Certification: Risk Based Inspection

Certification Full Name: Risk Based Inspection

Certification Provider: API

Exam Code: API-580

Exam Name: Risk Based Inspection

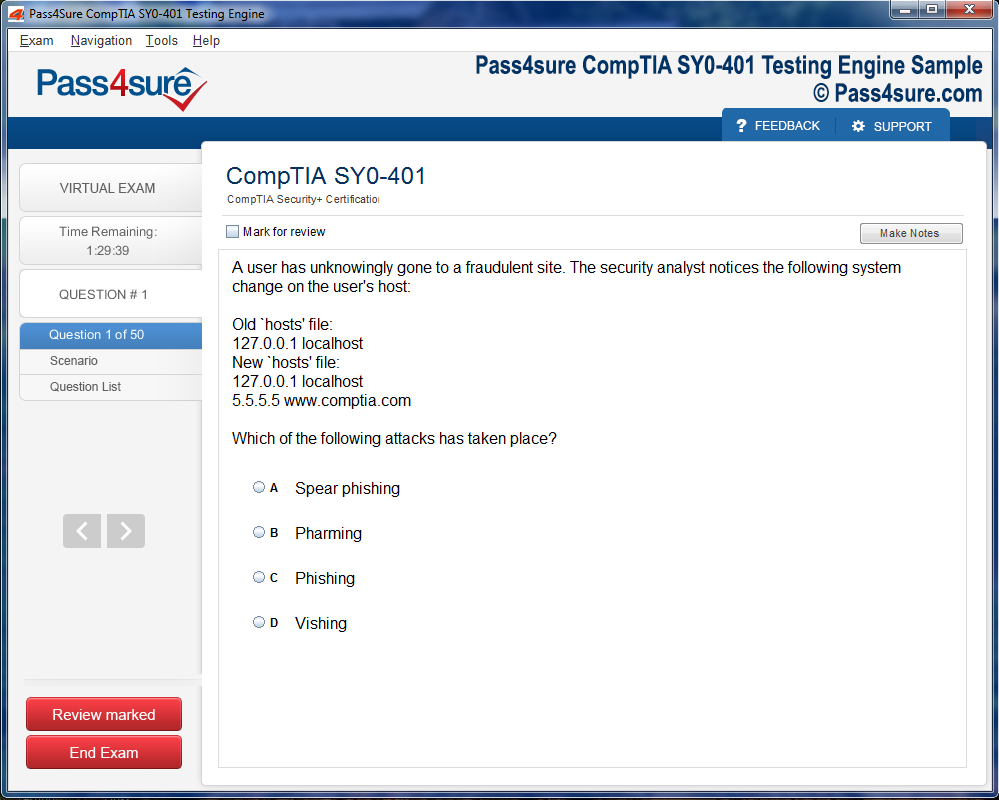

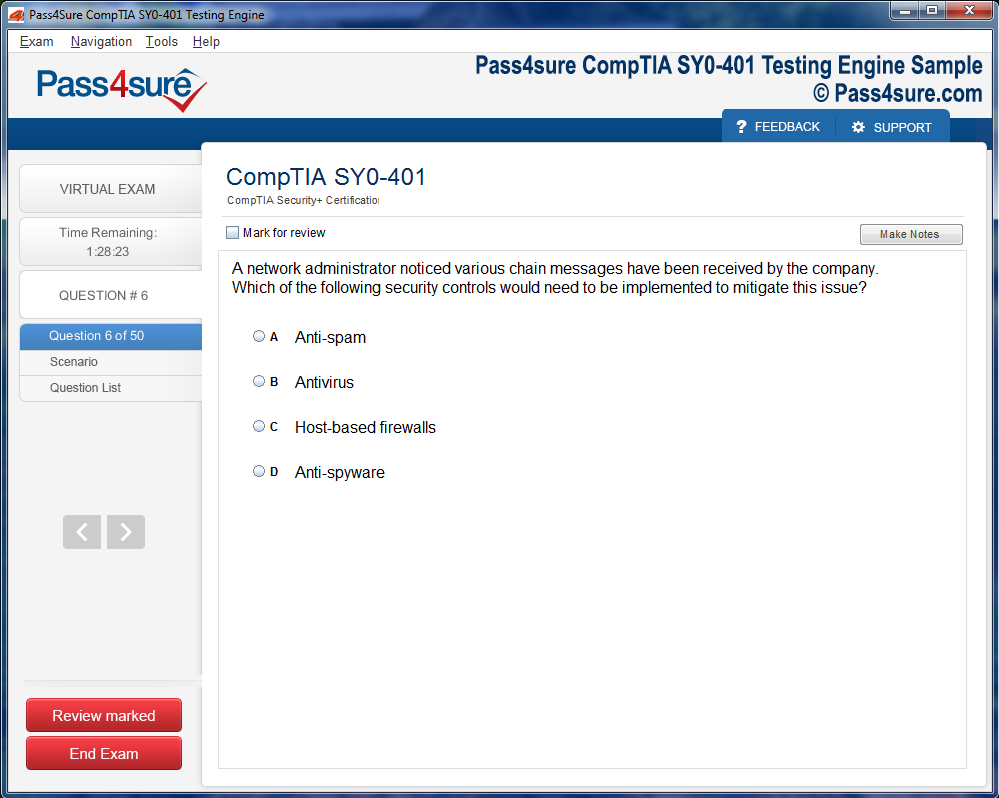

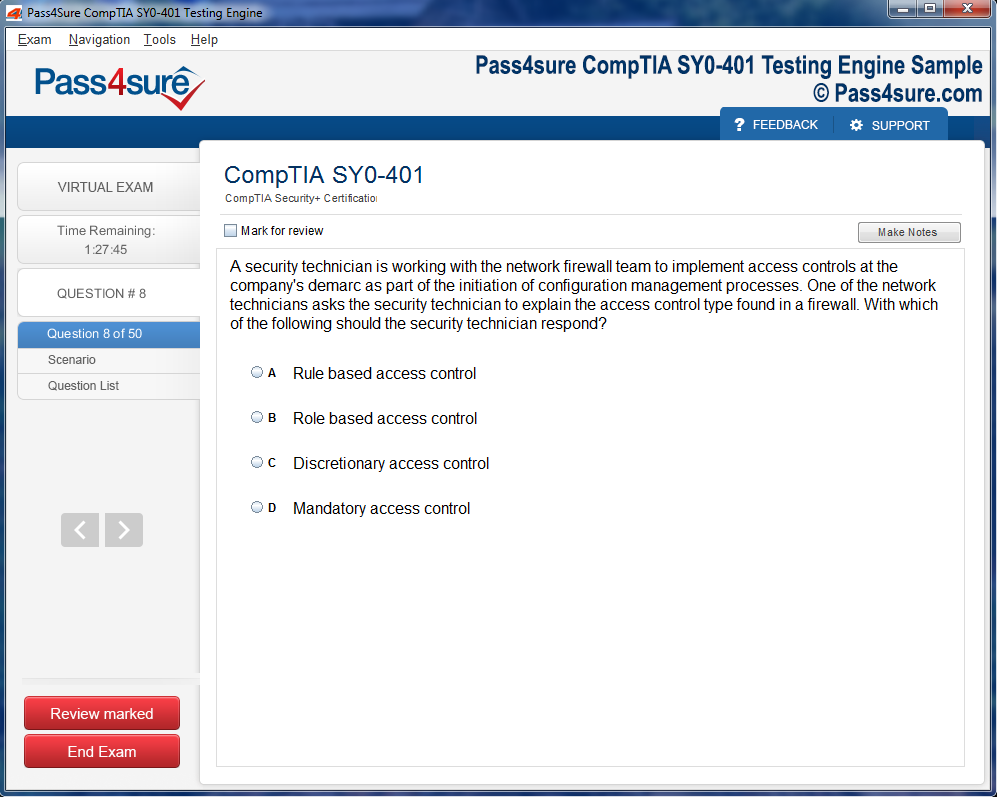

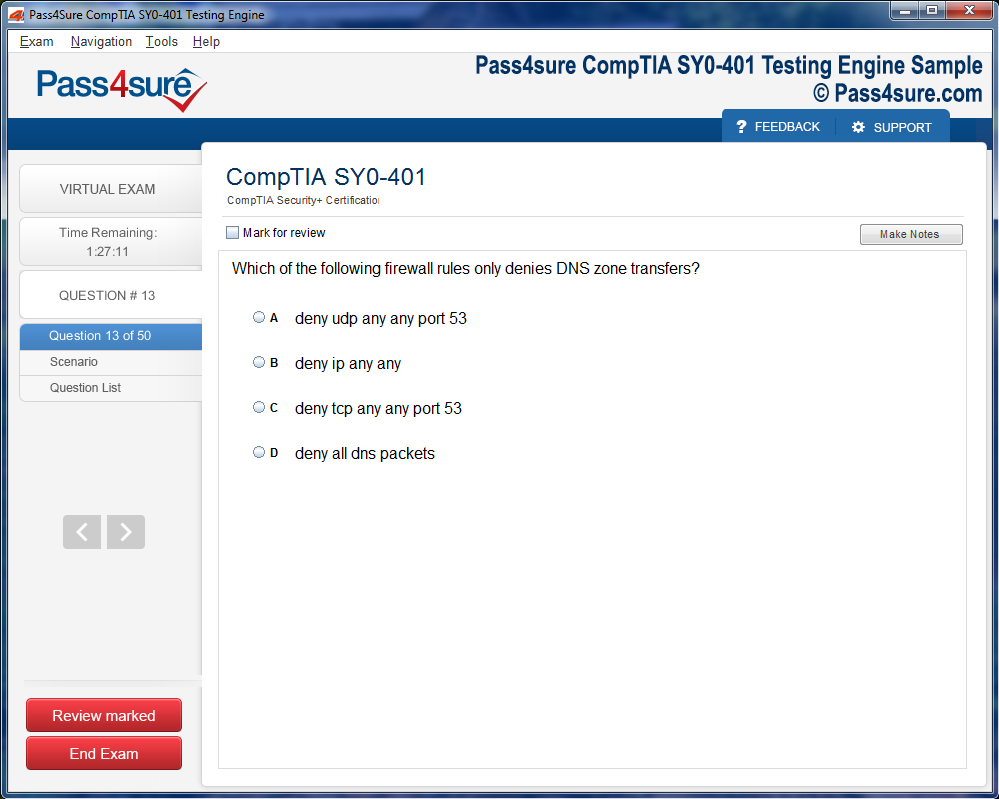

