Certification: Cisco Industrial Networking Specialist

Certification Full Name: Cisco Industrial Networking Specialist

Certification Provider: Cisco

Exam Code: 200-401

Exam Name: Managing Industrial Networks with Cisco Networking Technologies (IMINS)

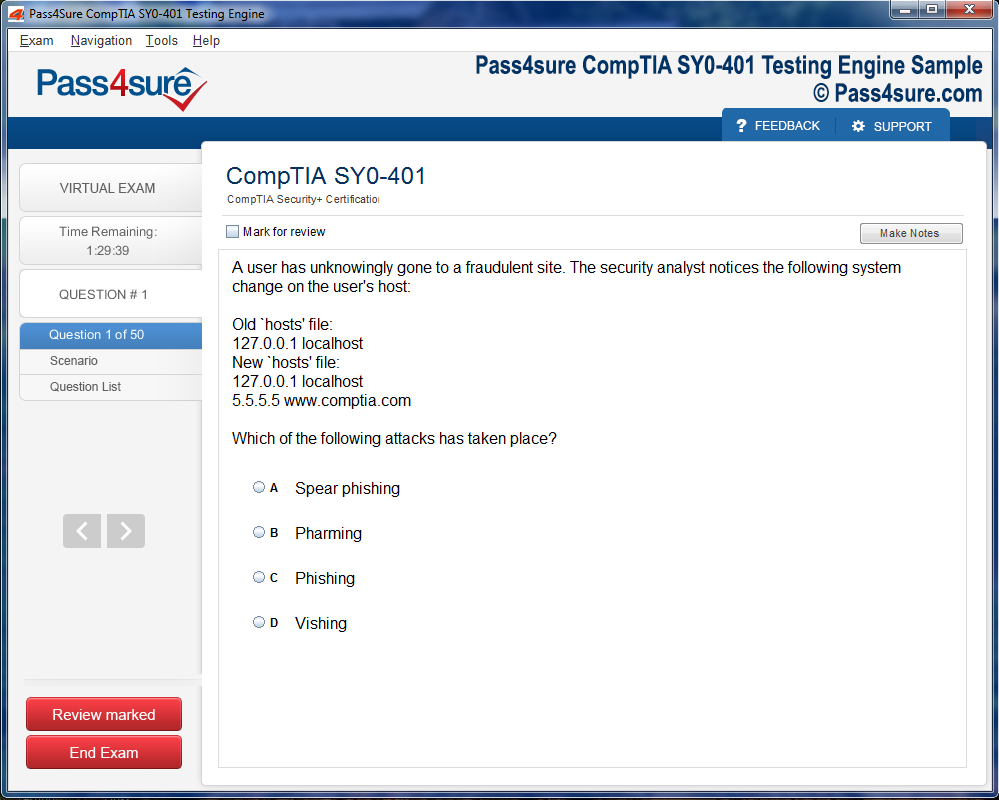

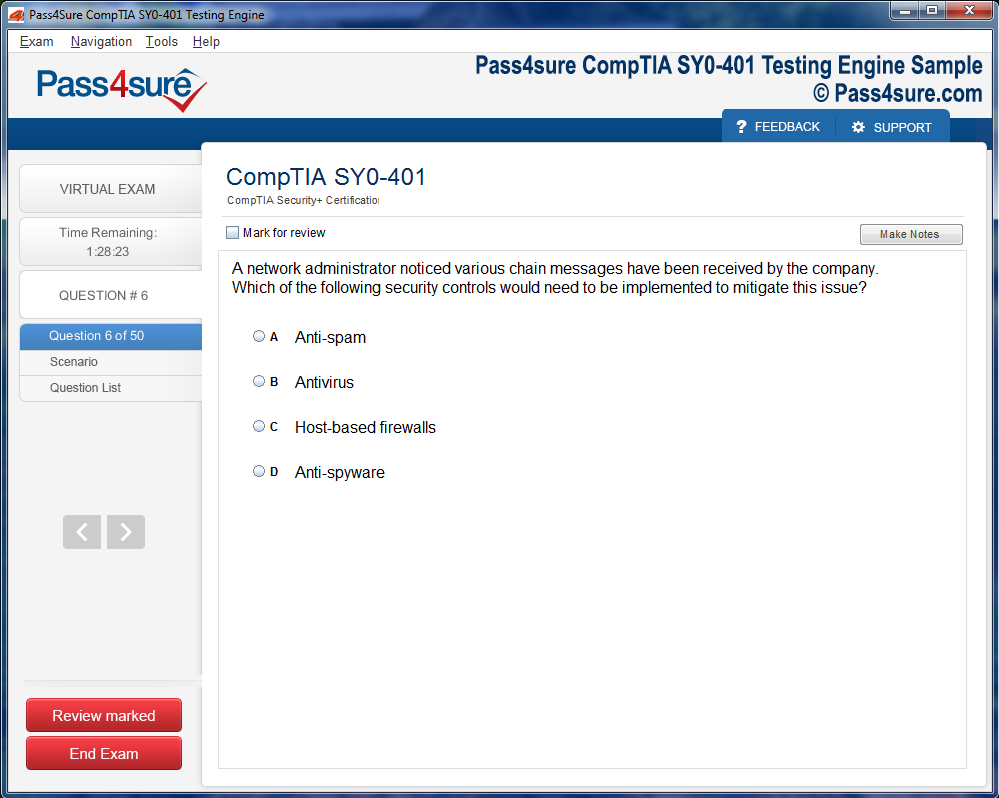

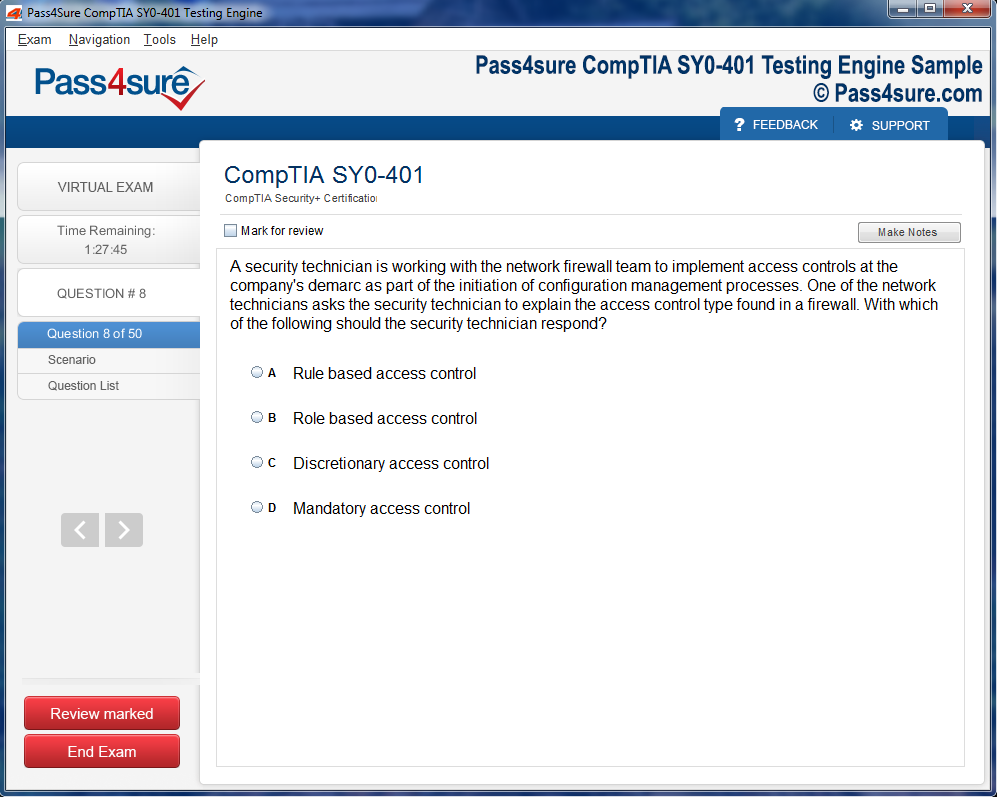

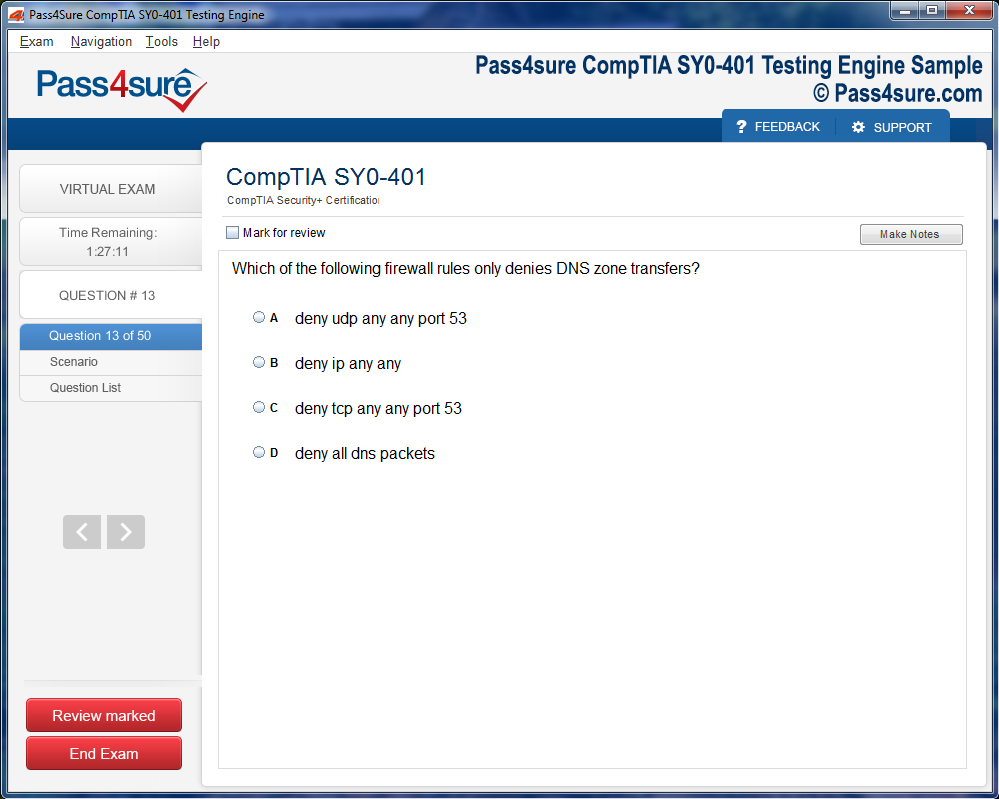

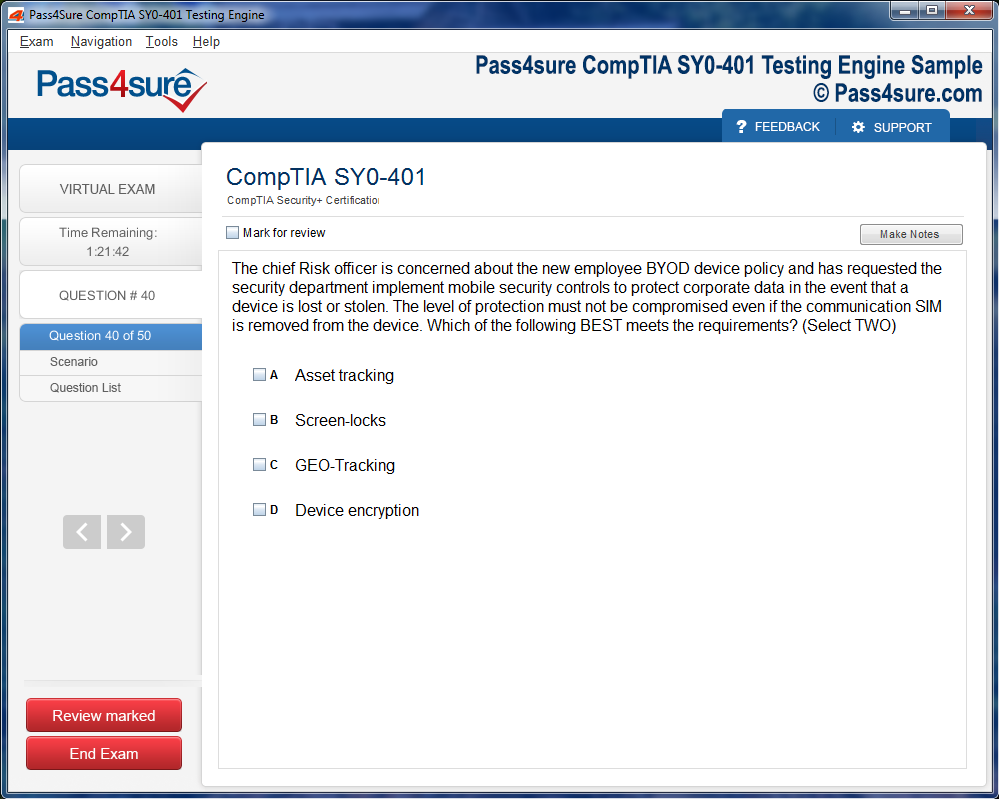

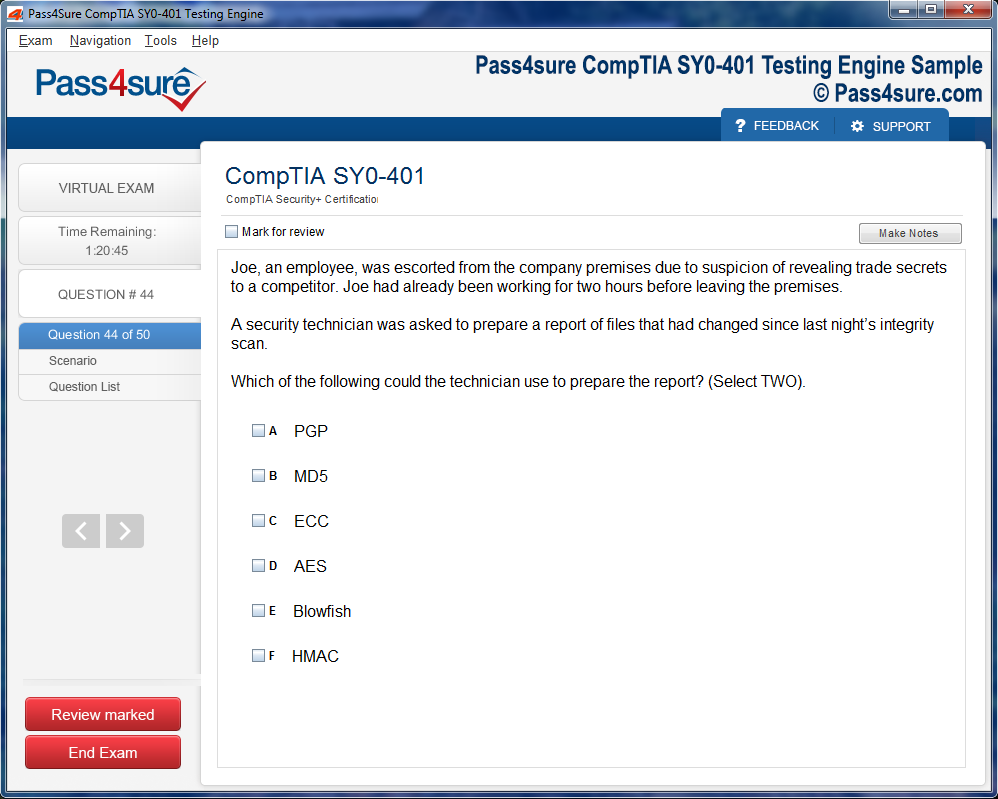

Product Screenshots

Cisco Industrial Networking Specialist Shaping Smart Manufacturing

Automation has fundamentally reshaped the way industries operate. The shift from manual labor to machine-driven processes has led to unprecedented increases in efficiency, precision, and consistency. Over the years, the progression of automation has evolved from simple mechanical processes to sophisticated, intelligent systems that can learn, adapt, and optimize production in real time. Today’s advanced automation is driven by an intricate network of interconnected devices, sensors, and artificial intelligence algorithms, which collectively enable machines to make decisions with minimal human intervention.

The integration of robotics into manufacturing processes is one of the most striking examples of this transformation. Robots, once seen as tools for specific, repetitive tasks, have evolved into complex systems capable of performing intricate assembly, quality control, and even creative design tasks. Powered by artificial intelligence, these robots can work alongside humans, learn from their environment, and make decisions based on real-time data. This collaborative approach, often referred to as "cobots" (collaborative robots), is revolutionizing industries ranging from automotive production to pharmaceuticals.

In addition to robotics, the rise of predictive maintenance has been another critical area of automation. With the help of machine learning and data analytics, manufacturing systems can now predict when a machine or system is likely to fail, allowing businesses to perform maintenance before a breakdown occurs. This not only reduces costly downtime but also extends the life of expensive machinery. The seamless communication between sensors, cloud platforms, and analytics tools enables manufacturers to monitor equipment health in real time and make proactive decisions, minimizing operational disruptions.

Furthermore, automation is unlocking opportunities for mass customization. Whereas traditional manufacturing focused on producing large volumes of identical products, modern systems can adjust quickly to produce highly personalized or bespoke items without a significant increase in production costs or time. With the help of connected networks, smart machines, and automated production lines, manufacturers can meet the increasingly diverse demands of consumers while maintaining cost-effectiveness and scalability.

