theoretical knowledge and functional competence.

Additionally, access to curated digital resources complements live training. Online question banks, mock exams, and interactive dashboards create opportunities for repetitive practice, reinforcing retention and confidence. The ability to test knowledge in timed conditions cultivates familiarity with exam logistics and reduces performance anxiety. Overall, comprehensive training programs offer a structured, immersive experience that bridges the gap between study and practical application.

Self-Directed Study Techniques

While formal training provides guidance, self-directed study is indispensable for deep understanding. Individual learners must cultivate personal strategies that align with their cognitive style and schedule. Among the most effective techniques is strategic reading. Selecting authoritative books and guides that are updated with contemporary Lean Six Sigma concepts ensures clarity and relevance. Annotating materials and creating marginal notes enhances engagement and facilitates quick reference during revisions.

Practice examinations serve as both diagnostic and reinforcing tools. By attempting questions in realistic scenarios, candidates identify knowledge gaps and refine problem-solving approaches. Over time, repeated exposure to varied question formats strengthens analytical agility and reduces hesitation. Creating concise, structured notes is equally beneficial. Summaries that highlight key DMAIC steps, control charts, and process improvement formulas become quick-access reference points during intensive study phases.

Visualization techniques significantly enhance comprehension. Flowcharts, diagrams, and infographics translate abstract processes into tangible representations. For example, mapping a process using swimlanes clarifies responsibilities and sequences, while fishbone diagrams expose potential root causes. These visual aids simplify complex relationships, allowing learners to internalize concepts efficiently. Integrating multiple study strategies optimizes retention and prepares candidates for both cognitive and applied challenges.

Practical Application and Project Engagement

Application solidifies theory. Candidates who engage in real-world or simulated projects gain experiential insight that enhances exam readiness and professional capability. Initiating small-scale process improvement initiatives provides hands-on experience with Lean tools and Six Sigma methodologies. For instance, improving a workflow within a department, analyzing performance data, or implementing waste reduction techniques exposes learners to practical constraints and iterative problem-solving.

Utilizing statistical software strengthens analytical skills. Software applications facilitate data analysis, hypothesis testing, and result visualization, allowing candidates to translate raw data into actionable insights. Mastery of these tools is essential for demonstrating competence during both project execution and examination scenarios. Additionally, integrating Lean principles into daily workflows reinforces habitual process thinking, fostering efficiency and strategic awareness.

Project engagement encourages reflection and continuous learning. By monitoring outcomes, documenting lessons, and refining strategies, candidates internalize the cyclical nature of DMAIC. This iterative practice not only consolidates technical knowledge but also cultivates leadership qualities essential for guiding organizational improvement initiatives. The combination of theoretical study and applied practice ensures a deep, versatile understanding of Lean Six Sigma principles.

Time Management and Study Discipline

A meticulous approach to time management underpins success. Lean Six Sigma Black Belt aspirants must allocate time judiciously across learning modules, practice sessions, and project engagement. A disciplined schedule, emphasizing regular intervals for review, application, and testing, prevents burnout and optimizes retention. Dividing the study into focused sessions enhances concentration and promotes progressive mastery over complex topics.

Effective time allocation involves balancing theoretical study, problem-solving practice, and hands-on application. Candidates benefit from rotating between activities to maintain cognitive freshness while reinforcing knowledge from multiple angles. Regular review cycles are crucial for strengthening areas of weakness, consolidating key tools, and internalizing methodologies. Structured time management instills accountability, reduces stress, and enhances overall learning efficiency, creating a sustainable pathway toward certification.

Prioritizing tasks according to difficulty and importance ensures that efforts yield maximum benefit. For instance, candidates may dedicate early sessions to mastering DMAIC stages, followed by focused statistical analysis practice. By sequencing tasks strategically, learners achieve incremental progress while avoiding cognitive overload. This methodical approach transforms preparation from a daunting task into a structured, achievable journey, reinforcing confidence and competence simultaneously.

