Exam Code: API-571

Exam Name: Corrosion and Materials

Certification Provider: API

Corresponding Certification: Corrosion and Materials

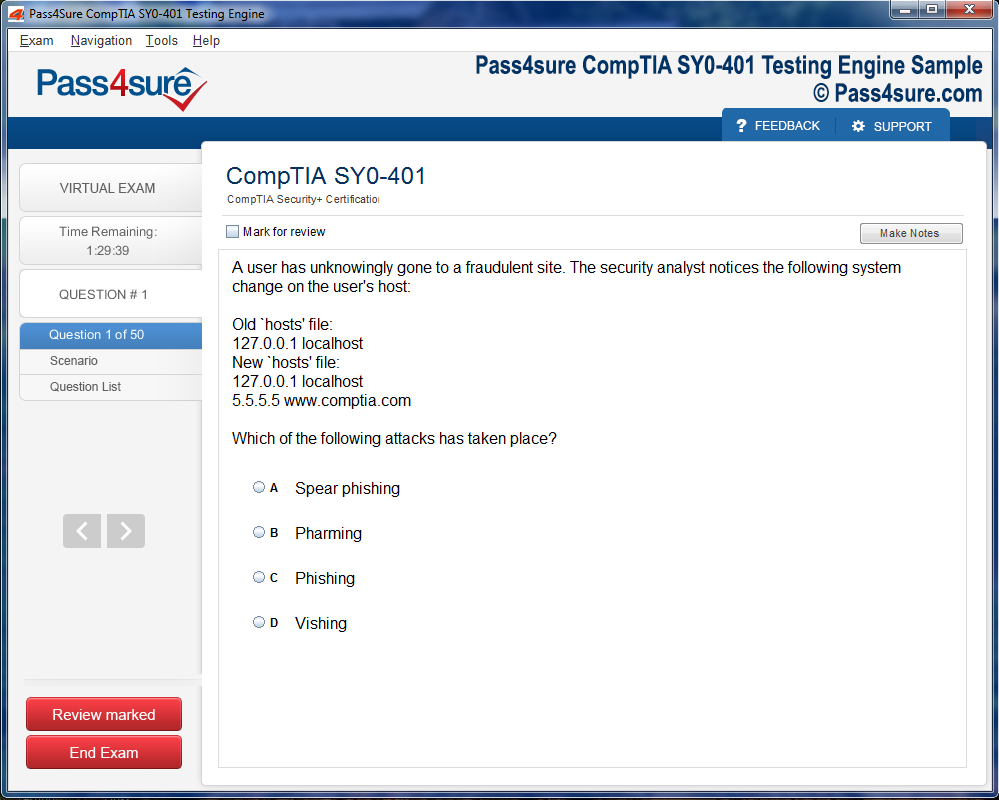

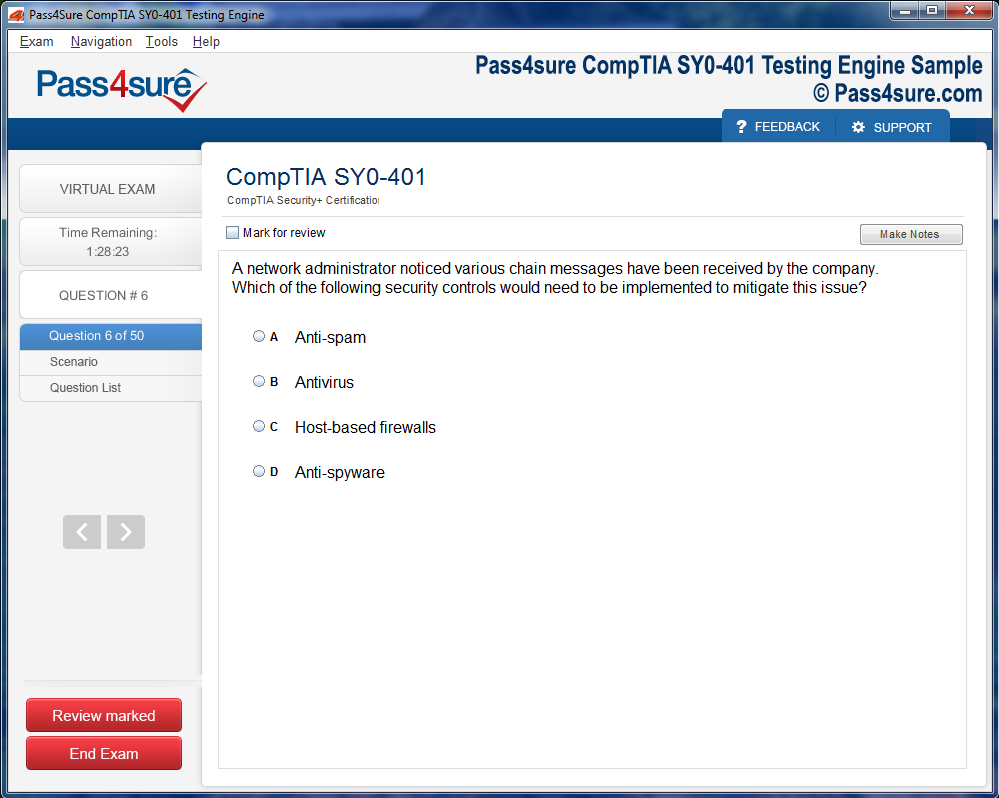

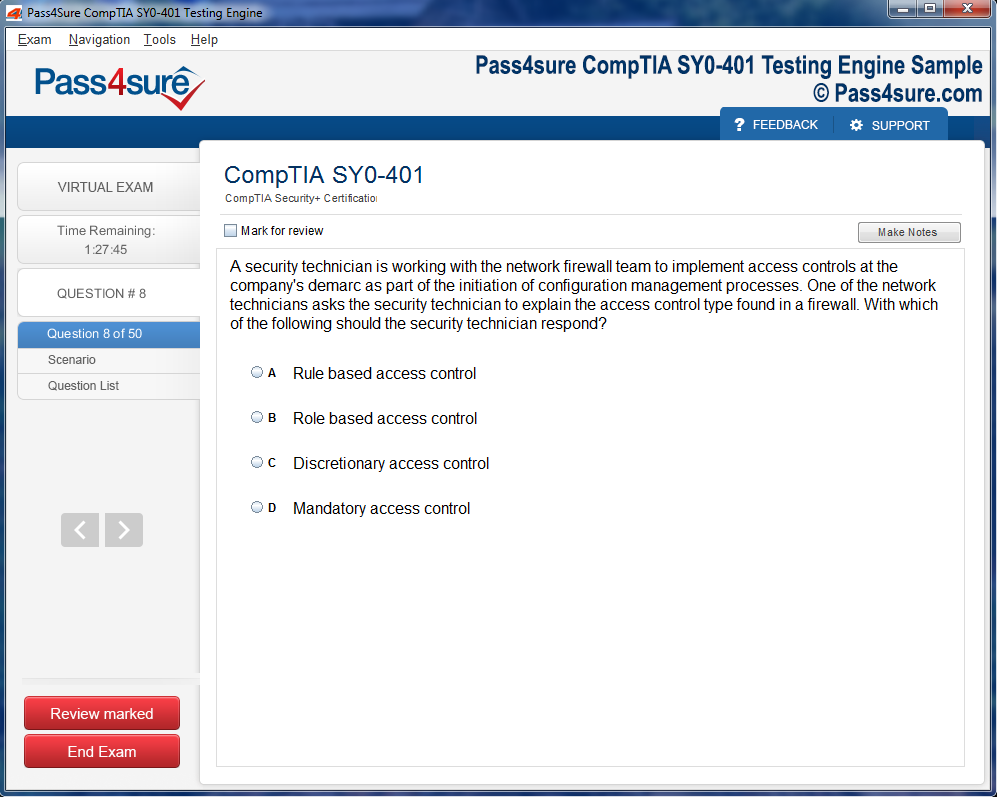

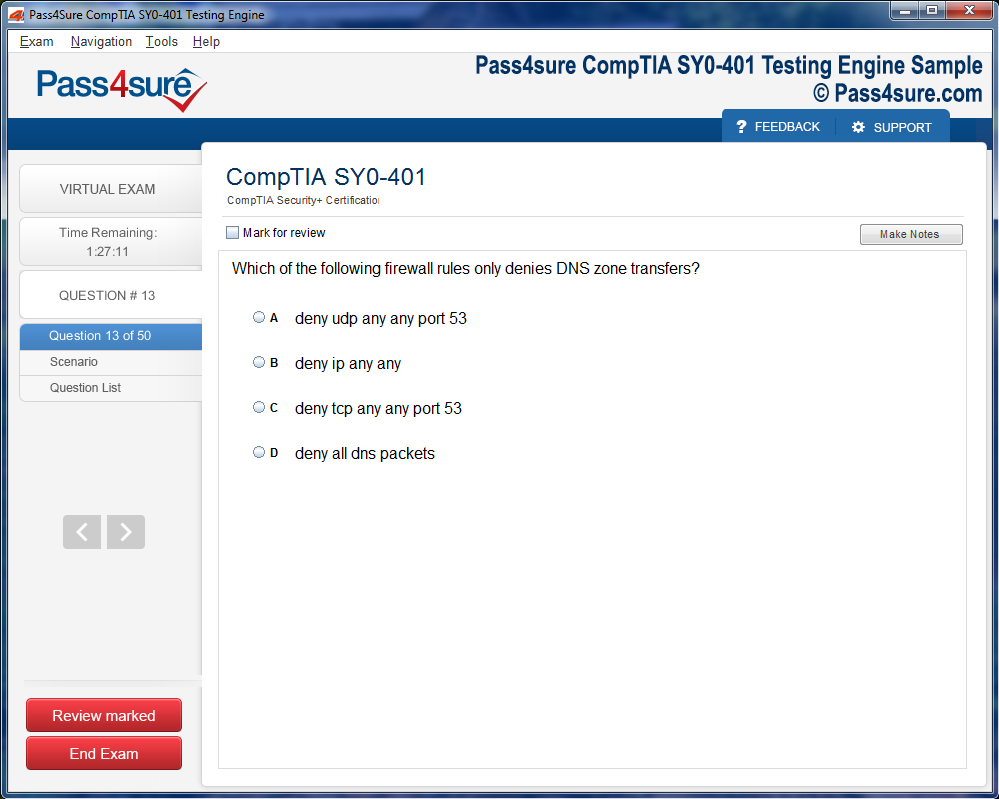

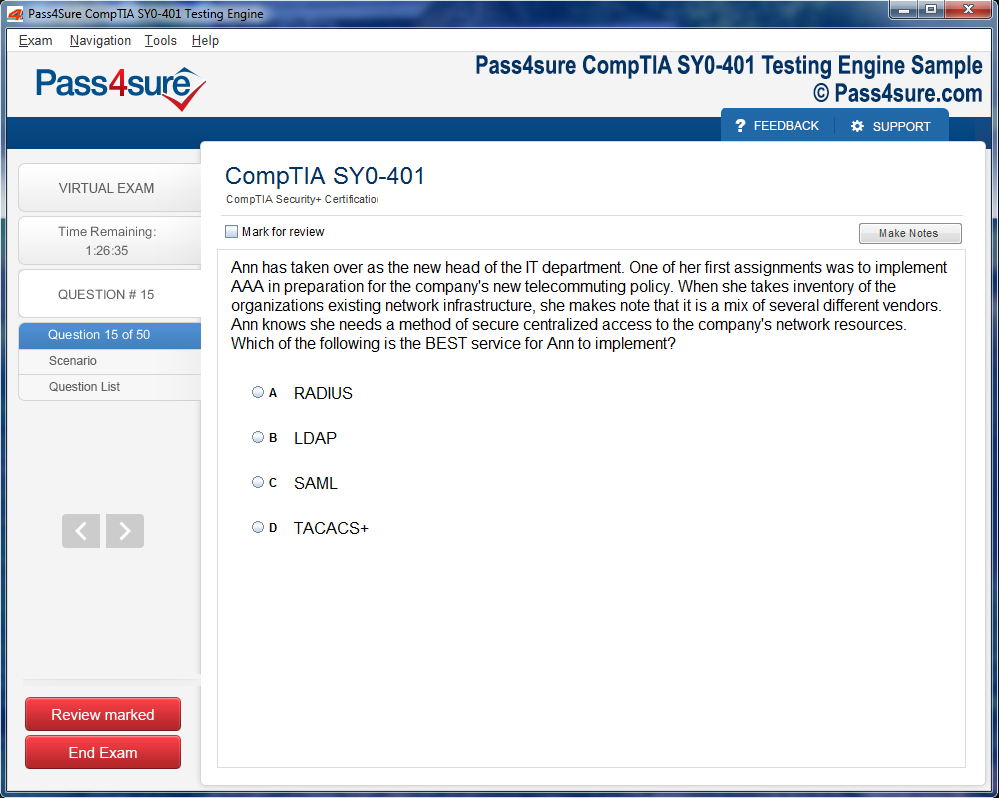

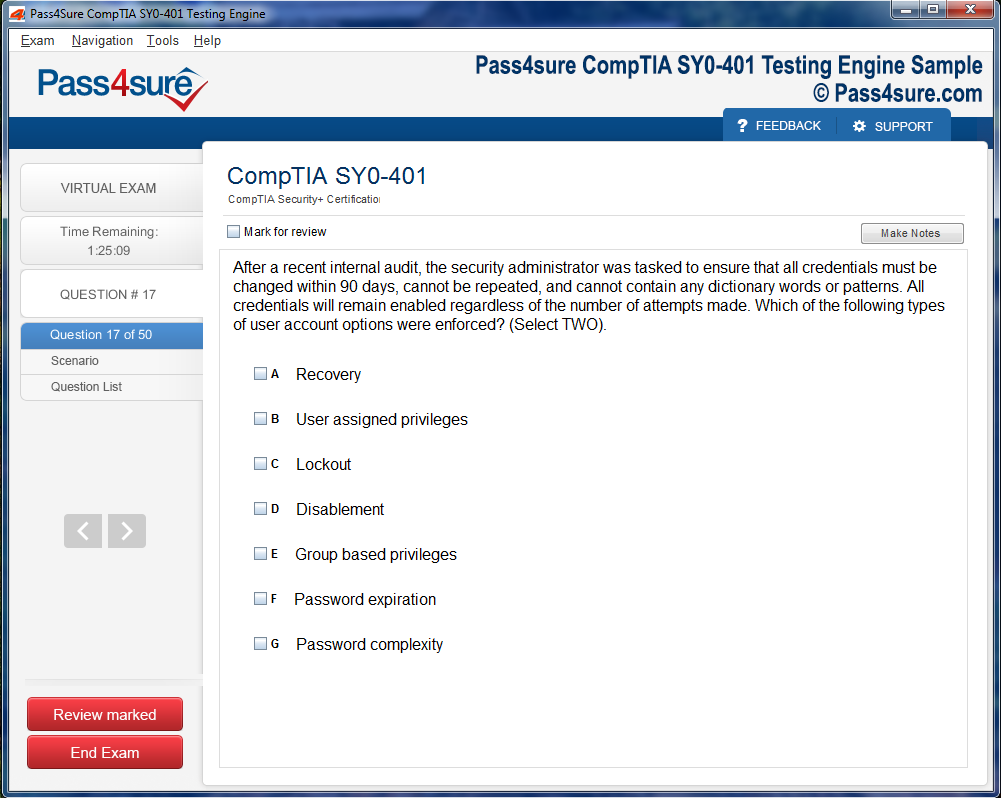

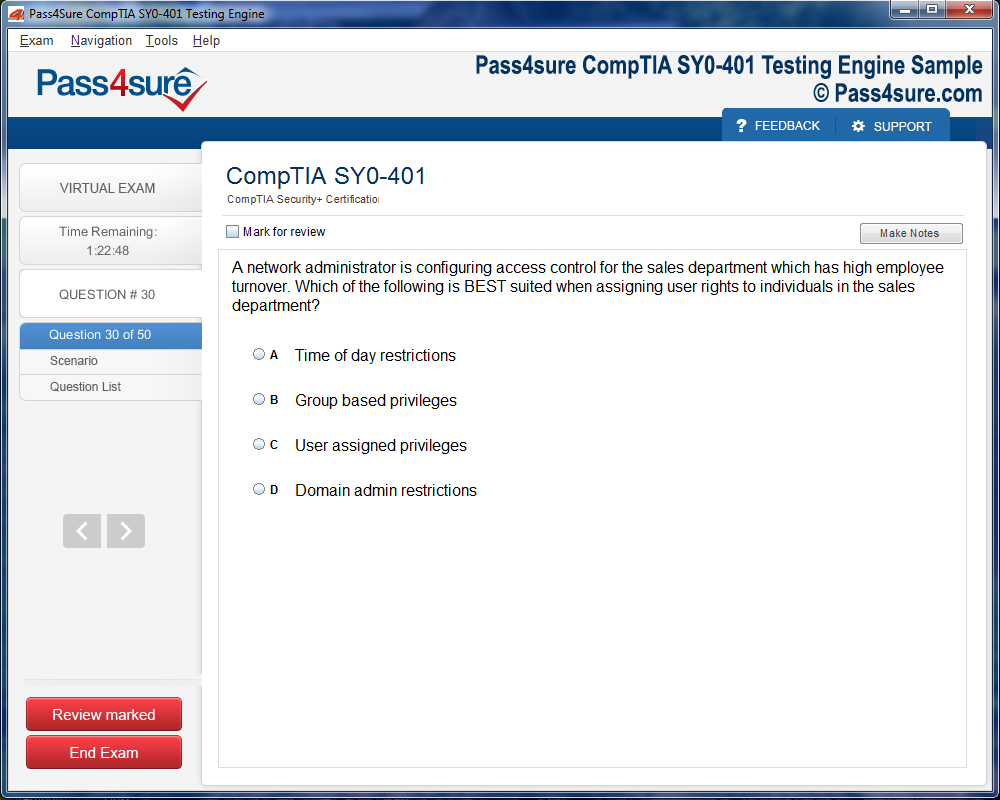

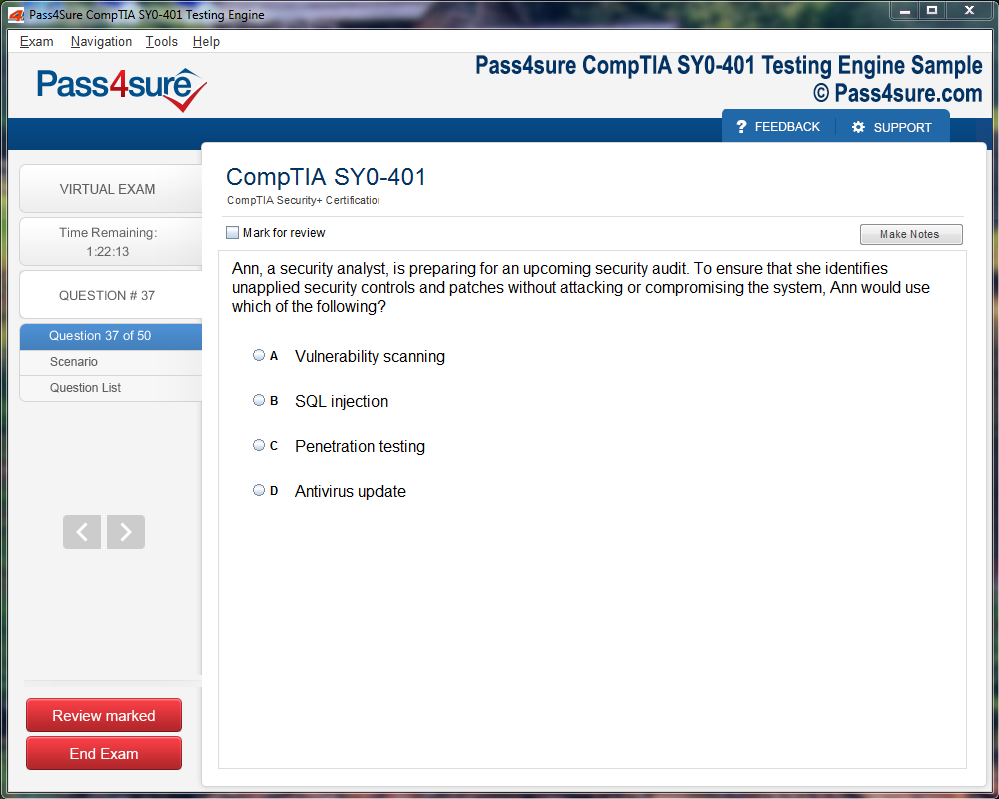

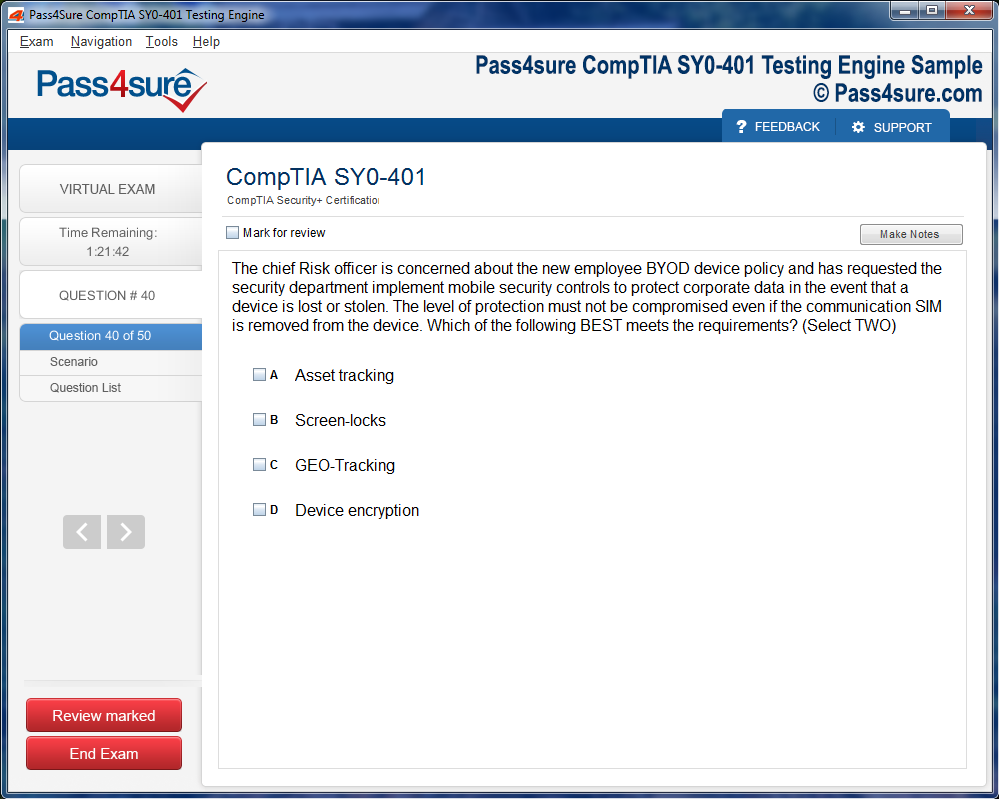

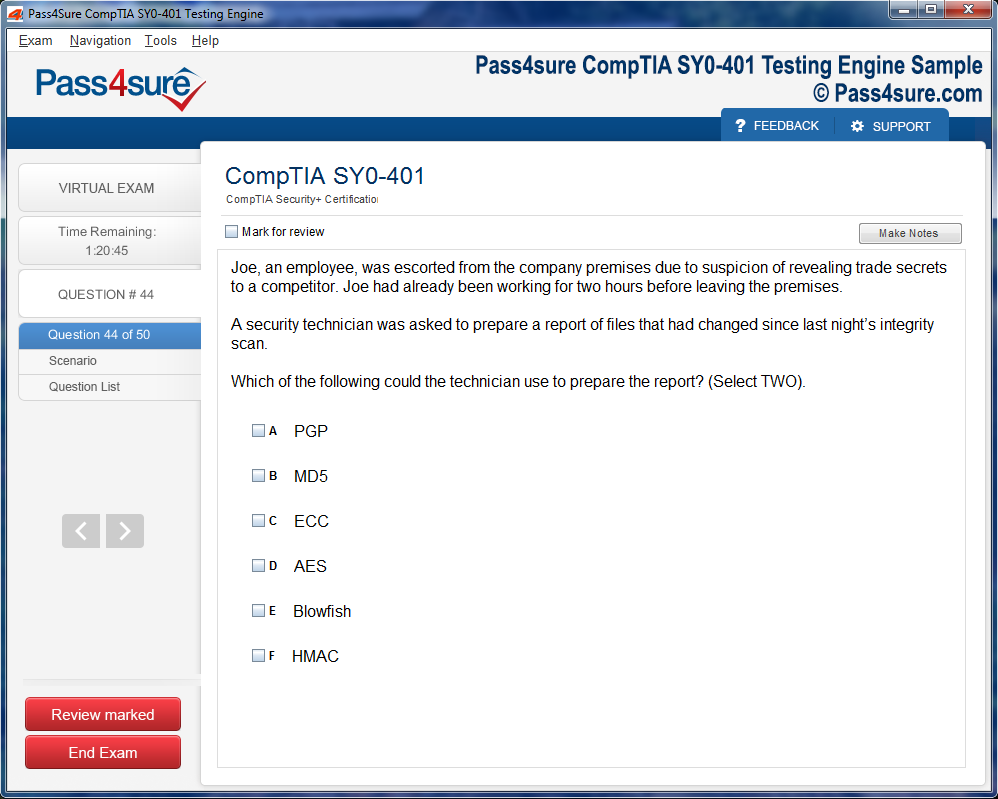

Product Screenshots

Frequently Asked Questions

How does your testing engine works?

Once download and installed on your PC, you can practise test questions, review your questions & answers using two different options 'practice exam' and 'virtual exam'. Virtual Exam - test yourself with exam questions with a time limit, as if you are taking exams in the Prometric or VUE testing centre. Practice exam - review exam questions one by one, see correct answers and explanations.