The overarching theme of these advancements is that automation is no longer about replacing workers but augmenting human capabilities. By handling repetitive or hazardous tasks, machines allow workers to focus on more creative, strategic, and high-value activities. This shift in roles leads to a more dynamic workforce, where humans and machines collaborate to produce better outcomes. As industries embrace these automation technologies, they are not only improving productivity but also laying the foundation for the next generation of manufacturing.

The Impact of Industrial IoT on Productivity

The Industrial Internet of Things (IIoT) is an innovation that has had a profound impact on the productivity of manufacturing industries. IIoT refers to the network of physical devices embedded with sensors, software, and other technologies that connect and exchange data with other devices and systems across the industrial environment. This network allows for real-time data collection, monitoring, and analysis, creating a vast ecosystem where machines, sensors, and systems work in harmony.

One of the most significant benefits of IIoT is its ability to enhance operational visibility. In the past, manufacturers often struggled to gain comprehensive insights into their processes. The introduction of IIoT enables companies to gather vast amounts of data from various points in the production process, from the assembly line to the supply chain. This data is then analyzed to identify patterns, bottlenecks, inefficiencies, and opportunities for improvement. The result is a more informed decision-making process that can drive continuous improvement across the entire operation.

For example, IIoT allows manufacturers to track the performance of machinery and equipment in real time, providing insights into factors such as speed, temperature, pressure, and vibration. With this data, maintenance teams can address issues before they escalate into significant problems, reducing unplanned downtime and extending the life of equipment. Additionally, this data can be used to optimize production schedules, allocate resources more effectively, and ensure that products meet the highest quality standards.

Moreover, IIoT enables supply chain optimization by providing real-time tracking of materials and products as they move through the production process. This level of transparency helps manufacturers coordinate production and distribution more efficiently, reducing lead times and minimizing waste. By connecting every link in the supply chain, from suppliers to customers, IIoT allows manufacturers to respond more swiftly to changes in demand or supply disruptions.

In addition to improving efficiency, IIoT plays a crucial role in reducing energy consumption and promoting sustainability. By providing insights into energy usage at various stages of production, manufacturers can identify areas where energy consumption can be reduced without compromising output. This not only reduces operational costs but also helps businesses align with increasingly stringent environmental regulations and sustainability goals.

Overall, the Industrial Internet of Things represents a seismic shift in how manufacturing operations are managed and optimized. With its ability to provide real-time data, predictive insights, and actionable intelligence, IIoT is empowering manufacturers to increase productivity, reduce costs, and maintain a competitive edge in a fast-changing market.

Cybersecurity in the Age of Connected Manufacturing

As manufacturing systems become more interconnected and data-driven, cybersecurity has become a critical concern. In the past, industrial networks were isolated and relatively easy to secure. However, as more devices, machines, and systems are connected to the internet, the attack surface has expanded, creating new vulnerabilities. Cyberattacks targeting manufacturing environments can have devastating consequences, from production disruptions to intellectual property theft and even safety risks for employees.

To address these challenges, manufacturers must implement robust cybersecurity measures that protect both their physical and digital assets. One of the first steps in securing connected manufacturing environments is to assess and manage the risks associated with industrial IoT devices. These devices often lack the same level of security as traditional IT systems, making them attractive targets for cybercriminals. Therefore, it is essential to ensure that devices are equipped with appropriate security features, such as encryption, authentication, and access control.

Additionally, network segmentation is a key strategy for improving cybersecurity in industrial environments. By separating critical systems from less-sensitive networks, manufacturers can limit the spread of cyberattacks and contain potential breaches. This approach helps protect vital operational systems, such as production control and supply chain management, from being compromised in the event of an attack.

Another crucial aspect of cybersecurity in manufacturing is the implementation of real-time monitoring and threat detection systems. By continuously analyzing network traffic and machine data, manufacturers can identify suspicious activity and respond quickly to potential threats. These monitoring systems can detect anomalies that may indicate a cyberattack, such as unauthorized access attempts or unusual data flows, allowing security teams to take immediate action before damage is done.

Furthermore, educating employees about cybersecurity best practices is essential to minimizing human error and reducing the risk of successful attacks. Training staff to recognize phishing emails, avoid using weak passwords, and adhere to proper security protocols can go a long way in preventing cyber incidents. Given the increasing complexity of manufacturing systems, fostering a culture of cybersecurity awareness and vigilance throughout the organization is critical.

As cybersecurity continues to evolve, manufacturers must stay ahead of emerging threats by adopting cutting-edge security technologies and collaborating with industry partners to share knowledge and best practices. In this digital age, cybersecurity is not just an IT issue but a fundamental part of a manufacturing organization’s overall strategy for success.

Embracing Artificial Intelligence for Smarter Manufacturing

Artificial intelligence (AI) has emerged as a game-changer in the world of manufacturing. AI systems are capable of processing vast amounts of data, identifying patterns, and making decisions with a level of speed and accuracy that far exceeds human capabilities. By integrating AI into manufacturing operations, companies can enhance efficiency, reduce costs, and unlock new opportunities for innovation.

One of the most impactful applications of AI in manufacturing is in predictive analytics. With AI-powered algorithms, manufacturers can analyze historical data and real-time performance metrics to predict when a machine or system is likely to fail. This predictive capability enables businesses to perform maintenance before a failure occurs, preventing unplanned downtime and costly repairs. Moreover, AI can optimize production schedules, adjust for fluctuations in demand, and recommend process improvements based on data-driven insights.

In addition to predictive maintenance, AI is revolutionizing quality control in manufacturing. Traditionally, quality inspection involved manual checks and subjective assessments, which could lead to human error or inconsistencies. AI-powered vision systems, however, can inspect products at a level of precision that surpasses human capabilities. These systems use machine learning algorithms to detect defects, measure tolerances, and assess product quality in real time. By automating this process, manufacturers can improve product consistency and reduce waste, all while enhancing customer satisfaction.

AI is also enabling greater innovation in product design and development. Generative design, a form of AI-driven design software, allows engineers to input design parameters, such as material properties and performance requirements, and then generate a range of optimized designs that meet those specifications. This approach accelerates the design process and leads to the creation of more efficient, innovative, and cost-effective products.

Furthermore, AI is driving improvements in supply chain management by predicting demand fluctuations and optimizing inventory levels. Machine learning algorithms analyze data from various sources, including customer orders, market trends, and seasonal patterns, to forecast future demand with greater accuracy. This enables manufacturers to reduce inventory costs, streamline procurement, and ensure that they are always prepared to meet customer needs.

As AI continues to evolve, its role in manufacturing will only grow. By embracing AI technologies, manufacturers can stay ahead of the competition, improve their operational efficiency, and drive innovation across every facet of their business.

The Shift Toward Sustainability in Manufacturing

In recent years, sustainability has become a central focus for manufacturers across the globe. As the environmental impact of industrial production becomes more apparent, businesses are seeking ways to reduce their carbon footprint, minimize waste, and conserve resources. This shift toward sustainable manufacturing practices is not only driven by regulatory pressures but also by a growing consumer demand for environmentally friendly products.

One of the key areas where sustainability is having an impact is in energy consumption. Traditional manufacturing processes are often energy-intensive, with high levels of electricity, water, and raw materials being used in production. By adopting energy-efficient technologies and optimizing production processes, manufacturers can significantly reduce their environmental impact. Smart factories, which leverage IIoT and AI technologies, are enabling manufacturers to monitor and control energy consumption in real time, adjusting processes to minimize waste and lower energy use.

Moreover, manufacturers are increasingly turning to renewable energy sources, such as solar and wind power, to power their operations. By transitioning to clean energy, businesses can reduce their dependence on fossil fuels and lower their greenhouse gas emissions. Many companies are also investing in energy storage solutions, allowing them to store excess energy generated from renewable sources for use during peak demand periods.

Waste reduction is another critical component of sustainable manufacturing. By adopting circular economy principles, manufacturers can reduce, reuse, and recycle materials at every stage of production. For example, waste products from one part of the manufacturing process can be repurposed as raw materials for another, minimizing the need for new resources and reducing the amount of waste sent to landfills. Additionally, sustainable packaging solutions, such as biodegradable or recyclable materials, are being used to reduce the environmental impact of products after they leave the factory.

Sustainability is also influencing product design. Manufacturers are increasingly focusing on creating products that are more durable, repairable, and recyclable. This not only extends the life cycle of products but also reduces the environmental impact of production and disposal. By incorporating sustainable design principles, companies can meet the growing demand for environmentally conscious products and contribute to a more sustainable future.

As the demand for sustainable manufacturing practices continues to rise, companies must embrace innovation and collaboration to create more efficient, eco-friendly production systems. By integrating sustainability into every aspect of their operations, manufacturers can contribute to a greener future while driving long-term business success.