Leveraging Collaborative Learning

Collaboration amplifies comprehension. Engaging with peers, mentors, and professional communities creates an environment rich in discussion, feedback, and diverse perspectives. Group study sessions allow participants to exchange insights, clarify misunderstandings, and explore alternative problem-solving techniques. Mentorship provides guidance, accelerates learning, and offers practical wisdom beyond textual resources. Engaging in forums or discussion groups expands exposure to varied scenarios and encourages adaptive thinking.

Collaborative learning also fosters accountability. When candidates commit to study schedules or project milestones with peers, motivation increases, and procrastination diminishes. Sharing experiences encourages reflective thinking, prompting learners to evaluate their approaches critically. Additionally, teaching or explaining concepts to others reinforces understanding and consolidates knowledge. This dynamic exchange of ideas cultivates a deeper appreciation for Lean Six Sigma principles and strengthens cognitive agility.

Optimizing Mental and Physical Readiness

Sustained focus and cognitive performance require attention to both mental and physical well-being. Regular breaks during study sessions enhance retention, prevent fatigue, and improve analytical precision. Incorporating mindfulness practices or brief meditative exercises promotes concentration, reduces stress, and cultivates mental resilience. Adequate sleep, nutrition, and physical activity further support cognitive function, enabling candidates to engage effectively with complex material.

Strategic preparation extends beyond knowledge acquisition. Candidates who cultivate a positive mindset, manage stress, and maintain balanced routines often outperform peers in both examinations and professional projects. Mental readiness influences recall, problem-solving efficiency, and decision-making under pressure. By integrating holistic self-care with disciplined study, aspirants ensure that their intellectual efforts translate into optimal performance, creating a synergistic foundation for success.

Understanding the Essence of Lean Six Sigma

Lean Six Sigma embodies a harmonious convergence of methodology and mindset, designed to enhance efficiency while eliminating redundancy in organizational processes. Its essence is not merely in the tools and techniques, but in the philosophy that continuous improvement is a relentless pursuit rather than a finite goal. Organizations that internalize Lean Six Sigma often experience a cultural transformation where every team member becomes a guardian of quality and productivity.

At its core, Lean Six Sigma integrates the structured, data-driven approach of Six Sigma with the efficiency-focused principles of Lean. While Lean emphasizes the removal of waste and optimization of flow, Six Sigma introduces statistical rigor to problem-solving, ensuring that processes achieve near-perfect performance. The combined approach encourages meticulous analysis of every operational step, identifying subtle inefficiencies that may otherwise escape notice. Professionals immersed in this practice cultivate a mindset attuned to precision, patience, and persistent refinement, which distinguishes them from conventional operational managers.

Implementation begins with a foundational understanding of value from the customer’s perspective. This perspective illuminates which activities genuinely enhance the end product or service and which merely consume resources without contributing meaning. The distinction, often nuanced and subtle, becomes the compass guiding process redesign, eliminating redundancies, and reinforcing procedures that consistently add value. Over time, this philosophy fosters organizational agility, resilience, and an ingrained culture of proactive problem-solving.

Core Principles and Methodologies

Lean Six Sigma thrives on several foundational principles that orchestrate its effectiveness. The first principle is clarity of purpose, emphasizing that every improvement initiative must align with strategic objectives. Without this alignment, efforts risk becoming fragmented or superficial, achieving incremental changes that fail to resonate at an organizational level. Clarity of purpose acts as the guiding beacon, ensuring that projects contribute measurable impact, enhance customer satisfaction, and optimize resource utilization.

Another central principle is data-driven decision-making. Lean Six Sigma practitioners rely on quantifiable evidence rather than intuition, employing metrics, statistical tools, and analytical frameworks to guide interventions. This rigorous approach minimizes subjectivity, enabling stakeholders to identify the root causes of inefficiencies and variability with precision. Tools such as control charts, process mapping, and hypothesis testing transform abstract observations into actionable insights, facilitating interventions grounded in tangible evidence.

DMAIC—Define, Measure, Analyze, Improve, Control—forms the backbone of Lean Six Sigma problem-solving. Each phase serves a critical function: defining project scope and objectives, quantifying current performance, analyzing data to uncover underlying causes, implementing improvements, and establishing mechanisms to sustain gains. Mastery of DMAIC enables professionals to navigate complex challenges systematically, fostering outcomes that are replicable and resilient.