How can I get the products after purchase?

All products are available for download immediately from your Member's Area. Once you have made the payment, you will be transferred to Member's Area where you can login and download the products you have purchased to your computer.

How long can I use my product? Will it be valid forever?

Pass4sure products have a validity of 90 days from the date of purchase. This means that any updates to the products, including but not limited to new questions, or updates and changes by our editing team, will be automatically downloaded on to computer to make sure that you get latest exam prep materials during those 90 days.

Can I renew my product if when it's expired?

Yes, when the 90 days of your product validity are over, you have the option of renewing your expired products with a 30% discount. This can be done in your Member's Area.

Please note that you will not be able to use the product after it has expired if you don't renew it.

How often are the questions updated?

We always try to provide the latest pool of questions, Updates in the questions depend on the changes in actual pool of questions by different vendors. As soon as we know about the change in the exam question pool we try our best to update the products as fast as possible.

How many computers I can download Pass4sure software on?

You can download the Pass4sure products on the maximum number of 2 (two) computers or devices. If you need to use the software on more than two machines, you can purchase this option separately. Please email sales@pass4sure.com if you need to use more than 5 (five) computers.

What are the system requirements?

Minimum System Requirements:

- Windows XP or newer operating system

- Java Version 8 or newer

- 1+ GHz processor

- 1 GB Ram

- 50 MB available hard disk typically (products may vary)

What operating systems are supported by your Testing Engine software?

Our testing engine is supported by Windows. Andriod and IOS software is currently under development.

