Certification: CLSSBB

Certification Full Name: Certified Lean Six Sigma Black Belt

Certification Provider: GAQM

Exam Code: CLSSBB

Exam Name: Certified Lean Six Sigma Black Belt

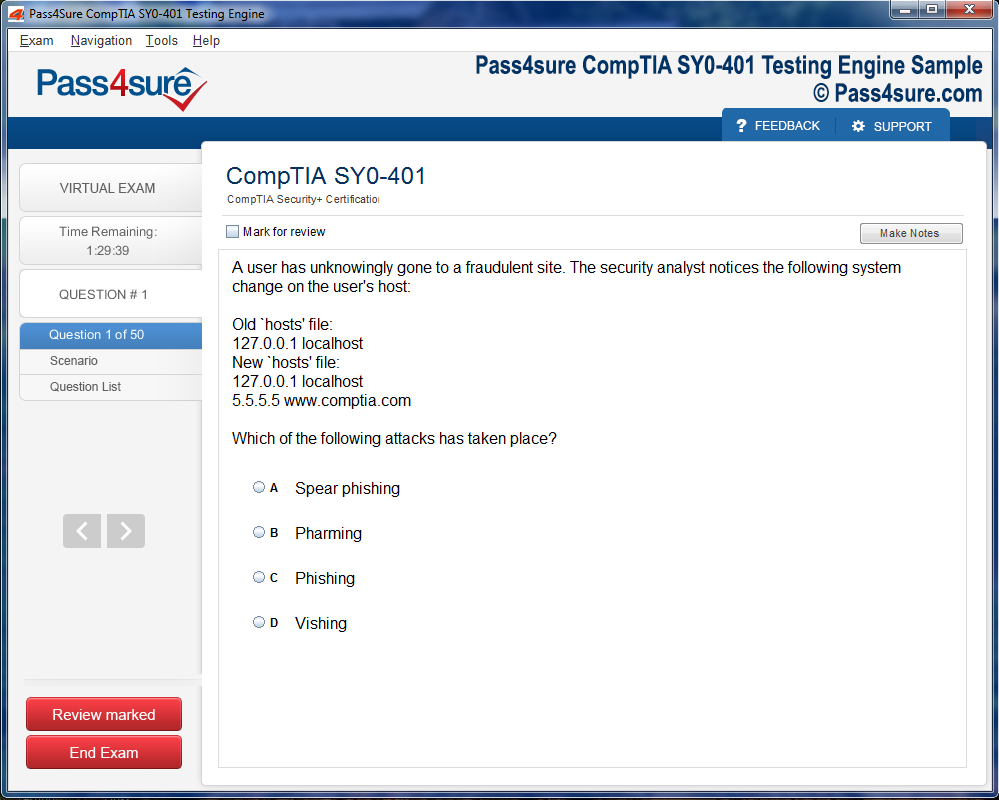

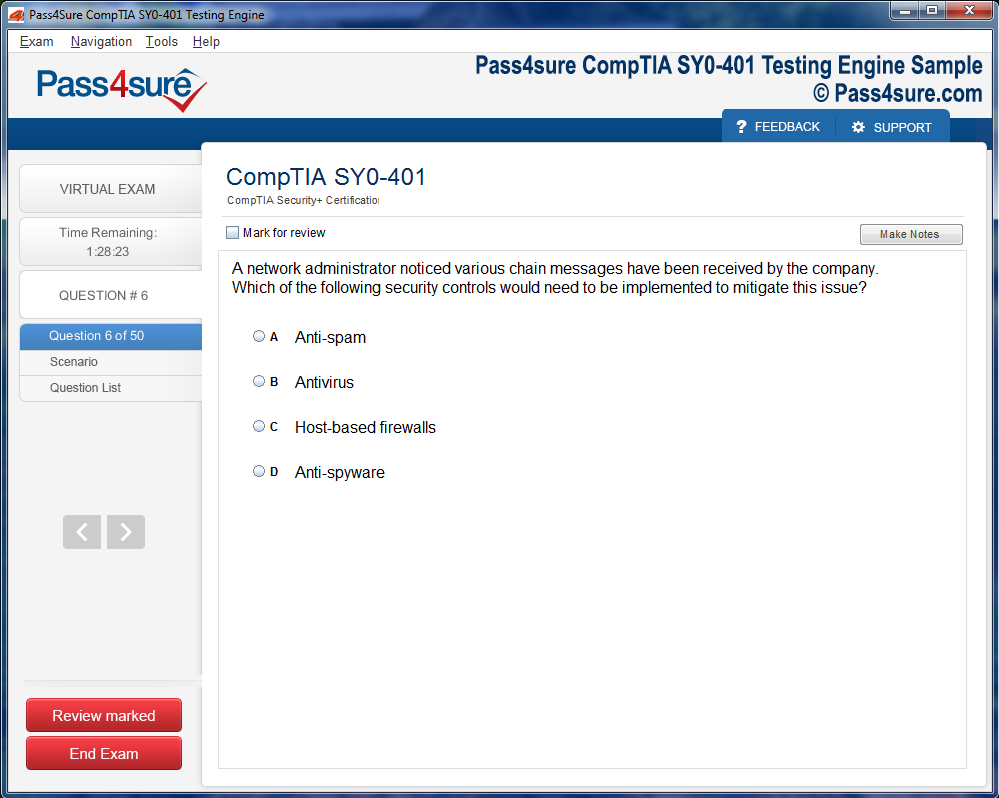

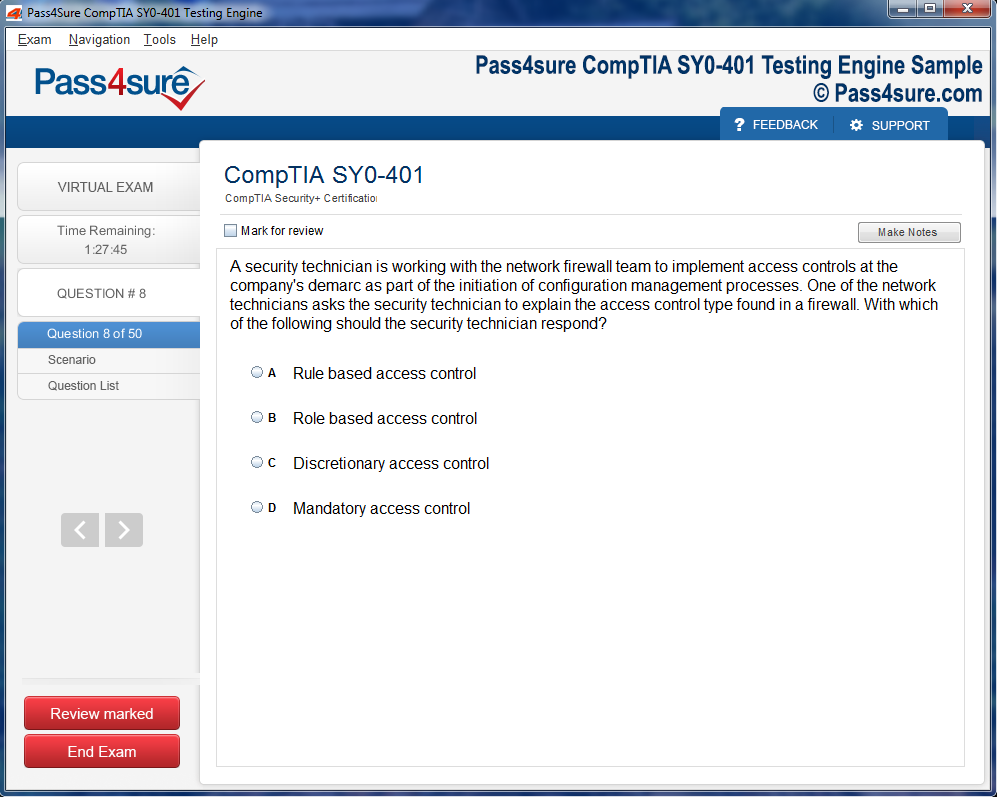

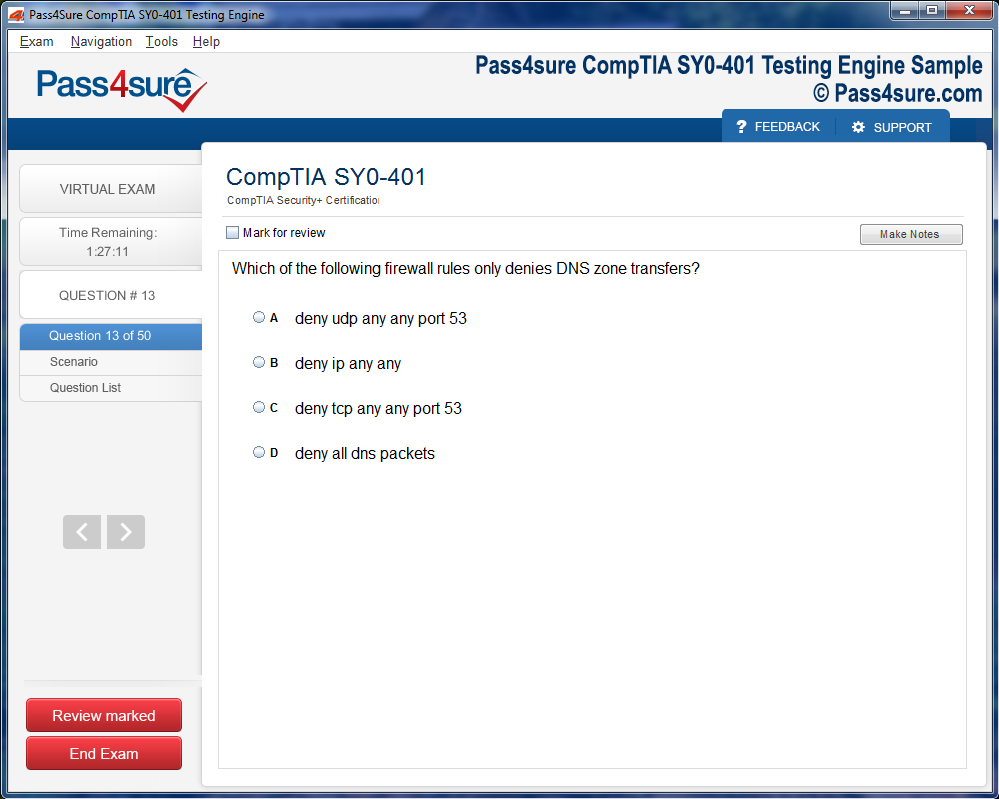

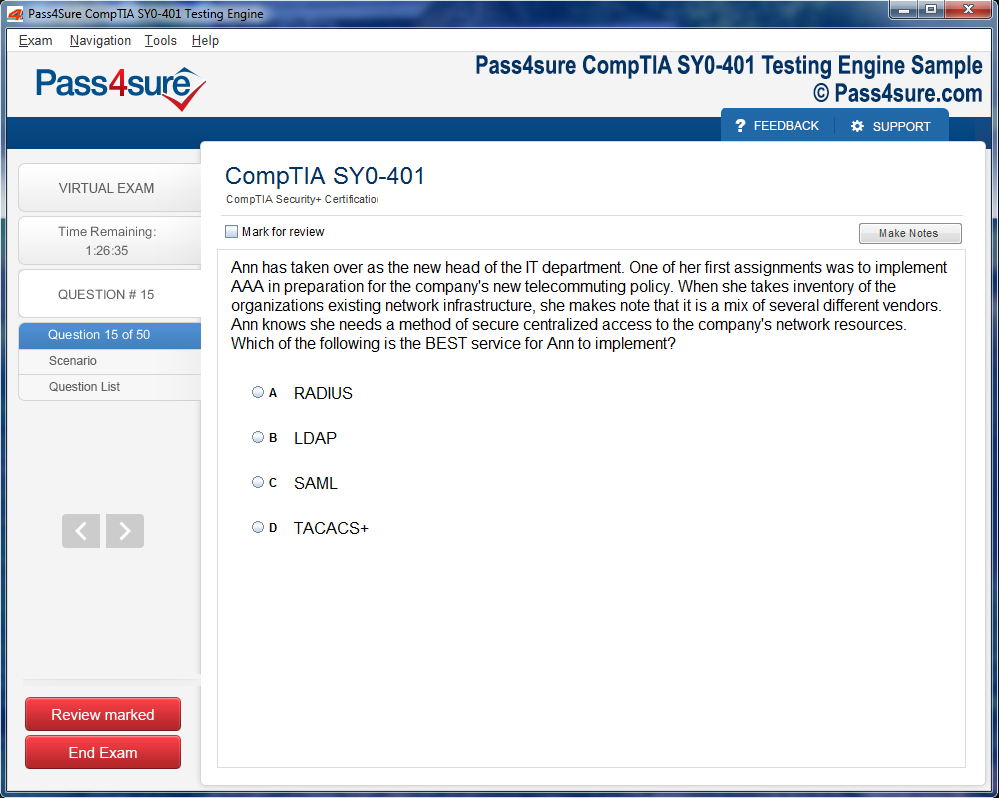

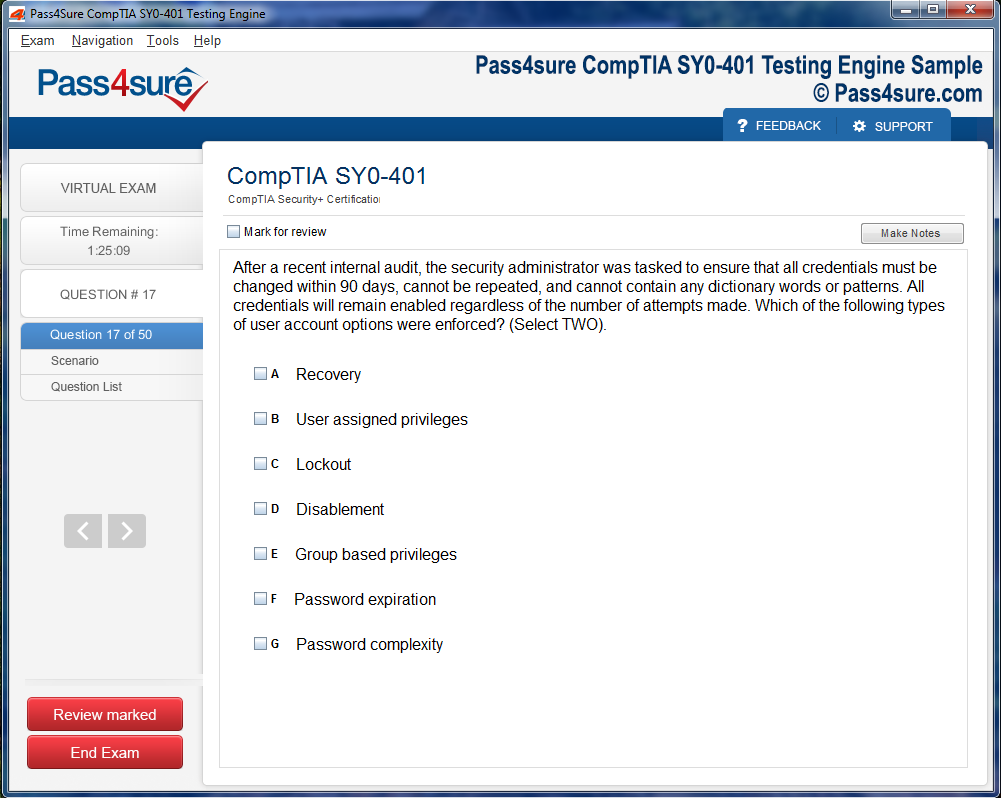

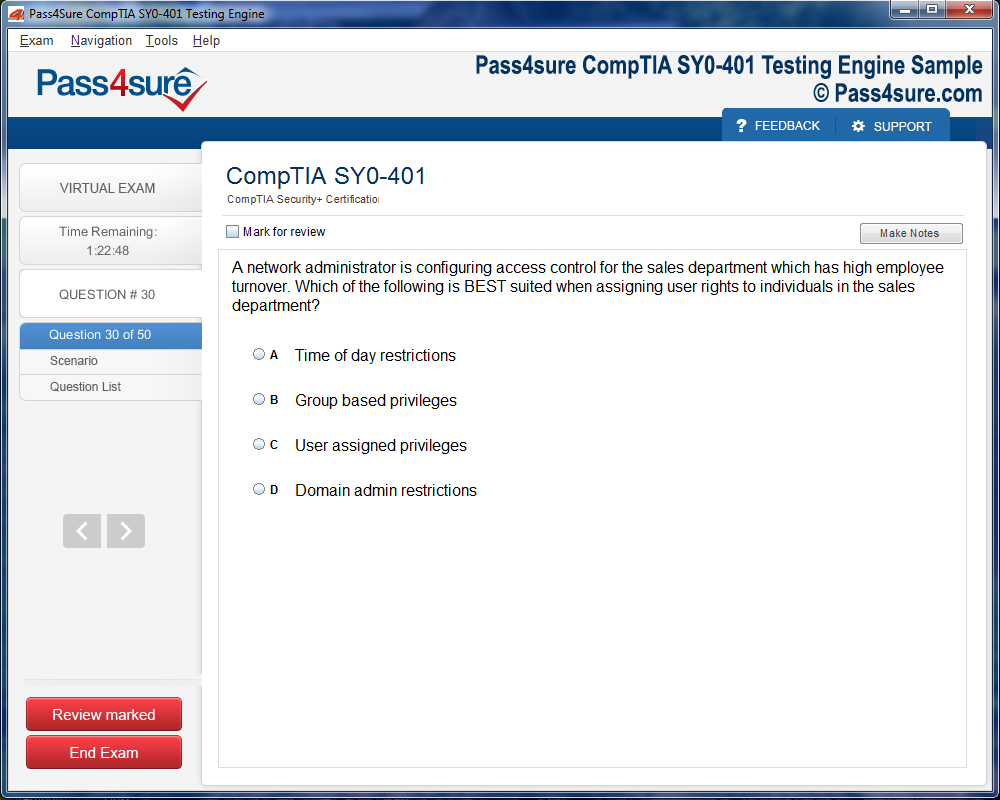

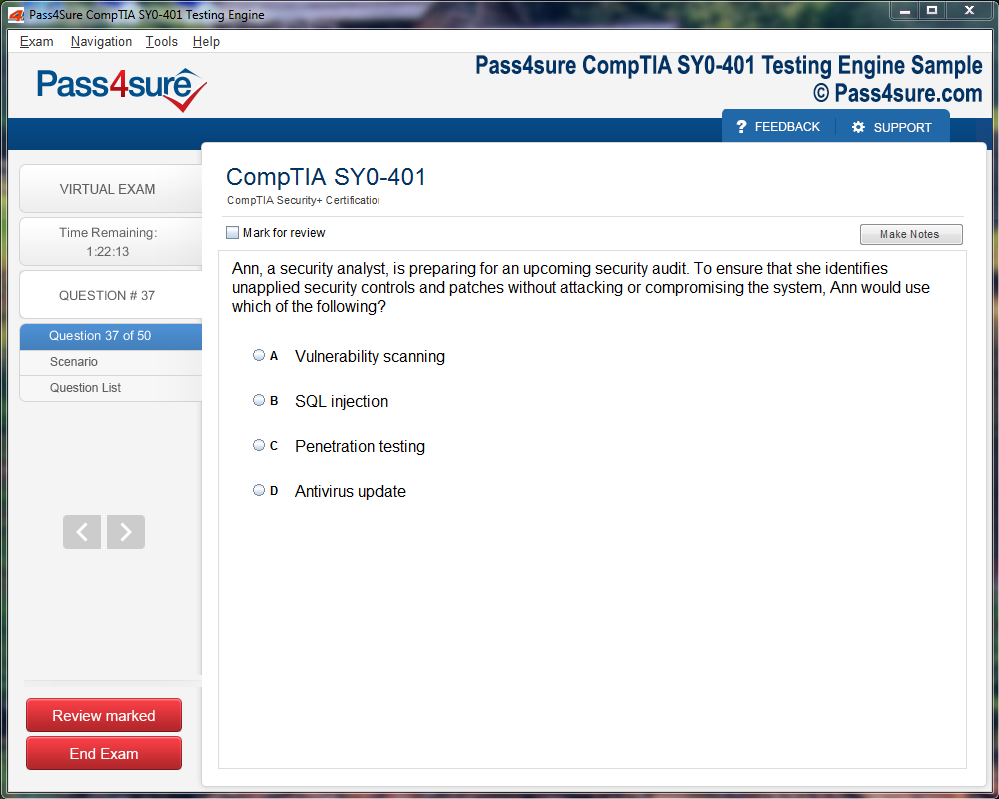

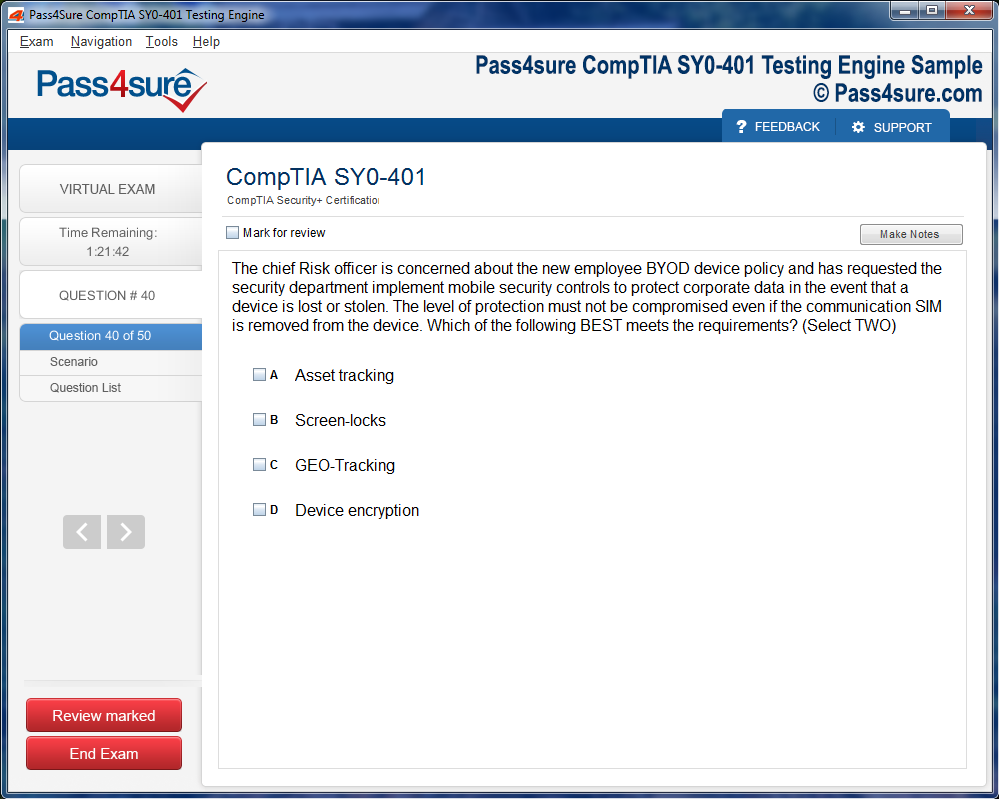

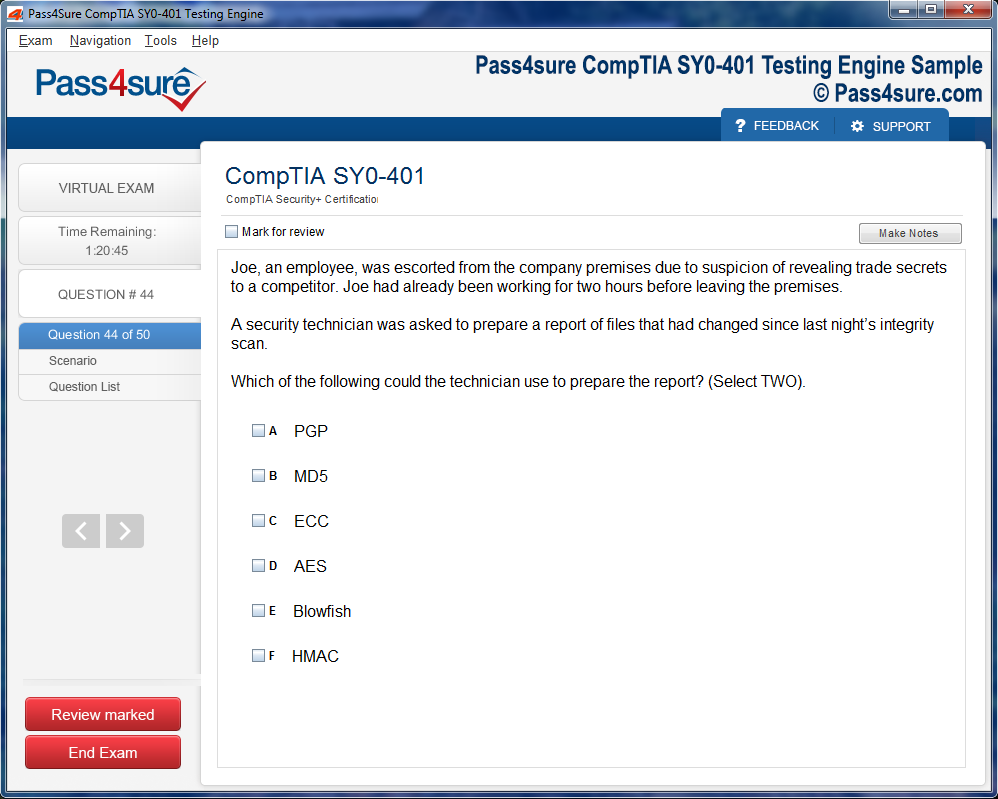

Product Screenshots

How to Become a Certified Lean Six Sigma Black Belt (CLSSBB)

Lean Six Sigma (CLSSBB) operates on the foundation of a few unyielding principles that guide organizations toward operational brilliance. At its essence, it encourages a mindset that relentlessly pursues perfection while