Equally significant are Lean tools like value stream mapping, 5S methodology, and kaizen events, which complement statistical rigor with pragmatic, operational insights. These methodologies collectively cultivate environments where inefficiencies are swiftly detected, corrected, and prevented from recurring, instilling a rhythm of continuous refinement throughout organizational processes.

Strategic Project Selection and Execution

The success of Lean Six Sigma initiatives hinges on judicious project selection and meticulous execution. Projects should be selected not only for potential impact but also for feasibility and alignment with organizational priorities. Ill-conceived projects can squander resources and dampen enthusiasm, whereas carefully chosen initiatives act as catalysts, demonstrating measurable improvements and reinforcing the value of structured problem-solving.

Project execution begins with detailed scoping, identifying specific objectives, deliverables, and success metrics. Clear articulation of goals ensures that every team member understands their responsibilities and the overarching purpose of the initiative. Additionally, well-defined timelines and milestones create accountability, providing structure for monitoring progress and evaluating results.

During execution, rigorous data collection and analysis are essential. Capturing accurate, relevant data is the cornerstone of evidence-based interventions, enabling teams to identify process bottlenecks, quantify defects, and measure variability. Analytical tools such as Pareto charts, root cause analysis, and regression modeling facilitate deeper understanding, transforming raw information into strategic insights that drive impactful improvements.

Equally important is stakeholder engagement. Lean Six Sigma projects often require collaboration across departments, necessitating effective communication, transparency, and shared commitment. Engaging stakeholders early and maintaining consistent dialogue throughout the project lifecycle fosters buy-in, mitigates resistance, and ensures that improvements are sustainable beyond the immediate initiative.

Navigating the Certification Process

The path to becoming a Certified Lean Six Sigma Black Belt involves multiple stages that extend beyond theoretical study. A clear understanding of the certification process equips candidates to plan effectively and avoid common pitfalls that can impede progress.

Registration and eligibility criteria form the initial gateway. Candidates must typically hold a Green Belt certification, possess a minimum of three years of relevant professional experience, and meet educational requirements specified by the certifying body. This ensures that candidates have foundational knowledge, practical exposure, and sufficient context to apply advanced problem-solving techniques effectively.

The examination itself encompasses multiple formats. Candidates encounter multiple-choice questions evaluating DMAIC comprehension, Lean tools, and statistical methods. Scenario-based questions assess analytical reasoning and problem-solving acumen, requiring candidates to demonstrate the application of methodologies to real-world challenges. In certain programs, practical exercises or case studies test the ability to implement improvements under time constraints, reflecting the dynamic demands of professional environments.

Beyond the exam, some certifying bodies mandate evidence of completed projects. Candidates must document detailed project plans, demonstrate systematic problem-solving, and evaluate outcomes in terms of efficiency gains, defect reduction, or cost savings. This ensures that certification reflects practical competence rather than theoretical knowledge alone.

Maintenance of certification is an ongoing endeavor. Professionals are encouraged to engage in continuous improvement activities, attend workshops, and stay abreast of evolving Lean Six Sigma practices. This lifelong commitment reinforces expertise, ensuring that the designation signifies sustained capability rather than a transient achievement.

Advanced Statistical Applications in Process Improvement

Statistical analysis lies at the heart of Lean Six Sigma, providing a robust framework for decision-making. Advanced statistical techniques enable practitioners to detect patterns, quantify variability, and predict outcomes with confidence. Mastery of these tools distinguishes proficient Black Belts from casual practitioners, transforming intuition into precision-guided interventions.

Techniques such as hypothesis testing, regression analysis, and design of experiments allow teams to discern causal relationships within complex systems. These methodologies illuminate the factors driving variability, revealing opportunities for optimization that might otherwise remain hidden. Control charts monitor ongoing performance, flagging deviations from expected norms and prompting timely corrective action.

Equally critical is the application of probability theory and statistical modeling to forecast potential outcomes. By simulating scenarios and estimating the likelihood of success for various interventions, practitioners can make informed decisions while minimizing risk. This analytical rigor complements Lean principles, ensuring that process improvements are both efficient and reliably effective.

