Exam Code: API-580

Exam Name: Risk Based Inspection

Certification Provider: API

Corresponding Certification: Risk Based Inspection

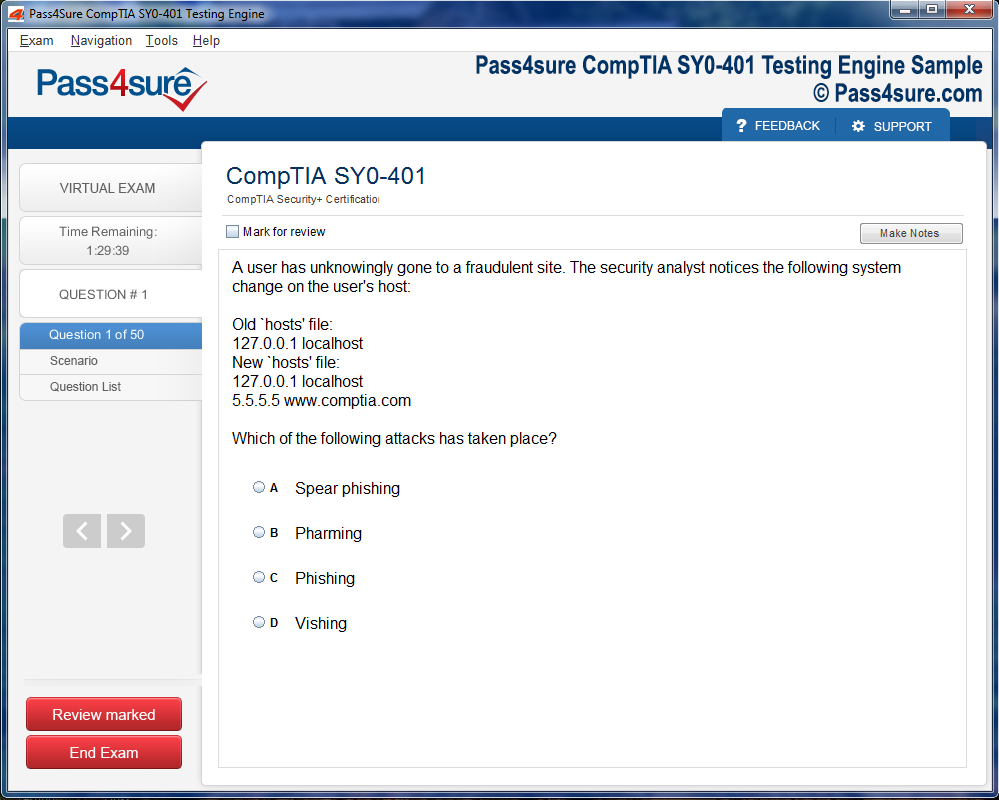

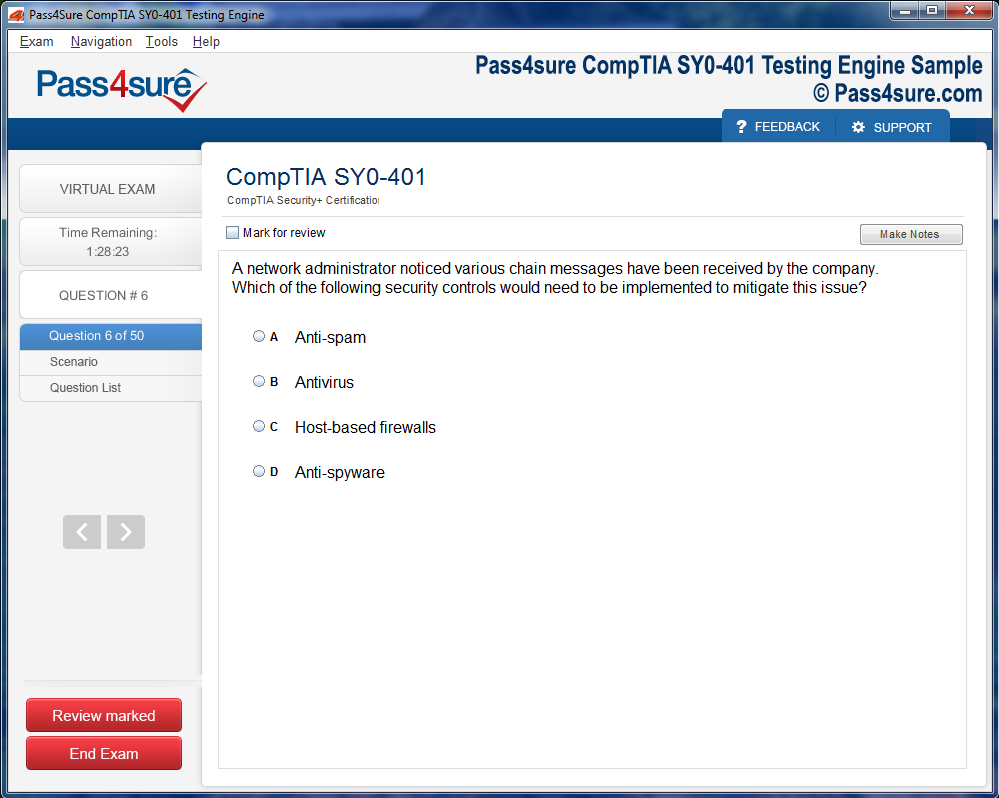

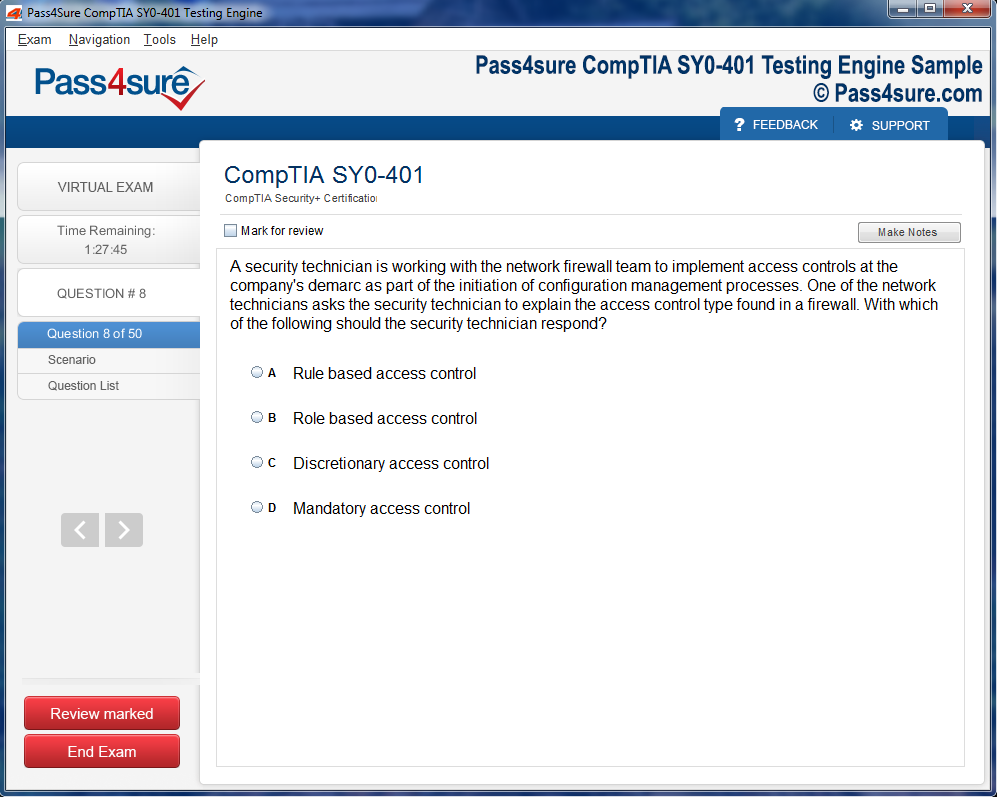

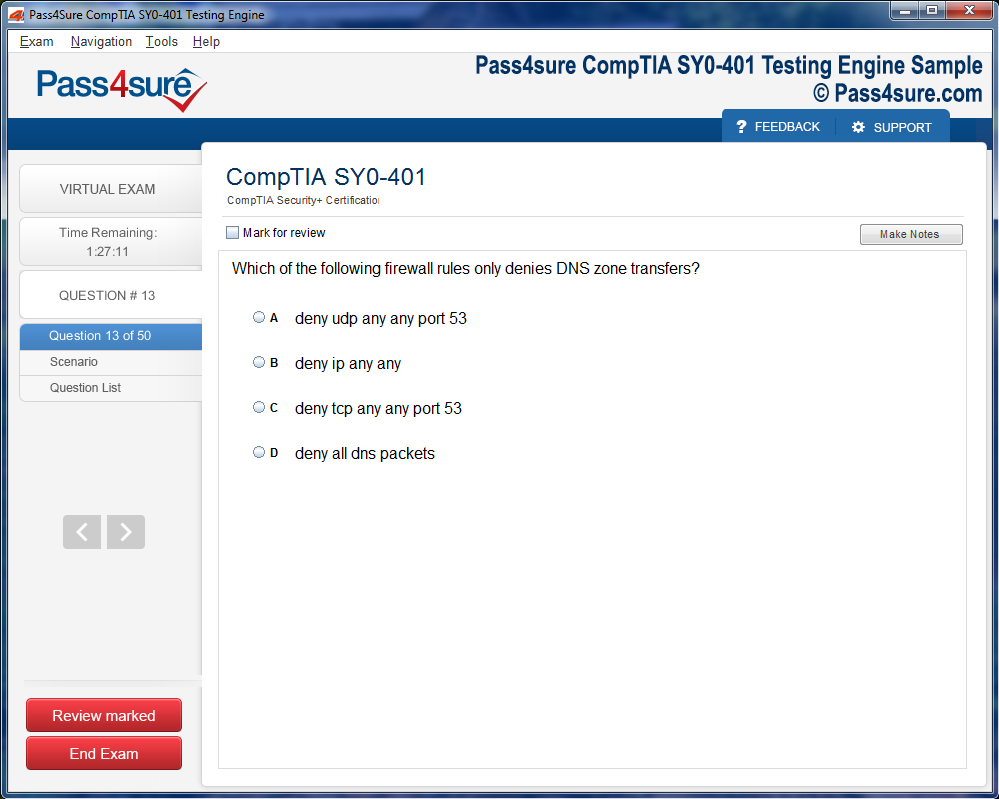

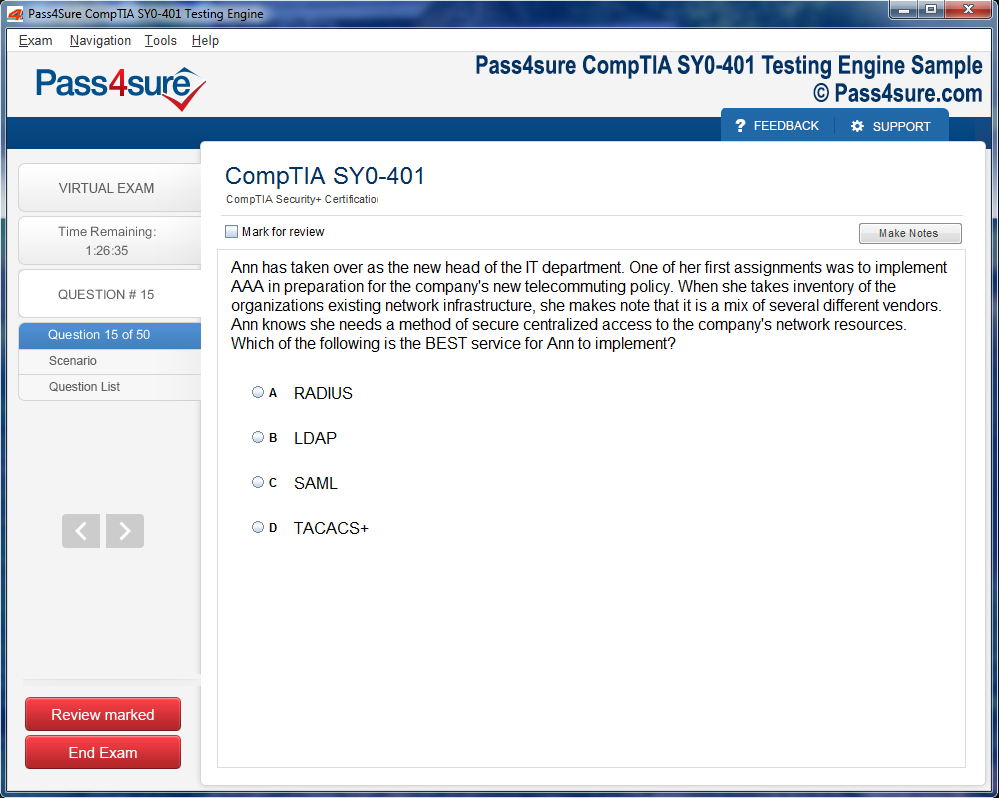

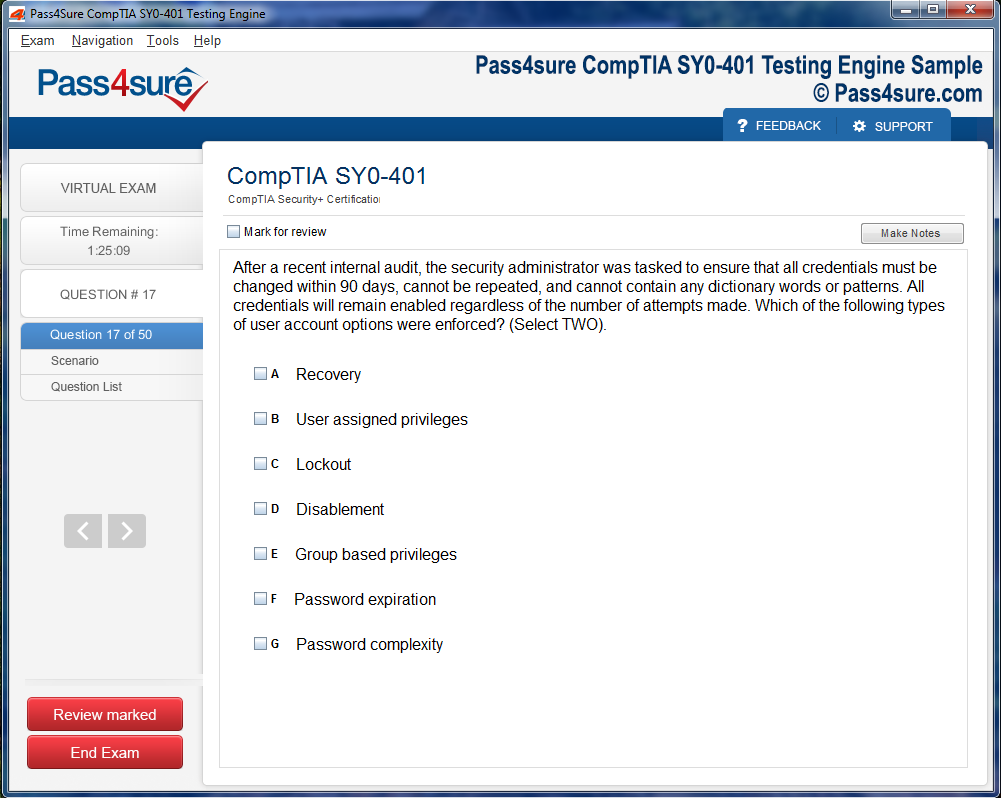

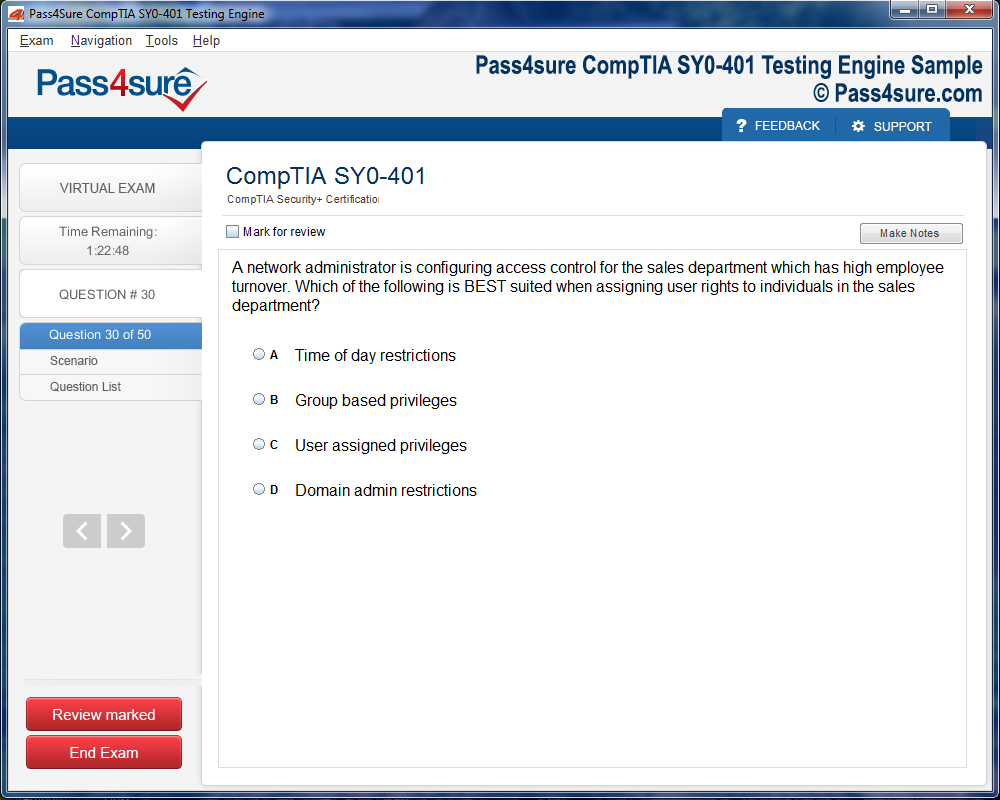

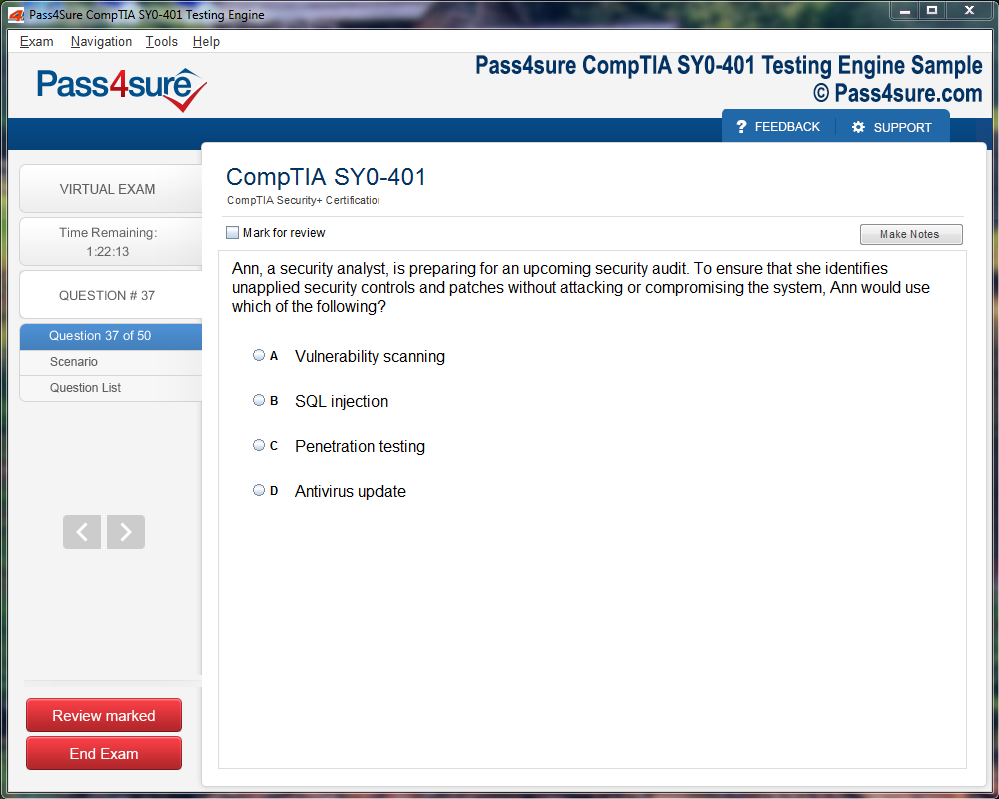

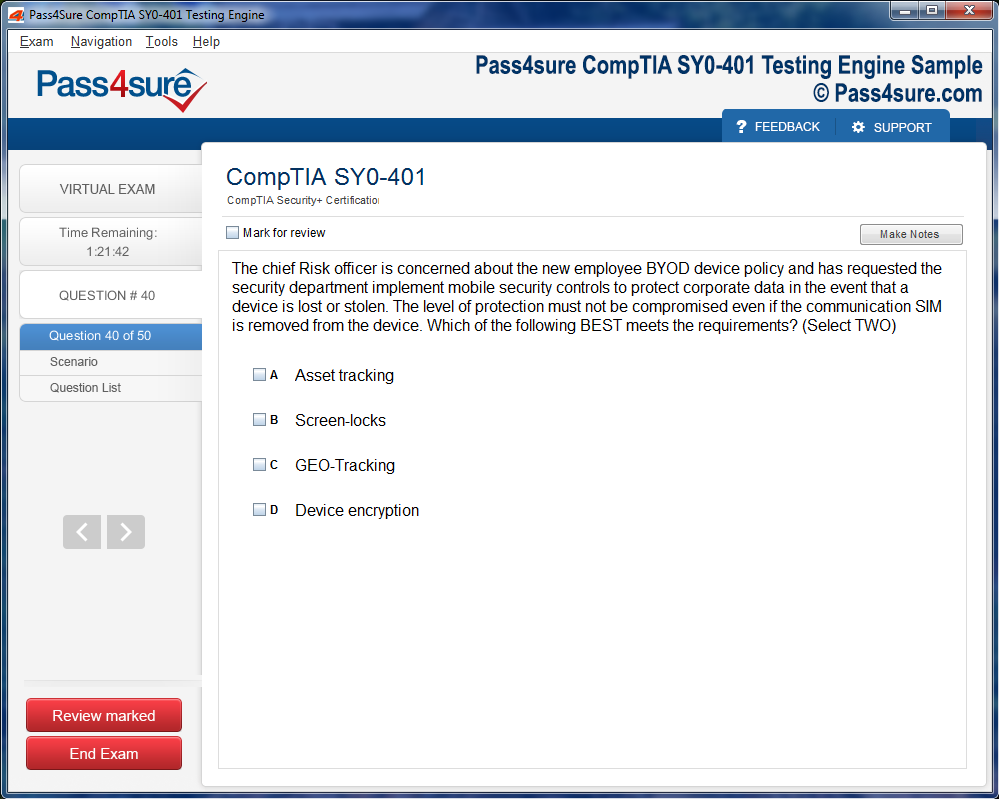

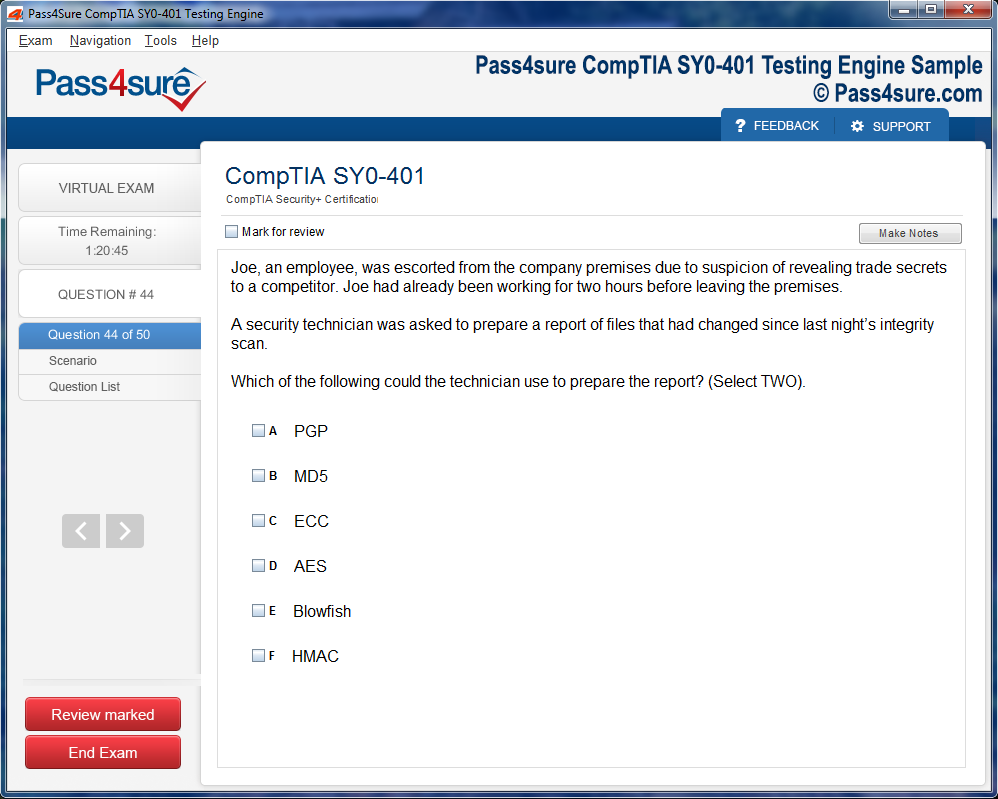

Product Screenshots

Frequently Asked Questions

How does your testing engine works?

Once download and installed on your PC, you can practise test questions, review your questions & answers using two different options 'practice exam' and 'virtual exam'. Virtual Exam - test yourself with exam questions with a time limit, as if you are taking exams in the Prometric or VUE testing centre. Practice exam - review exam questions one by one, see correct answers and explanations.