acknowledging the human and process limitations inherent in every system. The first principle is an unwavering focus on the customer. Everything within the process—every step, every decision, every innovation—must enhance customer value. Organizations that internalize this philosophy do not just chase efficiency for its own sake; they align every effort with the expectations and desires of their clientele. By embedding the voice of the customer into every strategic initiative, Lean Six Sigma ensures that improvement is tangible and perceptible.

Another cardinal principle is the eradication of waste. Waste, in this context, extends far beyond mere physical inefficiencies. It encompasses wasted time, redundant procedures, overproduction, excessive movement, and any activity that fails to contribute meaningfully to the end product or service. The lean dimension of Lean Six Sigma equips professionals with the tools to identify these latent inefficiencies, quantify their impact, and implement strategies that eliminate them without disrupting essential operations. When practiced rigorously, waste elimination results in processes that are not only faster and less costly but also more resilient to variability and error.

The focus on data-driven decision-making forms another core principle. Six Sigma introduces a rigor that transforms assumptions into verified insights. Professionals rely on statistical analysis to discern patterns, pinpoint deviations, and forecast outcomes with high confidence. This empirical approach cultivates an organizational culture where decisions are grounded in evidence rather than intuition. Leaders trained in Lean Six Sigma harness this principle to justify initiatives, allocate resources efficiently, and measure the tangible impact of improvements over time.