In the modern industrial landscape, the fusion of technology and operational processes has revolutionized how businesses approach efficiency and productivity. The rise of smart factories, the Internet of Things (IoT), and automation has spurred an unprecedented demand for high-performing networking infrastructure. As industries evolve to meet these demands, the need for robust, reliable, and secure networking solutions is critical. Cisco, a global leader in networking technology, provides innovative solutions designed to meet the unique challenges of industrial environments.

The complexities of modern industrial networks go far beyond simple data transmission. These networks are required to support a vast array of interconnected devices, from sensors and robotics to complex monitoring systems. As the volume of data generated by these devices grows, maintaining efficient, real-time communication and ensuring data security becomes paramount. Cisco Industrial Networking Specialist solutions are designed to address these concerns, offering businesses the tools they need to stay competitive in an increasingly digital world.

Cisco’s approach to Industrial Networking Specialist goes beyond simply providing infrastructure; it integrates the latest advancements in technology to optimize performance, enhance security, and improve scalability. By leveraging Cisco’s solutions, industries can better manage their operations, reduce costs, and build a foundation for future growth. In this article, we will explore the key benefits of Cisco networking solutions in industrial environments, emphasizing their role in improving operational efficiency, security, and scalability.

Real-Time Communication and Data Management

A core requirement in industrial environments is the ability to transmit data in real time. As the number of connected devices in manufacturing facilities increases, the need for seamless communication becomes even more pressing. Cisco’s networking solutions are designed to facilitate high-speed communication, ensuring that data can be exchanged instantaneously between devices, systems, and operators.

For instance, on a factory floor, sensors monitoring the health of machinery must relay information about performance, temperature, and other critical factors to central systems that control the operation of production lines. In the absence of real-time communication, delays in data transmission could lead to machine malfunctions, production delays, or even catastrophic failures. Cisco’s industrial networks ensure that such delays are minimized, providing manufacturers with the tools they need to maintain smooth operations.

Moreover, Cisco’s solutions include advanced data management capabilities. With the rise of big data in industrial settings, managing the massive amounts of data generated by devices and systems becomes a significant challenge. Cisco offers intelligent data routing and processing tools that enable businesses to efficiently manage this influx of information. The data is processed and analyzed in real time, enabling timely decision-making and predictive actions that can improve overall operational efficiency.

Through Cisco’s robust network solutions, businesses gain the ability to monitor and control every aspect of their operations in real-time, significantly improving their ability to respond to issues as they arise. This level of control is indispensable for businesses that seek to maintain a competitive edge in today’s fast-paced industrial world.

Enhanced Security Features for Industrial Networks

The security of industrial networks is a growing concern in today’s interconnected world. As more devices are integrated into industrial environments, the risk of cyberattacks increases. The consequences of such attacks can be devastating, ranging from costly downtime to irreparable damage to a company’s reputation. Cisco recognizes the importance of robust security and has integrated advanced security features into its Cisco Industrial Networking Specialist solutions to mitigate these risks.

One of the primary concerns in industrial settings is the protection of sensitive data. Manufacturing facilities generate enormous amounts of information, including proprietary designs, production schedules, and operational data. Without the proper security measures in place, this data is vulnerable to cyber threats. Cisco’s solutions include encryption protocols, intrusion detection systems, and secure access controls that protect this valuable data from unauthorized access or tampering.

In addition to protecting data, Cisco’s networking solutions also offer protection against network intrusions. With the rise of IoT devices, industrial networks are more vulnerable than ever to attacks. Cisco’s industrial networks are designed to provide real-time monitoring and threat detection, ensuring that any suspicious activity is identified and neutralized before it can cause significant harm. These features are essential for industries that rely on continuous, uninterrupted operations.

By proactively addressing cybersecurity risks, Cisco helps industrial businesses safeguard their operations against a wide range of threats. This level of security not only protects valuable data but also ensures that manufacturing processes remain free from interruptions caused by cyberattacks.

Scalability and Flexibility for Growing Industrial Networks

As industries grow and evolve, so too must their network infrastructures. Cisco Industrial Networking Specialist solutions are designed to be scalable, allowing businesses to expand their networks as their needs change. Whether a company is adding new devices, integrating additional production lines, or incorporating advanced technologies such as artificial intelligence and machine learning, Cisco’s flexible networking solutions can accommodate these changes with minimal disruption.

One of the most significant challenges faced by growing industries is the ability to scale their network infrastructures without causing delays or disruptions to ongoing operations. Traditional networking solutions often require significant overhauls or complicated upgrades to accommodate new devices or technologies. Cisco’s approach is different. Their solutions are built with scalability in mind, allowing businesses to add new devices, systems, or sensors without the need for extensive reconfiguration.

The flexibility offered by Cisco’s networks also extends to the types of devices that can be integrated. With the rise of IoT devices, industrial networks must be capable of supporting a wide variety of devices from different manufacturers. Cisco’s solutions are designed to be device-agnostic, allowing businesses to integrate a broad range of devices into their networks without compatibility issues. This flexibility is essential for businesses that need to stay agile and adapt to the rapid pace of technological advancement.

By providing scalable and flexible solutions, Cisco helps businesses future-proof their network infrastructure. This ensures that they can continue to expand and innovate without being hindered by limitations in their networking technology.

Cost Efficiency through Optimized Operations

Operational efficiency is a top priority for manufacturers and other industrial businesses. Cisco’s networking solutions play a key role in driving efficiency by enabling better connectivity, automation, and data management. By optimizing network performance, businesses can reduce operational costs, improve productivity, and enhance the overall quality of their products.

One of the primary ways in which Cisco’s networking solutions contribute to cost efficiency is through the automation of routine tasks. In industrial environments, manual monitoring and intervention can be time-consuming and costly. Cisco’s solutions allow for the automation of many processes, such as predictive maintenance, real-time performance monitoring, and system optimization. This reduces the need for manual labor, minimizes human error, and ensures that systems are operating at peak efficiency.

Additionally, by improving the flow of information across the network, Cisco’s solutions allow for better coordination between different departments and systems. For example, inventory management systems can be integrated with production lines, ensuring that raw materials are always available when needed. This level of coordination helps to reduce downtime and prevent delays in the production process, ultimately leading to cost savings and increased profitability.

Another important aspect of cost efficiency is the ability to monitor and optimize the performance of industrial equipment. With Cisco’s solutions, businesses can track the health of machines and identify potential issues before they lead to expensive breakdowns. This predictive maintenance approach helps to extend the lifespan of equipment and reduce the need for costly repairs.

Overall, Cisco’s networking solutions provide businesses with the tools they need to streamline their operations, reduce costs, and improve the quality of their products.

Seamless Integration with Industrial IoT

The integration of IoT devices into industrial environments has transformed how businesses collect and analyze data. From sensors that monitor machine performance to devices that track inventory and supply chain logistics, IoT technology has become an integral part of modern manufacturing. Cisco’s networking solutions are specifically designed to support the integration of IoT devices, providing businesses with the infrastructure needed to manage and leverage this data.

Cisco’s industrial IoT solutions are designed to handle the vast amounts of data generated by connected devices. These solutions enable businesses to collect, analyze, and act on data in real time, allowing for faster decision-making and more efficient operations. By integrating IoT technology with Cisco’s networking solutions, businesses can improve the monitoring of production lines, optimize supply chain management, and gain valuable insights into the performance of their equipment.

Moreover, Cisco’s solutions provide the scalability necessary to support the rapid growth of IoT networks. As new devices are added to the network, Cisco’s infrastructure can seamlessly accommodate the increased demand for bandwidth and data processing power. This ensures that businesses can continue to integrate new IoT devices without worrying about network congestion or performance degradation.

The ability to seamlessly integrate IoT devices into industrial networks is one of the key advantages of Cisco’s solutions. By enabling businesses to harness the power of IoT, Cisco helps companies unlock new levels of operational efficiency, productivity, and innovation.

Future-Proofing Industrial Networks

As technology continues to evolve, industries must be prepared for the changes that lie ahead. Cisco Industrial Networking Specialist solutions are designed with future growth in mind, ensuring that businesses are ready to embrace the next wave of technological advancements. Whether it’s the adoption of 5G networks, the proliferation of artificial intelligence, or the continued expansion of IoT, Cisco’s solutions provide the foundation needed to support these emerging technologies.

One of the key ways in which Cisco future-proofs industrial networks is through its commitment to innovation. Cisco regularly updates its networking solutions to incorporate the latest technologies and standards, ensuring that businesses can take advantage of new developments as they emerge. This ongoing commitment to innovation means that businesses can invest in Cisco’s solutions with confidence, knowing that their networks will remain relevant and effective for years to come.

In addition, Cisco’s networks are designed to be highly adaptable, allowing businesses to integrate new technologies as needed. Whether it’s upgrading to faster network speeds or incorporating advanced analytics tools, Cisco’s solutions can easily accommodate these changes without requiring a complete overhaul of the existing infrastructure.