How can I get the products after purchase?

All products are available for download immediately from your Member's Area. Once you have made the payment, you will be transferred to Member's Area where you can login and download the products you have purchased to your computer.

How long can I use my product? Will it be valid forever?

Pass4sure products have a validity of 90 days from the date of purchase. This means that any updates to the products, including but not limited to new questions, or updates and changes by our editing team, will be automatically downloaded on to computer to make sure that you get latest exam prep materials during those 90 days.

Can I renew my product if when it's expired?

Yes, when the 90 days of your product validity are over, you have the option of renewing your expired products with a 30% discount. This can be done in your Member's Area.

Please note that you will not be able to use the product after it has expired if you don't renew it.

How often are the questions updated?

We always try to provide the latest pool of questions, Updates in the questions depend on the changes in actual pool of questions by different vendors. As soon as we know about the change in the exam question pool we try our best to update the products as fast as possible.

How many computers I can download Pass4sure software on?

You can download the Pass4sure products on the maximum number of 2 (two) computers or devices. If you need to use the software on more than two machines, you can purchase this option separately. Please email sales@pass4sure.com if you need to use more than 5 (five) computers.

What are the system requirements?

Minimum System Requirements:

- Windows XP or newer operating system

- Java Version 8 or newer

- 1+ GHz processor

- 1 GB Ram

- 50 MB available hard disk typically (products may vary)

What operating systems are supported by your Testing Engine software?