Moreover, statistical competence fosters confidence among stakeholders. Decision-makers are more likely to embrace recommendations supported by quantitative evidence, enhancing organizational alignment and reinforcing the credibility of improvement initiatives.

Cultivating a Culture of Continuous Improvement

Beyond methodologies and certifications, the true power of Lean Six Sigma manifests in cultural transformation. Organizations that embrace continuous improvement create ecosystems where innovation, efficiency, and quality are interwoven into daily operations. Employees at all levels internalize a mindset that seeks to optimize, refine, and enhance processes consistently.

Leadership plays a pivotal role in this cultural evolution. By modeling commitment to improvement, providing resources for professional development, and recognizing contributions to efficiency gains, leaders reinforce the value of Lean Six Sigma principles. This encouragement nurtures intrinsic motivation, fostering a workforce that actively identifies inefficiencies and proposes solutions without external prompting.

Continuous improvement culture also emphasizes learning from setbacks. Rather than penalizing failures, organizations analyze deviations to extract lessons and implement safeguards. This perspective transforms mistakes into opportunities for growth, embedding resilience and adaptability into the organizational DNA.

Collaboration is another cornerstone of sustainable improvement culture. Cross-functional teams engage in knowledge sharing, collective problem-solving, and mutual accountability. This synergy accelerates the dissemination of best practices, promotes innovation, and ensures that improvements are systemic rather than isolated.

Ultimately, Lean Six Sigma transcends operational enhancement to become a philosophy that shapes mindset, behavior, and organizational identity. It cultivates an environment where excellence is pursued relentlessly, every process is scrutinized with care, and success is measured not only by outcomes but by the enduring capacity for innovation and efficiency.

Leveraging Technology for Lean Six Sigma Excellence

In the modern era, technology serves as a powerful enabler of Lean Six Sigma initiatives. Digital tools enhance data collection, facilitate complex analyses, and streamline project management, amplifying the reach and impact of improvement efforts.

Process automation reduces repetitive tasks, freeing practitioners to focus on strategic analysis and solution development. Real-time dashboards provide immediate visibility into key performance indicators, enabling swift identification of deviations and timely intervention. Advanced analytics platforms support predictive modeling, uncovering latent inefficiencies before they manifest as operational disruptions.

Collaboration tools further empower distributed teams, facilitating communication, document sharing, and joint problem-solving regardless of geographical constraints. Cloud-based repositories centralize project data, ensuring consistency, accessibility, and transparency across initiatives.

Technology also democratizes data-driven decision-making. Employees across levels can access analytical tools and performance metrics, fostering a participatory approach to process improvement. This widespread engagement accelerates the adoption of Lean Six Sigma principles and reinforces a culture of accountability and continuous learning.

By harnessing technological capabilities thoughtfully, organizations can amplify the benefits of Lean Six Sigma, achieving higher efficiency, superior quality, and enduring operational excellence.

Career Horizons Unveiled for Certified Professionals

Achieving the CLSSBB (Certified Lean Six Sigma Black Belt) credential is not merely a milestone; it is a gateway to a vast array of professional landscapes. Individuals equipped with this certification find themselves poised to traverse multiple domains, each offering distinct challenges and rewarding experiences. Organizations across sectors value Black Belt professionals for their acumen in streamlining processes, elevating efficiency, and fostering measurable growth. These credentials transform practitioners into pivotal drivers of innovation, enabling them to lead intricate projects and influence strategic decision-making. The breadth of opportunities extends from managerial positions to consultancy roles, each demanding a blend of analytical prowess and leadership dexterity.

The modern corporate environment thrives on individuals who can convert data into actionable insights. A CLSSBB professional is uniquely prepared to do so, leveraging statistical tools, process methodologies, and structured frameworks to implement sustainable improvements. Industries as diverse as healthcare, finance, information technology, and manufacturing are constantly on the lookout for such talent, recognizing that certified Black Belts provide a distinct competitive advantage. This certification is not just a testament to knowledge but a signal of capability, showcasing a professional’s commitment to excellence, precision, and transformational leadership.