By future-proofing industrial networks, Cisco helps businesses stay ahead of the curve and position themselves for long-term success in an ever-changing technological landscape.

The Rise of the Industrial Internet of Things (IIoT)

In the modern era, industrial operations are undergoing a profound transformation, powered by the Industrial Internet of Things (IIoT). The introduction of IIoT is reshaping how businesses approach manufacturing, resource management, and productivity. As a result, industries are embracing the opportunities provided by connected devices and data-driven insights. However, to fully harness the power of IIoT, organizations must navigate several challenges, including system integration, data management, and network security.

IIoT refers to the use of smart sensors, machines, and devices in industrial environments to collect, exchange, and analyze data in real time. This growing network of devices can monitor everything from machinery performance to environmental factors, enabling industries to optimize their processes. The data generated from these devices can offer invaluable insights into production efficiency, inventory management, and even predictive maintenance. By integrating this data into a company’s operations, businesses can improve their decision-making processes, minimize downtime, and enhance overall productivity.

This level of connectivity, however, requires reliable and efficient networks that can support the data traffic generated by these smart devices. The integration of IIoT into industrial settings is only successful when these devices can communicate seamlessly with enterprise networks. The key to unlocking the full potential of IIoT lies in robust network architecture that supports not only connectivity but also the high-speed transmission of data. This is where leading networking solutions, such as those provided by Cisco, come into play.

Cisco’s Role in IIoT Connectivity

As industries increasingly rely on IIoT devices to drive their operations, it’s essential to have a network infrastructure capable of supporting the massive data flow these devices generate. Cisco, a global leader in networking solutions, has made significant strides in integrating IIoT devices with industrial networks. With billions of connected devices expected to populate industrial environments in the coming years, the need for reliable, scalable, and high-performance network solutions has never been more critical. Cisco's networking technologies are designed to address this challenge by providing a seamless and secure framework for connecting IIoT devices.

Cisco's solutions are built to handle the complexities of modern industrial networks. These solutions ensure that IIoT devices can communicate in real time, minimizing latency and improving operational efficiency. In industries like manufacturing, where every second counts, ensuring that data from devices such as sensors, actuators, and machines is delivered with minimal delay is essential. Cisco’s networking equipment, including routers, switches, and wireless systems, are designed to offer the performance and reliability necessary for such demanding applications.

Cisco’s integration capabilities go beyond just connecting devices. The company provides tools and technologies that allow for the management and optimization of these networks. This enables businesses to create customized solutions tailored to their unique operational needs. Whether it’s monitoring equipment performance, tracking inventory, or gathering data on environmental conditions, Cisco’s network solutions ensure that IIoT devices remain integrated into the larger production ecosystem.

Enhancing Real-Time Data Processing

One of the primary advantages of IIoT in industrial settings is its ability to provide real-time data. By continuously collecting data from sensors and other connected devices, businesses can gain a deeper understanding of their operations. This enables them to make immediate adjustments to optimize performance and reduce waste. However, the real-time nature of IIoT also presents significant challenges in terms of data processing and transmission.

Without proper infrastructure, the data generated by IIoT devices can become a bottleneck, slowing down operations rather than enhancing them. Cisco addresses this challenge by providing high-performance networking solutions capable of handling large volumes of data without sacrificing speed or reliability. Cisco's networks are designed to support low-latency communications, ensuring that data from IIoT devices is processed and transmitted in real time. This allows businesses to act on insights as soon as they become available, rather than waiting for delays in data processing.

Moreover, Cisco’s networking solutions allow businesses to implement edge computing, where data is processed closer to the source rather than being sent to a centralized cloud server. Edge computing helps reduce latency by minimizing the distance data must travel, allowing for faster decision-making. This is particularly important in time-sensitive industrial applications where delays in data processing could result in costly downtime or inefficiencies.

Securing Industrial Networks

As industrial networks become increasingly connected, cybersecurity becomes a growing concern. IIoT devices are often viewed as potential entry points for cyberattacks, making the protection of industrial networks a top priority. Cybersecurity threats to industrial networks can lead to catastrophic consequences, including data breaches, equipment damage, and even safety risks for employees.

Cisco’s approach to securing IIoT networks is comprehensive and multi-layered. Cisco integrates advanced security features into its networking solutions, including encryption, authentication, and intrusion detection systems, to protect data and devices from potential cyber threats. These security measures are essential for safeguarding the integrity of the data being transmitted across the network. By implementing these technologies, Cisco helps ensure that IIoT devices remain protected from malicious actors seeking to compromise industrial systems.

The cybersecurity challenges in IIoT are unique because they involve not only traditional IT devices but also a wide range of industrial machinery, sensors, and control systems. Cisco’s solutions take these unique requirements into account, providing security measures that are tailored to the specific needs of industrial networks. This proactive approach to cybersecurity helps businesses avoid costly disruptions and maintain the reliability of their IIoT systems.

Scalability and Flexibility in IIoT Networks

Another critical factor for the success of IIoT in industrial environments is scalability. As industries grow and their operations become more complex, the networks supporting IIoT devices must be able to scale accordingly. Cisco’s networking solutions are designed with scalability in mind, ensuring that industrial networks can expand to accommodate new devices, applications, and data sources without compromising performance.

Cisco’s solutions provide businesses with the flexibility to scale their networks as needed, allowing for the easy addition of new devices and infrastructure. This scalability is particularly important in the context of IIoT, where the number of connected devices is expected to increase exponentially in the coming years. Cisco’s network architecture allows businesses to start small and gradually expand their IIoT systems as their needs evolve.

In addition to scalability, Cisco’s solutions are also highly adaptable, allowing businesses to customize their networks to suit specific operational requirements. Whether it’s integrating new devices, supporting different types of communication protocols, or ensuring compliance with industry-specific standards, Cisco’s networking technologies provide the flexibility necessary to meet the diverse needs of modern industrial environments.

Optimizing Operational Efficiency with Cisco Solutions

The integration of IIoT devices into industrial networks has the potential to significantly enhance operational efficiency. With real-time data and advanced analytics, businesses can identify inefficiencies, predict equipment failures, and optimize resource utilization. However, to fully realize these benefits, companies need a reliable network infrastructure that can support the high data demands of IIoT applications.

Cisco’s solutions provide businesses with the tools they need to optimize their operations and make data-driven decisions. With high-performance networking technologies, businesses can ensure that their IIoT devices are always connected and functioning at peak efficiency. Additionally, Cisco’s network management tools allow businesses to monitor and control their networks, providing real-time visibility into the performance of IIoT devices and identifying areas for improvement.

By providing a seamless and secure framework for IIoT devices, Cisco helps businesses unlock the full potential of their industrial networks. From predictive maintenance to real-time inventory tracking, Cisco’s solutions enable businesses to take full advantage of the data generated by their IIoT systems. As a result, organizations can reduce downtime, improve resource management, and increase overall productivity.

The Future of IIoT with Cisco Networking Solutions

As the IIoT ecosystem continues to evolve, so too will the technologies and solutions required to support it. Cisco is committed to driving innovation in the field of Cisco Industrial Networking Specialist, with a focus on providing the infrastructure necessary to support the growing demands of IIoT. With advancements in artificial intelligence (AI), machine learning (ML), and 5G connectivity, the future of IIoT looks even more promising.

Cisco’s ongoing research and development efforts are aimed at creating more intelligent and automated industrial networks. By integrating AI and ML capabilities into its networking solutions, Cisco is enabling businesses to not only collect and transmit data but also analyze and act on it in real time. This level of automation will further enhance operational efficiency and reduce the need for manual intervention.

Additionally, the rollout of 5G networks will provide even faster and more reliable connectivity for IIoT devices. Cisco’s solutions are designed to take full advantage of these advancements, ensuring that industries can continue to scale their IIoT networks without compromising performance. As the demand for more connected devices and smarter manufacturing processes grows, Cisco is well-positioned to remain at the forefront of the IIoT revolution.

By continuing to innovate and adapt to the changing needs of industries, Cisco will help businesses unlock the full potential of IIoT and pave the way for the next generation of industrial operations.

Embracing the Future of Smart Manufacturing Networks

Smart manufacturing, powered by advanced Cisco Industrial Networking Specialists, is transforming industries worldwide. It is a paradigm shift that integrates cutting-edge technologies, automated processes, and connected devices to create highly efficient and adaptive production environments. However, for manufacturers to fully leverage the potential of smart manufacturing, they must overcome numerous challenges. These include managing device diversity, ensuring robust cybersecurity, maintaining network reliability, and scaling systems to meet growing demands. Addressing these obstacles is vital for businesses to create seamless, intelligent operations that are capable of achieving significant improvements in productivity, quality, and operational efficiency.