Finally, a principle that distinguishes Lean Six Sigma (CLSSBB) from superficial improvement programs is the emphasis on sustainability. Improvements are valuable only when they endure. This principle underlines the importance of control mechanisms, continuous monitoring, and periodic reassessment of processes. Black Belts, in particular, are trained to design solutions that withstand evolving operational conditions, ensuring that short-term gains transform into long-term benefits. The integration of customer focus, waste reduction, data-driven insight, and sustainability forms the bedrock upon which high-performing organizations construct their competitive advantage.

Statistical Mastery and Analytical Prowess

At the heart of Lean Six Sigma Black Belt (CLSSBB) expertise lies statistical mastery. Black Belts are distinguished by their capacity to decode complex data and translate it into actionable strategies. While Green Belts develop foundational analytical skills, Black Belts delve deeper, exploring multivariate analysis, regression models, hypothesis testing, and advanced probability distributions. These tools enable them to uncover subtle correlations, isolate root causes, and anticipate the ripple effects of process adjustments across the organizational ecosystem.

Beyond the mechanics of statistics, analytical prowess demands a mindset that thrives on curiosity and intellectual rigor. Black Belts are trained to approach problems systematically, dissecting processes with precision and questioning assumptions at every turn. They learn to recognize hidden patterns, reconcile conflicting data, and construct models that simulate potential outcomes before interventions are implemented. This analytical lens transforms decision-making from reactive troubleshooting into proactive orchestration of performance improvement.

Moreover, statistical mastery is intimately tied to risk mitigation. By quantifying variation, forecasting outcomes, and modeling uncertainty, Black Belts provide organizations with the foresight needed to prevent errors, reduce defects, and avoid costly disruptions. This predictive capacity is particularly valuable in industries where precision and reliability are paramount. In this way, the Black Belt role transcends conventional process management, evolving into a strategic function that safeguards operational integrity while fostering innovation.

Project Leadership and Organizational Influence

Lean Six Sigma Black Belts (CLSSBB) are not merely technical experts; they are influential leaders who drive projects that reshape organizational landscapes. Leadership in this context demands more than authority—it requires the ability to inspire, mentor, and galvanize cross-functional teams toward shared goals. Black Belts are adept at translating complex analytical insights into clear, actionable plans that teams can execute effectively. They serve as catalysts for collaboration, ensuring that stakeholders from diverse departments align their efforts with strategic priorities.

The projects led by Black Belts often carry high stakes, encompassing process redesign, operational scaling, and quality enhancement. Success in these endeavors requires a fusion of technical expertise, strategic thinking, and interpersonal skill. Black Belts must anticipate resistance, navigate competing priorities, and communicate progress persuasively to senior management. Through this combination of analytical rigor and leadership acumen, they transform abstract improvement concepts into measurable outcomes that elevate organizational performance.

Mentoring is another critical dimension of project leadership. Black Belts are expected to cultivate the next generation of Lean Six Sigma practitioners, guiding Green Belts and Yellow Belts through the intricacies of problem-solving, project management, and data interpretation. By instilling best practices and fostering a culture of continuous improvement, Black Belts ensure that knowledge and expertise propagate throughout the organization, creating a self-reinforcing cycle of operational excellence.

Process Innovation and Continuous Enhancement

Innovation is inseparable from the Lean Six Sigma (CLSSBB) philosophy. Black Belts are trained not only to optimize existing processes but also to envision entirely new workflows that redefine efficiency and quality standards. Process innovation involves scrutinizing every step for opportunities to reduce variation, enhance throughput, and elevate customer satisfaction. It is a discipline that requires both creative thinking and analytical validation, ensuring that inventive ideas are grounded in practical feasibility and measurable outcomes.

Continuous enhancement is the corollary of process innovation. No improvement is ever truly complete; there is always room to refine, recalibrate, and optimize. Black Belts establish feedback loops, key performance indicators, and monitoring mechanisms that allow organizations to track progress and identify emerging inefficiencies. By institutionalizing a culture of ongoing assessment and adaptation, organizations remain agile in the face of changing market dynamics, regulatory requirements, and technological advancements. The Black Belt’s role is pivotal in embedding this ethos, ensuring that improvement is perpetual rather than episodic.

Technological integration amplifies process innovation. Black Belts increasingly leverage software tools for process mapping, statistical analysis, and real-time monitoring. Automation, data visualization, and predictive analytics become integral instruments, allowing teams to execute complex projects with precision and speed. The interplay of human ingenuity and technological capability magnifies the impact of Lean Six Sigma initiatives, reinforcing the organization’s capacity to achieve operational distinction.

Strategic Impact and Business Transformation

The influence of Lean Six Sigma Black Belts extends far beyond the operational sphere. Their work directly impacts strategic outcomes, shaping the organization’s trajectory in profound ways. By systematically improving quality, reducing waste, and optimizing processes, Black Belts contribute to financial performance, customer satisfaction, and market competitiveness. These improvements are quantifiable and often translate into significant cost savings, faster delivery cycles, and enhanced product reliability.

Black Belts also play a crucial role in embedding a culture of excellence within the organization. Their projects and leadership demonstrate the tangible benefits of disciplined problem-solving, motivating colleagues to adopt similar approaches in their own domains. This ripple effect fosters organizational resilience, ensuring that the principles of Lean Six Sigma permeate all levels of the enterprise rather than remaining confined to isolated projects.

Moreover, strategic impact manifests in the organization’s ability to anticipate and adapt to change. Black Belts equip companies with tools to analyze trends, predict customer needs, and implement proactive improvements. By aligning process excellence with strategic objectives, they create a synergistic effect that reinforces both operational efficiency and long-term competitiveness. In essence, Black Belts function as architects of transformation, guiding organizations from reactive management toward intentional, evidence-based evolution.

Cultivating a Mindset of Excellence

Underlying every technical skill and leadership capability is a mindset that distinguishes successful Black Belts (CLSSBB) from mere practitioners. This mindset is characterized by curiosity, resilience, discipline, and an unrelenting pursuit of improvement. Black Belts approach challenges not as obstacles but as opportunities for learning and innovation. They embrace complexity with composure, recognizing that meaningful improvement often requires navigating ambiguity, negotiating trade-offs, and reconciling competing priorities.

This mindset extends to collaboration and communication. Black Belts understand that analytical insight alone is insufficient; the ability to convey findings, influence decisions, and foster engagement is equally vital. They cultivate empathy, active listening, and persuasive articulation, ensuring that their recommendations resonate across diverse teams and hierarchical structures. By marrying technical mastery with interpersonal dexterity, they embody the ideal of holistic leadership in process improvement.

Finally, the mindset of excellence embraces continuous self-development. Lean Six Sigma (CLSSBB) methodologies evolve, industries transform, and customer expectations shift. Black Belts remain vigilant in updating their knowledge, refining their skills, and exploring emerging methodologies. This commitment to lifelong learning ensures that they remain indispensable assets to their organizations, capable of navigating complexity, driving innovation, and sustaining operational superiority over the long term.

Understanding the Essence of Lean Six Sigma Black Belt

Lean Six Sigma Black Belt is more than a credential; it is a paradigm shift in how organizations approach process improvement. It combines the precision of data analysis with the strategic insight of leadership, creating professionals capable of transforming operations and driving efficiency. The essence of this certification lies in its application, where theoretical knowledge meets practical impact. It is not merely about memorizing tools or statistical formulas but about understanding when, why, and how to implement them for tangible results. Those who embrace the philosophy of continuous improvement find that their skill set evolves beyond problem-solving, extending into organizational influence and strategic decision-making.

Black Belts operate at a nexus of technical proficiency and leadership competence. They are tasked with dissecting complex processes, identifying inefficiencies, and designing solutions that maximize value. The journey toward certification encourages professionals to cultivate analytical thinking, adaptability, and the ability to inspire collaboration. Mastery of Lean Six Sigma concepts is intertwined with the capacity to see beyond the numbers, translating data into narratives that guide informed decisions. This dual focus on process mastery and leadership forms the foundation for sustainable improvement and long-term organizational success.

Strategic Approaches to CLSSBB Preparation

Preparation for the Certified Lean Six Sigma Black Belt (CLSSBB) exam is an endeavor that blends structured study with experiential learning. Candidates must approach it with a strategy, allocating time wisely and integrating multiple learning methods. It is beneficial to create a preparation roadmap that encompasses technical mastery, project experience, and self-reflection. Spreading study sessions over weeks or months helps embed knowledge while minimizing burnout. Many aspirants find success in combining classroom instruction, online courses, and self-directed practice, thereby leveraging diverse perspectives and reinforcing retention.

Structured preparation also involves breaking down the curriculum into digestible modules. Lean Six Sigma encompasses a spectrum of topics, from process mapping and root cause analysis to advanced statistical methods and hypothesis testing. Each module demands attention to detail, and allocating specific time for hands-on exercises can solidify comprehension. Emphasis on real-world application ensures that concepts are not abstract but grounded in scenarios professionals encounter daily. By integrating practice and theory, candidates develop both confidence and competence, laying a strong foundation for exam success.

Selecting the Right Training Program

A pivotal decision in preparation is choosing the right training provider. Accredited programs offer a curriculum aligned with certification requirements and often include interactive elements that enhance learning. Quality training provides more than just technical instruction; it introduces candidates to project management techniques, leadership strategies, and organizational change dynamics. Programs with experienced instructors allow for clarifying doubts, understanding nuanced applications, and gaining insights from case studies and examples.