Our testing engine is supported by Windows. Andriod and IOS software is currently under development.

Master Risk-Based Inspection with API - 580 Certification

The oil and gas sector operates within a labyrinthine nexus of operational complexities where even minuscule aberrations can precipitate cascading consequences. Equipment reliability and procedural exactitude are not mere desiderata but existential imperatives, dictating both financial solvency and workforce safety. Within this milieu, organizations have increasingly gravitated toward methodical frameworks designed to codify inspection and maintenance processes, rendering them more predictable, quantifiable, and economically judicious. API 580, promulgated by the American Petroleum Institute, epitomizes this philosophy, championing risk-based inspection (RBI) as a fulcrum for aligning safety imperatives with operational efficiency. The standard enshrines a meticulous process wherein risk is quantified, resources are allocated based on probabilistic assessments, and interventions are prioritized according to the potential severity of failures.

API 580 is not a mere regulatory artifact but a strategic instrument for organizations seeking to transform latent uncertainties into actionable intelligence. The methodology mandates the assimilation of historical failure data, a nuanced understanding of equipment idiosyncrasies, and the deployment of analytical heuristics to discern high-risk nodes within operational matrices. By integrating these elements, professionals can preemptively address vulnerabilities, optimize inspection intervals, and curtail unscheduled downtime. In essence, API 580 transmutes reactive maintenance paradigms into anticipatory strategies that harmonize asset longevity, workforce safety, and fiscal prudence.

Certification in API 580 confers both technical acumen and cognitive dexterity. Professionals are trained to dissect complex risk scenarios, discerning not only the probability of equipment malfunction but also the attendant ramifications. This dual lens—probabilistic and consequential—facilitates the creation of inspection regimens that concentrate resources on components whose failure would be disproportionately deleterious. Consequently, organizations can eschew indiscriminate inspection schedules, instead channeling effort where it yields the most substantial return in safety and operational reliability. The resulting paradigm is one of measured vigilance, wherein maintenance interventions are neither capricious nor perfunctory but grounded in rigorous analytical rationale.

Central to API 580’s ethos is the deployment of risk evaluation models. These models operate as cognitive cartographies, transforming abstract probabilities into tangible operational directives. They synthesize disparate data streams—historical inspection logs, real-time operating parameters, environmental stressors—into cohesive risk matrices that illuminate the loci of critical vulnerability. By engaging with these analytical instruments, certified professionals cultivate the ability to extrapolate from granular data, identifying patterns that might elude conventional scrutiny. The iterative refinement of these models ensures that RBI strategies remain contemporaneous with evolving technological capabilities and shifting operational exigencies, embedding adaptability into the very architecture of asset management.

The examination underpinning API 580 certification rigorously probes both theoretical comprehension and applied acumen. Candidates are assessed across multiple dimensions, encompassing data acquisition, probabilistic risk modeling, and the translation of abstract assessments into operational interventions. Emphasis is placed not merely on technical knowledge but on the capacity to synthesize insights, prioritize corrective measures, and reconcile operational objectives with regulatory imperatives. Success in this evaluative crucible signals a professional’s readiness to assume responsibility for the stewardship of industrial assets, fostering environments where operational continuity and safety are mutually reinforcing rather than competing objectives.

Beyond credentialing, API 580 certification functions as a conduit to professional advancement. The oil and gas sector offers a panoply of roles wherein RBI expertise is indispensable. Positions such as inspection engineer, RBI analyst, and asset integrity manager rely on certified proficiency to architect inspection schedules, mitigate latent hazards, and implement data-driven maintenance regimes. Certification functions as a veritable signal to employers, attesting to a candidate’s mastery of analytical frameworks and capacity for judicious decision-making under conditions of operational uncertainty. Consequently, API 580 serves as both a technical standard and a career accelerator, imbuing professionals with credibility and expanding the ambit of their vocational opportunities.

The integration of risk-based inspection into asset management strategies represents a tectonic shift in maintenance philosophy. Conventional paradigms, often predicated on temporal schedules or arbitrary intervals, are supplanted by methodologies that prioritize intervention according to quantified risk. This approach enables organizations to allocate resources with surgical precision, eschewing expenditure on low-risk assets while concentrating scrutiny on components whose malfunction could precipitate catastrophic consequences. The downstream effect is a symbiosis of enhanced safety and economic efficiency, wherein operational resilience is augmented without incurring superfluous costs. API 580 thereby functions as a linchpin in contemporary asset stewardship, reconciling fiscal stewardship with the imperatives of industrial safety.

The analytical rigor mandated by API 580 is augmented by a holistic perspective on operational ecosystems. Risk is not construed in isolation but as a product of interdependent variables—mechanical stressors, environmental contingencies, human factors, and regulatory frameworks. Certified professionals are trained to navigate these interstices, discerning the confluence of factors that might precipitate failure. Such integrative thinking fosters a proactive orientation, wherein potential disruptions are identified and addressed before they manifest in operational aberrations. The resultant culture of preemptive vigilance cultivates resilience, enhancing both organizational confidence and workforce security.

API 580 also engenders a culture of continuous improvement. Risk assessments are not static evaluations but dynamic instruments, evolving in tandem with technological innovations and operational feedback. Inspection schedules, once established, are subject to periodic recalibration informed by new data, emergent trends, and lessons derived from previous interventions. This iterative process ensures that RBI methodologies remain optimally aligned with current operational realities, embedding flexibility and responsiveness into maintenance protocols. Organizations that embrace this adaptive ethos are better positioned to mitigate emergent risks, maintain regulatory compliance, and optimize asset performance over extended operational horizons.

The implications of API 580 extend beyond immediate operational domains, influencing strategic decision-making and capital allocation. By providing a quantifiable framework for assessing risk, the standard enables executives to make informed choices regarding equipment replacement, retrofitting, or decommissioning. Investments are directed toward assets with the highest potential for operational impact, ensuring that fiscal resources are deployed with maximum efficacy. This risk-informed approach to strategic planning reinforces the broader objective of sustainable industrial stewardship, wherein organizational growth and safety imperatives are not mutually exclusive but mutually reinforcing.

Moreover, the standard’s emphasis on data-driven decision-making catalyzes technological integration. Advanced diagnostic tools, condition monitoring systems, and predictive analytics platforms complement RBI frameworks, providing real-time insights into equipment health. Certified professionals leverage these technologies to enhance predictive accuracy, detect incipient faults, and calibrate inspection intervals with unprecedented precision. The symbiosis of API 580 methodologies with cutting-edge instrumentation underscores a transformative shift in industrial maintenance, wherein empirical evidence supplants intuition, and probabilistic reasoning supplants rote schedules.

Training for API 580 certification is itself an exercise in cultivating analytical acuity. Candidates engage with complex case studies, probabilistic modeling exercises, and scenario-based simulations designed to replicate real-world operational contingencies. This experiential learning fosters not only technical competence but cognitive dexterity, equipping professionals to navigate ambiguity, interpret multifactorial data, and devise intervention strategies under temporal and informational constraints. The pedagogical design of the certification process ensures that knowledge acquisition is both rigorous and operationally relevant, producing professionals capable of immediate, high-impact contributions.

The broader organizational benefits of API 580 adoption are multifaceted. Enhanced equipment reliability translates directly into reduced downtime, improved production continuity, and minimized risk of catastrophic failure. Simultaneously, risk-based inspection frameworks facilitate compliance with regulatory mandates, mitigating the potential for legal or financial sanctions. By embedding a culture of systematic vigilance, organizations foster operational predictability, workforce safety, and stakeholder confidence, reinforcing the strategic value of adopting standardized RBI methodologies.

API 580 also catalyzes cross-functional collaboration within organizations. Effective risk-based inspection necessitates coordination between engineering, operations, maintenance, and safety teams. Certified professionals function as integrative agents, translating complex analytical outputs into actionable directives that resonate across disciplinary boundaries. This collaborative orientation enhances organizational coherence, ensures alignment between operational priorities and safety mandates, and fosters a shared commitment to asset integrity. The standard thereby functions not merely as a technical framework but as an instrument for cultivating organizational synergy.

At its core, API 580 embodies a philosophical shift in industrial maintenance—a transition from reactive remediation to proactive stewardship. By quantifying risk, prioritizing interventions, and embedding iterative refinement into operational protocols, the standard reconceptualizes how organizations interact with their assets. Maintenance is no longer a perfunctory obligation but a strategic function, informed by empirical insight and guided by probabilistic reasoning. Professionals certified in API 580 are not merely technicians but custodians of operational continuity, entrusted with safeguarding both equipment and workforce against the vicissitudes of industrial activity.

The longevity of API 580’s impact is further reinforced by its alignment with contemporary sustainability imperatives. By optimizing inspection schedules and reducing unnecessary interventions, organizations minimize resource wastage, energy consumption, and environmental footprint. The standard’s emphasis on risk-informed resource allocation dovetails with broader initiatives to promote sustainable industrial practices, demonstrating that operational efficacy and ecological stewardship can coexist. In this sense, API 580 transcends its immediate technical remit, contributing to a more resilient and environmentally conscious industrial paradigm.