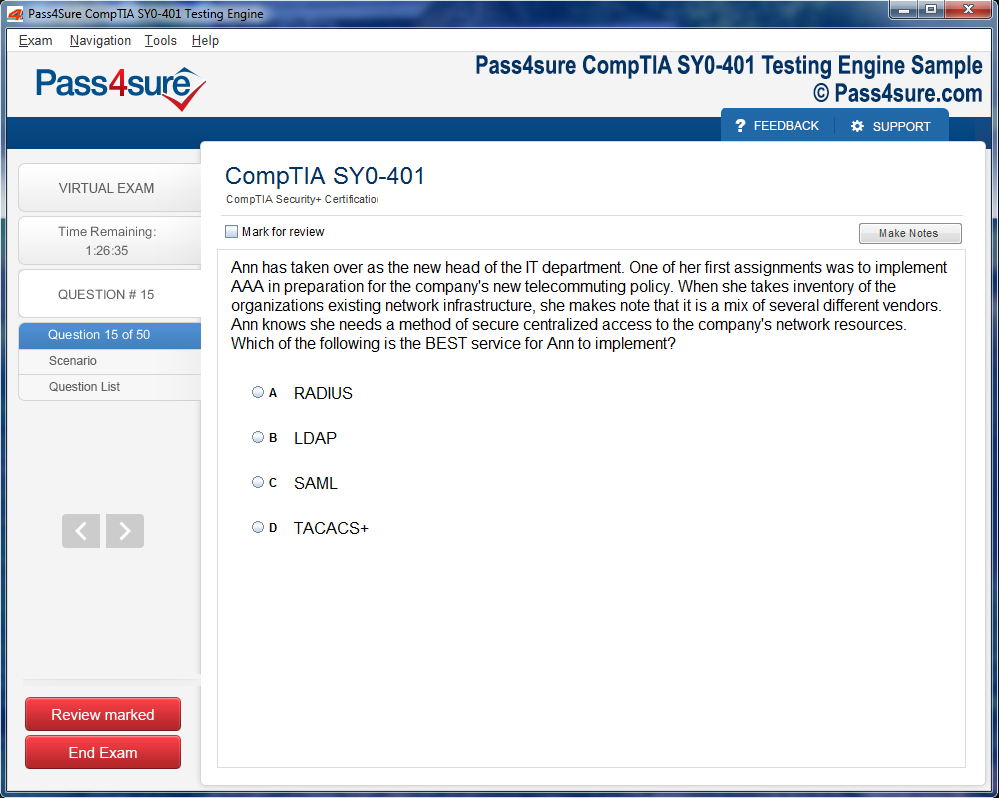

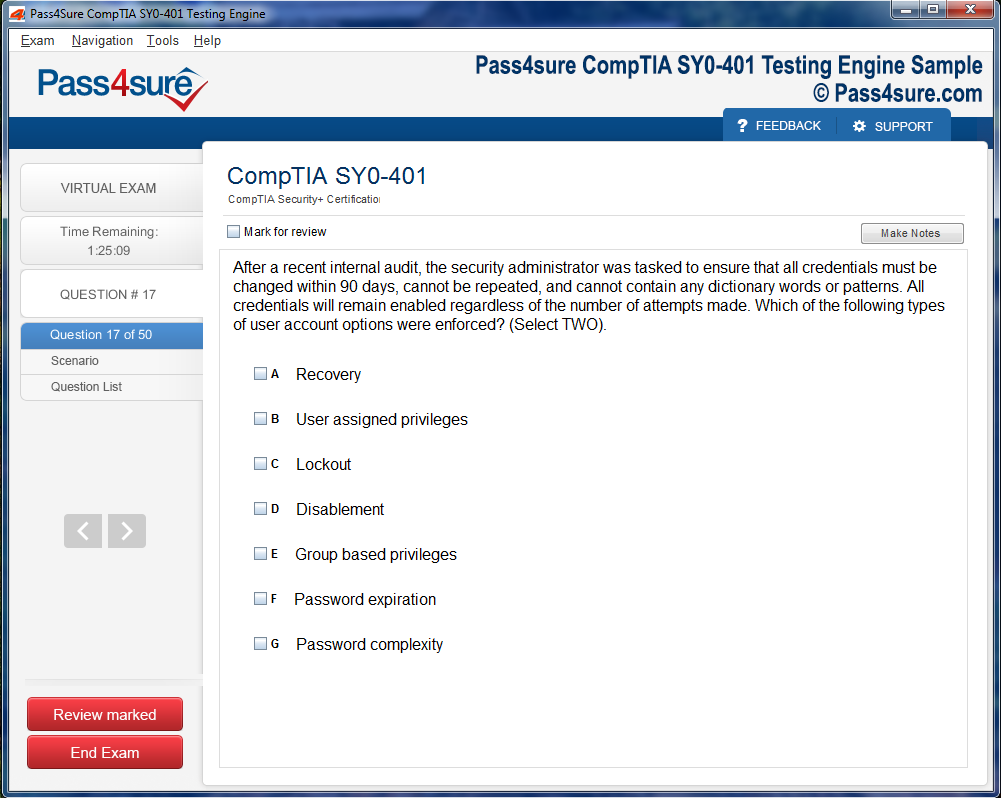

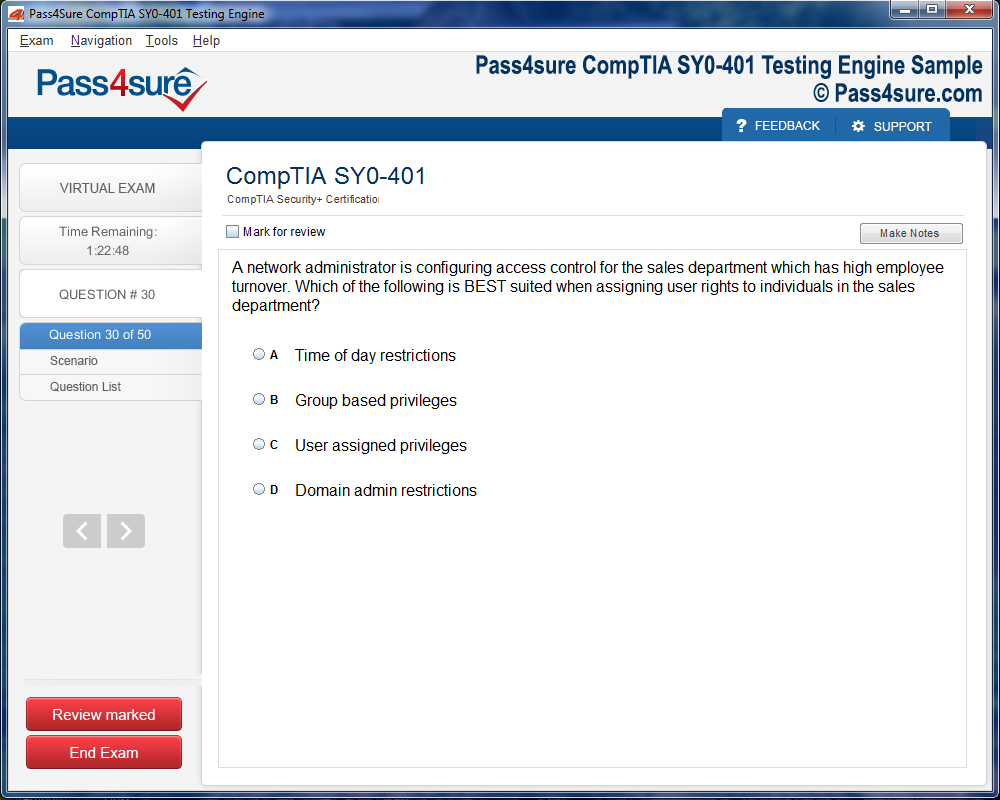

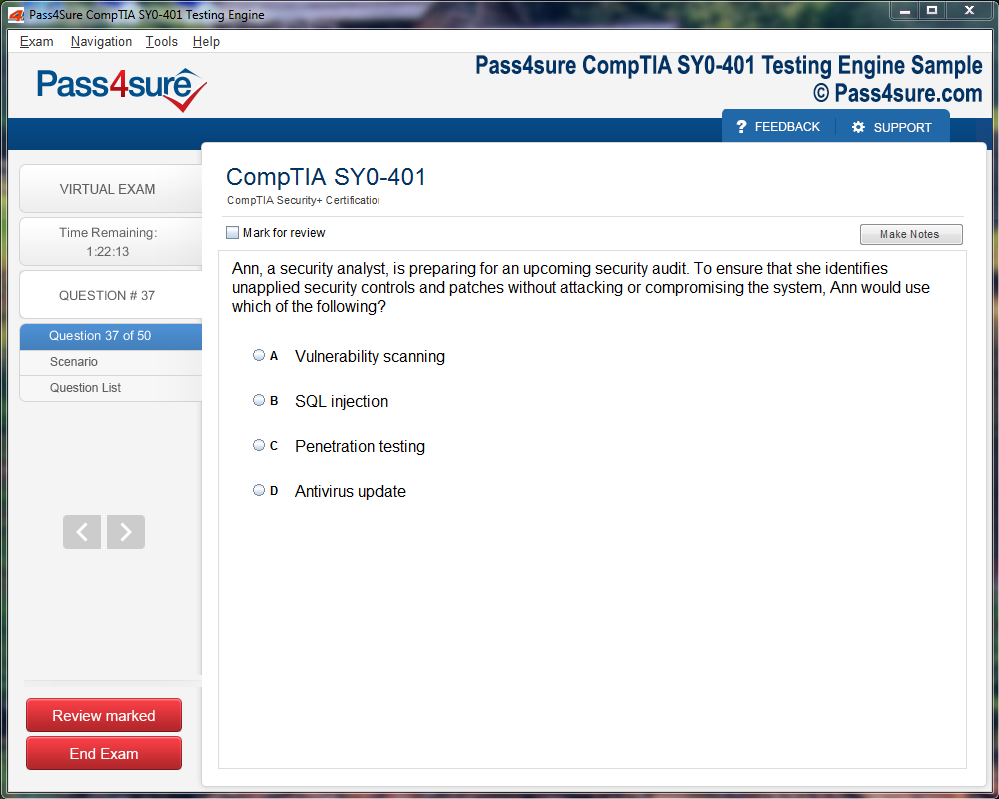

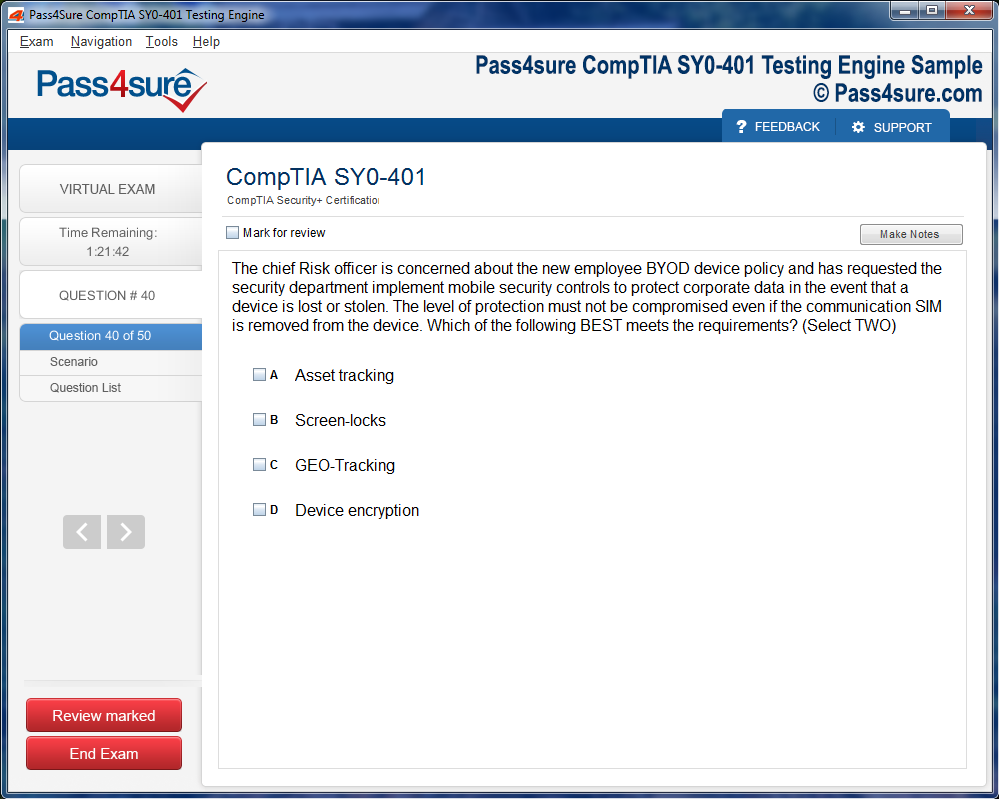

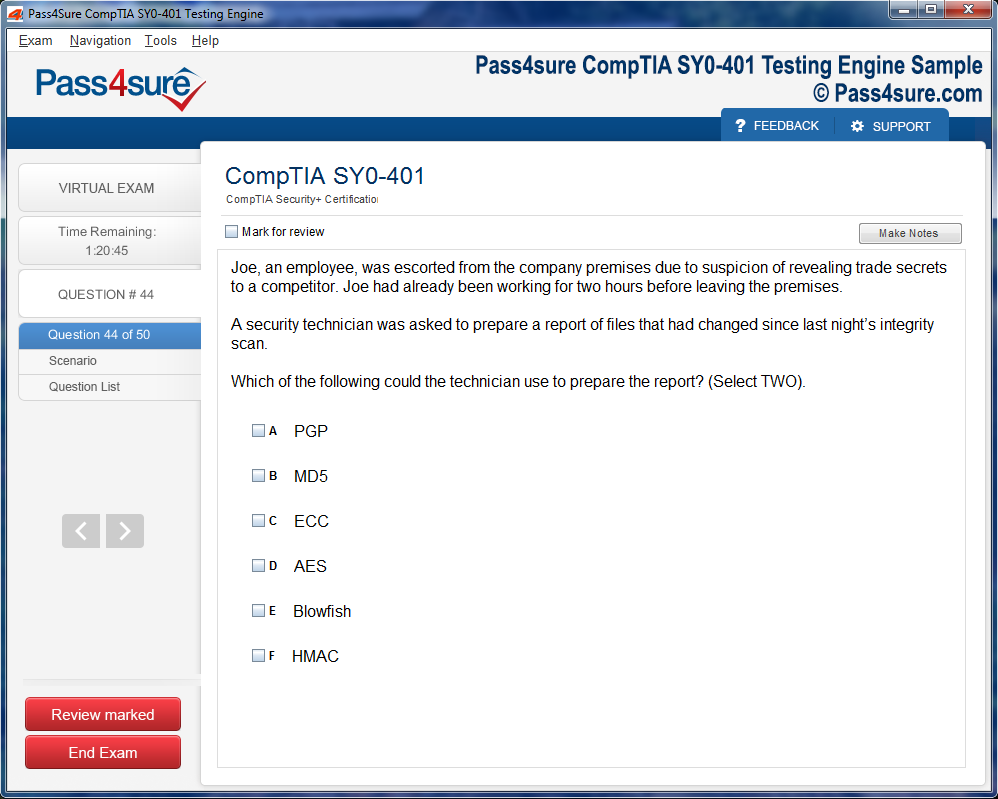

Product Screenshots

What is API Automation Testing: A Complete Guide to Risk Based Inspection

API Automation Testing plays an integral role in the world of software development. Its relevance has surged alongside the increasing complexity of modern software systems. APIs act as the backbone of communication between different systems and applications. They define how different software components interact with each other, allowing for seamless data exchange and operation.