Training programs that prioritize experiential learning are particularly effective. They encourage participants to engage in live projects, apply statistical tools to real operational issues, and present findings in professional settings. This approach not only reinforces learning but also cultivates the confidence to lead improvement initiatives. Additionally, well-structured programs often provide simulation exercises and mock exams, offering aspirants a glimpse of the examination environment and helping reduce performance anxiety. Selecting a program that balances technical content, leadership development, and practical application is crucial for comprehensive preparation.

Mastering Statistical Tools and Analytical Techniques

Statistical analysis forms the backbone of Lean Six Sigma (CLSSBB) methodologies. Candidates must achieve proficiency in software tools commonly employed in projects, such as Minitab, JMP, and advanced Excel functions. These platforms facilitate a wide range of analyses, including regression, process capability, hypothesis testing, and design of experiments. Mastery of such tools enables aspirants to approach process challenges analytically and derive actionable insights efficiently.

The ability to interpret statistical output is as important as running the analysis itself. Professionals must understand the significance of p-values, control charts, and variation trends, linking numerical results to operational decisions. Developing this skill involves repeated practice, working on sample datasets, and analyzing project outcomes. Candidates who invest time in statistical comprehension not only enhance their exam performance but also acquire a skill set highly valued in professional contexts. Analytical proficiency becomes a tool for decision-making, enabling leaders to implement improvements backed by data rather than intuition.

Experiential Learning Through Projects

Practical application is indispensable for the Black Belt journey. Candidates are encouraged to undertake projects that showcase their ability to drive measurable improvement. These projects vary in scope, from streamlining workflows and reducing cycle times to eliminating defects and cutting operational costs. The focus is on applying Lean Six Sigma principles to real challenges, demonstrating both technical acumen and leadership capability.

Documenting project work is crucial for the certification process. Detailed records of methodology, analysis, interventions, and results provide tangible evidence of competency. Additionally, working on diverse projects exposes candidates to varied organizational contexts, enhancing problem-solving versatility. Experiential learning fosters an understanding that process improvement is iterative, requiring continuous evaluation, adaptation, and reflection. Through these projects, aspirants develop a mindset oriented toward efficiency, quality, and sustainable results.

Time Management and Study Discipline

Effective preparation requires disciplined time management. The Black Belt curriculum is extensive, and without a structured approach, candidates may feel overwhelmed. Developing a study plan that allocates focused time for theory, practical exercises, and statistical analysis enhances learning efficiency. Revisiting challenging topics, testing comprehension through practice exercises, and gradually increasing the complexity of study material ensure thorough understanding.

Consistency is critical. Regular study sessions, even if brief, often yield better retention than sporadic, intensive efforts. Many candidates find that combining self-paced learning with scheduled classes or workshops maintains momentum while providing opportunities for clarification. Allocating specific blocks of time for project work, statistical practice, and theory review enables a holistic approach to preparation, ensuring that candidates remain well-rounded and confident in their capabilities.

Cultivating the Black Belt Mindset

The journey to becoming a Certified Lean Six Sigma Black Belt (CLSSBB) demands more than technical skill; it requires cultivating the right mindset. Patience, resilience, and analytical rigor are indispensable traits. Candidates must embrace challenges, persist through complex data analyses, and adapt strategies when initial approaches do not yield results. The mindset of continuous improvement extends beyond process optimization; it permeates professional growth, leadership style, and collaborative interactions.

Effective Black Belts approach problems methodically, balancing creativity with data-driven decisions. They communicate insights clearly, influence stakeholders, and foster environments conducive to improvement. Developing this mindset involves reflective practice, learning from both successes and setbacks, and nurturing curiosity about processes and systems. A strong mindset amplifies the value of technical expertise, ensuring that candidates are not just proficient analysts but strategic leaders capable of driving organizational transformation.

The Multifaceted Role of a Black Belt

The Certified Lean Six Sigma Black Belt (CLSSBB) occupies a distinctive position within organizations, blending technical acumen with strategic influence. Unlike purely operational roles, the Black Belt bridges the gap between data-driven insights and organizational leadership. This position requires not only understanding the intricacies of processes but also envisioning the broader impact of improvements on business outcomes. Professionals in this role often manage high-stakes projects that can transform entire departments or functions, necessitating a balanced approach to analysis, execution, and people management. Their work transcends the mere application of statistical tools, demanding foresight, intuition, and adaptability in complex environments.

Black Belts are often catalysts for innovation within an organization. By observing patterns, identifying inefficiencies, and proposing interventions, they create a culture of continuous improvement. This culture is not limited to measurable outcomes but extends to behavioral and procedural transformations. Their influence permeates the organization, from frontline employees to senior executives, fostering a shared understanding of quality, efficiency, and value creation. The role, therefore, is as much about shaping mindsets as it is about optimizing processes, requiring a delicate balance between technical rigor and empathetic leadership.

Analytical Mastery and Statistical Expertise

At the heart of Black Belt (CLSSBB) competencies lies a profound understanding of analytics and statistics. These professionals are expected to interpret complex datasets, uncover trends, and translate numbers into actionable insights. Mastery over tools such as regression analysis, control charts, and design of experiments is not optional but essential. These techniques enable Black Belts to quantify variations, measure process capabilities, and predict the impact of changes before implementation. The ability to distinguish between normal variation and meaningful anomalies ensures that interventions are precisely targeted, reducing waste and improving outcomes.

Beyond the technical mechanics of analysis, Black Belts exercise judgment in selecting appropriate methodologies. They must understand the context of data, the limitations of measurement systems, and the implications of statistical assumptions. This discernment allows for tailored approaches to problem-solving that are both effective and sustainable. Moreover, their analytical prowess equips them to provide evidence-based recommendations to leadership, enhancing credibility and fostering informed decision-making at all organizational levels.

Leadership and Organizational Influence

Leadership is a defining attribute of a successful Black Belt. Guiding cross-functional teams demands more than project management skills; it requires the ability to inspire, coordinate, and align diverse stakeholders toward a shared objective. Black Belts navigate complex organizational landscapes, often addressing resistance, conflicting priorities, and deeply ingrained cultural norms. Their role is to unify efforts, create clarity around goals, and ensure that team members are empowered to contribute their expertise fully.

Effective leadership by a Black Belt extends to coaching and mentoring. Developing the capabilities of team members ensures that improvements are sustainable and that knowledge is disseminated across the organization. By modeling collaborative behaviors and fostering trust, Black Belts cultivate an environment where individuals are encouraged to explore, innovate, and challenge the status quo. Their influence is subtle yet pervasive, shaping not only the success of individual projects but also the overall capacity of the organization to embrace continuous improvement.

Advanced Problem-Solving Techniques

Black Belts are distinguished by their capacity to approach challenges with structured creativity. Problem-solving in this context goes far beyond conventional troubleshooting; it involves dissecting complex processes, identifying root causes, and designing solutions that are both practical and transformative. Structured frameworks, such as DMAIC (Define, Measure, Analyze, Improve, Control), provide a systematic pathway, but the Black Belt’s judgment and ingenuity drive the real breakthroughs.

Creative thinking complements analytical rigor. Black Belts explore unconventional avenues, anticipate potential obstacles, and develop solutions that not only resolve immediate issues but also prevent recurrence. This dual focus on resolution and sustainability ensures that improvements have long-lasting effects, contributing to organizational resilience. Moreover, their problem-solving extends to interdepartmental challenges, where understanding interdependencies and the broader operational ecosystem is essential for meaningful outcomes.

Change Management and Cultural Transformation

Implementing process improvements requires more than technical solutions; it demands a strategic approach to change. Black Belts play a central role in guiding organizations through transitions, addressing resistance, and embedding new practices. Change management competency involves understanding human behavior, communication dynamics, and organizational culture. Black Belts anticipate points of friction, craft persuasive narratives around benefits, and design interventions that facilitate adoption at all levels.

Training, coaching, and continuous reinforcement are critical aspects of this process. Black Belts ensure that improvements are not ephemeral by monitoring adherence, providing feedback, and adapting strategies based on observed results. Their work fosters a culture where change is not feared but embraced, and where process excellence becomes part of the organizational identity. This cultural transformation is subtle, requiring patience, insight, and a relentless focus on aligning individual actions with broader strategic goals.

Interpersonal Communication and Influence

Communication is the conduit through which a Black Belt’s impact is realized. The ability to convey complex data insights in simple, compelling terms distinguishes effective practitioners from purely technical analysts. Black Belts translate statistical findings into narratives that resonate with diverse audiences, from executives to operational staff. Their recommendations are not only evidence-based but also actionable, fostering alignment and commitment across the organization.

Interpersonal skills extend beyond verbal communication. Black Belts excel at active listening, conflict resolution, and empathy. These attributes enable them to build trust, navigate sensitive situations, and motivate teams to embrace new approaches. Influence is exerted through credibility, clarity, and the demonstration of tangible results. In this way, the Black Belt serves as both a technical expert and a change agent, orchestrating improvements that are measurable, enduring, and widely accepted.

Continuous Learning and Professional Growth

The journey of a Black Belt does not conclude with certification; it is marked by ongoing development and refinement of competencies. Continuous learning encompasses staying abreast of evolving methodologies, emerging technologies, and industry best practices. Black Belts engage in reflective practice, examining the outcomes of projects, identifying lessons, and applying insights to future initiatives. This commitment to growth ensures that their contributions remain relevant and impactful in dynamic organizational landscapes.