Smart manufacturing networks hinge on the ability of various interconnected devices to communicate, collaborate, and operate in harmony. This involves the integration of legacy systems with modern solutions, a process that often presents significant hurdles. Ensuring seamless data exchange across disparate systems requires a robust network that can support diverse communication protocols and accommodate the needs of various technologies, all while maintaining a high level of security and reliability. The evolution of Cisco Industrial Networking Specialist technologies has made it possible to create more integrated and intelligent manufacturing environments, where systems can adapt in real-time to fluctuations in demand and production conditions. The role of networking solutions in this transformation cannot be overstated, as they provide the foundation for everything from data collection and analysis to real-time process optimization.

Navigating Device Complexity in Smart Factories

One of the most challenging aspects of smart manufacturing networks is managing the integration of diverse devices and systems from multiple vendors. In a typical modern factory, equipment and devices may come from different manufacturers and support various communication protocols. These devices may not be inherently compatible with one another, making it challenging to establish a unified network where all systems can seamlessly share data and interact with each other.

In smart factories, devices range from industrial machines and sensors to robots and other automated systems, all of which play a role in ensuring operational efficiency. However, to make the most of these technologies, manufacturers must overcome the complexity of connecting disparate systems and ensuring they work together harmoniously. Without the right infrastructure, integration can become cumbersome, resulting in delays, inefficiencies, and even failures in the system.

To tackle this issue, smart manufacturing solutions need to support multiple communication protocols and standards, offering manufacturers the flexibility to integrate new technologies while preserving the functionality of their existing systems. Unified platforms that simplify integration are key to ensuring that diverse devices, regardless of their origin or communication method, can interact in a cohesive manner. These platforms offer the ability to manage and control all devices from a single interface, ensuring that the production process runs smoothly and in real-time.

Securing the Smart Manufacturing Ecosystem

As smart manufacturing networks grow in complexity, so too do the cybersecurity risks. The more connected the systems, the greater the exposure to potential threats. In industrial settings, the stakes are even higher, as cybersecurity breaches can lead to downtime, data loss, and even physical damage to equipment. As manufacturers become more reliant on interconnected devices, they need to ensure their networks are secure and protected from cyberattacks.

Cybersecurity in the context of smart manufacturing involves more than just protecting data. It extends to securing the network infrastructure itself, safeguarding the devices that are part of the production process, and ensuring that all connected systems are resistant to unauthorized access. Traditional IT security approaches may not be sufficient in industrial environments, where the requirements for real-time data processing, low latency, and constant availability are critical.

Advanced cybersecurity solutions, such as network segmentation, encryption, and threat intelligence, are essential to mitigate risks. Network segmentation involves creating isolated network zones to limit access to critical systems and sensitive data, reducing the potential attack surface for malicious actors. Encryption ensures that any data being exchanged across the network is protected from unauthorized interception, even if a breach occurs. Threat intelligence tools help manufacturers stay ahead of evolving cybersecurity threats by providing real-time insights into potential vulnerabilities, allowing them to proactively address risks before they result in damage.

Moreover, ensuring cybersecurity in a smart manufacturing environment requires ongoing monitoring and maintenance. Security protocols must evolve in response to new vulnerabilities and attack vectors, requiring a commitment to continuous improvement and vigilance.

Ensuring Network Reliability in Industrial Environments

In industrial settings, network reliability is paramount. A disruption in network connectivity can halt production, leading to costly downtime, lost productivity, and significant financial losses. Unlike traditional office environments where brief disruptions may be tolerated, manufacturing environments operate under tight timelines, and even a short interruption in connectivity can lead to serious consequences.

To ensure uninterrupted operations, smart manufacturing networks need to be highly resilient and capable of recovering quickly from failures. This involves designing networks with built-in redundancy and fault tolerance, so that the system can continue to function even if a part of the network goes down. Redundancy refers to the duplication of critical components, such as network links and power supplies, so that if one fails, another can take over without disrupting operations.

Intelligent routing is another key feature that helps maintain network reliability. By dynamically adjusting the paths that data takes through the network, intelligent routing ensures that data continues to flow even when certain routes are unavailable. This adaptability is particularly crucial in environments where real-time data is critical for process optimization and decision-making.

The combination of redundancy and intelligent routing allows smart factories to maintain high levels of uptime and reliability, even in the face of hardware failures or other network issues. This resilience is a key component in achieving the continuous, high-quality production that defines successful smart manufacturing environments.

Adapting to Growth: Scalability in Smart Manufacturing Networks

As businesses grow, so do their technological needs. The ability to scale manufacturing networks to meet the increasing demands of production is a critical factor for long-term success. Whether it's adding more devices, incorporating new technologies like artificial intelligence (AI) and machine learning, or expanding to new locations, a smart manufacturing network must be able to adapt to the evolving requirements of the business.

Scalability is not just about adding more devices to the network; it also involves ensuring that the network can handle the increased volume of data generated by additional devices, sensors, and processes. Smart manufacturing systems must be capable of expanding seamlessly without compromising on performance or security.

To achieve this, manufacturers need flexible networking solutions that can grow with their needs. Cisco Industrial Networking Specialist solutions, for example, are designed with scalability in mind, allowing businesses to easily add new devices and expand their network infrastructure as needed. Whether it's incorporating new automation systems or integrating advanced analytics capabilities, a scalable network provides the flexibility to support future innovations.

In addition to scalability, manufacturers must also consider the future of technology in their planning. The rise of AI, robotics, and other advanced technologies is shaping the future of manufacturing. As these technologies become more prevalent, networks must be prepared to accommodate the data-intensive requirements of these systems. Investing in scalable infrastructure today ensures that manufacturers can continue to innovate and grow without the need for costly overhauls down the road.

The Role of Artificial Intelligence in Smart Manufacturing Networks

Artificial intelligence (AI) has become an integral part of the smart manufacturing ecosystem, offering a wealth of opportunities for improving efficiency, quality, and decision-making. AI algorithms can process vast amounts of data in real time, identifying patterns, optimizing processes, and even predicting maintenance needs before failures occur. This level of insight and automation is transforming manufacturing operations, enabling businesses to produce high-quality products more efficiently and at lower costs.

AI plays a critical role in the management of smart manufacturing networks. By analyzing data from sensors, machines, and other connected devices, AI can identify inefficiencies, detect anomalies, and suggest improvements. For example, AI can monitor production lines in real time, adjusting parameters such as speed and temperature to optimize performance based on current conditions. It can also predict when a machine is likely to fail, allowing maintenance teams to address potential issues before they result in costly downtime.

The integration of AI into smart manufacturing networks also extends to the optimization of supply chains. AI-powered systems can track inventory levels, forecast demand, and automatically adjust production schedules to meet changing market conditions. This ability to adapt to fluctuating demands is crucial for businesses looking to stay competitive in an increasingly fast-paced and dynamic market.

The Road Ahead for Smart Manufacturing Networks

As smart manufacturing networks continue to evolve, the challenges and opportunities presented by this technology will only grow. Manufacturers that are able to navigate the complexities of device integration, cybersecurity, network reliability, and scalability will be well-positioned to reap the rewards of smarter, more efficient operations.

The future of smart manufacturing is undoubtedly exciting, with advancements in AI, automation, and data analytics driving innovation across industries. As businesses continue to adopt these technologies, the importance of robust Cisco Industrial Networking Specialist solutions will only increase. The ability to seamlessly connect, manage, and secure devices, while ensuring the reliability and scalability of networks, will be crucial for manufacturers looking to stay ahead in an increasingly competitive global market.

Embracing Sustainability and Resilience with Advanced Network Solutions

As industries rapidly transition towards digital transformation, the convergence of sustainability and resilience has become a pivotal focus for organizations seeking to future-proof their operations. This transformation is not limited to adopting new technologies but extends to how these technologies are integrated to enhance long-term operational efficiency while reducing the environmental footprint. In particular, the evolution of smart manufacturing has opened up vast opportunities to leverage robust networking infrastructures to ensure sustainability and resilience in industrial settings. Companies increasingly recognize that having a flexible, secure, and sustainable network infrastructure is essential for maintaining competitive advantage in an ever-evolving market.

The concept of sustainability in manufacturing today goes far beyond the simple reduction of emissions or energy consumption. It encapsulates the idea of creating systems that are designed to thrive in the long term—systems that are efficient, environmentally responsible, and capable of adapting to a wide range of challenges. At the heart of this transformation lies the role of cutting-edge network technologies that can help industries achieve these ambitious goals.

In this regard, advanced network solutions, especially those that integrate Internet of Things (IoT) devices and artificial intelligence (AI), are proving to be indispensable. Through real-time data monitoring, predictive analytics, and intelligent automation, manufacturers can track and optimize energy use, improve resource efficiency, and minimize waste across every stage of production. Networked sensors and devices allow organizations to capture granular insights about their operational processes, enabling them to take proactive actions that reduce their environmental impact. Furthermore, the increasing sophistication of smart networks facilitates the collection and analysis of data that drives better decision-making, ultimately leading to both economic and environmental benefits.