Traditionally, software testing was performed manually, which meant developers and testers had to execute repetitive tasks over and over again. This process was not only time-consuming but also prone to human error. As the need for faster development cycles and higher-quality products became apparent, automation in testing emerged as a powerful solution.

In the realm of API testing, automation reduces the manual effort significantly. Through specialized tools and scripts, tests are run automatically at the click of a button. This significantly speeds up the testing process, reduces errors, and ensures consistency. By leveraging automation, businesses can test APIs more frequently and more thoroughly, which increases the overall reliability of their applications. The process also helps teams focus their efforts on more complex tasks, leaving routine checks to automation.

Key Elements of API Risk based Inception Automation Testing

For any API Automation Testing framework to be successful, it needs to be built on some foundational elements. These components help define the scope of testing, streamline the testing process, and ensure the quality of the results.

One of the first elements is the test case definition. A solid set of test cases is essential for verifying that an API functions as expected. Test cases should cover all possible scenarios, including edge cases, where the API may behave unexpectedly or fail. These test cases serve as a blueprint for the automation framework, ensuring that all aspects of the API are adequately tested.

The next key element is the tool selection. There are several tools available in the market that help automate the testing of APIs, such as Postman, SoapUI, and RestAssured. The choice of tool depends on various factors such as the type of API being tested (REST, SOAP), the complexity of the test cases, and the technology stack used by the development team. Choosing the right tool is crucial for ensuring smooth test execution and effective test coverage.

Another vital component is test data management. Effective testing requires realistic data that mirrors the real-world scenarios in which the API will be used. Managing test data ensures that tests are executed with accurate and relevant information. In some cases, this may involve setting up mock services to simulate the behavior of external systems that the API communicates with.

Finally, reporting and logging play an essential role in API testing. After executing the tests, detailed logs and reports are generated, highlighting the areas where the API performed well and identifying any potential issues. These reports provide valuable insights that guide the development team in troubleshooting and improving the API.

Understanding Risk-Based Inspection in API Risk based Inception Testing

Risk-Based Inspection is an approach that helps prioritize testing efforts based on the potential risks associated with each part of the software. In API testing, this method is particularly valuable because not all components of an API carry the same level of risk. Some parts of the API may be used frequently and interact with sensitive data, while others may be seldom accessed and have minimal impact on the overall system.

Risk-Based Inspection takes into account several factors when evaluating risks. One of the most critical factors is the usage frequency of specific API endpoints. Endpoints that are used more often are more likely to experience issues, simply because they are accessed by a larger number of users and applications. For instance, authentication and payment APIs are typically high-risk because they handle sensitive data and are integral to the system’s functionality.

Another factor is complexity. APIs that are more complex, with intricate logic and multiple dependencies, are more prone to errors. Testing such APIs requires a more comprehensive approach to ensure that every interaction is handled correctly. This could involve setting up more detailed test scenarios and simulations to capture all possible failures.

Business impact is another essential consideration. Some API functions may be critical to the business, affecting the company’s revenue, security, or user experience. For example, a payment API failure could lead to significant financial losses or damage to the company’s reputation. In contrast, a less critical endpoint might not require as much focus, though it still needs to be tested to ensure overall system reliability.

By applying Risk-Based Inspection, teams can focus their testing efforts on the high-risk areas while reducing the testing intensity for lower-risk components. This strategy leads to more efficient use of resources and ensures that the most critical aspects of the API receive the necessary attention.

The Role of Automation in Risk Based Inspection

While Risk-Based Inspection focuses on identifying and prioritizing risks, API Automation plays a crucial role in addressing those risks effectively. Automation ensures that the most critical parts of the API are tested thoroughly and efficiently, allowing teams to detect and fix issues before they impact end users.

In API testing, automation can be applied selectively to the most vulnerable parts of the system. For instance, the testing team might use automation to run stress tests on high-risk API endpoints, simulating heavy traffic or complex interactions to see how the system responds under pressure. By automating these tests, teams can quickly identify weaknesses and take corrective actions before deployment.

Automated tests also make it easier to execute tests more frequently. Since high-risk API endpoints are often subject to frequent changes, running automated tests after every code update ensures that new changes do not introduce errors into critical areas. This continuous testing process allows developers to catch issues earlier in the development cycle, reducing the time spent on bug fixes later on.

Moreover, automation provides a level of consistency that manual testing cannot match. It eliminates the variability introduced by human testers, ensuring that each test is executed the same way every time. This consistency helps identify subtle issues that might otherwise go unnoticed, improving the overall quality of the API.

Balancing Thoroughness and Efficiency in API Testing

One of the biggest challenges in API testing is finding the right balance between thoroughness and efficiency. Testing every component of an API in-depth would be ideal, but it is not always feasible due to time and resource constraints. In these cases, Risk-Based Inspection and automation come together to help make the testing process both efficient and effective.

The key to balancing thoroughness and efficiency is prioritization. Through Risk-Based Inspection, testing teams can identify which areas of the API require the most attention. These high-risk areas are then tested with greater frequency and intensity, ensuring that the most critical parts of the application are free of defects.

At the same time, low-risk areas are tested less intensively. This doesn’t mean they are neglected; rather, they are subjected to lighter testing cycles, such as running basic functionality checks rather than exhaustive stress tests. By focusing on what matters most, teams can allocate their resources wisely, ensuring that the API is reliable without overburdening the testing process.

Efficiency is also enhanced by automation. Automated tests can be executed in parallel, allowing the team to test multiple aspects of the API simultaneously. This speeds up the overall testing process and reduces the time required for each testing cycle. As a result, businesses can release updates more quickly without sacrificing quality.

Continuous Improvement with API Risk based inspection Testing

API testing, like all aspects of software development, benefits from continuous improvement. Over time, as more is learned about the API’s behavior and how it interacts with different systems, testing strategies can be refined to enhance accuracy and coverage.

One of the ways to ensure continuous improvement is through feedback loops. After each round of testing, teams analyze the results and use that information to adjust their testing strategies. If a previously untested endpoint begins to show signs of instability, the team can revise the testing approach to include that endpoint in future tests. Likewise, if a particular type of failure occurs repeatedly, the team can identify areas for improvement in their testing scripts or framework.

By continuously refining the testing process, teams can stay ahead of potential issues, ensuring that the API remains robust and adaptable to changes. Automation, with its ability to run tests repeatedly and consistently, plays a vital role in this process, providing the foundation for ongoing optimization.

Testing in isolation, however, is not enough. Collaboration between different teams—developers, testers, business analysts—ensures that the API is tested from multiple perspectives. This collaborative approach guarantees that all aspects of the API are considered, from functionality and performance to security and usability.

Through the continuous refinement of both the testing process and the underlying system, businesses can deliver APIs that are resilient, efficient, and secure. By embracing both automation and Risk-Based Inspection, companies can ensure that their software remains high-quality and prepared to meet the demands of modern users.

Understanding the Significance of API Testing in Modern Software Development

In the world of modern software development, APIs are an essential building block that facilitates communication between different systems and components. As the backbone of much of today’s interconnected digital ecosystem, APIs enable applications to interact, exchange data, and function cohesively. However, ensuring that APIs work as expected and integrate smoothly into the larger system is no small feat. This is where API testing comes into play.

API testing is a type of software testing that focuses on verifying the functionality, performance, and reliability of APIs. It ensures that the data and interactions passed between systems or modules are processed as expected. If an API fails to meet its intended performance standards, the overall system can be compromised, leading to a breakdown in service, security vulnerabilities, and potential damage to the business’s reputation.

A robust API testing process is crucial not only for identifying bugs and defects but also for ensuring that the application delivers a seamless user experience. API tests verify that endpoints return correct responses, confirm that the data passed is accurate, and check for performance and security issues that may arise under specific conditions. API testing offers confidence that APIs will perform optimally under varying circumstances, such as high traffic or system failures.