Professional growth also involves expanding influence beyond immediate projects. Black Belts often participate in strategic planning, process innovation, and organizational design initiatives. By leveraging their analytical skills, leadership capabilities, and problem-solving acumen, they contribute to shaping the direction of the organization. This role demands adaptability, resilience, and a proactive mindset, allowing Black Belts to remain at the forefront of operational excellence and continuous improvement.

Understanding the Lean Six Sigma Black Belt Framework

The Lean Six Sigma Black Belt framework is a meticulous structure that integrates both strategic oversight and tactical execution. It is grounded in the dual principles of eliminating inefficiencies and optimizing quality outcomes. At its core, the framework emphasizes a systematic approach to problem-solving, encouraging professionals to move beyond intuition and rely on data-driven insights. By adopting this mindset, individuals can navigate complex organizational processes, identifying bottlenecks, waste, and variation with precision.

Each element of the framework serves a critical purpose. The DMAIC cycle—Define, Measure, Analyze, Improve, Control—forms the backbone of every project, providing a structured roadmap for achieving tangible results. Define focuses on establishing project scope and objectives, ensuring alignment with organizational goals. Measure involves collecting accurate data and evaluating current process performance, creating a foundation for subsequent analysis. Analyze delves into root causes, uncovering patterns, correlations, and anomalies. Improve emphasizes solution design, piloting interventions, and validating their effectiveness. Control ensures that improvements are sustained over time through monitoring and standardization.

The Black Belt framework also integrates leadership competencies. Unlike earlier Lean Six Sigma levels, Black Belts are expected to guide cross-functional teams, mentor Green Belts, and influence organizational culture. This combination of technical proficiency and leadership acumen differentiates a Black Belt from other certification levels, positioning them as catalysts for systemic change.

Building Advanced Analytical Skills

Mastering Lean Six Sigma at the Black Belt level demands an elevated understanding of analytical techniques. Professionals must move beyond basic statistics to embrace advanced methodologies that enable precise diagnosis of process inefficiencies. This involves not only understanding descriptive statistics but also inferential statistics, regression analysis, and multivariate techniques. These tools allow practitioners to make predictions, quantify risk, and evaluate the impact of proposed solutions before implementation.

Proficiency in tools such as control charts, process capability indices, and hypothesis testing provides a quantifiable basis for decisions. For instance, control charts monitor variation over time, signaling when corrective action is necessary. Process capability indices evaluate whether a system consistently meets specifications. Hypothesis testing allows for evidence-based conclusions, reducing the reliance on subjective judgment. Each of these analytical tools is not just a technical exercise but a way to instill confidence in decision-making, ensuring interventions are backed by solid empirical evidence.

Beyond statistical tools, Black Belts must cultivate a mindset that embraces continuous curiosity and critical evaluation. Analytical skill is as much about interpretation as calculation. It requires the ability to discern meaningful patterns from seemingly chaotic data, synthesize insights, and communicate findings in a manner that stakeholders can understand and act upon. Cultivating this dual capacity for quantitative rigor and interpretive clarity is what elevates professionals to the Black Belt echelon.

Navigating Project Management Challenges

Effective Lean Six Sigma Black Belts excel not only in analysis but also in orchestrating complex projects. Project management within this context involves balancing technical tasks with interpersonal dynamics. From defining objectives to final implementation, Black Belts must ensure projects remain on schedule, within budget, and aligned with organizational priorities. This requires meticulous planning, resource allocation, and risk anticipation.

Projects often encounter unforeseen obstacles, ranging from data inconsistencies to resistance from team members. Black Belts must leverage problem-solving frameworks to navigate these hurdles. Techniques such as root cause analysis, failure mode and effect analysis, and Pareto evaluation allow teams to prioritize efforts and focus on changes that deliver the most significant impact. Additionally, communication skills play a pivotal role in managing stakeholders, aligning expectations, and fostering collaboration.

An essential aspect of project management is documenting results. Capturing lessons learned, process modifications, and performance improvements ensures knowledge is retained and leveraged for future initiatives. This documentation becomes a reference for continuous improvement, allowing organizations to scale successful strategies across multiple processes and departments.

Emphasizing Leadership and Influence

Leadership is the linchpin of the Black Belt role. While technical mastery underpins effective process improvement, the ability to influence, inspire, and guide teams is equally crucial. Black Belts operate at the intersection of strategy and execution, translating analytical insights into actionable plans that drive meaningful change.

Influence is exercised through both formal and informal channels. Formal influence involves directing teams, allocating resources, and setting performance expectations. Informal influence, however, requires emotional intelligence, empathy, and the capacity to foster a culture of collaboration. Black Belts often mentor Green Belts, guiding while encouraging autonomy. They also advocate for change at executive levels, presenting data-driven recommendations that resonate with leadership priorities.

The impact of strong leadership extends beyond individual projects. By cultivating trust, clarity, and accountability, Black Belts contribute to a broader organizational mindset that values efficiency, quality, and continuous improvement. Their presence becomes a catalyst for cultural transformation, reinforcing Lean Six Sigma principles across teams and processes.

Integrating Continuous Improvement Culture

A hallmark of Lean Six Sigma Black Belts is the ability to embed continuous improvement into the organizational DNA. Rather than being confined to discrete projects, process enhancement becomes an ongoing, iterative journey. Black Belts champion initiatives that identify inefficiencies, optimize workflows, and create sustainable value. They view every process as a living system capable of evolution, constantly seeking opportunities for refinement.

Embedding this culture involves both structural and behavioral strategies. Structurally, organizations may adopt standardized frameworks for documenting improvements, implementing feedback loops, and measuring performance metrics. Behaviorally, it requires nurturing a mindset of curiosity, accountability, and proactive problem-solving among employees. Black Belts play a critical role in modeling these behaviors, coaching teams to identify areas for improvement, experiment with solutions, and learn from outcomes without fear of failure.

The continuous improvement culture also emphasizes measurement and validation. Metrics are not merely numbers but signals that indicate whether changes yield the desired impact. Black Belts ensure that data collection, monitoring, and reporting are integral components of every initiative, creating a self-sustaining ecosystem where improvement becomes habitual rather than episodic.

Mastering Change Management Strategies

Change management is a subtle yet powerful component of Lean Six Sigma Black Belt responsibilities. Successful process improvements are not solely dependent on technical solutions; they hinge on the ability to navigate human dynamics and organizational inertia. Change management involves anticipating resistance, communicating the rationale for improvement, and ensuring adoption at all levels.

Black Belts employ structured approaches to facilitate smooth transitions. This may include stakeholder mapping, identifying change agents, and designing communication plans that convey both the benefits and expectations of new processes. Training sessions, workshops, and interactive demonstrations reinforce understanding and acceptance. By aligning technical solutions with human readiness, Black Belts increase the likelihood of sustained improvement.

Equally important is the ability to maintain momentum post-implementation. Black Belts monitor progress, celebrate successes, and address setbacks promptly. They cultivate a mindset where continuous adaptation becomes normal, ensuring improvements are resilient to organizational changes, personnel shifts, or evolving market demands.

Mastering Operational Excellence Through Strategic Project Selection

Attaining proficiency in process excellence is only the inception of a transformative journey. The true essence of mastery lies in translating theoretical knowledge into tangible improvements that ripple through organizational frameworks. For practitioners who hold advanced certifications, the selection of projects is pivotal. Choosing initiatives that resonate with strategic imperatives ensures that every effort contributes meaningfully to both operational performance and stakeholder satisfaction. The art of project selection is not a trivial task; it requires acute perception, foresight, and a deep understanding of systemic interdependencies. By meticulously analyzing organizational processes, leaders can pinpoint bottlenecks, redundancies, and latent inefficiencies that might otherwise remain obscured in daily operations.

The selection phase encompasses evaluating the potential impact of interventions, balancing ambition with feasibility, and considering the alignment with long-term corporate visions. Projects that promise measurable improvements in cost efficiency, cycle time, defect reduction, and customer experience often yield the highest value. Black Belts must navigate the intricate interplay between operational exigencies and strategic aspirations, ensuring that selected initiatives resonate with overarching objectives while remaining pragmatic in scope. Establishing clear objectives, defining performance metrics, and obtaining robust stakeholder commitment serve as the cornerstone for successful project execution. Without these foundational elements, even the most promising endeavors risk dilution and underperformance.

Data-Driven Diagnosis and Analytical Prowess

In the realm of process improvement, data is the lifeblood that informs decisions, validates assumptions, and guides interventions. Practitioners must cultivate an analytical mindset that transcends superficial observation and delves into the nuanced behavior of processes. Rigorous data collection, meticulous validation, and careful interpretation are essential for constructing a precise understanding of operational landscapes. Every process possesses inherent variability, and the practitioner’s task is to disentangle signal from noise, isolating factors that materially influence outcomes.

Statistical methodologies provide the scaffolding for analytical rigor. Techniques such as regression analysis, control charts, and cause-and-effect mapping empower leaders to identify root causes rather than merely addressing symptoms. The Pareto principle becomes a navigational compass, highlighting the few critical issues that contribute disproportionately to defects or delays. By embracing evidence-based approaches, practitioners mitigate the influence of intuition, anecdote, and bias. Analytical excellence is not merely a technical skill; it is a philosophical commitment to understanding reality as it exists rather than as it appears. This depth of comprehension informs solution design, ensuring that interventions are precise, targeted, and sustainable.