Step-by-Step Preparation for API 571 Corrosion & Damage Exam

In the labyrinthine realm of oil, gas, and petrochemical operations, the reliability of equipment transcends mere technical necessity; it becomes a strategic fulcrum upon which operational efficacy pivots. Equipment failures are not trivial inconveniences—they propagate cascades of financial hemorrhaging, safety quandaries, and environmental jeopardy. Mastery over the mechanisms that induce equipment degradation is therefore non-negotiable. Within this context, API 571 certification emerges as an intellectual lodestar, equipping engineers, inspectors, and maintenance specialists with the perspicacity to discern and mitigate deleterious processes. The certification encompasses a kaleidoscope of damage typologies—ranging from insidious corrosion to pernicious cracking and material attrition—illuminating how these maladies proliferate under diverse operational matrices. By elucidating the antecedents of both abrupt and progressive failures, API 571 empowers professionals to implement anticipatory and preventive stratagems that preserve both asset longevity and operational continuity.

Understanding Damage Mechanisms and Material Degradation

Damage mechanisms in industrial settings manifest as a confluence of physical, chemical, and mechanical stresses. Corrosion, for instance, is not merely a surface blemish but a complex electrochemical phenomenon influenced by environmental variables, material microstructure, and operational parameters. Stress corrosion cracking, localized pitting, and erosion-corrosion represent subtle yet potent adversaries that, if unrecognized, can escalate into catastrophic failures. API 571 dissects these processes meticulously, enabling professionals to map the interplay of stressors that precipitate material degradation. Such insight is invaluable, as it informs the selection of materials, coatings, and inhibitors, while also guiding inspection protocols that preempt equipment compromise. The framework provided by API 571 allows practitioners to decode subtle signals—minute fissures, discoloration, or micro-pitting—that herald emergent failures, thereby converting empirical observation into actionable foresight.

Prerequisites and Pathways to Certification

Achieving API 571 certification is contingent upon a synthesis of formal education and hands-on experience. The American Petroleum Institute delineates eligibility criteria with precision, balancing academic attainment against practical immersion. Professionals possessing a bachelor’s degree in engineering or a cognate discipline may suffice with one year of verifiable industry engagement, whereas those with alternative educational backgrounds must demonstrate extended experiential tenure. This stratification ensures candidates possess the cognitive scaffolding requisite for deep assimilation of complex concepts. Immersive preparation involves exhaustive engagement with API 571 study materials, encompassing topics from fundamental corrosion kinetics to multifactorial failure mechanisms. Specialized training courses augment this preparation, translating theoretical precepts into operationally relevant competencies.

Navigating the Certification Process

The formal journey toward API 571 certification begins with a meticulously completed application to the API, documenting academic credentials, professional history, and ancillary certifications. Upon approval, candidates may schedule examinations at authorized centers where rigorous assessment awaits. The API 571 exam is crafted to evaluate a comprehensive understanding of damage mechanisms, metallurgical principles, and inspection methodologies. Successful candidates exhibit proficiency in diagnosing equipment conditions, forecasting potential failures, and executing preemptive interventions. Certification signifies not only mastery but also a commitment to continuous professional development, demanding sustained engagement with emergent industry knowledge and technological advancements.

Organizational Impact and Strategic Advantages

The ramifications of API 571 certification extend beyond individual acumen, yielding strategic dividends for organizations. Certified professionals serve as vanguards of equipment reliability, reducing operational vulnerabilities and optimizing maintenance cadences. Early detection of anomalies—such as stress corrosion cracking, fatigue fissures, or localized corrosion—mitigates the risk of unplanned downtime and process interruptions. The knowledge framework provided by certification equips personnel to interpret inspection data astutely, implement mitigation measures proactively, and refine maintenance protocols for maximal efficacy. This capability is particularly critical in petrochemical operations, where process continuity and asset integrity underpin both economic performance and regulatory compliance.

Bridging Theory and Practice

Structured API 571 training programs exemplify the synthesis of theoretical and practical learning. Participants engage in experiential exercises that illuminate the nuances of damage mechanisms, from identifying microstructural vulnerabilities to executing precise inspection methodologies. Such hands-on exposure transforms conceptual understanding into operational dexterity, empowering professionals to make evidence-based decisions that enhance both safety and efficiency. The capacity to translate knowledge into practice is pivotal; it transforms certification from a credential into a tangible asset that fortifies the reliability culture within organizations.

Cultivating a Culture of Reliability

API 571 certification also fosters a pervasive culture of reliability. Certified personnel often function as repositories of specialized knowledge, guiding colleagues in recognizing early indicators of equipment deterioration. They champion best practices in corrosion management, material selection, and inspection scheduling, embedding reliability into the operational ethos. In industries where even brief downtime can precipitate multimillion-dollar losses or ecological crises, the presence of such experts is indispensable. Certification reinforces regulatory alignment, ensuring organizations adhere to recognized standards while cultivating operational excellence. This confluence of expertise, practical application, and professional recognition positions certified individuals as pivotal contributors to the resilience of refining, petrochemical, and energy enterprises.

Continuous Professional Evolution

Sustaining API 571 credentials necessitates ongoing engagement with industry developments. Professionals are encouraged to pursue continuous education, remain attuned to emerging technologies, and assimilate best practices that evolve alongside operational demands. This commitment to perpetual learning ensures that certified personnel remain adaptive, innovative, and prepared to address novel challenges. The dynamic nature of industrial operations mandates that professionals not only respond to current issues but also anticipate future vulnerabilities, a skill cultivated through rigorous API 571 training and practical experience.

Integration into Operational Strategy

Beyond individual competence, API 571 certification informs strategic decision-making at organizational levels. Certified experts contribute to asset management strategies, risk assessments, and capital planning, offering insights that reconcile operational demands with equipment limitations. Their expertise underpins the formulation of preventive maintenance schedules, the specification of materials resilient to operational stressors, and the implementation of monitoring systems that detect incipient failures. By embedding this knowledge into the organizational fabric, companies achieve heightened reliability, operational continuity, and cost optimization.

Global Relevance and Industry Recognition

API 571 holds international recognition, positioning certified professionals as valuable assets in global energy and petrochemical operations. The principles of damage mechanism identification, corrosion control, and material integrity transcend regional practices, offering a universally applicable framework. This standardization facilitates collaboration across multinational teams, harmonizes inspection and maintenance methodologies, and ensures that reliability practices conform to globally acknowledged benchmarks. Consequently, API 571 certification not only enhances local operational performance but also enables professionals to contribute effectively in diverse industrial contexts worldwide.

Enhancing Safety and Environmental Stewardship

A critical dimension of API 571 certification lies in its contribution to safety and environmental stewardship. By equipping personnel with the expertise to preempt equipment failures, the certification indirectly mitigates risks of hazardous incidents and environmental contamination. The identification of corrosion hotspots, stress points, and material vulnerabilities allows for interventions that prevent leaks, spills, and catastrophic failures. In sectors where the consequences of oversight are magnified, this proactive approach safeguards human life, preserves ecological integrity, and maintains public trust in industrial operations.

Optimizing Maintenance and Operational Efficiency

Maintenance efficiency is profoundly influenced by the knowledge imparted through API 571 certification. Certified professionals can implement condition-based monitoring, prioritize inspection activities, and allocate resources to areas of highest risk. This informed approach reduces unnecessary downtime, optimizes workforce deployment, and enhances the lifespan of critical assets. Through predictive maintenance strategies, organizations can anticipate degradation patterns and address them before they escalate, translating expertise into measurable operational gains.

Elevating Professional and Organizational Competence

In summation, API 571 certification represents a confluence of theoretical mastery, practical proficiency, and strategic insight. For individuals, it validates expertise in identifying and mitigating damage mechanisms, equips them with the skills to ensure operational continuity, and fosters ongoing professional growth. For organizations, it catalyzes enhanced reliability, safety, and efficiency, embedding a culture of vigilance and preventive action. The rigorous training, comprehensive understanding of material behavior, and practical application inherent in API 571 certification collectively elevate both professional competence and organizational resilience, establishing a benchmark of excellence in the oil, gas, and petrochemical industries.

Understanding the Labyrinthine Dynamics of Material Degradation

In the labyrinthine realm of oil, gas, and petrochemical industries, the comprehension of material degradation is not merely advantageous—it is imperative. Equipment in these sectors confronts a maelstrom of extreme stimuli, encompassing elevated thermodynamic states, immense pressures, and chemically caustic milieus. Such vicissitudes accelerate corrosion kinetics, potentiate microcracking, and amplify fatigue phenomena at the metallurgical scale. API 571 certification furnishes practitioners with the perspicacity to navigate these intricate contingencies. Through rigorous exploration of the physicochemical processes that precipitate structural deterioration, aspirants acquire the acumen to prognosticate equipment failures and engineer interventions that safeguard operational fidelity. The purview of this knowledge spans static apparatus such as pressure vessels and heat exchangers, as well as rotating machinery including pumps and turbines, offering a holistic vantage that undergirds proactive maintenance paradigms, thus shielding assets and human life alike.