In today's agile development environment, speed is key. With frequent deployments and continuous integration, automated API testing has become a vital tool to ensure that these tests are carried out swiftly, consistently, and accurately. Manual testing, while still useful in some cases, cannot keep pace with the rapid demands of modern development cycles. Automation ensures that tests can be executed repeatedly without the need for human intervention, significantly reducing the time it takes to deliver quality software.

The Core Components of API Automation Testing

API Risk Based Inception automation testing refers to the use of specialized software tools to automate the process of testing APIs, enabling developers and testers to execute large-scale tests without manual effort. The primary objective is to run tests across different scenarios, validate expected results, and ensure that APIs operate reliably in various conditions. This significantly enhances the efficiency of the testing process, reducing human error and ensuring that repetitive tasks are handled with precision.

The process of API automation testing typically begins with the creation of test cases, which are designed to verify different aspects of the API’s functionality. These test cases can include tests for input validation, output validation, error handling, performance, security, and more. The next step is to configure the automation tool, such as Postman, SoapUI, or RestAssured, which simulates different API requests and checks for the expected responses.

One of the advantages of API automation testing is the ability to execute tests across multiple environments and platforms without requiring manual intervention. This is particularly beneficial for applications that need to be tested in various configurations, such as different operating systems, browsers, or mobile devices. By automating the testing process, organizations can ensure that APIs work as expected regardless of the environment in which they are deployed.

Furthermore, automated testing allows for greater scalability in testing. As software development becomes more complex, APIs are often more intricate, with multiple endpoints and numerous potential interactions. Automated tests can be scaled to cover a vast array of use cases, ensuring that all critical scenarios are tested before the product is released.

Key Benefits of API Automation Testing

Automated API testing offers a multitude of benefits that can significantly improve the efficiency and effectiveness of the testing process. One of the most notable advantages is the speed with which tests can be executed. In traditional manual testing, each test requires human effort, which can lead to delays, especially in large-scale testing scenarios. With automation, tests can be run much faster, which is especially important when continuous integration and continuous delivery (CI/CD) pipelines are involved.

Another key benefit is the ability to run tests repeatedly without the risk of human error. In manual testing, testers may inadvertently overlook certain steps, make mistakes in test execution, or fail to follow consistent procedures. Automated tests, on the other hand, are highly repeatable, ensuring that each test is executed in the same way every time. This consistency is vital for detecting subtle issues that might otherwise go unnoticed.

API automation testing also facilitates better resource management. Since tests can be executed automatically, testers and developers can focus on more complex and value-added activities rather than spending time on repetitive tasks. This not only improves productivity but also allows teams to prioritize higher-level testing activities, such as performance testing or security assessments, which require more specialized expertise.

Additionally, automated tests can be run continuously as part of the CI/CD pipeline, ensuring that every change made to the codebase is immediately tested for potential issues. This continuous feedback loop helps identify bugs and vulnerabilities early in the development process, reducing the cost of fixing issues and improving the overall quality of the application.

The Role of Risk-Based Inspection in API Testing

One of the most effective strategies in API testing is risk-based inspection, a technique that prioritizes testing efforts based on the potential risk each component poses to the overall system. Not all APIs are created equal, and some API endpoints carry greater risk than others. Risk-based inspection helps ensure that testing resources are focused on the most critical components of the system, rather than spreading efforts too thin across less important or low-risk APIs.

In practice, risk-based inspection involves evaluating the potential consequences of an API failure and determining the likelihood of such a failure occurring. APIs that are critical to the core functionality of the application, or those that handle sensitive data, will be given higher priority in testing. On the other hand, APIs that perform less important tasks or are isolated from key system functions may be subject to less intensive testing.

By focusing on the most critical parts of the application, risk-based inspection helps optimize the testing process. This ensures that limited testing resources are used effectively, maximizing the likelihood of identifying significant issues before they escalate. This approach is especially useful in large applications with numerous APIs, where testing every single endpoint in detail may not be feasible within the time and resource constraints of the development cycle.

Risk-based inspection also allows teams to adjust their testing efforts dynamically based on the changing needs of the project. For example, if new features are added to the application that increase the importance of a particular API, additional testing can be performed to ensure the new functionality does not introduce any defects or vulnerabilities.

Integrating API Testing into the Continuous Integration Pipeline

In modern software development, agility and speed are paramount. Developers and testers must work in tandem to deliver updates quickly, without compromising quality. This is where the integration of API testing into the continuous integration (CI) pipeline becomes crucial.

Continuous integration is a practice in which developers merge their code changes into a shared repository frequently, often multiple times a day. Each change triggers an automated build process, which includes various types of tests, including API tests. By integrating API tests into the CI pipeline, teams can ensure that any changes to the codebase are immediately validated, catching issues before they can affect the application’s functionality.

This continuous feedback loop allows for faster development cycles, as developers are alerted to issues as soon as they occur. It also helps reduce the risk of defects being introduced into production, as testing is performed automatically every time code changes are made. Moreover, automated tests in the CI pipeline can be easily updated to reflect new changes or additional features, keeping the testing process aligned with the evolving application.

Incorporating API testing into the CI/CD pipeline also improves collaboration between developers, testers, and operations teams. By automating the testing process and integrating it into the development workflow, everyone involved in the project can work more efficiently and with greater confidence that the application is being thoroughly tested at every stage of the development lifecycle.

Ensuring Security Through API Testing and Automation

Security is a paramount concern in today’s digital landscape, where data breaches and cyberattacks are increasingly common. APIs, being an integral part of many modern applications, can serve as entry points for malicious actors if not properly secured. As such, ensuring the security of APIs through thorough testing is critical for safeguarding sensitive data and maintaining the integrity of the application.

API testing plays a key role in identifying potential security vulnerabilities, such as unauthorized access, data leaks, or improper authentication. Automated testing tools can be configured to test for common security issues, such as SQL injection, cross-site scripting (XSS), and improper encryption. These tools can simulate attacks on the API and verify that security measures, such as encryption protocols and authentication mechanisms, are functioning as intended.

By automating security testing, organizations can ensure that security checks are conducted regularly and consistently, reducing the risk of vulnerabilities being overlooked. Automated security tests can be incorporated into the CI/CD pipeline, ensuring that security is prioritized throughout the development process and that any potential issues are addressed before they can be exploited.

Security testing in the API domain requires specialized knowledge and skills to identify potential risks and ensure that proper safeguards are in place. Automation tools help streamline this process, allowing teams to test multiple endpoints quickly and identify security flaws in real-time. As a result, organizations can reduce the risk of costly breaches and protect both their users and their brand reputation.

The Future of API Testing and Automation

As technology continues to evolve, so too will the practices surrounding API testing and automation. The growing complexity of modern applications, coupled with the increasing reliance on APIs, means that testing these systems will only become more important in the years ahead.

One area of growth is the increasing use of artificial intelligence (AI) and machine learning (ML) in the realm of software testing. AI-driven testing tools have the potential to automate many aspects of the testing process, including the creation of test cases, identification of bugs, and prediction of potential failures. These advancements promise to make API testing even more efficient, helping teams deliver high-quality applications faster than ever before.

Furthermore, as APIs continue to evolve and become more integrated into everyday applications, new testing strategies will emerge to address the unique challenges posed by emerging technologies such as microservices, serverless computing, and containerization. The future of API testing will likely involve a combination of automation, AI, and advanced analytics to ensure that APIs perform optimally in increasingly complex environments.

The continued growth of API automation testing will play a critical role in

shaping the future of software development, enabling teams to deliver faster, more reliable, and secure applications to users across the globe.

Risk-Based Inspection (RBI) plays an essential role in the efficient execution of API automation testing. It allows development and testing teams to prioritize resources, focusing on the most critical parts of an application while minimizing time spent on less significant areas. This approach is particularly vital for API testing, where the complexity and interdependencies of different API endpoints can make exhaustive testing both time-consuming and resource-draining. By implementing Risk-Based Inspection, teams can ensure that their API testing efforts are both effective and efficient, concentrating on high-risk components that have the most potential to cause system failures.

The Core Principles of Risk-Based Inspection in API Testing

Risk-Based Inspection hinges on understanding and evaluating the potential risks associated with different parts of an application. In the context of API automation, it entails recognizing which APIs could have the most profound impact if they were to fail. This requires an in-depth assessment of the business logic, data flows, and user interactions that each API serves. By assigning a risk score to each API, testers can determine which endpoints should be prioritized for more intensive testing. This risk assessment typically considers factors such as API complexity, the frequency of interactions with other services, and the consequences of a failure, both in terms of user experience and business impact.