Designing Solutions with Precision and Practicality

Once the analytical groundwork is established, attention shifts to the design of solutions that address identified deficiencies. Solution design is a blend of creativity, pragmatism, and systemic awareness. Interventions must reconcile multiple priorities: they should be effective in addressing root causes, feasible in implementation, and sustainable over time. This requires collaboration across functional boundaries, as solutions often necessitate behavioral adjustments, technological integration, or procedural redesign.

Designing effective interventions is an iterative process. Initial concepts are refined through pilot testing, feedback loops, and performance monitoring. Leaders must consider potential unintended consequences, ensuring that improvements in one domain do not inadvertently degrade performance in another. Practical considerations, such as resource availability, organizational culture, and employee readiness, influence both the pace and scope of implementation. By combining methodical planning with adaptive flexibility, practitioners create solutions that are both robust and resilient.

Driving Change Through Leadership and Collaboration

The successful implementation of improvements hinges on the practitioner’s ability to inspire, guide, and coordinate teams. Operational excellence is not achieved in isolation; it is a collective endeavor that relies on the engagement, commitment, and expertise of those executing processes on the front lines. Change management emerges as an essential competency, encompassing communication, motivation, and conflict resolution.

Resistance to change is an intrinsic aspect of human behavior, often stemming from uncertainty, perceived risk, or disruption of established routines. Leaders must navigate these dynamics with empathy, clarity, and consistency. Training programs, visual management systems, and ongoing feedback mechanisms cultivate understanding and proficiency among team members. By fostering a culture of transparency and inclusion, practitioners mitigate resistance and build enthusiasm for transformation. The most effective leaders balance assertiveness with empathy, blending directive guidance with participatory collaboration to ensure that process improvements are internalized rather than superficially adopted.

Monitoring, Measuring, and Sustaining Improvements

Implementation is not the terminus of the improvement journey; it is a milestone within an ongoing continuum of performance management. Sustaining gains requires systematic monitoring, rigorous measurement, and continuous refinement. Key performance indicators (KPIs) provide the framework for assessing progress, detecting deviations, and signaling opportunities for further enhancement. These metrics must be carefully selected to reflect both efficiency and effectiveness, capturing the multidimensional nature of process performance.

Sustaining improvements demands vigilance, adaptability, and a proactive mindset. Processes are not static; they evolve in response to market conditions, technological advancements, and organizational changes. Continuous monitoring enables early detection of regressions, allowing timely intervention before minor issues escalate into systemic deficiencies. Moreover, embedding a culture of accountability ensures that teams maintain focus on performance objectives, celebrate achievements, and embrace iterative learning. By institutionalizing measurement and monitoring practices, organizations create a feedback-rich environment conducive to enduring operational excellence.

Capturing Knowledge and Amplifying Organizational Learning

An often-overlooked aspect of project execution is the codification and dissemination of knowledge. Every improvement initiative generates insights that extend beyond immediate results, offering lessons applicable to future projects and organizational practices. Documenting outcomes, methodologies, and decision rationales transforms tacit understanding into explicit knowledge, accessible for broader organizational learning.

Knowledge management fosters continuity, reduces redundancy, and accelerates the adoption of best practices. Comprehensive reports, detailed process maps, and structured presentations serve as vehicles for transmitting expertise across teams, departments, and locations. By institutionalizing knowledge-sharing mechanisms, organizations enhance their collective intelligence, empower employees, and create a sustainable competitive advantage. For practitioners, the ability to articulate and communicate insights amplifies professional influence, establishes credibility, and reinforces the strategic value of process excellence initiatives.

Leveraging Continuous Improvement for Strategic Impact

The pursuit of operational excellence is an iterative journey rather than a finite destination. Each project, each intervention, and each insight contributes to a growing reservoir of organizational capability. Continuous improvement transcends tactical fixes, evolving into a strategic instrument that shapes competitiveness, innovation, and resilience. By embedding process excellence into the organizational fabric, leaders enable enterprises to anticipate challenges, adapt to change, and sustain high performance.

Strategic impact is achieved through alignment of projects with long-term objectives, rigorous application of analytical methodologies, and cultivation of a performance-oriented culture. Black Belt practitioners serve as catalysts for this transformation, bridging the gap between vision and execution. Through disciplined project selection, data-driven analysis, thoughtful solution design, effective change leadership, robust monitoring, and comprehensive knowledge management, organizations can unlock latent potential and realize measurable value. The cumulative effect of these efforts is a resilient, agile, and continuously evolving enterprise capable of thriving in dynamic environments.

The Transformative Power of Lean Six Sigma Certification

The journey toward Lean Six Sigma Black Belt certification is more than an academic pursuit; it represents a profound transformation in professional capability and mindset. The skills acquired through rigorous training enable individuals to dissect complex processes, identify inefficiencies, and implement solutions with measurable outcomes. Unlike traditional management training, Lean Six Sigma merges analytical precision with practical execution, equipping professionals to tackle challenges across industries. Organizations increasingly recognize the value of certified professionals who can bridge strategy with operations, translating theoretical knowledge into tangible results. The certification instills a methodology for continuous improvement, emphasizing data-driven decision-making, root cause analysis, and structured problem-solving. This transformation does not merely enhance technical competency; it cultivates a mindset attuned to innovation, resilience, and the pursuit of excellence. Black Belts become not only experts in process optimization but also strategic thinkers capable of influencing the trajectory of entire organizations.

Mastery of Data-Driven Decision Making

At the core of Lean Six Sigma lies the ability to harness data effectively. Certified Black Belts develop advanced analytical skills that enable them to quantify performance, forecast outcomes, and assess the impact of interventions. This mastery transcends simple numerical analysis; it involves interpreting complex datasets, identifying hidden patterns, and converting insights into actionable strategies. The professional becomes adept at statistical modeling, hypothesis testing, and predictive analytics, all of which form the backbone of high-stakes decision-making. As businesses operate in increasingly competitive and data-rich environments, this skill set positions Black Belts as indispensable contributors to operational and strategic initiatives. The ability to back recommendations with empirical evidence fosters credibility, instills confidence among stakeholders, and enhances influence across functional areas. Beyond individual projects, data-driven proficiency empowers professionals to spearhead organizational transformation, reduce variability, and ensure sustained excellence in processes and outcomes.

Cultivating Leadership and Influence

Certification equips professionals not only with technical skills but also with the ability to lead with impact. Leadership in the context of Lean Six Sigma extends beyond managing teams; it involves inspiring others to embrace a culture of continuous improvement. Black Belts often oversee cross-functional initiatives, coordinating diverse teams toward common objectives while resolving conflicts and aligning priorities. This leadership demands emotional intelligence, strategic vision, and the capacity to communicate complex ideas with clarity and conviction. As professionals gain experience, their influence often expands to mentoring roles, guiding Green Belts and project teams in the application of methodologies. Such mentorship fosters a cycle of knowledge transfer, ensuring that the principles of operational excellence permeate throughout the organization. Leaders emerge not merely as managers of projects but as architects of systemic improvement, shaping organizational culture, driving engagement, and cultivating environments where efficiency, quality, and innovation coexist.

Strategic Thinking and Organizational Alignment

Achieving certification marks the beginning of a journey into strategic thinking. Black Belts learn to evaluate initiatives through a lens that balances immediate operational gains with long-term business objectives. They develop the acumen to align process improvement projects with corporate strategy, ensuring that every initiative contributes measurable value. This strategic alignment requires understanding financial metrics, market dynamics, and organizational priorities, translating complex operational data into decisions that propel the business forward. Professionals refine their ability to assess risk, forecast potential outcomes, and make recommendations that optimize resources while maximizing impact. Over time, this perspective fosters a holistic understanding of organizational dynamics, enabling Black Belts to anticipate challenges, capitalize on opportunities, and position themselves as critical drivers of growth and innovation.

Navigating Career Advancement and Opportunities

Post-certification, career progression becomes a multifaceted endeavor, opening doors to roles that demand both expertise and vision. Black Belts are increasingly sought after for leadership positions, process excellence roles, and strategic management opportunities that influence organizational performance at senior levels. Career advancement is often accelerated by the ability to demonstrate measurable impact, such as improved efficiency, cost reduction, or quality enhancement. Professionals who document outcomes, share best practices, and continuously refine their skills establish themselves as authorities in their field. Engaging in professional communities, attending workshops, and networking with peers further expandcareer horizons, exposing individuals to emerging trends, innovative methodologies, and collaborative opportunities that reinforce expertise and elevate professional standing. For many, these experiences form the foundation for transitioning into roles such as Master Black Belts, operational excellence directors, or strategic advisors, where the scope of influence extends beyond individual projects to organizational transformation.

Continuous Learning and Methodological Evolution

The journey of a Lean Six Sigma Black Belt is characterized by perpetual growth. Certification represents mastery of a defined methodology, but true excellence demands ongoing learning and adaptation. Professionals are encouraged to explore emerging tools, methodologies, and technologies that enhance process improvement capabilities. Areas such as data analytics, process automation, and operational innovation evolve rapidly, and staying informed ensures that Black Belts remain at the forefront of their disciplines. Continuous learning also involves reflection on past projects, evaluating successes and setbacks, and translating lessons into improved approaches. Engaging with professional networks, participating in forums, and attending educational events contribute to a dynamic knowledge ecosystem, reinforcing expertise and fostering a culture of intellectual curiosity. By embracing continuous learning, professionals maintain relevance, enhance versatility, and cultivate a skill set that adapts fluidly to evolving organizational and industry demands.