Leadership Roles and Strategic Influence

The spectrum of leadership roles accessible to certified Black Belts is expansive and deeply impactful. Beyond conventional supervisory positions, these professionals often inhabit roles such as Process Improvement Managers, Operations Excellence Directors, or Quality Assurance Leaders. Each role requires the capability to navigate complex organizational systems, identify bottlenecks, and deploy strategies that ensure optimal performance. By spearheading large-scale projects, Black Belts cultivate environments where efficiency is not an abstract goal but a tangible outcome.

The influence of a Black Belt extends beyond operational efficiency; it permeates organizational culture. Leaders with this certification often act as mentors, guiding Green Belts and emerging professionals through the intricacies of Lean Six Sigma methodologies. They instill a culture of continuous improvement, emphasizing data-driven decision-making and fostering analytical thinking throughout their teams. The leadership of a Black Belt is thus both technical and inspirational, combining the ability to dissect complex problems with the vision to drive meaningful change across entire departments or business units.

Cross-Industry Applications and Mobility

One of the most compelling aspects of CLSSBB certification is its applicability across industries. While the principles of Lean Six Sigma originated in manufacturing, they have evolved to meet the nuanced demands of healthcare, banking, logistics, and technology. In healthcare, for instance, certified professionals streamline patient care processes, reducing waiting times and improving resource allocation. In banking and finance, they optimize workflows, minimize transactional errors, and enhance compliance mechanisms.

Moreover, the certification offers unparalleled professional mobility. Black Belts are often sought after internationally, as the methodologies they master are universally recognized. This global applicability enables professionals to explore diverse roles in different cultural and organizational settings. The ability to adapt Lean Six Sigma principles to unique contexts distinguishes Black Belts as versatile problem solvers, capable of delivering consistent results regardless of industry constraints or geographic boundaries.

Mentorship and Knowledge Dissemination

Post-certification, the role of a Black Belt frequently expands into mentoring and knowledge dissemination. Experienced professionals guide Green Belts and other team members through the practical application of Lean Six Sigma tools, ensuring that the organization benefits not only from completed projects but from a sustained culture of process excellence. Mentorship also provides an avenue for Black Belts to refine their leadership skills, enhancing their ability to communicate complex ideas with clarity and inspire collective action.

The transfer of knowledge is not confined to formal training sessions. Black Belts influence organizational practices by embedding continuous improvement frameworks into everyday workflows. They demonstrate the utility of data analysis in decision-making, encourage cross-functional collaboration, and facilitate the adoption of best practices. In doing so, they elevate not just project outcomes but the overall competency and resilience of the workforce, creating ripple effects that extend far beyond individual initiatives.

Analytical Mastery and Problem-Solving Expertise

A hallmark of the CLSSBB journey is the cultivation of advanced analytical and problem-solving capabilities. Certified professionals master techniques such as statistical process control, root cause analysis, and predictive modeling, equipping them to tackle complex operational challenges with precision. These skills enable Black Belts to identify inefficiencies, design innovative solutions, and implement changes that yield measurable benefits.

The analytical prowess of a Black Belt is complemented by strategic thinking. Beyond addressing immediate problems, certified professionals anticipate future challenges, design preventative strategies, and holistically assess risk factors. This combination of technical expertise and foresight positions them as indispensable assets within their organizations, capable of steering projects that not only resolve existing issues but also create sustainable pathways for growth and resilience.

Personal Development and Professional Recognition

The journey toward becoming a certified Black Belt is transformative, fostering personal growth alongside professional competence. Individuals develop confidence in managing cross-functional teams, navigating high-pressure environments, and making decisions that impact organizational outcomes. Leadership capabilities are strengthened, allowing professionals to inspire teams, negotiate effectively, and implement strategies that align with corporate objectives.

Recognition within the industry is another significant benefit. Holding a CLSSBB certification signals to peers, employers, and clients that a professional possesses not only knowledge but practical mastery of Lean Six Sigma principles. This recognition opens doors to consulting roles, advisory positions, and invitations to participate in high-stakes projects. The professional identity of a Black Belt is thus characterized by credibility, expertise, and influence, ensuring long-term career sustainability and continuous advancement.