A successful Risk-Based Inspection strategy goes beyond merely identifying failure-prone APIs. It incorporates a holistic view of the API ecosystem, ensuring that even less complex APIs are evaluated in the context of their contribution to the overall system. By aligning testing efforts with risk profiles, development teams can optimize their testing strategies, dedicating more time and resources to areas that are critical while avoiding overtesting less critical components.

Identifying Critical APIs Through Risk Assessment

One of the fundamental components of Risk-Based Inspection is the risk assessment of APIs. This process involves analyzing APIs based on their role within the application, their interaction with other services, and the potential impact of a failure. Critical APIs often deal with sensitive or high-impact functions such as financial transactions, user authentication, and data encryption. If these APIs were to fail, they could compromise the application's security, lead to financial losses, or create significant user dissatisfaction.

A thorough risk assessment starts by identifying which APIs are most integral to the application’s core functions. APIs involved in payment gateways, personal data handling, or mission-critical operations are deemed high-risk and warrant extensive testing. On the other hand, APIs that merely provide auxiliary services, like internal logging or non-essential notifications, may be considered lower risk and can be tested with less intensity. By performing this risk assessment, testing teams can focus on areas that could result in the greatest consequences, ensuring that high-risk areas are properly scrutinized while not wasting resources on less critical components.

Streamlining API Automation Testing with Risk-Based Inspection

Incorporating Risk-Based Inspection into API automation testing transforms the entire process by making it more efficient and targeted. Traditional testing methods often involve testing each API equally, regardless of its risk profile. This can lead to wasted time and effort, especially when testing low-risk components that have minimal impact on the application’s overall functionality. By adopting a risk-based approach, teams can prioritize which APIs to automate first, ensuring that the most critical parts of the system are adequately tested before others.

When automation tools are deployed with a risk-based mindset, they help create a smarter, more adaptive testing cycle. High-risk APIs can be tested more thoroughly and frequently, while lower-risk APIs can be tested less frequently or with less detail. This tiered approach helps reduce the overall testing time without sacrificing the quality of the test coverage. It ensures that the areas most likely to cause critical failures are given the attention they deserve, while also preventing unnecessary duplication of effort in low-risk areas.

Balancing Testing Efforts for Low and High-Risk APIs

Risk-Based Inspection helps maintain a delicate balance between testing high-risk and low-risk APIs, ensuring that neither category is neglected. High-risk APIs require meticulous testing because a failure could result in severe consequences. However, focusing solely on high-risk APIs could lead to inefficiencies, as it might result in testing certain components more than necessary. On the other hand, ignoring low-risk APIs could result in unexpected issues that arise from these components later in the process.

The key to successful Risk-Based Inspection lies in adjusting the testing efforts according to the risk level. This dynamic approach ensures that all APIs are tested to an appropriate degree based on their potential impact. High-risk APIs are tested with rigorous and comprehensive automated test cases that thoroughly cover all potential scenarios, while lower-risk APIs undergo lighter testing. This balance prevents resource overutilization while ensuring sufficient coverage across the entire application.

Mitigating Potential Failures Through Targeted Testing

One of the primary goals of Risk-Based Inspection in API automation testing is to mitigate potential system failures that could disrupt the user experience, harm business operations, or compromise security. By identifying the most critical APIs, development teams can ensure that they are thoroughly tested to avoid any catastrophic failures post-deployment. A failure in a high-risk API could result in system outages, data breaches, or financial losses, making it essential to test these areas with extra care.

By focusing on high-risk APIs, testing teams can ensure that all critical business logic, sensitive data handling, and essential functionality are fully validated. This minimizes the risk of severe defects making it to production and maximizes the likelihood of a smooth, seamless user experience. Additionally, this strategy supports the identification of edge cases and unexpected scenarios that might otherwise go unnoticed in a typical, non-risk-based testing cycle.

Reducing Testing Overhead with Risk-Based Inspection

Another significant advantage of implementing Risk-Based Inspection is the reduction of testing overhead. Software testing is often a resource-intensive process, especially in the context of API automation, where multiple test cases need to be created, executed, and maintained for every API endpoint. With limited testing resources and time, attempting to test every API equally can lead to unnecessary redundancy and wasted effort.

By focusing resources on high-risk APIs, teams can reduce the overall testing time and resource allocation. Low-risk APIs, which typically have fewer dependencies and simpler logic, can be tested with fewer resources, and possibly even with manual testing or simplified automation. This allows the development team to streamline their testing process, improving both speed and efficiency without sacrificing quality. By applying Risk-Based Inspection, testing becomes more intelligent and strategic, reducing unnecessary testing and focusing resources where they matter most.

Enhancing Quality and Reducing Risk of Post-Deployment Failures

Risk-Based Inspection not only optimizes the testing process but also significantly enhances the overall quality of the application. By prioritizing high-risk APIs, teams can ensure that they are adequately tested to withstand the pressures of real-world use. Thorough testing of critical APIs reduces the likelihood of encountering major defects in production, improving the stability and performance of the application.

Furthermore, by addressing risk early in the development process, Risk-Based Inspection helps to identify potential issues before they reach production. This proactive approach minimizes the chances of catastrophic failures that could lead to system downtime or security breaches. As a result, the overall application quality improves, and the risk of post-deployment issues is significantly reduced.

Optimizing Resource Allocation with a Risk-Based Approach

Efficient resource allocation is essential in any software development process. Testing resources, including time, manpower, and automated tools, are finite, making it crucial to allocate them in the most effective way possible. Risk-Based Inspection ensures that resources are allocated based on the importance and complexity of each API, ensuring that high-risk areas receive the attention they deserve.

By aligning testing efforts with risk profiles, teams can allocate resources more effectively, ensuring that critical components are tested with adequate rigor while reducing effort on low-risk components. This enables development teams to maintain high testing standards while optimizing their resource utilization. The result is a more efficient testing process that delivers both comprehensive coverage and faster release cycles.

Improving Collaboration Between Development and Testing Teams

A Risk-Based Inspection approach not only enhances the testing process but also fosters greater collaboration between development and testing teams. By working together to identify the most critical APIs and assess their risk levels, developers and testers can ensure that the most important aspects of the application are given the proper attention during testing. This collaboration helps build a deeper understanding of the application's functionality and potential failure points, creating a shared focus on ensuring the application’s reliability and security.

Incorporating a risk-based strategy also encourages continuous communication throughout the development and testing phases, which can lead to faster identification of issues and more efficient problem-solving. As development teams receive feedback on the testing of high-risk APIs, they can make adjustments more quickly, ensuring that critical bugs are addressed before they make it to production. This collaboration not only improves the quality of the application but also reduces the time it takes to bring a product to market.

Risk-Based Inspection (RBI) is a methodology that has been gaining prominence in various sectors, particularly in software development and testing. It enables teams to optimize their testing processes by focusing resources on high-risk areas that could potentially disrupt the functionality, performance, or security of the system. With the advent of automation tools and Continuous Integration (CI) pipelines, integrating Risk-Based Inspection into automated testing workflows has become more practical and effective. By identifying and addressing the most critical components early in the development cycle, teams can ensure the stability and reliability of the system while reducing the chances of undetected defects that may harm end users.

Automated testing has revolutionized the way software development is carried out, making it faster and more efficient. However, without a proper risk-based approach, testing can become a tedious and exhaustive process. Integrating Risk-Based Inspection into automated workflows streamlines testing efforts by ensuring that the highest priority components are thoroughly tested, while less critical areas receive appropriate attention without overburdening the testing teams. This approach optimizes resource allocation, saves time, and contributes to higher-quality software.

Defining Risk in Software Testing

Before diving into how Risk-Based Inspection can be integrated into automated testing workflows, it is essential to understand the concept of "risk" in the context of software testing. Risk, in this scenario, refers to the potential for failure that can lead to adverse consequences for the business, the end user, or the system itself. The risk level associated with any component of the software is determined by evaluating the likelihood of failure and the severity of its impact.

In software testing, risk is often divided into two main categories: technical risk and business risk. Technical risk refers to the likelihood of a defect occurring due to issues such as code complexity, system performance, or security vulnerabilities. Business risk, on the other hand, involves the consequences that a defect might have on the organization's operations, reputation, or customer satisfaction. Both types of risks must be considered when implementing Risk-Based Inspection.

High-risk areas typically require more intensive and frequent testing, while lower-risk components can be tested less rigorously. For example, a core API responsible for user authentication would be classified as high risk due to the potential for security breaches if it fails, while a simple API providing system status information may be classified as low risk, as its failure would not have significant consequences.