The Imperative of Measurable Impact

Demonstrating tangible outcomes is the hallmark of a successful Lean Six Sigma Black Belt. Organizations place ha igh value on professionals who can provide clear evidence of project success, including cost savings, efficiency gains, and quality improvements. This emphasis on measurable impact extends beyond isolated achievements; it encompasses the ability to influence systemic change and elevate organizational performance holistically. Black Belts who consistently deliver quantifiable results earn credibility, secure leadership opportunities, and position themselves as indispensable contributors to long-term strategic objectives. Meticulous documentation, effective communication, and the sharing of best practices reinforce authority and trust, enabling professionals to lead with influence and shape organizational priorities. Over time, a track record of measurable success establishes a professional reputation grounded in expertise, reliability, and the capacity to drive transformative change across complex operational landscapes.

Understanding Lean Six Sigma Black Belt Certification

The Lean Six Sigma Black Belt certification (CLSSBB) represents one of the highest levels of proficiency in process improvement and quality management. Professionals who achieve this credential demonstrate advanced knowledge in identifying inefficiencies, reducing waste, and improving organizational performance. Unlike entry-level certifications, a Black Belt focuses on leadership, strategic project management, and the application of complex statistical tools to solve problems. It is not just a badge; it is proof that an individual can lead cross-functional teams, drive meaningful change, and contribute to measurable business outcomes.

This certification is recognized worldwide and highly valued by organizations in manufacturing, healthcare, finance, and service industries. Its relevance stems from the ability of certified professionals to blend analytical rigor with leadership skills. By obtaining a CLSSBB, individuals open doors to managerial roles, consultancy positions, and project leadership opportunities, making it a transformative credential for career advancement.

Meeting the Eligibility Requirements

Becoming a Certified Lean Six Sigma Black Belt requires meeting specific prerequisites. Typically, candidates need a certain amount of professional experience in process improvement or project management, along with prior completion of a Green Belt or equivalent certification. Some programs accept candidates with extensive work experience even without a prior Lean Six Sigma credential, though this may require additional training hours.

Education also plays a role. While there is no strict degree requirement, a background in engineering, business, or operations management can be helpful. Many training providers recommend at least three to five years of work experience involving process improvement, problem-solving, or data analysis. These requirements ensure that candidates have a solid foundation to understand advanced tools, methodologies, and strategic applications of Lean Six Sigma principles.

Selecting the Right Training Program

Choosing a reputable training program is a crucial step toward achieving CLSSBB certification. Many organizations offer online, in-person, or hybrid courses designed to prepare candidates for the rigorous Black Belt exam. When selecting a program, it is important to verify its accreditation and alignment with recognized standards. Accredited programs provide structured curricula, qualified instructors, and practical project experience, ensuring that participants gain both theoretical knowledge and applied skills.

Training programs typically cover topics such as the DMAIC methodology (Define, Measure, Analyze, Improve, Control), advanced statistical analysis, project management techniques, and change leadership. They also emphasize real-world case studies, enabling candidates to practice solving complex business problems. The duration of training varies, but comprehensive courses often range from eight weeks to six months, depending on the intensity and format.

Gaining Practical Project Experience

Hands-on experience is a cornerstone of CLSSBB certification. Unlike lower-level certifications, Black Belt candidates are expected to lead projects that demonstrate measurable improvements in organizational processes. These projects provide an opportunity to apply advanced tools such as regression analysis, hypothesis testing, process mapping, and control charts. Successfully completing projects showcases the candidate’s ability to translate theoretical knowledge into actionable solutions.

Many certification programs require candidates to submit project documentation as part of the application or exam process. These projects typically focus on reducing defects, improving efficiency, or enhancing customer satisfaction. The experience not only strengthens technical skills but also develops leadership and team management capabilities. By guiding teams, allocating resources, and tracking results, candidates gain confidence in their ability to lead complex initiatives in professional environments.

Preparing for the Certification Exam

The CLSSBB exam is a comprehensive assessment of a candidate’s knowledge and practical skills. Preparation is essential, as the test evaluates both theoretical understanding and the ability to apply Lean Six Sigma tools in real-world scenarios. Candidates are advised to study key topics, including statistical analysis, Lean principles, process improvement frameworks, risk management, and project leadership strategies.

Practice exams, study guides, and instructor-led review sessions can greatly enhance readiness. Many candidates benefit from forming study groups, which allow for discussion of concepts, problem-solving exercises, and peer feedback. Consistent practice in interpreting data, creating process improvement plans, and solving case studies is crucial for success. Passing the exam signifies that the candidate has attained mastery of advanced Lean Six Sigma techniques and is capable of leading complex improvement initiatives.

Applying for Certification

After completing training, gaining practical experience, and preparing for the exam, candidates can formally apply for CLSSBB certification. The application process usually involves submitting documentation of completed projects, proof of training hours, and confirmation of eligibility criteria. Some certifying bodies may also require letters of recommendation or verification from employers to confirm the candidate’s role in leading projects.

Once approved, candidates schedule the exam, which may be offered online or at designated testing centers. Maintaining careful records of project results, analysis reports, and improvement outcomes is important, as these materials may be reviewed during the certification process. The application process ensures that certified professionals meet rigorous standards of competence, leadership, and ethical practice in process improvement.

Advancing Your Career with CLSSBB Certification

Obtaining a Certified Lean Six Sigma Black Belt can transform a professional’s career trajectory. Certified individuals are often sought after for leadership roles, operational management positions, and consulting opportunities. Their ability to analyze processes, implement improvements, and deliver measurable results makes them valuable assets to any organization.

Beyond immediate job benefits, CLSSBB certification fosters long-term professional growth. It enhances credibility with employers, clients, and colleagues, opening doors to mentorship, networking, and collaboration with industry experts. Certified Black Belts are equipped to drive strategic initiatives, lead cross-functional teams, and influence organizational decision-making, creating opportunities for promotions, higher salaries, and increased responsibility.

By combining technical expertise with leadership skills, the certification ensures that professionals remain competitive in an evolving job market. It also cultivates a mindset of continuous improvement, encouraging individuals to embrace challenges, innovate solutions, and sustain high performance over the course of their careers.

Conclusion

Becoming a Certified Lean Six Sigma Black Belt is more than earning a credential; it is a transformative journey that equips professionals with the skills, mindset, and leadership capabilities to drive meaningful change. From understanding the principles of lean and Six Sigma, preparing rigorously for certification, mastering statistical and analytical tools, to applying knowledge in real-world projects, each step builds the foundation for operational excellence.

The Black Belt certification validates not only technical expertise but also strategic thinking, effective communication, and the ability to lead cross-functional teams. It opens doors to career advancement, empowering professionals to influence organizational success at the highest levels. Moreover, the journey instills a culture of continuous improvement, encouraging lifelong learning and adaptation in a dynamic business environment.

Ultimately, the path to becoming a CLSSBB is about embracing precision, discipline, and curiosity. It is a commitment to excellence that extends beyond certification, enabling professionals to deliver measurable results, inspire teams, and shape the future of the organizations they serve. By dedicating effort, practicing rigorously, and applying insights effectively, aspiring Black Belts transform themselves into catalysts of change, driving efficiency, quality, and innovation across industries.

Frequently Asked Questions

How does your testing engine works?

Once download and installed on your PC, you can practise test questions, review your questions & answers using two different options 'practice exam' and 'virtual exam'. Virtual Exam - test yourself with exam questions with a time limit, as if you are taking exams in the Prometric or VUE testing centre. Practice exam - review exam questions one by one, see correct answers and explanations).

How can I get the products after purchase?

All products are available for download immediately from your Member's Area. Once you have made the payment, you will be transferred to Member's Area where you can login and download the products you have purchased to your computer.

How long can I use my product? Will it be valid forever?

Pass4sure products have a validity of 90 days from the date of purchase. This means that any updates to the products, including but not limited to new questions, or updates and changes by our editing team, will be automatically downloaded on to computer to make sure that you get latest exam prep materials during those 90 days.

Can I renew my product if when it's expired?

Yes, when the 90 days of your product validity are over, you have the option of renewing your expired products with a 30% discount. This can be done in your Member's Area.

Please note that you will not be able to use the product after it has expired if you don't renew it.

How often are the questions updated?

We always try to provide the latest pool of questions, Updates in the questions depend on the changes in actual pool of questions by different vendors. As soon as we know about the change in the exam question pool we try our best to update the products as fast as possible.

How many computers I can download Pass4sure software on?

You can download the Pass4sure products on the maximum number of 2 (two) computers or devices. If you need to use the software on more than two machines, you can purchase this option separately. Please email sales@pass4sure.com if you need to use more than 5 (five) computers.

What are the system requirements?

Minimum System Requirements:

- Windows XP or newer operating system

- Java Version 8 or newer

- 1+ GHz processor

- 1 GB Ram

- 50 MB available hard disk typically (products may vary)

What operating systems are supported by your Testing Engine software?

Our testing engine is supported by Windows. Andriod and IOS software is currently under development.