Long-Term Benefits and Career Sustainability

The long-term advantages of achieving CLSSBB certification extend beyond immediate career opportunities. Certified professionals often enjoy higher earning potential, reflecting the premium placed on their expertise and strategic impact. Global recognition further enhances their marketability, providing opportunities for international assignments, consulting engagements, and leadership roles in diverse organizational contexts.

Networking is another enduring benefit. Black Belts join a community of like-minded professionals who exchange knowledge, share experiences, and collaborate on innovative projects. This professional network amplifies opportunities for career growth, mentorship, and collaboration. By integrating technical proficiency with leadership capability, Black Belts cultivate a career trajectory marked by both personal fulfillment and organizational influence.

Understanding the CLSSBB Certification and Its Importance

The Certified Lean Six Sigma Black Belt (CLSSBB) certification has emerged as a powerful credential for professionals seeking to elevate their careers and organizational influence. In today’s competitive business landscape, efficiency, process optimization, and strategic decision-making are highly prized. The CLSSBB provides a structured framework for mastering these skills, enabling professionals to lead complex initiatives, reduce process variation, and foster operational excellence.

Unlike introductory certifications, the Black Belt emphasizes leadership, advanced analytics, and strategic implementation. Professionals holding this credential are capable of navigating intricate business challenges, mentoring colleagues, and deploying methodologies that improve overall organizational performance. The certification acts not only as an indicator of skill but also as a bridge to leadership roles that require decision-making acumen, analytical reasoning, and an aptitude for process innovation.

The importance of CLSSBB extends beyond individual advancement. Organizations benefit from Black Belts’ ability to streamline operations, eliminate waste, and implement sustainable improvements. Through the disciplined application of Lean and Six Sigma principles, certified professionals can enhance quality, reduce costs, and improve customer satisfaction. This makes CLSSBB holders highly valuable assets in industries ranging from manufacturing to healthcare, finance, and technology.

Furthermore, the certification contributes to personal growth. The rigorous study and application of Lean Six Sigma tools enhance problem-solving, critical thinking, and strategic planning abilities. It instills confidence in handling complex projects and navigating challenges with precision and insight. As a result, professionals not only improve their career prospects but also develop skills that are transferable across industries and roles.

Prerequisites and Eligibility for CLSSBB

Before embarking on the path to CLSSBB certification, aspiring candidates must satisfy specific prerequisites that ensure they possess a solid foundation in Lean Six Sigma principles. The certification is designed for experienced professionals who have already demonstrated competence at the Green Belt level.

A primary requirement is holding a valid Lean Six Sigma Green Belt certification. This prerequisite ensures that candidates have a foundational understanding of DMAIC methodology, process improvement tools, and basic statistical analysis techniques. The Green Belt acts as a stepping stone, providing the knowledge necessary to tackle the more advanced concepts explored in the Black Belt program.

Professional experience is equally crucial. Candidates should possess a minimum of three years of experience in roles related to process improvement, quality management, or operational leadership. This experience provides practical exposure to the challenges and opportunities inherent in process optimization, allowing candidates to apply theoretical knowledge effectively.

Educational qualifications, while flexible, typically favor individuals with backgrounds in engineering, business administration, or related fields. Familiarity with data analysis, statistical software, and project management further enhances readiness for the certification journey. Candidates are also encouraged to have led or actively participated in Lean Six Sigma projects, demonstrating practical application of the methodologies.

Meeting these prerequisites ensures that candidates are adequately prepared to handle the rigor of CLSSBB training, examination, and project documentation. It creates a baseline of knowledge and experience that allows professionals to maximize the value of the certification, both for themselves and for the organizations they serve.

Core Topics and Methodologies in CLSSBB

The CLSSBB curriculum is structured to cover a comprehensive range of topics, blending theoretical frameworks with practical applications. At its core lies the DMAIC methodology—Define, Measure, Analyze, Improve, and Control—which provides a systematic approach to process improvement.

The Define phase focuses on identifying project objectives, understanding stakeholder expectations, and mapping key processes. Candidates learn to articulate project charters, determine scope, and align initiatives with broader organizational goals. Mastery of this stage ensures clarity in project direction and sets the foundation for effective problem-solving.