Introduction to Risk-Based Inspection

Understanding risk-based inspection necessitates a profound appreciation of the intricate principles enshrined in API 580. This codex delineates a meticulous approach to evaluating potential hazards linked to equipment and operational processes. It transcends conventional reactive maintenance paradigms by fostering anticipatory strategies that mitigate the probability of failure before it materializes. Through this prescient methodology, organizations not only enhance safety but also optimize resource allocation, curtail unplanned downtime, and achieve economic efficiency by concentrating attention on assets with the highest risk profiles. Risk-based inspection, therefore, emerges as a symbiotic blend of foresight, analysis, and strategic action, guided by empirical evidence and systematic procedures.

The Genesis of Risk Assessment

The genesis of risk-based inspection lies in comprehensive risk assessment, which forms the nucleus of API 580. Practitioners collect historical performance data, scrutinize operational conditions, and incorporate environmental variables to construct a robust foundation for quantitative evaluation. Advanced risk models are then employed to translate multifaceted operational dynamics into actionable intelligence. These models quantify both the likelihood and consequence of potential failures, enabling decision-makers to identify assets of paramount concern. By leveraging this prioritization, organizations can deploy inspection resources judiciously, ensuring that critical equipment is subjected to rigorous scrutiny while minimizing redundant efforts on lower-risk assets.

Integration with Asset Management

Central to API 580 is the integration of risk-based inspection into holistic asset management. This paradigm reframes maintenance planning from an arbitrary schedule to a strategic, data-driven process. Asset integrity managers utilize risk-based methodologies to ascertain whether specific equipment warrants immediate intervention, scheduled monitoring, or periodic evaluation. Such a tailored approach not only mitigates operational hazards but also curtails superfluous expenditures on inspections that yield minimal safety value. The outcome is a harmonious system in which operational reliability, fiscal prudence, and workforce safety converge, fostering an ecosystem of continuous improvement and strategic foresight.

Certification and Professional Proficiency

The API 580 certification embodies a rigorous assessment of a professional’s mastery of these concepts. Examination content typically encompasses risk assessment methodologies, statistical and probabilistic analysis, inspection planning, and regulatory compliance. Candidates are expected to demonstrate the capacity to rank risks objectively, design inspection schedules predicated on risk hierarchy, and integrate these principles into an overarching operational framework. Certification signifies an individual’s proficiency in translating theoretical constructs into pragmatic strategies, thereby contributing to industrial resilience and operational excellence. Achieving this credential is a testament to both analytical acumen and practical insight, equipping professionals with the tools to safeguard critical infrastructure effectively.

Specialized Roles and Industry Impact

Occupational trajectories associated with API 580 are both specialized and indispensable within the industrial domain. Positions such as RBI analysts and inspection engineers entail the meticulous evaluation of equipment reliability, the identification of potential failure loci, and the formulation of targeted inspection strategies to attenuate risk. Asset integrity managers operate at a macro level, orchestrating inspection policies to align seamlessly with organizational imperatives. Possession of API 580 certification enhances professional credibility, opening avenues toward senior management and strategic oversight roles, while signaling competence in deploying sophisticated risk management methodologies within high-stakes operational environments.

Data Stewardship and Analytical Rigor

A salient dimension of API 580 pertains to the stewardship of operational data. Accurate, comprehensive data underpins effective risk assessment, enabling practitioners to discern emergent patterns, anticipate failures, and implement preemptive measures. Professionals are trained to acquire, validate, and analyze data with rigor, transforming disparate datasets into coherent, actionable insights. This analytical prowess ensures that inspection strategies evolve dynamically, reflecting real-time operational realities and shifting risk landscapes. The ability to leverage data strategically engenders inspection plans that are not only precise but adaptive, fortifying the organization’s resilience against unforeseen contingencies.

Organizational and Environmental Benefits

The ramifications of API 580 extend beyond singular enterprises, shaping the collective ethos of industrial safety and sustainability. By institutionalizing a culture of vigilance and proactive maintenance, the standard diminishes the incidence of catastrophic equipment failures, thereby reducing environmental impacts, financial liabilities, and operational disruptions. It fosters a shared lexicon and methodological consistency across the industry, facilitating collaboration and knowledge exchange among professionals. Consequently, API 580 functions as a linchpin for enhancing sector-wide integrity, promoting the preservation of critical infrastructure, and underpinning the long-term viability of industrial operations.

Probabilistic Foresight in Maintenance

At the core of risk-based inspection is the notion of probabilistic foresight, a paradigm shift from deterministic maintenance schedules to intelligence-driven interventions. By embracing uncertainty as a quantifiable parameter, API 580 empowers organizations to allocate resources with surgical precision, targeting high-risk equipment while conserving effort on less critical assets. This epistemic approach reduces operational entropy, optimizes maintenance expenditures, and fortifies safety protocols. Furthermore, it encourages a mindset wherein operational anomalies are not merely tolerated but systematically analyzed, fostering an organizational culture attuned to vigilance, learning, and continuous refinement.

Multidisciplinary Execution

The practical execution of API 580 principles necessitates a fusion of multidisciplinary knowledge. Chemical, mechanical, and process engineering insights converge with statistical acumen to inform risk prioritization and inspection strategies. Professionals must navigate the complex interplay of operational stressors, material degradation mechanisms, and environmental contingencies, translating theoretical risk models into tangible inspection schedules. This multidimensional competence underscores the sophistication of risk-based inspection as both an intellectual endeavor and a practical safeguard, demanding precision, analytical dexterity, and strategic foresight.

Technological Integration and Innovation

Innovation in inspection methodologies also emerges as a natural corollary of API 580 implementation. Non-destructive testing, predictive analytics, and digital twin technologies synergize with risk assessment frameworks to enhance accuracy, reduce human error, and anticipate degradation trajectories. By integrating these advanced modalities, organizations cultivate a proactive posture, preempting failures before they escalate into critical events. This convergence of technology and methodology exemplifies the transformative potential of risk-based inspection, positioning it as a catalyst for industrial evolution and operational resilience.

The Enduring Value of API 580

In summation, risk-based inspection, as articulated in API 58,0, represents a confluence of strategic foresight, empirical rigor, and operational prudence. Its principles elevate maintenance from reactive response to anticipatory stewardship, fostering safety, efficiency, and sustainability. By embedding probabilistic assessment, data-driven decision-making, and multidisciplinary collaboration into organizational practice, API 580 equips professionals with a robust toolkit for safeguarding critical infrastructure. Its impact reverberates across individual organizations and the broader industrial landscape, cultivating a culture of vigilance, accountability, and continuous improvement that underpins the enduring integrity of complex operational systems.

The Strategic Imperative of API 580 Adoption

The adoption of API 580 has metamorphosed into a strategic imperative for organizations intent on amalgamating reliability with fiscal prudence. This standard transcends conventional maintenance dogma, advocating a risk-based inspection (RBI) paradigm that accentuates predictive over reactive interventions. By prioritizing assets according to the probability and severity of potential failures, organizations engender a more judicious allocation of resources. The methodology inherent to API 580 encourages a synthesis of empirical data, experiential acumen, and operational foresight, thereby transforming traditional maintenance schemas into dynamic, intelligence-driven frameworks. Operational resilience, once contingent upon periodic inspections and heuristic judgment, becomes codified through a structured evaluative matrix that identifies vulnerabilities and anticipates failure modalities.

Risk Evaluation: The Core Tenet of API 580

Central to API 580 is the meticulous evaluation of risk, a process that interweaves statistical inference with seasoned judgment. Professionals trained under this standard cultivate the capacity to discern nuanced failure probabilities, integrating historical incident logs, operational anomalies, and environmental contingencies into comprehensive risk indices. This hierarchy of risk empowers organizations to prioritize inspections where the intersection of likelihood and consequence is most acute. The analytical rigor demanded by API 580 ensures that inspection protocols are not arbitrary but instead reflective of a probabilistic calculus that safeguards both personnel and capital assets. The ability to stratify equipment based on vulnerability fosters a culture of anticipatory maintenance, wherein potential disruptions are preemptively mitigated rather than reactively addressed.

Certification and Competency: Forging Skilled Practitioners

API 580 certification functions as a crucible for professional competency, equipping candidates with the cognitive and technical faculties necessary for real-world application. Examination content encompasses risk assessment methodologies, data interpretation paradigms, and inspection planning frameworks, ensuring that certified practitioners possess a multidimensional skill set. Beyond procedural knowledge, the certification evaluates the candidate’s aptitude for integrating RBI within overarching asset management systems, harmonizing operational imperatives with regulatory mandates. Certification thus signifies more than a credential; it represents the endorsement of an individual’s capability to orchestrate risk-informed decision-making, bolster organizational resilience, and contribute strategically to asset stewardship.

Career Pathways and Organizational Impact

The professional avenues enabled by API 580 certification are both diverse and strategically consequential. RBI analysts, for instance, leverage probabilistic risk models to prioritize maintenance interventions, thereby enhancing equipment reliability while minimizing operational disruptions. Inspection engineers apply these principles to devise inspection regimens that optimize resource utilization and mitigate failure risk. Asset integrity managers extend the influence of RBI by ensuring that inspection strategies cohere with regulatory compliance and organizational objectives. Certification often serves as a catalyst for advancement into senior roles where strategic decision-making intersects with operational oversight, positioning professionals as pivotal actors in the orchestration of enterprise-wide reliability initiatives.