Pathways to API 571 Credential Acquisition

Embarking upon the journey toward API 571 certification entails a meticulous evaluation of candidate eligibility. Prospective participants must align their academic credentials with pertinent industrial experience, ensuring a symbiosis of theoretical comprehension and practical adeptness. For instance, a mechanical engineer endowed with a four-year degree may possess limited field exposure, whereas a technician with a two-year vocational certification may require protracted operational tenure to satisfy prerequisites. This adaptable framework democratizes access to the credential while preserving rigorous standards of proficiency. Preparation methodologies often involve a dual-pronged approach: autonomous study complemented by structured instruction. Canonical texts elucidate foundational principles, while interactive coursework immerses learners in scenario-based simulations, fostering application-oriented cognition. Such immersion ensures that aspirants internalize technical constructs beyond rote memorization, equipping them to confront real-world exigencies with assured judgment.

The Crucible of Examination and Competency Validation

Scheduling and undertaking the API 571 examination constitutes a crucible wherein theoretical mastery and practical discernment are simultaneously evaluated. Candidates must exhibit fluency in identifying an array of damage mechanisms, from sulfidation and pitting to hydrogen-induced cracking. Assessment criteria extend beyond mere recognition; examinees are scrutinized on their aptitude for root cause analysis, severity quantification, and formulation of mitigation strategies. Successful certification signals not only technical acumen but also operational readiness, affirming that the individual can meaningfully contribute to the stewardship of industrial apparatus. The triennial validity of the credential necessitates recertification, thereby ensuring alignment with emerging technological paradigms, contemporary industry standards, and evolving mechanisms of material failure—a reflection of the inherently dynamic nature of energy and petrochemical domains.

Organizational Imperatives and Operational Advantages

Enterprises that endorse API 571 certification within their workforce accrue substantive operational dividends. Certified personnel are empowered to spearhead inspection initiatives, refine maintenance regimes, and institute corrosion control frameworks that prolong the lifecycle of critical assets. Early identification of damage mechanisms forestalls catastrophic disruptions that could imperil production continuity, compromise safety, and erode organizational reputation. Structured training programs, exemplified by immersive, scenario-driven instruction, equip participants with experiential insight, enabling the translation of theoretical knowledge into pragmatic detection of incipient deterioration. This proficiency enhances operational confidence and decision-making acuity, particularly when navigating high-stakes industrial environments where equipment reliability is non-negotiable.

Augmenting Professional Trajectories and Strategic Foresight

API 571 certification transcends technical competency, catalyzing professional maturation and career ascension. Certified experts frequently evolve into pivotal resources within their institutions, mentoring colleagues, codifying operational best practices, and ensuring adherence to stringent safety protocols. The amalgamation of theoretical sagacity, empirical experience, and anticipatory foresight empowers them to preempt malfunctions before they escalate into systemic crises. This strategic advantage is especially salient in refining and petrochemical operations, where equipment failures engender cascading operational, environmental, and safety ramifications. By pursuing certification, professionals articulate a commitment to excellence and cultivate a competitive edge, while organizations concurrently bolster operational resilience, mitigate risk exposure, and enhance long-term sustainability.

Intricacies of Corrosion Phenomena and Material Fatigue

The phenomenon of corrosion represents a multifaceted confluence of electrochemical reactions and environmental stressors, modulated by temperature, pH, and the presence of aggressive ions. Understanding these subtleties is crucial for predicting degradation pathways and instituting preventative countermeasures. Material fatigue, conversely, arises from cyclic loading, engendering microstructural perturbations that culminate in crack nucleation and propagation. API 571 candidates delve into these phenomena with precision, learning to quantify stress intensity factors, evaluate fracture mechanics, and integrate non-destructive testing methodologies. This knowledge enables predictive maintenance regimes that forestall unanticipated failures, thereby safeguarding both infrastructure and personnel.

Predictive Analytics and Maintenance Optimization

Modern industrial operations increasingly leverage predictive analytics to anticipate damage mechanisms. Certified professionals harness data from vibration analysis, ultrasonic inspection, and thermographic imaging to construct prognostic models, enabling preemptive interventions. Such foresight minimizes unplanned downtime, optimizes resource allocation, and enhances lifecycle management of critical assets. API 571 training integrates these analytical techniques with empirical experience, cultivating a cadre of professionals adept at transforming raw operational data into actionable maintenance strategies.

Integration of Safety, Environmental, and Economic Considerations

The application of API 571 expertise extends beyond mere mechanical reliability; it encompasses safety stewardship, environmental stewardship, and economic prudence. Mitigating corrosion and fatigue not only preserves equipment integrity but also prevents leaks, emissions, and catastrophic failures that can have profound ecological and financial consequences. Certified individuals are trained to balance technical imperatives with regulatory compliance and fiscal responsibility, ensuring that operational decisions uphold a triad of industrial sustainability, human safety, and profitability.

Synergy Between Theoretical Knowledge and Practical Acumen

A distinguishing feature of API 571 certification is its emphasis on harmonizing conceptual understanding with hands-on proficiency. Candidates engage with real-world scenarios, examining corroded pipelines, stress-fractured heat exchangers, and fatigue-prone rotating equipment. This experiential learning fosters nuanced judgment, enabling professionals to recognize subtle early-warning indicators that might elude less trained eyes. By bridging the gap between abstraction and tangible application, the certification cultivates practitioners capable of safeguarding critical infrastructure with both intellectual rigor and pragmatic skill.

The Dynamic Landscape of Industrial Challenges

The oil, gas, and petrochemical sectors are characterized by perpetual evolution, driven by technological innovation, regulatory shifts, and fluctuating market dynamics. Damage mechanisms and maintenance paradigms evolve correspondingly, necessitating continuous professional development. API 571 certification, with its triennial recertification requirement, ensures that credentialed professionals remain attuned to contemporary challenges, integrating emergent knowledge into operational frameworks. This adaptability is vital for sustaining competitive advantage, minimizing downtime, and reinforcing the resilience of industrial systems.

Perspectives on Certification and Industrial Stewardship

In summation, mastery of damage mechanisms and attainment of API 571 certification represent a confluence of intellectual rigor, practical expertise, and strategic foresight. Professionals equipped with this knowledge are positioned to anticipate and mitigate material degradation, optimize maintenance strategies, and champion safety and sustainability within high-stakes industrial milieus. Organizations that invest in cultivating such expertise reap multifaceted benefits, from prolonged asset longevity to enhanced operational efficiency and reputational fortitude. In a sector defined by complexity, risk, and relentless environmental and operational pressures, API 571 certification emerges not merely as a credential but as a linchpin of industrial stewardship, empowering professionals to navigate the intricate interplay of materials, mechanics, and human ingenuity.

The Intricacies of Petrochemical Equipment Integrity

The labyrinthine world of petrochemical operations necessitates a perspicacious understanding of equipment reliability and failure phenomena. Modern facilities rely on a vast array of interdependent systems where minute material anomalies or operational deviations can precipitate cascading malfunctions. In this context, API 571 certification functions as a codified schema that equips professionals with the acumen to dissect and mitigate damage mechanisms. Proficiency encompasses recognizing corrosive patterns, fatigue-induced fissures, erosive wear, and stress-corrosion interactions, each presenting unique morphological characteristics contingent on metallurgical composition, operational pressures, thermal gradients, and chemical aggressors.

Navigating these complex processes demands both cognitive dexterity and experiential insight. While analytical methodologies provide theoretical frameworks, field-level acumen illuminates subtle deviations that could herald incipient failures. API 571 training, therefore, bridges the chasm between abstract understanding and pragmatic application, empowering practitioners to extrapolate inspection data, anticipate potential debilitation, and institute preemptive countermeasures. Emphasis is placed on proactive stewardship of assets, fostering a paradigm where anticipatory intervention supersedes reactive remediation. The intricate interplay of mechanical forces, chemical interactions, and environmental stressors underscores the necessity for such structured education.

Eligibility Criteria and Preparatory Rigors

Embarking on the API 571 certification journey commences with adherence to stipulated eligibility requisites. The API enforces a meticulous evaluation process designed to verify a synergistic blend of formal education and industry tenure. Such prerequisites ensure that aspirants possess the foundational knowledge requisite for grappling with intricate concepts and applying them to operational exigencies. Prospective candidates must demonstrate proficiency not only in theoretical constructs but also in the nuanced interpretation of field phenomena.

The preparatory phase demands rigorous engagement with reference compendia and immersive training modules. Candidates delve into corrosion typologies, encompassing localized pitting, intergranular attack, and crevice phenomena, alongside fatigue manifestations such as crack initiation and propagation in cyclically loaded structures. Stress-related anomalies in pressurized vessels and piping networks are scrutinized with meticulous attention to boundary conditions and metallurgical susceptibilities. Training regimens integrate simulations and case-based exercises, enabling participants to synthesize theoretical knowledge with practical exigencies. Such comprehensive preparation ensures that candidates are adept at discerning subtle failure precursors and formulating robust mitigation strategies.

Examination Structure and Competency Evaluation

The API 571 examination constitutes a rigorous assessment of both cognitive comprehension and applied discernment. Candidates are evaluated on their capacity to identify latent vulnerabilities, comprehend the multifactorial drivers of material degradation, and prescribe judicious corrective actions. Mastery of chemical kinetics, thermomechanical stress interactions, and corrosion propagation dynamics is imperative for successful completion. The exam tests not merely rote memorization but the ability to contextualize information within operationally realistic scenarios, reflecting the decision-making acumen required in petrochemical environments.