The Measure phase emphasizes data collection, measurement system analysis, and process mapping. Candidates are trained to identify critical metrics, ensure data integrity, and use statistical tools to quantify process performance. This phase develops the analytical rigor necessary for informed decision-making and sets the stage for identifying root causes of inefficiencies.

An analysis involves examining data to pinpoint underlying issues, using advanced statistical techniques such as regression analysis, hypothesis testing, and multivariate analysis. Candidates learn to uncover patterns, correlations, and causative factors that affect process outcomes. This analytical expertise allows professionals to propose targeted, evidence-based improvements.

The Improve phase focuses on designing and implementing solutions to eliminate waste, enhance efficiency, and optimize processes. Candidates are exposed to Lean principles, including value stream mapping, 5S, and Kaizen strategies, to foster continuous improvement. Practical exercises simulate real-world scenarios, reinforcing the application of these tools to achieve measurable results.

Finally, the Control phase ensures long-term sustainability of improvements. Black Belts learn to establish monitoring systems, control charts, and documentation protocols that maintain process stability. Emphasis is placed on knowledge transfer, stakeholder engagement, and risk mitigation to prevent regression and ensure lasting impact.

Additionally, CLSSBB covers strategic deployment, leadership, and project management. Candidates develop skills in mentoring Green Belts, managing cross-functional teams, and aligning initiatives with organizational strategy. Statistical analysis, data-driven decision-making, and Lean tools are integrated throughout, equipping professionals to handle complex operational challenges.

Strategies for Successful CLSSBB Preparation

Achieving success in the CLSSBB certification requires deliberate and structured preparation. The journey demands mastery of advanced concepts, practical application skills, and strategic thinking, all of which can be cultivated through effective study techniques.

Developing a structured study plan is the first step. Candidates should segment their preparation into modules, focusing on each DMAIC phase, Lean principles, statistical analysis, and leadership competencies. Allocating dedicated time for each topic ensures comprehensive coverage while preventing overwhelm.

High-quality study materials are essential for reinforcing learning. Comprehensive manuals, practice exams, scenario-based exercises, and interactive platforms provide a multi-dimensional approach to understanding the curriculum. These resources facilitate cognitive engagement, retention, and the practical application of theoretical concepts.

Collaborative learning enhances understanding. Study groups allow participants to discuss challenges, clarify doubts, and simulate real-world project scenarios. Mentorship from experienced Black Belts provides guidance, shares nuanced strategies, and imparts insights into navigating complex projects and organizational dynamics.

Hands-on experience is critical. Candidates should seek opportunities to apply Lean Six Sigma principles within their workplace or through hypothetical projects. This practical exposure reinforces learning, enhances analytical skills, and builds a portfolio that can be presented during the certification process.

Time management and cognitive reinforcement strategies, such as spaced repetition and active recall, optimize retention. Short, focused study sessions interspersed with practical exercises ensure sustained engagement and reduce fatigue.

By combining structured study, high-quality resources, collaborative learning, practical application, and disciplined time management, candidates can approach the CLSSBB exam with confidence and preparedness.

Navigating the CLSSBB Certification Process

The certification process for CLSSBB involves multiple steps, each designed to verify knowledge, experience, and practical competency. Understanding this process is essential for candidates aiming to achieve the credential efficiently.

The first step is eligibility verification, ensuring that candidates meet the prerequisites for Green Belt certification, professional experience, and project involvement. Accurate documentation of education, certifications, and work experience prevents delays and ensures a smooth enrollment process.

Candidates then enroll in accredited training programs that cover the breadth of Black Belt competencies. These programs provide guided learning, practical exercises, workshops, and assessments, allowing candidates to consolidate knowledge and gain hands-on experience.

An integral component of certification is the project documentation requirement. Candidates must submit a project demonstrating the application of Lean Six Sigma principles to a real or simulated business challenge. Documentation should detail problem definition, data collection, analytical methods, improvement implementation, and control measures. Thorough documentation showcases practical expertise and adherence to methodology, forming a critical part of the evaluation process.

The examination assesses both theoretical knowledge and practical skills, focusing on DMAIC, Lean principles, statistical analysis, and project management. Passing the exam signifies readiness to apply advanced process improvement techniques independently and effectively.