Financial Prudence through Targeted Inspections

API 580’s utility extends beyond operational resilience into the domain of cost optimization. Traditional inspection paradigms often incur inefficiencies by treating all assets uniformly, irrespective of risk profile. By contrast, RBI concentrates efforts on high-risk equipment, obviating superfluous expenditures on low-risk assets. This calibrated approach harmonizes safety imperatives with economic stewardship, yielding a dual benefit of risk mitigation and budgetary efficiency. Moreover, the iterative nature of RBI facilitates continuous improvement; insights derived from inspections feed forward into future risk evaluations, engendering a self-reinforcing loop that incrementally enhances operational reliability while controlling maintenance outlays.

Data Analytics: The Nexus of Insight and Action

In the contemporary industrial milieu, data is both voluminous and variegated. API 580 mandates that professionals harness this data through rigorous analytics, converting operational records, inspection logs, and condition-monitoring outputs into actionable intelligence. Such analytical acuity enables the early detection of incipient equipment degradation, providing a temporal advantage that permits preventive interventions. The capacity to decipher complex datasets ensures that inspection schedules remain responsive to evolving operational realities, technological advances, and emergent risk vectors. By transforming raw data into predictive insight, organizations achieve a synthesis of foresight and responsiveness that underpins sustainable operational excellence.

Regulatory Compliance and Ethical Stewardship

API 580 certification also encompasses a profound understanding of regulatory frameworks, instilling in professionals an ability to navigate the intricate lattice of safety and environmental statutes. Compliance extends beyond mere adherence to legal prescriptions; it reflects an organizational ethos predicated on ethical stewardship and accountability. Integrating risk-based inspection within regulatory paradigms ensures that operational strategies do not merely seek efficiency but also embody a culture of responsibility. The harmonization of predictive maintenance, regulatory adherence, and ethical conduct cultivates an operational environment wherein safety, sustainability, and fiscal prudence coexist synergistically.

Continuous Improvement and Organizational Learning

The philosophy underpinning API 580 champions continuous improvement as a core operational principle. Inspections are not isolated events but integral components of a feedback-rich ecosystem wherein lessons learned are codified and disseminated. Historical failure data, near-miss analyses, and inspection outcomes inform subsequent risk evaluations, generating a cyclical mechanism of learning and refinement. This iterative process imbues organizations with adaptive resilience, enabling the evolution of inspection strategies in tandem with technological advancements, shifting operational contexts, and emerging risk profiles. Consequently, API 580 fosters an organizational culture that prizes learning, foresight, and proactive risk management.

Integrative Applications Across Industrial Sectors

While originating in the oil and gas sector, API 580’s principles exhibit versatile applicability across a panoply of industrial domains. Power generation, chemical processing, petrochemical manufacturing, and heavy industry all benefit from the structured, risk-based approach to asset inspection. The universality of risk assessment methodologies allows organizations to transpose analytical frameworks from one sector to another, adapting predictive models to sector-specific operational exigencies. The cross-industry relevance of API 580 enhances its strategic utility, rendering it a linchpin for organizations intent on embedding reliability and safety within diverse operational landscapes.

Risk Communication and Decision-Making

A less often highlighted dimension of API 580 is its emphasis on risk communication. Professionals are trained to articulate risk profiles, inspection priorities, and mitigation strategies in a manner intelligible to both technical and executive stakeholders. This capacity ensures that risk-informed decisions are understood, endorsed, and operationalized across hierarchical strata. Transparent communication of potential failure modes and their implications fosters organizational alignment, reduces uncertainty, and facilitates informed decision-making. By bridging the gap between technical analysis and strategic oversight, API 580 cultivates a coherent decision-making ecosystem in which risk considerations are fully integrated into operational strategy.

Technological Synergies and Predictive Analytics

The efficacy of API 580 is amplified through the integration of contemporary technological modalities. Condition-based monitoring, digital twins, sensor networks, and predictive analytics coalesce to furnish high-fidelity operational intelligence. API 580 practitioners harness these technologies to refine risk assessments, simulate failure scenarios, and anticipate maintenance exigencies with unprecedented precision. The symbiosis of methodology and technology elevates RBI from a procedural exercise to a sophisticated predictive instrument, enabling organizations to preempt failures, optimize maintenance schedules, and extend asset longevity.

Cultivating Organizational Resilience

At its core, API 580 serves as a conduit for cultivating organizational resilience. By embedding risk-conscious decision-making, predictive maintenance, and continuous learning into operational frameworks, organizations acquire the agility necessary to navigate both anticipated and unforeseen challenges. Equipment reliability, workforce safety, and financial sustainability converge as interdependent outcomes of a disciplined, risk-based inspection philosophy. Organizations that internalize API 580 principles do not merely react to equipment failures—they anticipate, mitigate, and adapt, thereby transforming vulnerability into strategic advantage.

Knowledge Dissemination and Professional Communities

API 580 also fosters the development of professional communities oriented around best practices, knowledge sharing, and methodological rigor. Certified professionals often contribute to forums, workshops, and industry symposia, disseminating insights gleaned from field applications. This collective intelligence accelerates the refinement of risk-based inspection methodologies, cultivates innovation, and establishes benchmarks of excellence. By participating in such communities, professionals reinforce their own expertise while contributing to the broader evolution of industry standards and operational paradigms.

Synergistic Asset Management

Integration of API 580 within comprehensive asset management strategies yields a synergistic amplification of operational performance. RBI does not exist in isolation; it intersects with maintenance planning, reliability engineering, and operational risk management. This confluence ensures that inspection strategies are not merely reactive or perfunctory but are harmonized with lifecycle management, regulatory imperatives, and strategic objectives. The resulting architecture of asset stewardship is both resilient and adaptable, capable of sustaining operational continuity amid fluctuating environmental, technological, and economic conditions.

Future Trajectories and Emerging Paradigms

The evolution of API 580 is poised to embrace emerging paradigms in artificial intelligence, machine learning, and digital transformation. Predictive algorithms, real-time analytics, and automated inspection technologies are expected to refine risk assessment precision, accelerate decision cycles, and reduce human error. As these innovations are assimilated, the core tenets of risk-based inspection—prioritization, predictive foresight, and resource optimization—will be enhanced by unprecedented computational power. The trajectory of API 580 thus aligns with a broader industrial movement toward intelligence-driven operations, embedding reliability, safety, and efficiency into the very fabric of organizational design.

A Strategic Catalyst for Excellence

API 580 embodies a strategic confluence of predictive maintenance, risk assessment, and organizational resilience. Its adoption transforms inspection practices from rote procedural exercises into sophisticated, data-informed strategies that optimize resource allocation and enhance operational safety. Through rigorous certification, analytical acumen, and integration with broader asset management systems, professionals empowered by API 580 catalyze transformative improvements in reliability, cost efficiency, and strategic decision-making. As industries confront escalating complexity, regulatory scrutiny, and technological evolution, API 580 stands as a beacon of methodological rigor and strategic foresight, ensuring that organizations are not merely reactive but proactively resilient, adaptive, and future-ready.

The Quintessence of Risk-Based Inspection in Hydrocarbon Operations

Risk-based inspection, epitomized through the framework of API 580, constitutes an indispensable paradigm for safeguarding operational integrity within hydrocarbon processing and extraction enterprises. This methodology transcends traditional prescriptive maintenance schedules, advocating for a meticulous, analytical approach wherein inspection priorities are dictated by calculated probabilities of failure and consequential severity. By harmonizing inspection efforts with quantified risk, organizations engender a resilient operational architecture capable of mitigating catastrophic failures while optimizing fiscal stewardship.

The conceptual underpinning of risk-based inspection lies in the discernment of asset criticality and vulnerability. Equipment subjected to incessant mechanical, chemical, or thermal stressors necessitates nuanced scrutiny, as undetected degradation may precipitate operational discontinuity or environmental catastrophe. API 580 delineates a structured protocol for codifying these hazards, facilitating systematic prioritization that reconciles safety imperatives with economic pragmatism. The resultant inspection strategy is not merely reactive but predictive, orchestrating maintenance interventions in anticipation of emergent threats rather than post-failure remediation.

Methodologies of Risk Assessment and Prioritization

The procedural nucleus of API 580 implementation resides in rigorous risk assessment. Practitioners meticulously evaluate both the likelihood of component failure and the gravity of its repercussions, employing historical incident data, operational analytics, and environmental contingency matrices. Such assessment engenders a comprehensive risk profile for each asset, enabling informed prioritization of inspection schedules. High-risk equipment, by virtue of its elevated potential for disruption or hazard, receives preemptive attention, while low-risk units are monitored with calibrated restraint. This triage methodology optimizes resource allocation, reduces unplanned downtime, and accentuates operational resilience.

A sophisticated risk assessment transcends mere probability calculations; it integrates nuanced considerations of operational dynamics, material degradation mechanisms, and environmental susceptibilities. Variables such as corrosion kinetics, fatigue stress accumulations, and process fluid interactions are systematically evaluated to discern latent vulnerabilities. By amalgamating these factors into a holistic risk matrix, organizations achieve an unprecedented granularity of inspection planning that fortifies reliability and operational safety.