The Role of Networking in Advancing Smart Manufacturing Systems

Smart manufacturing is fundamentally changing how industries approach production, creating smarter, more efficient systems that use interconnected devices to gather, share, and process data. One of the most profound shifts enabled by these advanced networks is the ability to track every aspect of production in real-time, making it possible to predict issues before they occur and optimize processes for both cost-effectiveness and sustainability.

At its core, smart manufacturing relies on a network infrastructure that supports high levels of connectivity. Cisco Industrial Networking Specialist solutions, for instance, provide robust, scalable networks that can handle the large volumes of data generated by IoT sensors, automated machinery, and other smart systems. This infrastructure enables manufacturers to monitor the entire lifecycle of a product, from raw material acquisition through to production and end-of-life disposal. By providing clear visibility into every stage of production, companies can identify inefficiencies, detect faults, and reduce energy consumption, all of which contribute to a greener, more sustainable operation.

In addition to energy optimization, smart networks also enhance supply chain transparency. Manufacturers are increasingly adopting a more holistic approach to supply chain management, integrating real-time data from suppliers, logistics providers, and even consumers. This connectivity allows for precise tracking of goods, helping organizations reduce the need for excess inventory, improve demand forecasting, and minimize unnecessary shipping—all of which contribute to a reduction in carbon emissions. With the ability to streamline logistics and optimize transportation routes, smart manufacturing networks are playing an essential role in minimizing the environmental impact of industrial operations.

Resilience in the Face of Global Challenges

Resilience has become one of the most vital aspects of modern industrial networks. Manufacturers today face a range of unpredictable challenges, from natural disasters to global supply chain disruptions to the increasing threat of cyberattacks. In this context, the ability to maintain continuity in operations while responding to unforeseen events is critical to sustaining business operations.

The resilience offered by advanced network solutions cannot be overstated. For example, Cisco’s networking infrastructure is designed with multiple layers of security to ensure that critical systems remain protected against both external and internal threats. This level of security allows manufacturers to maintain operations even when faced with cyber disruptions, reducing the likelihood of costly downtime. Furthermore, the network’s built-in redundancy features provide manufacturers with the flexibility to recover quickly from network failures, minimizing the impact on production schedules and overall business performance.

On a broader scale, resilience in the context of smart manufacturing is also about agility—the capacity to adapt to sudden changes in market conditions, consumer demands, or technological advancements. By leveraging flexible and scalable network solutions, manufacturers can more easily reconfigure production lines, adjust workflows, and scale operations up or down to meet new demands. This level of adaptability is becoming increasingly important in a world characterized by rapid technological change and economic uncertainty.

In addition to ensuring operational continuity during crises, resilient networks also support more effective collaboration between manufacturers and external partners. Whether it’s coordinating with suppliers in distant regions or collaborating with research and development teams, resilient networks enable seamless communication and data exchange, ensuring that businesses can continue to innovate and grow even in challenging times.

The Interplay Between Sustainability and Resilience

While sustainability and resilience are often treated as separate goals, they are inextricably linked. A sustainable manufacturing operation is one that is not only efficient but also capable of withstanding disruptions. The same principles that drive sustainability—resource optimization, energy efficiency, and waste reduction—also contribute to resilience by ensuring that businesses can maintain production even when faced with unexpected challenges.

Advanced networking solutions, such as those offered by Cisco, enable manufacturers to strike a balance between these two objectives. By integrating IoT sensors and real-time data analytics into their network infrastructure, manufacturers can monitor energy usage, resource consumption, and machinery performance continuously. This level of insight enables them to identify inefficiencies, predict maintenance needs, and optimize production schedules, all of which contribute to both sustainability and operational resilience.

Moreover, the increasing adoption of circular economy principles within manufacturing processes is another area where sustainability and resilience intersect. Through smart networks, manufacturers can track the entire lifecycle of a product, ensuring that materials are reused or recycled wherever possible. By enabling more efficient resource management, these networks help reduce waste and conserve raw materials, while also ensuring that production remains uninterrupted by supply chain fluctuations or material shortages.

Future-Proofing Industrial Networks for Long-Term Success

One of the key benefits of investing in advanced network solutions is the ability to future-proof industrial operations. As industries continue to evolve, so too must the technologies that power them. Cisco’s focus on creating flexible, scalable, and secure networking solutions ensures that manufacturers can adapt to future technological developments without the need for a complete overhaul of their infrastructure.

For example, the integration of artificial intelligence and machine learning into industrial networks is a trend that is expected to grow in the coming years. These technologies can help manufacturers optimize production schedules, predict machine failures, and enhance overall operational efficiency. By investing in networks that support these innovations today, manufacturers are positioning themselves for long-term success by ensuring that their systems remain agile and capable of incorporating new technologies as they emerge.

In addition, the move towards 5G networks offers a further opportunity for manufacturers to enhance both sustainability and resilience. With 5G’s ultra-low latency and high data throughput, manufacturers can connect an even greater number of devices and sensors across their operations, providing deeper insights into every aspect of production. The ability to process vast amounts of data in real time will help manufacturers make more informed decisions, optimize resource usage, and respond more quickly to disruptions or changing market conditions.

Remote Monitoring and Maintenance for Greater Efficiency

Another crucial aspect of modern industrial networks is the ability to monitor and maintain operations remotely. As more manufacturing facilities incorporate digital twins, augmented reality (AR), and other advanced technologies, the need for on-site intervention is decreasing. Through advanced network infrastructures, manufacturers can access real-time data from anywhere in the world, enabling them to detect issues before they escalate and resolve problems quickly without the need for physical presence.

Remote monitoring not only helps improve operational uptime but also contributes to sustainability by reducing the need for travel and lowering the associated environmental costs. Technicians and engineers can diagnose issues, perform system updates, and oversee production processes remotely, eliminating the need for on-site visits that often involve significant travel and resource consumption. This ability to manage operations from a distance allows manufacturers to stay ahead of potential issues while minimizing their carbon footprint.

Furthermore, remote maintenance capabilities are particularly valuable in the context of resilience. In times of crisis—whether caused by a natural disaster, geopolitical conflict, or supply chain disruption—remote monitoring and troubleshooting ensure that manufacturing operations can continue uninterrupted. This level of responsiveness enhances operational resilience, ensuring that businesses can maintain production even when physical access to facilities is limited.

By investing in advanced network solutions that enable remote monitoring and maintenance, manufacturers are not only improving their operational efficiency but also enhancing their sustainability efforts and resilience in the face of global challenges.

Cisco Industrial Networking Specialist has undergone a remarkable transformation in recent years, evolving from simple communication systems into highly sophisticated, integrated ecosystems. The backbone of this evolution lies in the increasing reliance on high-speed internet, robust data protocols, and cutting-edge technologies that allow machines, sensors, and operators to communicate seamlessly. As industries around the world continue to embrace digital solutions, networking becomes a critical element for future growth, efficiency, and innovation.

Historically, industrial networks were confined to isolated systems with limited interconnectivity. However, as global supply chains and production methods have become more complex, the demand for real-time data exchange has skyrocketed. With the advent of the Internet of Things (IoT), factories and manufacturing plants are now equipped with sensors and devices capable of transmitting vast amounts of information. This has paved the way for advanced networking solutions that can handle these demands.

One significant trend shaping industrial networks is the move towards centralized, cloud-based platforms that enable manufacturers to manage their operations from anywhere in the world. This shift allows for greater scalability, easier maintenance, and more effective data analysis. By leveraging cloud technology, industries are able to consolidate their operations onto a single, streamlined network that can be monitored, adjusted, and optimized remotely. As this technology becomes more prevalent, businesses are able to reduce costs, increase uptime, and enhance productivity through better data-driven decision-making.

The integration of artificial intelligence (AI) and machine learning (ML) into Cisco Industrial Networking Specialist systems further amplifies their capabilities. These technologies can identify patterns, predict maintenance needs, and optimize production schedules without the need for human intervention. This automated approach significantly reduces the risk of errors and increases operational efficiency. The role of AI and ML in Cisco Industrial Networking Specialist is only expected to grow, with new breakthroughs in predictive analytics allowing businesses to stay one step ahead of potential issues.

Smart Manufacturing: The Intersection of Automation and Data

The world of smart manufacturing is on the brink of a revolution. As industries strive to maintain a competitive edge, the combination of automation and data-driven decision-making is driving change at an unprecedented rate. In the heart of smart manufacturing lies the concept of digital twins, which involves creating virtual replicas of physical assets. These digital representations are continually updated with real-time data, enabling manufacturers to monitor performance, predict failures, and optimize operations.

Smart manufacturing also extends to the development of autonomous systems. Robotic arms, conveyor systems, and even entire production lines are now capable of operating with minimal human intervention. These autonomous systems rely on highly sophisticated algorithms and sensors to ensure precision and efficiency. Networking plays a pivotal role in connecting these systems to a central platform, where data can be processed and analyzed for further optimization.