Finally, continuous professional development ensures that Black Belts remain updated with evolving methodologies and best practices. Engaging in workshops, webinars, and ongoing learning strengthens competencies and enhances career longevity.

Career Opportunities and Organizational Impact

Earning the CLSSBB credential opens pathways to strategic roles, leadership positions, and cross-industry opportunities. Certified professionals are often entrusted with high-impact projects and decision-making responsibilities that shape organizational efficiency and growth.

Leadership positions, such as Operations Excellence Manager, Process Improvement Director, and Quality Assurance Leader, allow Black Belts to influence organizational strategy, optimize processes, and mentor teams. Their analytical and problem-solving skills make them indispensable assets in implementing sustainable improvements.

The versatility of the certification ensures applicability across industries. From manufacturing and healthcare to finance and technology, Black Belts bring measurable value by enhancing process flow, reducing waste, and improving customer satisfaction. This adaptability provides flexibility for career mobility and growth.

Financially, certification enhances earning potential and professional recognition. Organizations value the tangible benefits Black Belts bring, including cost reduction, process optimization, and quality improvement. Certified professionals often experience accelerated promotions, higher compensation, and broader influence within their organizations.

Additionally, Black Belts can explore consulting or entrepreneurial ventures. Their expertise in process improvement, strategic implementation, and organizational optimization is highly sought after by companies seeking transformative change. Consulting roles offer exposure to diverse challenges, industries, and business environments.

Beyond individual success, the CLSSBB certification fosters organizational transformation. Certified professionals drive continuous improvement cultures, embed structured problem-solving methodologies, and leave a lasting impact on processes, quality, and team performance. Their influence creates long-term value, ensuring that organizations thrive in competitive and dynamic environments.

Conclusion

The Certified Lean Six Sigma Black Belt (CLSSBB) certification is more than just an advanced professional credential—it is a transformative journey that equips individuals with the skills, knowledge, and leadership required to drive meaningful change within organizations. From the foundational understanding of Lean Six Sigma principles to mastering complex tools and methodologies, the CLSSBB program prepares professionals to tackle real-world challenges with precision, creativity, and strategic insight.

At its core, CLSSBB focuses on the DMAIC framework—Define, Measure, Analyze, Improve, and Control—which provides a structured approach to problem-solving and process improvement. By mastering this methodology, professionals gain the ability to identify inefficiencies, optimize processes, and implement sustainable solutions that yield measurable results. The program also emphasizes the application of Lean principles, statistical analysis, and advanced tools, enabling candidates to make data-driven decisions that enhance productivity, reduce costs, and improve quality across industries.

One of the unique aspects of CLSSBB is its emphasis on leadership and strategic thinking. Certified Black Belts are not only experts in process improvement but also mentors, team leaders, and change agents. They possess the skills to guide cross-functional teams, influence organizational culture, and align process improvement initiatives with business objectives. This combination of technical expertise and leadership acumen makes CLSSBB professionals highly sought after in manufacturing, healthcare, finance, IT, and other sectors.

The certification journey is rigorous, requiring candidates to have prior Green Belt certification, professional experience, and a solid understanding of process management. Through formal training, self-study, and practical application, aspirants develop a deep comprehension of Lean Six Sigma tools and techniques while also learning to apply them in real-world scenarios. Successfully navigating the exam and project requirements demonstrates not only mastery of methodology but also the ability to deliver tangible business outcomes.

Beyond organizational impact, CLSSBB certification brings significant personal and professional benefits. It opens doors to senior leadership roles, enhances earning potential, and provides global recognition. The skills acquired through the program foster critical thinking, analytical ability, and problem-solving, which are invaluable in any professional context. Furthermore, certified professionals become part of a global network of Lean Six Sigma experts, allowing for continuous learning, collaboration, and career growth.

In summary, the CLSSBB certification is a gateway to excellence for professionals committed to advancing their careers while contributing meaningfully to their organizations. By combining technical mastery, leadership skills, and strategic insight, it empowers individuals to transform processes, drive innovation, and create lasting value. For aspirants seeking career growth, organizational impact, and professional recognition, CLSSBB is not just a certification—it is a defining milestone in their journey toward becoming true agents of change.