Categorizing APIs Based on Risk Levels

The first step in integrating Risk-Based Inspection into an automated testing workflow is to categorize the different components of the software, particularly APIs, based on their risk level. APIs are often the backbone of modern applications, handling critical functions such as user authentication, data storage, and communication between different parts of the system. Therefore, categorizing APIs according to their risk potential is vital for optimizing the testing process.

To categorize APIs effectively, several factors should be taken into account:

Business Impact: How critical is the API to the system’s core functionality? Does it directly impact revenue generation or customer satisfaction? For example, an API responsible for processing financial transactions is high risk, while an API that provides metadata about the system may be low risk.

User Base: APIs that serve a large number of users or handle high traffic volumes are more likely to have a greater impact if they fail. A login API, which is used by all users of the system, would be considered high risk, while an API that is used less frequently, like one for administrative purposes, may be lower risk.

Complexity: The more complex an API, the higher the chance that it could fail due to various interconnected factors. APIs with intricate logic or dependencies on external services are often riskier than simpler ones.

Frequency of Use: APIs that are invoked frequently are more susceptible to issues and should be prioritized for testing. Conversely, less frequently used APIs may have fewer defects and can be tested less frequently.

Once these factors are considered, the APIs can be grouped into risk categories, ranging from high to low. High-risk APIs should be tested exhaustively to ensure they perform as expected under various conditions, while lower-risk APIs can be tested using simpler, less resource-intensive methods.

Automation Tools and Risk-Based Inspection Integration

After the APIs have been categorized, the next step is to integrate Risk-Based Inspection into the automated testing workflow. Automation tools play a significant role in ensuring that high-risk APIs receive the attention they deserve while optimizing testing efforts for lower-risk areas. These tools help streamline the testing process by executing tests automatically based on predefined schedules or triggers, ensuring that tests are run consistently and frequently.

There are a few key strategies for integrating Risk-Based Inspection into automated testing workflows:

1. Prioritization of Tests

Once APIs are categorized based on their risk level, automation tools can be configured to prioritize high-risk APIs for testing. This involves assigning different levels of testing intensity to each API category. High-risk APIs may be subjected to a battery of tests, including functional, performance, and security testing. Automated tests can be scheduled to run multiple times a day to ensure that these critical components are continuously monitored.

On the other hand, low-risk APIs may be tested using lighter test cases that focus on basic functionality and edge cases. The goal is to reduce the frequency and complexity of testing for components that are less likely to fail, thereby conserving testing resources and time.

2. Continuous Integration and Continuous Testing

Risk-Based Inspection can be effectively integrated into the Continuous Integration (CI) pipeline. By automating tests for high-risk APIs and scheduling them to run as part of the CI process, teams can detect issues early in the development cycle. Automated tests for high-risk components can be run every time code is pushed to the repository, ensuring that potential issues are identified and resolved promptly.

For lower-risk APIs, the testing frequency may be reduced, and tests can be executed periodically, based on the project's specific needs. This helps to maintain a balance between testing high-priority components regularly and testing lower-priority components when necessary.

3. Test Coverage Optimization

Another benefit of integrating Risk-Based Inspection into automated testing workflows is the optimization of test coverage. By identifying high-risk areas, teams can focus their testing efforts on the most critical parts of the application. This ensures that the testing coverage is aligned with the areas that matter the most, increasing the likelihood of identifying defects before they reach production.

Test coverage optimization is particularly important when dealing with large and complex applications, as it prevents the unnecessary execution of tests on components that are unlikely to fail. Instead of testing every component with the same intensity, the team can allocate resources more effectively, leading to faster testing cycles and more efficient workflows.

Reducing Test Fatigue and Increasing Efficiency

One of the key challenges in software testing is the potential for test fatigue. Test fatigue occurs when testing teams are overwhelmed by the sheer volume of tests that need to be executed. This can lead to burnout, inefficiency, and missed defects. Risk-Based Inspection helps mitigate test fatigue by reducing the number of tests that need to be executed on low-risk components, allowing teams to focus their efforts on higher-priority areas.

By focusing on the most critical components, teams can avoid spending excessive time on testing areas that are unlikely to fail. This approach reduces the overall testing workload, making the process more manageable and less prone to human error. Testers can devote more attention to high-risk areas, increasing the chances of uncovering issues early and ensuring that the most important aspects of the software are thoroughly tested.

Adapting Risk-Based Inspection to Changing Software Environments

As software systems evolve and new features or APIs are introduced, the risk profile of different components may change. An API that was once considered low risk may become high risk due to changes in its functionality or its role within the system. This dynamic nature of software development means that Risk-Based Inspection must be continuously reassessed and adjusted to reflect the current state of the application.

Teams should regularly revisit their risk categorization to ensure that the most critical components are being tested effectively. As new APIs are added or existing ones are modified, the risk levels should be recalculated to determine whether they require more rigorous testing. Automation tools should be configured to adapt to these changes, ensuring that testing efforts remain aligned with the evolving risk landscape.

Additionally, Risk-Based Inspection can be extended to cover other areas of the software development lifecycle, such as code quality, security, and performance. By continually assessing risk across all aspects of the development process, teams can create a more comprehensive and proactive testing strategy.

Leveraging Feedback for Continuous Improvement

Incorporating Risk-Based Inspection into automated testing workflows also provides valuable feedback that can drive continuous improvement. As tests are executed, the results can be analyzed to identify patterns or recurring issues that may indicate underlying problems in the software. This feedback loop enables teams to make data-driven decisions about where to focus their efforts in future development cycles.

By regularly reviewing test results, teams can gain insights into which components are more prone to defects and which areas may need additional resources or attention. This allows for a more targeted approach to risk management, helping to prioritize testing efforts and ensure that resources are used efficiently.

Furthermore, the insights gained from testing can inform the development process itself. If certain APIs are consistently found to be high risk, development teams can take proactive measures to address these issues early, such as refactoring code, improving security protocols, or simplifying complex logic.

Integrating Risk-Based Inspection into automated testing workflows is a powerful approach that enables teams to focus on high-priority areas, optimize testing resources, and reduce the chances of defects going undetected. By categorizing APIs and other components based on their risk levels, teams can prioritize testing efforts and ensure that the most critical parts of the system are thoroughly tested. As software systems evolve, Risk-Based Inspection must be continuously reassessed to reflect the changing risk landscape. By leveraging automation tools, optimizing test coverage, and reducing test fatigue, teams can enhance the overall efficiency of their testing processes and improve the quality of the final product.

In the ever-evolving world of software development, APIs (Application Programming Interfaces) have become fundamental building blocks that enable seamless communication between systems. As the digital landscape grows increasingly complex, the need for robust testing mechanisms that ensure the reliability, security, and efficiency of APIs has never been more critical. API Automation Testing has already proven to be a valuable asset for developers, but when coupled with Risk-Based Inspection (RBI), its capabilities are magnified, offering a deeper, more focused approach to identifying potential issues before they become catastrophic.

As organizations move toward more sophisticated architectures, such as microservices and cloud-native applications, the traditional methods of manual testing are becoming outdated. The fast-paced nature of modern software development demands automation that not only expedites testing processes but also reduces the likelihood of critical failures. This is where Risk-Based Inspection becomes a game-changer. By concentrating on the most vulnerable or high-risk areas of an application, Risk-Based Inspection offers targeted testing, ensuring that resources are invested where they matter most.

The fusion of API Automation Testing and Risk-Based Inspection represents the future of quality assurance in software development. In the years to come, this methodology will continue to evolve, leveraging advanced technologies like Artificial Intelligence (AI) and Machine Learning (ML) to enhance the accuracy, efficiency, and precision of testing strategies. By examining the intricate synergy between these two elements, we gain valuable insights into how they will shape the future of API testing and quality assurance practices.

The Role of Risk-Based Inspection in API Testing

Risk-Based Inspection is not a new concept in software engineering, but its application to API testing has the potential to redefine how developers approach testing in general. The core principle of Risk-Based Inspection is to prioritize testing efforts based on the risk associated with different parts of the system. In the context of APIs, this could mean identifying which endpoints, methods, or components are most likely to fail and targeting those areas with more intensive testing efforts.

One of the main challenges in API testing is that not all parts of an API carry the same weight when it comes to potential impact on the overall application. Some API endpoints might be used frequently, while others are rarely called. Others might handle sensitive data, making them more critical in terms of security. Risk-Based Inspection helps in understanding these differences by focusing on the likelihood of failure, the severity of failure, and the impact on end-users or the business. By concentrating testing efforts on the high-risk components, teams can optimize resources and reduce unnecessary testing of low-risk elements.