Certification conferred by passing the examination signifies a confluence of technical competence and operational sagacity. It affirms the individual’s ability to safeguard equipment integrity and enhance system longevity. The three-year validity period underscores the dynamic nature of the field, compelling continuous engagement with emergent technologies, evolving industry standards, and innovative mitigation methodologies. Recertification is an essential vector for sustaining expertise, ensuring that certified professionals remain conversant with novel materials, advanced inspection techniques, and evolving failure paradigms. In effect, the credential functions as both a marker of proficiency and a catalyst for lifelong professional development.

Organizational Advantages of Certification

From an institutional vantage, API 571 certification yields substantial strategic dividends. Organizations benefit from heightened asset reliability, reduced incidence of catastrophic failure, and prolonged equipment service life. Certified personnel provide authoritative guidance in inspection scheduling, corrosion abatement strategies, and maintenance prioritization, optimizing resource allocation while minimizing operational interruptions. The infusion of specialized knowledge cultivates a culture of anticipatory risk management, reinforcing both safety and economic efficiency.

Training programs that meld theoretical exposition with experiential exercises are particularly efficacious. Participants engage in simulated operational contingencies, encountering scenarios that necessitate rapid analysis, problem-solving, and intervention planning. Such immersive methodologies bolster cognitive retention and fortify confidence in navigating complex failure landscapes. Consequently, organizations equipped with API 571-certified personnel exhibit enhanced resilience, operational continuity, and an elevated standard of procedural rigor.

Corrosion Phenomena and Metallurgical Considerations

A pivotal component of API 571 instruction centers on corrosion characterization and mitigation. Practitioners study a spectrum of corrosive mechanisms, from uniform thinning to localized pitting, intergranular deterioration, and stress-assisted corrosion. Each mechanism exhibits distinctive kinetics influenced by environmental chemistry, fluid velocity, temperature gradients, and material composition. For example, high-chloride environments may accelerate pitting in stainless steel, whereas high-pressure hydrogen exposure exacerbates sulfide stress cracking. Understanding these nuances is critical for the development of predictive models and the implementation of preventive measures.

Metallurgical considerations are equally paramount. Material selection, heat treatment, and fabrication techniques determine susceptibility to various degradation modes. API 571 training elucidates the interplay between microstructural characteristics and operational stressors, enabling professionals to forecast potential failure sites and design inspections that are both targeted and comprehensive. Knowledge of metallurgical behavior under combined mechanical and chemical stress is indispensable for ensuring long-term equipment reliability.

Fatigue, Creep, and Mechanical Degradation

Beyond chemical degradation, mechanical deterioration represents a significant threat to petrochemical infrastructure. Fatigue failure, engendered by cyclic loading, is often insidious, initiating as microscopic fissures that propagate under repeated stress. API 571 education emphasizes the identification of fatigue-sensitive regions, assessment of stress concentrations, and evaluation of operating cycles to preempt catastrophic failure. Creep, the slow deformation of materials under sustained load at elevated temperatures, is also explored, with attention to metallurgical phases, grain boundary mobility, and stress relaxation phenomena.

Mechanical degradation is further complicated by combined loading conditions, where tensile, compressive, and torsional forces interact in non-linear ways. Professionals trained under the API 571 framework learn to employ analytical tools, such as fracture mechanics and life prediction models, to quantify remaining service life and prescribe corrective measures. The integration of mechanical and chemical failure analysis fosters a holistic perspective, empowering engineers to mitigate multifaceted threats with precision.

Erosion and Abrasive Interactions

Erosive wear, frequently encountered in pipelines and high-velocity fluid systems, represents another focal point of API 571 instruction. Particulate-laden fluids, turbulent flow regimes, and abrupt directional changes exacerbate material loss, potentially compromising structural integrity. Trainees explore the kinetics of erosion, the influence of particle morphology, and the interaction between flow-induced stress and material hardness. Understanding these factors enables the formulation of mitigation strategies, such as flow optimization, material selection, and protective coatings.

Abrasive interactions, while superficially similar to erosion, often involve contact with foreign solids and may be amplified by synergistic chemical corrosion. API 571 certification equips professionals with the ability to distinguish between these phenomena, interpret inspection findings, and implement corrective protocols. Mastery of erosive and abrasive degradation mechanisms ensures that infrastructure maintains its intended operational lifespan even under aggressive service conditions.

Proactive Maintenance and Risk Mitigation

API 571 certification underscores a philosophy of proactive maintenance and risk reduction. Early detection of incipient failures through non-destructive evaluation, condition monitoring, and predictive modeling forms the cornerstone of effective equipment stewardship. Professionals are trained to integrate inspection data with operational history, environmental factors, and material characteristics to generate risk-based maintenance plans. This anticipatory approach reduces unplanned downtime, enhances safety, and optimizes resource expenditure.

The proactive ethos extends to organizational culture, encouraging cross-functional collaboration, meticulous documentation, and continuous improvement. Certified personnel often serve as catalysts for such cultural shifts, championing best practices and instilling vigilance across engineering, operations, and maintenance teams. In doing so, organizations cultivate a resilient operational environment capable of withstanding both predictable wear and unforeseen perturbations.

Career Advancement and Professional Prestige

Beyond technical competence, API 571 certification augments professional stature and career trajectory. Certified individuals are recognized for their specialized expertise in equipment integrity management, often gaining preferential consideration for leadership roles, project oversight, and strategic planning responsibilities. The credential signifies a commitment to ongoing professional development and adherence to rigorous industry standards, enhancing employability and internal recognition.

In sectors where operational reliability, safety, and regulatory compliance are paramount, the presence of API 571-certified professionals bolsters organizational credibility. Their contributions extend beyond immediate technical problem-solving to encompass long-term strategic planning, risk management, and process optimization. The certification thus functions as both a personal asset and an organizational lever, aligning individual accomplishment with institutional resilience.

Integrating Theory with Practical Application

The transformative impact of API 571 training derives from its integration of theoretical foundations with practical application. Simulation exercises, real-world case studies, and field inspections provide a dynamic learning environment, reinforcing cognitive comprehension through experiential engagement. Participants analyze authentic operational scenarios, diagnose potential failure modes, and implement intervention strategies under guided supervision. This dual emphasis cultivates critical thinking, situational awareness, and operational agility.

By bridging abstract knowledge and tangible experience, API 571 certification produces professionals capable of addressing the full spectrum of equipment integrity challenges. The training methodology encourages reflective learning, iterative problem-solving, and adaptive application, ensuring that certified individuals remain effective in diverse operational contexts. The resulting competence extends beyond technical proficiency to encompass leadership, judgment, and strategic foresight.

Sustaining Knowledge through Recertification

Recognition of the field’s dynamism underpins API 571’s recertification mandate. The three-year validity period necessitates ongoing engagement with emerging technologies, novel failure mechanisms, and revised best practices. Recertification fosters continuous learning, ensuring that certified professionals remain conversant with contemporary operational paradigms, inspection techniques, and mitigation strategies.

Sustained knowledge retention is critical in environments where incremental degradation can culminate in catastrophic failure. Regular recertification enables practitioners to recalibrate their expertise, assimilate new insights, and maintain alignment with industry advancements. In this manner, API 571 functions as a living framework, evolving with technological innovation while preserving the rigor and depth of its foundational principles.

Enhancing Organizational Resilience

The deployment of API 571-certified professionals directly enhances organizational resilience. By embedding expertise in failure analysis, corrosion management, and preventive maintenance, companies mitigate operational disruptions and safeguard capital-intensive assets. Certified personnel facilitate strategic decision-making, prioritize interventions based on risk, and optimize inspection schedules, thereby reducing both maintenance costs and unplanned downtime.

Moreover, the presence of certified experts cultivates an ethos of vigilance, analytical rigor, and proactive stewardship across the organization. This cultural shift enhances overall operational discipline, aligns practices with regulatory expectations, and fortifies the organization against both internal and external contingencies. In industries where reliability underpins profitability and safety, such resilience constitutes a vital competitive advantage.

The Strategic Imperative of API 571 Certification

In sum, API 571 certification represents a confluence of technical mastery, operational insight, and strategic acumen. By elucidating the complex interplay of corrosion, fatigue, erosion, and mechanical degradation, the certification equips professionals to anticipate failures, optimize maintenance, and safeguard equipment integrity. It enhances career prospects, reinforces professional credibility, and drives organizational excellence through structured knowledge application and proactive risk management.

For both individuals and organizations, API 571 serves as an essential instrument in the quest for operational reliability, safety, and strategic resilience. Its emphasis on continuous learning, practical application, and anticipatory stewardship ensures that petrochemical operations remain robust in the face of evolving challenges. Ultimately, the certification embodies a commitment to precision, foresight, and excellence, translating specialized knowledge into tangible benefits for professionals, organizations, and the broader industry ecosystem.

Navigating the Labyrinth of Equipment Integrity in Hydrocarbon Industries

Maintaining the integrity of equipment within the oil, gas, and petrochemical domains is an intricate endeavor, replete with nuanced challenges. The operational milieu is beset with multifarious damage mechanisms, including corrosion, micro-cracking, fatigue-induced fissures, and erosive wear, each of which imperils the reliability of critical infrastructure. Understanding these phenomena requires an amalgamation of material science, operational acumen, and environmental awareness. Professionals entrusted with safeguarding equipment functionality must adopt a vigilant, anticipatory posture, ensuring that minor anomalies do not escalate into catastrophic failures. The convergence of chemical exposure, mechanical stressors, and fluctuating operational parameters creates a delicate equilibrium that must be meticulously monitored.