The Imperative of API 580 Certification

Certification under API 580 signifies professional mastery of risk-based inspection paradigms. Candidates are rigorously examined on risk evaluation methodologies, inspection design optimization, and regulatory congruence, ensuring comprehensive competency in both theoretical and applied dimensions. Beyond procedural familiarity, the certification validates an individual’s acumen in translating risk insights into actionable inspection and maintenance strategies, facilitating tangible operational improvements.

The credential serves as both an endorsement of technical expertise and a conduit for career advancement. Professionals equipped with API 580 certification often assume pivotal roles such as inspection engineers, asset integrity managers, and RBI analysts. In these capacities, they orchestrate inspection programs, calibrate maintenance interventions, and implement preventive measures designed to mitigate operational risks. Their work underpins organizational safety, bolsters reliability metrics, and affirms adherence to industry best practices.

Strategic Integration of Risk-Based Inspection

The strategic implementation of risk-based inspection encompasses a confluence of analytical rigor, operational intelligence, and foresighted planning. By concentrating inspections on high-risk assets, organizations avert the inefficiencies inherent in uniform maintenance regimes. This risk-aligned approach facilitates the conservation of human, temporal, and financial resources while simultaneously elevating overall operational efficacy.

Moreover, API 580 fosters an iterative culture of continuous improvement. Insights gleaned from inspections are not static; they inform subsequent risk assessments, refine predictive models, and recalibrate inspection priorities. This dynamic feedback loop ensures that risk-based inspection strategies evolve congruently with technological advancements, operational modifications, and emergent threat vectors, thereby sustaining effectiveness across temporal horizons.

The Role of Data Analytics in Risk-Based Inspection

Data stewardship is the cornerstone of effective API 580 implementation. Professionals are trained to meticulously gather, validate, and interrogate inspection and operational datasets, transforming raw information into prescriptive intelligence. Analytical outputs facilitate trend identification, anomaly detection, and predictive modeling, empowering organizations to implement anticipatory maintenance measures.

In practice, this entails rigorous evaluation of degradation patterns, environmental exposures, and operational stressors. Statistical analyses and probabilistic models converge to elucidate latent vulnerabilities, enabling precision-targeted interventions. By leveraging data as a strategic asset, organizations ensure that inspection efforts are neither arbitrary nor myopic but are instead informed, evidence-driven, and aligned with overarching operational imperatives.

Enhancement of Safety and Operational Reliability

The cardinal objective of API 580 is the augmentation of safety and operational reliability. By prioritizing inspection activities based on empirically derived risk profiles, organizations significantly reduce the probability of catastrophic failures. The foresight afforded by risk-based inspection safeguards both personnel and assets, mitigating exposure to hazardous events and environmental incidents.

In tandem, this approach enhances reliability metrics by ensuring that critical equipment remains operationally robust. Failures that would otherwise precipitate unplanned shutdowns are preempted through timely interventions, while maintenance resources are judiciously allocated to areas of genuine necessity. Consequently, organizations achieve a harmonious equilibrium between operational continuity, workforce protection, and fiscal prudence.

Economic Optimization Through Risk-Based Inspection

API 580 inherently facilitates cost optimization within industrial operations. Traditional inspection paradigms, predicated on fixed intervals, often result in superfluous interventions or deferred attention to genuinely critical assets. By contrast, risk-based inspection directs resources toward high-risk equipment, eliminating redundant inspections and minimizing expenditure on low-priority items.

Furthermore, the predictive nature of this methodology curtails the financial impact of unplanned downtime and emergency repairs. The early identification of degradation phenomena permits preemptive maintenance, which is typically less disruptive and more cost-effective than reactive strategies. In essence, risk-based inspection aligns economic efficiency with operational resilience, yielding a dual benefit of financial prudence and enhanced reliability.

Regulatory Conformance and Industry Benchmarking

API 580 also reinforces regulatory compliance and the adoption of industry best practices. Practitioners are adept at aligning inspection strategies with statutory safety mandates, environmental regulations, and corporate governance frameworks. This alignment mitigates organizational liability, enhances public and stakeholder confidence, and fosters a culture of accountability and diligence.

By institutionalizing risk-based inspection, organizations transcend mere compliance. They achieve a proactive posture wherein regulatory adherence, operational safety, and cost-effectiveness are synergistically integrated. This strategic convergence not only mitigates operational hazards but also positions enterprises as exemplars of industry stewardship, setting benchmarks for peers and competitors alike.

Predictive Maintenance and Asset Longevity

The predictive ethos embedded within API 580 extends the lifespan of critical assets. By anticipating failure mechanisms and addressing vulnerabilities preemptively, organizations mitigate cumulative wear and tear. Equipment operates within optimal parameters for longer durations, reducing the frequency of capital-intensive replacements and extending the economic lifecycle of assets.

Predictive maintenance, as a derivative of risk-based inspection, transforms maintenance philosophy from reactive to anticipatory. This paradigm shift engenders operational stability, minimizes disruption, and fosters a culture of foresight, where proactive intervention supersedes crisis-driven responses. The result is a sustainable operational model capable of adapting to evolving technological and environmental conditions.

Risk Communication and Decision-Making Dynamics

An often-overlooked dimension of API 580 is its emphasis on risk communication. Effective implementation necessitates that technical insights are translated into actionable intelligence comprehensible to decision-makers. This ensures that inspection priorities, resource allocations, and remedial actions are grounded in empirical risk understanding rather than intuition or convention.

Decision-making is consequently enhanced through clarity, precision, and contextual awareness. Risk profiles, probabilistic forecasts, and degradation analyses inform executive deliberations, enabling leadership to allocate capital, personnel, and time with maximal efficacy. The integration of technical acumen with strategic foresight underscores the holistic value proposition of risk-based inspection.

Technological Synergy and Digital Transformation

Emergent technologies magnify the efficacy of API 580 methodologies. Digital twins, sensor networks, and predictive analytics platforms synergize with risk-based inspection to enable real-time monitoring, enhanced predictive modeling, and automated anomaly detection. These innovations facilitate more granular, timely, and accurate risk assessments, further refining inspection prioritization and resource allocation.

The integration of digital tools also promotes operational agility. Rapid data acquisition, automated processing, and predictive visualization empower organizations to respond dynamically to evolving threats. Consequently, risk-based inspection transcends conventional procedural boundaries, becoming a digitally augmented, intelligence-driven discipline capable of sustaining high-performance standards in complex operational environments.

Organizational Culture and Knowledge Retention

Effective risk-based inspection extends beyond technical execution; it necessitates a cultural commitment to proactive integrity management. Organizations must cultivate an ethos of vigilance, accountability, and continuous learning, wherein insights from inspections are systematically documented, analyzed, and institutionalized. Knowledge retention ensures that risk mitigation strategies are preserved across personnel transitions, maintaining operational continuity and cumulative expertise.

Training programs, mentorship, and procedural documentation reinforce this culture. Employees internalize principles of risk assessment, inspection methodology, and data-driven decision-making, embedding resilience within the organizational fabric. Such a culture not only fortifies operational safety but also enhances human capital value, aligning workforce competency with strategic organizational objectives.

Future Trajectories and Strategic Implications

As industrial operations evolve, the relevance of risk-based inspection is poised to intensify. Increasingly complex systems, heightened regulatory scrutiny, and escalating environmental sensitivities necessitate sophisticated, predictive maintenance strategies. API 580 provides a robust foundation for these imperatives, enabling organizations to navigate uncertainty with precision, foresight, and resilience.

Strategically, the adoption of risk-based inspection facilitates long-term competitiveness. Organizations capable of preempting failures, optimizing resource utilization, and maintaining operational continuity position themselves advantageously within the industrial ecosystem. The fusion of analytical rigor, technological integration, and cultural alignment ensures that risk-based inspection remains a cornerstone of sustainable, high-performance operations.

The Enduring Value of Risk-Based Inspection

Risk-based inspection, codified within API 580, embodies a transformative approach to operational integrity in the hydrocarbon sector. By harmonizing safety, reliability, and cost efficiency, it transcends traditional maintenance paradigms, offering a predictive, data-driven framework for asset management. The structured methodology empowers professionals to identify vulnerabilities, prioritize inspections, and implement preemptive measures, thereby mitigating risk while optimizing resource allocation.

Beyond technical utility, API 580 fosters regulatory adherence, professional development, and organizational resilience. Certified practitioners become pivotal agents in safeguarding operational continuity, extending asset lifespans, and cultivating a culture of vigilance and continuous improvement. As industrial systems grow more complex and operational stakes escalate, risk-based inspection emerges not merely as a procedural requirement but as an essential strategic instrument for sustainable, high-performance operations.

The Paradigm of Risk-Based Industrial Oversight

API 580 inaugurates a sophisticated paradigm within industrial asset governance, signaling a transition from conventional, rote maintenance schedules to an erudite, analytical, and risk-focused methodology. Traditional maintenance modalities often hinge upon temporal regularity, performing inspections at predetermined intervals irrespective of operational exigencies. API 580 diverges sharply, advocating a prescient and prioritized inspection schema, where resources are judiciously allocated based on probabilistic analysis of equipment failure and the potential ramifications thereof. By concentrating on high-impact contingencies, enterprises can avert catastrophic failures, curtail unplanned downtime, and optimize fiscal expenditure, cultivating a culture of preemptive vigilance.