The integration of Risk-Based Inspection into API Automation Testing also allows for continuous monitoring and prioritization. This is particularly important in modern, agile development environments, where rapid deployment cycles mean that the software is always in flux. As new features are added or changes are made to existing code, Risk-Based Inspection can dynamically adjust, ensuring that the most critical areas continue to receive the attention they need.

The Emergence of AI and Machine Learning in Testing

Artificial Intelligence and Machine Learning are revolutionizing nearly every aspect of the software development lifecycle, and testing is no exception. In the context of API testing, AI and ML can be leveraged to automate the risk assessment process, taking into account vast amounts of historical data to predict potential failure points. By analyzing patterns in API traffic, response times, and error rates, AI systems can help testers identify which parts of the API are most vulnerable to issues and should therefore be prioritized in testing.

Incorporating AI-driven tools into API Automation Testing enhances the efficiency of Risk-Based Inspection. For example, AI algorithms can monitor how an API is used in real time, identifying patterns that suggest a higher likelihood of failure. These patterns might not always be immediately obvious to human testers but can be recognized by machine learning models that have been trained on large datasets. With this knowledge, testing efforts can be dynamically adjusted to focus on areas with the highest risk, further streamlining the testing process and reducing the time and resources spent on less critical components.

Moreover, AI can assist in predicting potential security vulnerabilities by analyzing historical security breaches and known weaknesses in the API ecosystem. With this information, API testing tools can proactively target areas that are known to be prone to attacks or failures, improving the overall security and reliability of the application. By automating the risk assessment and prioritization process, AI and ML contribute to a more comprehensive, proactive approach to testing, rather than a reactive one.

Integrating Risk-Based Inspection into DevOps Pipelines

The integration of Risk-Based Inspection into continuous integration and continuous delivery (CI/CD) pipelines is a natural progression for organizations embracing DevOps practices. DevOps is a set of practices that combine software development and IT operations, aiming to shorten the development lifecycle and provide high-quality software continuously. With API Automation Testing and Risk-Based Inspection integrated into DevOps pipelines, teams can achieve higher levels of efficiency and speed while maintaining the reliability and security of their applications.

One of the key benefits of incorporating Risk-Based Inspection into CI/CD pipelines is that it enables teams to detect and address issues earlier in the development process. By automatically prioritizing testing efforts based on risk, teams can catch potential problems before they reach later stages of development or production. This early detection is crucial for reducing the cost and time associated with fixing issues that could otherwise go undetected until after deployment.

Another advantage of integrating API Automation Testing with Risk-Based Inspection into the CI/CD pipeline is that it aligns perfectly with the iterative nature of DevOps. In a DevOps environment, software is developed, tested, and deployed in short cycles. The ability to continuously assess and mitigate risk in real-time means that development teams can focus their attention on the areas that need it most. Rather than relying on static, one-time testing efforts, Risk-Based Inspection allows testing to evolve alongside the software, adapting to changes and new risks as they arise.

The synergy between Risk-Based Inspection and DevOps ensures that API testing is not just an afterthought or a final check before deployment. Instead, it becomes an integral part of the development process, ensuring that high-risk areas are constantly monitored and addressed throughout the lifecycle of the software.

The Future of Automated Testing with Cloud-Based Solutions

As cloud computing continues to grow in popularity, cloud-based solutions are transforming the way software is developed, deployed, and tested. In the realm of API Automation Testing, cloud-based solutions offer scalable, cost-effective, and flexible testing environments that can support complex, distributed applications. With cloud-native architectures becoming increasingly common, it is essential for testing strategies to evolve alongside these innovations.

Cloud-based testing platforms can provide several advantages over traditional on-premises solutions. For instance, they allow teams to run tests in parallel across multiple environments, simulating different configurations and user scenarios. This level of scalability is crucial for modern applications that need to handle a large volume of API requests and support a wide range of devices and platforms.

Moreover, cloud-based testing solutions can seamlessly integrate with other cloud-native tools, such as containerization and orchestration platforms like Kubernetes. This integration allows for more efficient testing, as the testing environment can be easily replicated and scaled based on the needs of the application. Risk-Based Inspection can be applied across these environments to ensure that high-risk components are tested thoroughly, regardless of where the application is deployed.

Additionally, cloud-based solutions offer flexibility in terms of resource allocation. With the ability to scale up or down based on demand, teams can ensure that their testing infrastructure is always optimized for the task at hand. Whether testing a small API or a large, complex microservices architecture, cloud-based platforms enable testing teams to dynamically allocate resources to match the scale and complexity of their application.

Continuous Improvement in API Testing Methodologies

The future of API Automation Testing will be defined by continuous improvement, with testing methodologies constantly evolving to keep pace with advancements in technology and the changing demands of software development. The integration of Risk-Based Inspection with automation tools is just one example of how testing strategies are becoming more sophisticated and tailored to the unique needs of modern applications.

As new technologies like 5G, edge computing, and the Internet of Things (IoT) become more prevalent, testing strategies will need to evolve to accommodate the increased complexity of these systems. API testing will become even more critical in these environments, as the number of connected devices and services continues to grow. In response, testing tools will need to adapt, incorporating more advanced capabilities for monitoring and analyzing API performance, security, and reliability.

Furthermore, as software development continues to move toward a more collaborative, cross-functional model, testing will become more integrated into the development process. Teams will work together more closely to identify risks early in the development cycle and prioritize testing efforts accordingly. This will lead to more efficient and effective testing, as well as a more seamless and continuous approach to quality assurance.

In the rapidly changing world of software development, API Automation Testing combined with Risk-Based Inspection represents the future of quality assurance. By focusing testing efforts on the areas of greatest risk, teams can ensure that their applications are more reliable, secure, and performant. The integration of AI and ML, the adoption of cloud-based solutions, and the seamless incorporation of testing into CI/CD pipelines will all contribute to a more efficient and proactive approach to API testing.

As technology continues to advance and software architectures become more complex, the need for sophisticated testing methodologies will only grow. Embracing a risk-based, automated approach to testing will empower organizations to deliver high-quality software faster and with greater confidence. The future of API Automation Testing is not just about testing for the sake of testing; it is about optimizing testing strategies to align with the needs of modern software development and ensuring that the applications of tomorrow are as secure and reliable as possible.

Conclusion

Risk-Based Inspection represents a paradigm shift in the way API automation testing is approached. By focusing efforts on high-risk APIs, this strategy ensures that resources are optimized, defects are minimized, and overall application quality is improved. Through risk assessment, prioritization, and targeted testing, development teams can create a more efficient and effective testing process that delivers reliable, secure applications with reduced risk of post-deployment failures. By embracing Risk-Based Inspection, teams can ensure that their API testing efforts are aligned with business goals and user needs, ultimately delivering a superior user experience.

Frequently Asked Questions

How does your testing engine works?

Once download and installed on your PC, you can practise test questions, review your questions & answers using two different options 'practice exam' and 'virtual exam'. Virtual Exam - test yourself with exam questions with a time limit, as if you are taking exams in the Prometric or VUE testing centre. Practice exam - review exam questions one by one, see correct answers and explanations).

How can I get the products after purchase?

All products are available for download immediately from your Member's Area. Once you have made the payment, you will be transferred to Member's Area where you can login and download the products you have purchased to your computer.

How long can I use my product? Will it be valid forever?

Pass4sure products have a validity of 90 days from the date of purchase. This means that any updates to the products, including but not limited to new questions, or updates and changes by our editing team, will be automatically downloaded on to computer to make sure that you get latest exam prep materials during those 90 days.

Can I renew my product if when it's expired?

Yes, when the 90 days of your product validity are over, you have the option of renewing your expired products with a 30% discount. This can be done in your Member's Area.

Please note that you will not be able to use the product after it has expired if you don't renew it.

How often are the questions updated?

We always try to provide the latest pool of questions, Updates in the questions depend on the changes in actual pool of questions by different vendors. As soon as we know about the change in the exam question pool we try our best to update the products as fast as possible.

How many computers I can download Pass4sure software on?

You can download the Pass4sure products on the maximum number of 2 (two) computers or devices. If you need to use the software on more than two machines, you can purchase this option separately. Please email sales@pass4sure.com if you need to use more than 5 (five) computers.

What are the system requirements?

Minimum System Requirements:

- Windows XP or newer operating system

- Java Version 8 or newer

- 1+ GHz processor

- 1 GB Ram

- 50 MB available hard disk typically (products may vary)

What operating systems are supported by your Testing Engine software?

Our testing engine is supported by Windows. Andriod and IOS software is currently under development.