The Significance of API 571 Certification

API 571 certification serves as a pivotal framework for navigating these complexities. It endows professionals with the perspicacity to anticipate, detect, and mitigate equipment failures across diverse operational scenarios. The curriculum elucidates the intricate interplay between metallurgical properties, environmental aggressors, and operational stressors, providing a holistic lens through which degradation mechanisms can be deciphered. Certified individuals cultivate the ability to implement preemptive strategies that prolong equipment longevity, enhance safety margins, and optimize maintenance cycles. By instilling a culture of proactive management, the certification discourages reactive interventions and fosters operational resilience.

Prerequisites and Pathways to Certification

The journey toward API 571 certification is structured to ensure that candidates possess both theoretical knowledge and practical exposure. Eligibility criteria stratify applicants based on educational attainment and industry experience, creating a balanced approach to certification readiness. Professionals with advanced academic credentials may require limited field experience, whereas those with lesser formal education must demonstrate extended operational engagement. This framework ensures that every candidate is equipped to assimilate the specialized knowledge conveyed during training. Preparation involves rigorous study of API 571 reference materials, attendance at focused instructional courses, and immersion in practice scenarios that replicate field conditions, thereby bridging the gap between theory and praxis.

Examination as a Crucible of Competence

Scheduling and undertaking the API 571 examination represents a seminal milestone in professional development. The exam rigorously evaluates a candidate’s understanding of diverse damage mechanisms and their capacity to apply knowledge in situational contexts. Prospective certificants must exhibit proficiency in early detection of degradation, severity assessment, and recommendation of remedial measures. Successful completion signifies not merely technical aptitude but also situational awareness, reinforcing the professional’s ability to contribute meaningfully to operational safety and reliability. Certification remains valid for three years, with recertification mandated to align competencies with evolving industry practices, underscoring the necessity for continuous intellectual engagement.

Organizational Advantages of Certified Personnel

Employing API 571-certified professionals confers substantial strategic advantages to organizations. These individuals are capable of orchestrating inspection protocols, devising corrosion mitigation strategies, and optimizing maintenance workflows. By identifying incipient failures, certified personnel minimize unplanned downtime, extend the operational lifespan of critical equipment, and bolster efficiency. Immersive training programs, emphasizing scenario-based learning, equip participants with practical skills that complement theoretical knowledge, reinforcing operational confidence. Through their expertise, certified professionals ensure that refineries, pipelines, and petrochemical plants maintain a state of readiness and resilience.

Enhancing Operational Reliability Through Proactive Management

Proactive equipment management, as advocated by API 571 principles, involves more than routine inspection; it necessitates a sophisticated understanding of degradation kinetics, environmental interactions, and stress distribution. Professionals must discern subtle indicators of distress, such as micro-pitting, embrittlement, or localized corrosion, that presage more severe deterioration. Implementing timely interventions based on these insights prevents escalation and mitigates safety hazards. Maintenance strategies informed by API 571 knowledge emphasize predictive analytics, data-driven scheduling, and judicious material selection, fostering a robust operational framework that withstands the vagaries of industrial exigencies.

Interdisciplinary Expertise in Material Science and Environmental Chemistry

Central to API 571’s ethos is the confluence of material science and environmental chemistry. Professionals must comprehend how metallurgical characteristics, such as grain structure, alloy composition, and heat treatment history, interact with corrosive agents, mechanical loading, and thermal fluctuations. Likewise, environmental factors—ranging from aqueous chloride concentrations to hydrocarbon contaminants and elevated temperatures—exacerbate degradation pathways. This interdisciplinary perspective enables informed decision-making regarding inspection frequency, repair prioritization, and the deployment of protective technologies, including coatings, inhibitors, and cathodic protection systems.

The Role of Scenario-Based Learning in Certification

Scenario-based learning is a linchpin of API 571 training. Immersive simulations expose participants to realistic operational challenges, fostering analytical rigor and decision-making agility. Through controlled exercises, professionals practice diagnosing corrosion morphology, evaluating crack propagation, and assessing fatigue thresholds under variable stress conditions. This experiential methodology reinforces comprehension of theoretical concepts and hones practical acumen, bridging the often-cited gap between classroom instruction and field application. By encountering simulated contingencies, candidates cultivate resilience, adaptability, and foresight—qualities essential for safeguarding complex industrial systems.

Fostering a Culture of Safety and Regulatory Compliance

API 571 certification reinforces a culture of safety and compliance within organizations. Certified professionals are adept at translating technical knowledge into actionable policies that align with regulatory frameworks. Their expertise enables systematic identification of risk zones, prioritization of maintenance efforts, and documentation of integrity assessments for auditing purposes. By embedding proactive measures into operational routines, organizations reduce exposure to environmental incidents, workplace hazards, and financial liabilities. Consequently, API 571-certified personnel act as catalysts for cultivating an organizational ethos where safety, reliability, and compliance are inseparable objectives.

Career Advancement and Professional Recognition

For individuals, API 571 certification constitutes a significant credential, enhancing professional credibility and career trajectory. Certified practitioners gain recognition for their ability to manage complex integrity challenges, positioning themselves for leadership roles, project oversight responsibilities, and cross-functional assignments. The credential signals mastery over both the science and practice of equipment management, reflecting a commitment to continuous learning, adherence to industry best practices, and proficiency in navigating operational exigencies. As a result, professionals leverage certification to expand career horizons, contribute strategically to organizational goals, and influence industry standards.

Strategic Implementation of Corrosion Control Programs

A salient benefit of API 571 certification is the capacity to implement sophisticated corrosion control programs. Certified professionals evaluate the susceptibility of equipment to diverse forms of corrosion, including uniform, pitting, crevice, and stress-corrosion cracking. They integrate monitoring techniques such as ultrasonic thickness measurements, radiographic inspection, and electrochemical analysis to assess material integrity. By orchestrating maintenance schedules informed by these evaluations, they ensure optimal allocation of resources, mitigate failure risks, and enhance the longevity of assets. Strategic corrosion control, grounded in API 571 principles, fosters both operational continuity and financial prudence.

Addressing Fatigue and Mechanical Degradation

Beyond corrosion, fatigue, and mechanical degradation pose persistent threats to equipment reliability. API 571 training equips professionals with the analytical tools to quantify cyclic stress impacts, identify crack initiation sites, and predict failure timelines. Understanding the interrelationship between load cycles, environmental stressors, and material microstructure enables the formulation of preventative measures, including load redistribution, design modification, and stress relief techniques. By anticipating fatigue-related vulnerabilities, certified professionals mitigate unplanned outages, preserve structural integrity, and uphold the operational mandate of industrial facilities.

Enhancing Decision-Making Through Predictive Analytics

Predictive analytics forms a cornerstone of contemporary equipment integrity management. API 571-certified professionals harness data from inspections, sensors, and historical performance records to model degradation trajectories, forecast failure probabilities, and prioritize interventions. Advanced analytical techniques, such as probabilistic risk assessment and corrosion rate modeling, enable evidence-based decision-making that optimizes maintenance efficacy. This data-driven approach reduces reliance on reactive measures, aligns resource allocation with operational criticality, and cultivates a foresighted maintenance culture that anticipates rather than reacts to degradation.

Integration of Technology in Equipment Integrity

Technological integration amplifies the efficacy of API 571 principles. Non-destructive testing methodologies, digital twins, and remote monitoring platforms provide continuous insight into equipment health, enabling early detection of anomalies. Certified professionals leverage these innovations to supplement traditional inspection regimes, interpret complex datasets, and validate predictive models. By embracing technological augmentation, organizations enhance situational awareness, streamline maintenance workflows, and achieve superior operational reliability. The synergy of technical expertise and digital tools ensures that equipment management remains agile, precise, and adaptive.

Sustaining Long-Term Operational Excellence

Sustaining operational excellence demands a commitment to continuous learning and process refinement. API 571 certification embodies this ethos by emphasizing cyclical recertification, knowledge updates, and exposure to emerging best practices. Professionals remain attuned to evolving material technologies, environmental challenges, and industry standards, ensuring that equipment integrity strategies remain contemporary. Long-term excellence is predicated on the ability to synthesize accumulated experience, apply advanced methodologies, and anticipate operational contingencies. This dynamic stewardship fosters a resilient infrastructure capable of meeting the rigorous demands of the oil, gas, and petrochemical sectors.

The Imperative of Proactive Integrity Management

In the complex realm of hydrocarbon operations, equipment integrity is neither incidental nor static. It is a product of informed intervention, scientific insight, and disciplined oversight. API 571 certification equips professionals with the intellectual and practical arsenal necessary to navigate this complexity, transforming theoretical understanding into actionable strategies. Certified individuals anticipate degradation, mitigate risks, and contribute to a culture of safety, efficiency, and reliability. For organizations and practitioners alike, API 571 represents a commitment to excellence, ensuring that critical assets remain functional, resilient, and aligned with the highest operational standards.