Foundations of Risk Appraisal

Central to API 580 is the systematic application of risk evaluation. Practitioners employ a multifaceted approach, synthesizing historical operational datasets, environmental parameters, material degradation indices, and process dynamics. These vectors coalesce into a comprehensive risk matrix, which ranks equipment according to the likelihood of malfunction and the severity of prospective consequences. Such prioritization enables precise allocation of inspection and maintenance effort, ensuring that high-stakes machinery is scrutinized with augmented rigor while low-risk components are monitored with proportionate restraint. The methodology transcends mere compliance, fostering an analytical ethos in asset stewardship and engendering operational continuity.

Precision Through Certification

Certification in API 580 embodies not only theoretical mastery but practical aptitude in risk-based inspection. Candidates undergo rigorous evaluation encompassing risk assessment models, inspection planning techniques, and regulatory alignment. Beyond technical acumen, certification signifies an ability to transmute empirical data into actionable strategies for operational integrity. Professionals who achieve this credential are equipped to navigate complex asset ecosystems, design bespoke inspection regimes, and influence organizational risk mitigation policies. The credential is a testament to an individual’s capability to reconcile safety imperatives with operational efficiency, affirming their strategic value to asset-intensive enterprises.

The Ecosystem of Professional Roles

API 580 catalyzes a spectrum of career pathways integral to industrial resilience. Roles such as RBI analysts, inspection engineers, and asset integrity managers leverage their expertise to identify vulnerability vectors, prioritize inspection schedules, and implement preemptive interventions. These professionals operate at the confluence of engineering, analytics, and risk governance, orchestrating inspection strategies that preserve safety and optimize resource deployment. API 580 certification enhances professional gravitas, signaling to employers an individual’s capacity for analytical rigor, operational foresight, and systemic reliability. Consequently, these roles are pivotal in translating risk-based frameworks into tangible improvements in asset performance and organizational efficacy.

Operational Efficiencies Through Targeted Inspections

The tangible advantages of API 580 extend into operational economics. By directing inspections toward assets with the greatest risk profile, enterprises eschew superfluous maintenance, curtailing unnecessary resource expenditure while concentrating scrutiny on equipment whose failure could have profound repercussions. The iterative integration of inspection outcomes into subsequent risk evaluations engenders a virtuous cycle of continuous improvement. Over time, organizations cultivate a dynamic, adaptive inspection protocol that evolves with operational insights, technological innovations, and changing regulatory landscapes. This iterative sophistication ensures that risk-based inspections retain relevance, efficacy, and strategic precision.

Data-Driven Prognostication

Data analysis underpins the API 580 methodology, transforming inspection metrics and operational telemetry into predictive intelligence. Professionals are trained to acquire, verify, and synthesize data streams, converting empirical observations into strategic foresight. This predictive capacity facilitates anticipatory maintenance, allowing organizations to preempt failures and optimize inspection cadence. By integrating probabilistic modeling with empirical observation, risk-based inspection transcends reactive paradigms, establishing a proactive framework for operational stewardship. The nexus of analytics and risk assessment cultivates resilience, ensuring uninterrupted operations, heightened safety, and judicious resource utilization.

Regulatory Synergy and Compliance Alignment

API 580 serves as a fulcrum for harmonizing industrial operations with regulatory and environmental mandates. The framework encourages practitioners to embed compliance considerations into inspection strategies, ensuring alignment with safety codes, environmental protocols, and corporate governance standards. This regulatory synergy engenders a dual benefit: organizations satisfy statutory obligations while simultaneously fostering a culture of operational prudence and ethical stewardship. By institutionalizing risk-based inspection, enterprises cultivate an ecosystem where regulatory adherence, asset integrity, and operational efficiency are mutually reinforcing rather than divergent objectives.

Risk Quantification and Mitigation Strategies

A cornerstone of API 580 is the meticulous quantification of risk. Professionals employ analytical models to ascertain both the probability of equipment failure and the projected severity of its consequences. These dual dimensions form the basis for decision matrices that prioritize inspection and intervention. Mitigation strategies derived from these analyses can encompass engineering modifications, preventive maintenance schedules, or operational constraints, each calibrated to minimize exposure while optimizing resource allocation. Such data-informed approaches empower organizations to convert uncertainty into manageable variables, transforming latent vulnerabilities into orchestrated interventions.

Evolution of Industrial Asset Stewardship

API 580 heralds an evolution in asset stewardship, privileging intellectual rigor over procedural rote. Organizations that adopt this standard transition from reactive maintenance paradigms to proactive risk governance, embedding predictive intelligence into operational DNA. The approach is both strategic and adaptive: inspection regimes are continuously refined based on empirical evidence, technological advancements, and emergent operational hazards. This evolution signifies a maturation of industrial asset management, where foresight, analytics, and systematic prioritization converge to safeguard both human and financial capital.

Strategic Implications for Organizational Leadership

For organizational leadership, API 580 is more than a technical framework; it represents a strategic lever. Leaders empowered with RBI insights can allocate capital with precision, anticipate operational disruptions, and embed resilience into corporate planning. The standard provides a vocabulary and methodology for articulating risk to stakeholders, facilitating data-driven decision-making that harmonizes safety, reliability, and profitability. In this sense, API 580 bridges operational engineering with executive strategy, creating an integrated approach to risk-informed governance.

Integration with Emerging Technologies

API 580’s principles are increasingly augmented by emergent technologies such as predictive analytics, digital twins, and real-time sensor networks. These innovations enhance the granularity and timeliness of risk assessment, allowing organizations to monitor asset health continuously and adjust inspection priorities dynamically. The convergence of technology and methodology amplifies the efficacy of risk-based inspection, providing a continuously updated cognitive map of operational vulnerabilities. By embracing these advancements, practitioners extend the reach of API 580 from static planning to responsive, intelligent oversight, redefining the potential for asset reliability.

Enhancing Safety Culture Through Risk Awareness

Beyond operational metrics, API 580 cultivates a pervasive culture of risk consciousness. Personnel are trained to perceive hazards not as anomalies but as quantifiable variables requiring systematic analysis and intervention. This cognitive shift reinforces safety behavior at all organizational levels, from frontline operators to strategic decision-makers. By codifying risk evaluation and response as core competencies, enterprises foster an environment where vigilance, accountability, and analytical rigor are normalized, embedding resilience into the organizational psyche.

Financial Prudence and Resource Optimization

The economic ramifications of API 580 are substantial. By prioritizing inspection effort according to risk, organizations reduce superfluous expenditure while safeguarding high-value assets. Preventive maintenance, informed by probabilistic modeling, diminishes the likelihood of catastrophic failures, curtailing costly downtime and production losses. Simultaneously, iterative learning from inspections informs capital allocation, enabling investment in asset modifications or technological upgrades where they yield maximal risk reduction. This confluence of analytical foresight and financial prudence underscores the standard’s strategic relevance in resource-intensive industries.

Ethical Dimensions of Risk-Based Inspection

API 580 also impinges upon ethical stewardship within industrial contexts. By systematizing risk evaluation and preemptive intervention, the framework ensures that human and environmental safety are central to operational decision-making. Organizations adopting this approach demonstrate a commitment to responsible governance, aligning operational imperatives with societal expectations. Ethical adherence is thus not ancillary but integral to API 580 implementation, reinforcing both organizational credibility and public trust.

The Future Trajectory of Risk-Based Frameworks

Looking forward, the principles of API 580 are poised to influence broader industrial governance paradigms. As industries grapple with increasingly complex operational ecosystems, the emphasis on probabilistic analysis, predictive maintenance, and data-driven decision-making will become ever more critical. The framework’s adaptability allows it to integrate new technologies, regulatory requirements, and operational insights, ensuring sustained relevance. Consequently, API 580 is not merely a standard but a dynamic blueprint for resilient, intelligent, and sustainable asset management in an era of escalating complexity.

Synergistic Collaboration Across Disciplines

Effective deployment of API 580 requires interdisciplinary collaboration. Engineers, data scientists, safety professionals, and operational managers converge to analyze asset behavior, design inspection protocols, and implement mitigative measures. This collaboration generates a multidimensional understanding of risk, facilitating decisions that are analytically robust and operationally feasible. By promoting cross-disciplinary engagement, API 580 transcends siloed thinking, engendering a holistic, systems-oriented approach to industrial stewardship.

Cultivating Analytical Acumen

Ultimately, API 580 fosters an intellectual ethos in industrial operations. Professionals trained under its auspices develop analytical acumen, probabilistic reasoning skills, and strategic foresight. These competencies empower them to convert complex datasets into actionable intelligence, design adaptive inspection regimes, and anticipate emergent hazards. By cultivating this cognitive sophistication, organizations ensure that their risk management strategies are not static but evolve with operational realities, technological advancements, and emergent challenges, sustaining long-term resilience and efficiency.

Conclusion

API 580 represents a seminal shift in industrial asset management, where foresight supplants reactivity and analysis informs action. By embedding probabilistic risk assessment, predictive maintenance, and data-driven decision-making into operational paradigms, organizations enhance safety, operational continuity, and fiscal efficiency. Certification in API 580 validates individual expertise while promoting systemic excellence, equipping professionals to navigate complex industrial environments with strategic insight. As enterprises increasingly confront operational complexity and regulatory scrutiny, the adoption of risk-based inspection methodologies becomes both a pragmatic necessity and a strategic differentiator, shaping the future of industrial resilience and sustainability.