The Imperative of Damage Mechanism Mastery in Hydrocarbon Industries

In the labyrinthine domains of hydrocarbon processing, the ramifications of mechanical or chemical failure transcend mere operational inconvenience. Unanticipated equipment degradation can catalyze cascading crises, disrupting production, jeopardizing safety, and imposing staggering financial burdens. Professionals versed in damage mechanisms navigate this perilous terrain with prescience, employing an intricate lexicon of metallurgical, chemical, and operational insights. Understanding the nuanced interplay between stressors, environmental conditions, and material susceptibilities transforms reactive maintenance into strategic stewardship. Mastery of these mechanisms is not a peripheral competency—it is a linchpin in safeguarding both infrastructure and human capital within oil, gas, and petrochemical enterprises.

API 571 Certification as a Keystone in Risk Mitigation

API 571 certification represents a formidable benchmark in the professional calibration of petrochemical operatives. This credential is not merely symbolic; it codifies an extensive corpus of knowledge surrounding failure phenomena, encompassing localized and generalized corrosion, fatigue-induced cracking, sulfide stress cracking, and other insidious forms of material deterioration. Beyond identification, the certification emphasizes mitigation: elucidating preventative methodologies that reduce susceptibility and prolong operational longevity. For organizations, the presence of certified personnel translates into a tangible bulwark against unplanned outages, fortifying both production continuity and asset integrity.

Understanding Corrosion Phenomena in Industrial Contexts

Corrosion, though superficially understood, manifests in forms that can confound even seasoned engineers. API 571 delves into the subtle gradations between uniform surface corrosion, pitting, crevice corrosion, and intergranular degradation, illuminating the microstructural vulnerabilities that exacerbate material attrition. Environmental parameters such as temperature oscillations, moisture content, chemical aggressors, and operational cycles are scrutinized for their synergistic impact on metallic substrates. Professionals trained in this discipline can anticipate loci of failure, prescribe material substitutions, and recommend protective strategies, including coatings, inhibitors, and cathodic protection, thereby transforming reactive repair into proactive management.

The Nexus Between Stress and Structural Degradation

Mechanical stress is an omnipresent specter in hydrocarbon facilities. API 571 emphasizes the correlation between cyclic loading, residual stress, and fatigue crack initiation. Professionals explore stress corrosion cracking, hydrogen embrittlement, and thermal fatigue, learning to decipher subtle indicators that presage catastrophic failure. The curriculum underscores metallurgical causality, illustrating how grain boundary weaknesses, inclusions, and phase heterogeneities contribute to stress susceptibility. By integrating theoretical comprehension with practical inspection techniques, certified individuals can design maintenance schedules that preempt failure, optimize resource allocation, and minimize unscheduled downtime.

Eligibility Criteria and the Pathway to Certification

Pursuing API 571 certification entails a confluence of education and experiential acumen. Candidates with advanced technical degrees may leverage academic exposure to compensate for limited field tenure, whereas individuals with extensive operational experience but minimal formal training must demonstrate sustained engagement with petrochemical systems. The eligibility framework ensures that certified professionals possess both cognitive dexterity and practical insight, equipping them to apply abstract principles within real-world contexts. This dual requirement safeguards the credibility of the certification, ensuring that only those capable of nuanced analysis and informed intervention attain recognition.

Preparation Methodologies for Proficient Practitioners

Success in the API 571 examination demands meticulous preparation. Candidates engage in immersive study of reference texts, case studies, and failure analyses, cultivating a mental repository of exemplars that inform judgment under operational duress. Training programs often incorporate scenario-based simulations, replicating environmental conditions and stress profiles encountered in refineries. This pedagogical approach bridges the chasm between theoretical understanding and empirical application, fostering cognitive agility and enhancing decision-making under uncertainty. Such preparation imbues professionals with the confidence to recognize precursors of degradation and to implement corrective strategies with precision.

Examination Rigor and the Evaluation of Operational Judgment

The certification exam itself is a crucible, assessing both analytical competence and applied discernment. Candidates must interpret complex data sets, identify incipient signs of equipment deterioration, and propose interventions grounded in metallurgical and chemical reasoning. Passing this evaluation signifies not merely rote memorization but operational sagacity—the capacity to synthesize diverse informational streams into coherent, actionable insights. The triennial recertification requirement ensures that professionals remain conversant with evolving materials, technologies, and regulatory standards, perpetuating a culture of continuous improvement and adaptive expertise.

Enhancing Organizational Value Through Certified Expertise

API 571-certified professionals confer profound value upon their organizations. Early detection of damage mechanisms reduces catastrophic failures, curtails repair expenditures, and extends equipment longevity. Certified practitioners optimize maintenance schedules, balancing operational continuity against cost efficiency. Their insight into inspection methodologies, material selection, and preventive interventions equips companies to preemptively address vulnerabilities, thereby stabilizing production outputs and bolstering financial resilience. Organizations benefit not only from technical acumen but also from the strategic foresight embedded in the decision-making processes of these certified operatives.

The Synergy of Theory and Practice in Training Programs

High-caliber training programs exemplify the integration of theoretical rigor with practical experience. Participants engage in laboratory simulations, failure analyses, and field inspections, confronting corrosion patterns, fatigue cracks, and stress anomalies firsthand. Such experiential immersion fortifies cognitive recognition with tactile familiarity, enabling professionals to internalize abstract principles and apply them in operational contexts. The iterative feedback inherent in these programs cultivates adaptive expertise, fostering an intuitive grasp of equipment behavior under complex stressors and enhancing the capacity for swift, informed intervention.

Career Advancement and Professional Recognition

API 571 certification catalyzes career progression. Certified individuals command professional respect, demonstrating mastery of specialized knowledge and operational competence. Such recognition often translates into elevated responsibilities, leadership opportunities, and strategic decision-making roles. From an organizational perspective, a workforce enriched with certified professionals reinforces operational resilience, supports compliance with safety and environmental standards, and enhances the collective capacity to manage industrial contingencies. The credential thus represents a symbiotic asset, advancing both individual careers and institutional robustness.

Strategic Foresight in Maintenance Planning

The ability to anticipate and preempt equipment failure is central to the API 571 framework. Professionals learn to integrate diagnostic data, operational history, and environmental variables into predictive maintenance schemas. By forecasting degradation trajectories and aligning interventions with operational priorities, organizations achieve optimal resource utilization. This strategic foresight mitigates unplanned downtime, maximizes asset efficiency, and fortifies safety protocols. The predictive lens also facilitates the prioritization of inspections, allocation of repair budgets, and selection of resilient materials, ensuring that operational decisions are informed by both empirical evidence and theoretical acumen.

Sustainability and Long-Term Operational Resilience

Sustainability in hydrocarbon industries is inextricably linked to equipment integrity. API 571-certified professionals contribute to environmental stewardship by preventing catastrophic failures that can precipitate spills, emissions, or hazardous exposure. Their expertise supports the deployment of durable materials, minimizes waste, and enhances process efficiency. Through judicious maintenance and early intervention, these professionals underpin long-term operational resilience, aligning organizational objectives with regulatory mandates and societal expectations. The intersection of technical mastery, ethical responsibility, and strategic planning positions certified individuals as pivotal actors in sustainable industrial practice.

Integrating Multidisciplinary Knowledge for Holistic Management

The complexity of petrochemical operations demands a multidisciplinary approach. Certified practitioners synthesize insights from metallurgy, chemistry, thermodynamics, and operational engineering to construct a comprehensive understanding of damage mechanisms. This integrative perspective enables nuanced risk assessment, informed material selection, and adaptive problem-solving. By leveraging diverse knowledge domains, professionals can navigate uncertainties, anticipate emergent failure modes, and implement interventions that are both scientifically grounded and operationally feasible. The holistic lens cultivated through API 571 training enhances both analytical depth and practical efficacy.

The Evolution of Industry Standards and Continuous Learning

The dynamic nature of petrochemical industries necessitates perpetual professional evolution. Materials, processes, and operational paradigms continuously advance, introducing novel vulnerabilities and opportunities. API 571 recertification ensures that practitioners remain conversant with these developments, fostering a culture of lifelong learning. Certified individuals not only maintain technical proficiency but also contribute to the refinement of best practices, the incorporation of innovative technologies, and the continuous improvement of safety and reliability protocols. In this manner, the certification transcends credentialing, embodying a commitment to professional excellence and adaptive competence.

Leveraging Certification for Strategic Organizational Advantage

Organizations that cultivate API 571-certified talent gain a strategic advantage in a competitive landscape. Enhanced operational reliability reduces unplanned expenditures, improves regulatory compliance, and bolsters reputation among stakeholders. The presence of certified professionals facilitates knowledge transfer, supports cross-functional collaboration, and enhances crisis responsiveness. By embedding expertise in damage mechanisms within the organizational fabric, companies achieve both tactical resilience and long-term strategic positioning, ensuring sustained productivity, safety, and profitability.

Conclusion

In summation, mastery of damage mechanisms is a cornerstone of operational excellence in the oil, gas, and petrochemical industries. API 571 certification equips professionals with the requisite knowledge, practical acumen, and strategic foresight to manage complex industrial systems with precision and confidence. Through rigorous preparation, multidisciplinary integration, and continuous professional development, certified practitioners enhance equipment longevity, operational safety, and organizational resilience. For both individuals and institutions, the certification represents not merely a credential but a transformative asset—anchoring technical mastery in practical application, fostering career advancement, and fortifying the enduring sustainability of industrial operations.