Another defining aspect of smart manufacturing is the integration of augmented reality (AR) and virtual reality (VR) technologies. These immersive tools allow operators and technicians to visualize complex processes, troubleshoot issues, and receive remote assistance. By using AR and VR, manufacturers can reduce downtime, improve training efficiency, and enhance collaboration across geographically dispersed teams.

The connectivity offered by Cisco Industrial Networking Specialist is the cornerstone of smart manufacturing. With seamless communication between machines, devices, and control systems, manufacturers are better equipped to respond to dynamic market conditions. As production schedules become increasingly flexible, the ability to adapt to shifting demand becomes critical. The power of data, coupled with advanced networking infrastructure, enables manufacturers to achieve this adaptability.

The Role of Edge Computing in Manufacturing Networks

As the industrial sector becomes more data-intensive, the need for localized data processing has never been more apparent. This is where edge computing comes into play. Rather than sending all data to a centralized cloud server, edge computing processes data closer to its source. This approach minimizes latency, reduces bandwidth usage, and improves the overall efficiency of manufacturing processes.

Edge computing is particularly useful in environments where real-time decision-making is crucial. For example, in a factory setting, sensors embedded in machinery can generate large amounts of data. If this data were to be sent to a cloud server for analysis, delays in transmission could result in costly downtime. By using edge computing, the data can be processed immediately on-site, allowing operators to take swift action if an issue arises. This real-time capability enables manufacturers to prevent equipment failures, optimize energy consumption, and streamline production lines.

Moreover, edge computing supports the growing trend of distributed manufacturing. As factories become more globalized, the ability to process and analyze data at the edge ensures that operations in various locations can be synchronized. Edge devices can communicate with each other, exchanging vital information to ensure consistency across production sites. This approach enhances collaboration and promotes greater efficiency in a globally connected supply chain.

The implementation of edge computing is also crucial in supporting autonomous systems. As smart factories become more reliant on robotics and AI-driven machines, the need for low-latency communication increases. Edge computing facilitates this by providing the necessary computing power and storage capacity at the device level, enabling faster decision-making and enhancing the performance of autonomous systems.

Cybersecurity in Industrial Networks: Safeguarding the Digital Ecosystem

With the growing reliance on interconnected devices and systems, cybersecurity has emerged as one of the most pressing concerns in the industrial sector. As cyber threats continue to evolve, protecting the integrity of industrial networks has become paramount. A single breach could lead to significant financial losses, intellectual property theft, or even disruptions to production.

Industrial networks are increasingly targeted by cybercriminals due to their critical nature and the potential impact of an attack. These networks are often complex, with a wide range of devices, sensors, and legacy systems, making them vulnerable to intrusion. Additionally, many industrial organizations are still playing catch-up in terms of cybersecurity, having focused on production efficiency rather than security in the past.

To combat these threats, manufacturers must adopt a proactive approach to cybersecurity. This involves the implementation of robust security protocols, real-time monitoring systems, and regular software updates. Moreover, manufacturers must ensure that employees are trained to recognize potential threats, such as phishing attempts or social engineering attacks, which often serve as gateways for cybercriminals.

The integration of advanced encryption methods and secure communication protocols also plays a vital role in safeguarding industrial networks. By ensuring that data is securely transmitted between devices and control systems, manufacturers can protect sensitive information from unauthorized access. Multi-factor authentication (MFA) and biometric security are increasingly being used to bolster access controls, providing an additional layer of protection against malicious actors.

Furthermore, as the adoption of IoT devices in industrial environments grows, manufacturers must pay close attention to the security of these devices. IoT devices are often designed with functionality in mind, but their security is frequently overlooked. Ensuring that IoT devices are secure from the outset will prevent them from becoming weak points in the network.

The Impact of 5G Technology on Industrial Networks

The rollout of 5G technology is poised to bring about a seismic shift in the way industrial networks operate. With its ultra-fast speeds, low latency, and massive device connectivity, 5G promises to unlock new possibilities for smart manufacturing, automation, and industrial IoT applications. As more industries begin to leverage 5G, the implications for network design and performance will be profound.

One of the most significant advantages of 5G technology is its ability to handle high volumes of data with minimal delay. In an industrial context, this is crucial for applications that require real-time monitoring and control. For example, autonomous vehicles and robots on the factory floor will rely on 5G to communicate instantaneously with central control systems, enabling them to adapt to changes in their environment without lag.

The low latency of 5G also makes it ideal for applications involving augmented reality (AR) and virtual reality (VR). In these use cases, the ability to stream high-quality video and data in real-time is essential for providing operators with immersive, interactive experiences. Whether it’s remote troubleshooting or real-time data visualization, 5G ensures that these applications can function smoothly, even in complex industrial settings.

Another advantage of 5G is its ability to support massive device connectivity. In modern manufacturing environments, thousands of devices—ranging from sensors to robots—are connected to the network. 5G’s capacity to handle such a large number of simultaneous connections ensures that industrial networks can scale efficiently without compromising performance. This scalability is particularly important as industries adopt more IoT devices and smart machines.

The advent of 5G will also enable the creation of private, secure networks tailored to the specific needs of manufacturers. With 5G, businesses can build dedicated networks with guaranteed performance and security, ensuring that critical operations are not disrupted by external traffic or interference. This flexibility allows manufacturers to create the ideal network infrastructure for their unique requirements.

Future of Cisco Industrial Networking Specialist

Looking ahead, the future of Cisco Industrial Networking Specialist holds exciting possibilities. The ongoing integration of advanced technologies such as artificial intelligence, machine learning, and blockchain will continue to push the boundaries of what is possible in manufacturing and industry. As industries evolve, the need for smarter, more efficient, and more secure networks will become even more pronounced.

One of the most exciting developments is the rise of autonomous systems, which will play an increasingly important role in the manufacturing sector. Self-driving vehicles, autonomous robots, and AI-driven machines will transform how factories operate, requiring sophisticated networking solutions to support their functionality. These systems will rely on high-speed, low-latency connections, and industrial networks will need to evolve to accommodate these demands.

Furthermore, as industries embrace sustainability and circular economy principles, the role of data in optimizing resource usage and reducing waste will become even more critical. Industrial networks will be central to enabling this shift, as they will provide the connectivity and data infrastructure needed to support sustainable manufacturing practices.

Ultimately, the future of Cisco Industrial Networking Specialist is one of continuous innovation and adaptation. As the digital landscape evolves, businesses will need to stay agile, embracing new technologies and adapting their networks to meet changing demands. With the right infrastructure in place, manufacturers will be well-equipped to navigate the challenges and seize the opportunities that lie ahead.

Conclusion

As we’ve explored throughout this series, the convergence of Cisco Industrial Networking Specialist and smart manufacturing is fundamentally transforming the way factories operate across the globe. Cisco has positioned itself as a key enabler in this transformation by offering reliable, scalable, and secure networking solutions that connect the increasingly complex and data-driven manufacturing ecosystems of today. From optimizing production processes and enhancing automation to ensuring sustainability and resilience, Cisco’s Cisco Industrial Networking Specialist solutions provide the infrastructure that empowers manufacturers to unlock the full potential of their operations.

The rise of connected devices, advanced analytics, and automation technologies in smart factories relies heavily on seamless, high-performance networking. Cisco’s ability to facilitate real-time communication, data exchange, and integration across a wide range of IoT devices is instrumental in driving efficiencies, improving decision-making, and reducing costs. By addressing key challenges such as cybersecurity, network complexity, and scalability, Cisco helps manufacturers navigate the complexities of modern industrial environments with ease.

Moreover, the ability to foster sustainability and resilience through intelligent networking is becoming an increasingly important aspect of the manufacturing landscape. Cisco’s solutions are not just about enhancing performance—they’re about creating a future-proof infrastructure that supports long-term success. Whether it’s enabling energy savings, reducing waste, or improving supply chain efficiency, Cisco’s Cisco Industrial Networking Specialist technologies play a crucial role in helping manufacturers meet their sustainability goals while staying agile in a rapidly changing world.

As we look to the future, the potential for growth and innovation in smart manufacturing is limitless. The integration of emerging technologies like AI, machine learning, and edge computing will continue to push the boundaries of what’s possible, and Cisco’s forward-thinking solutions ensure that manufacturers will be equipped to embrace these advancements. Ultimately, the industrial networks of tomorrow will be characterized by their ability to adapt, evolve, and thrive in an increasingly connected and dynamic world.

In conclusion, Cisco is not just shaping the future of Cisco Industrial Networking Specialist—it's empowering manufacturers to lead the way in creating smarter, more efficient, and more sustainable operations. By investing in Cisco’s innovative networking solutions, manufacturers are setting the stage for a new era of industrial success, where technology, performance, and sustainability come together to drive growth and competitive advantage.

Frequently Asked Questions

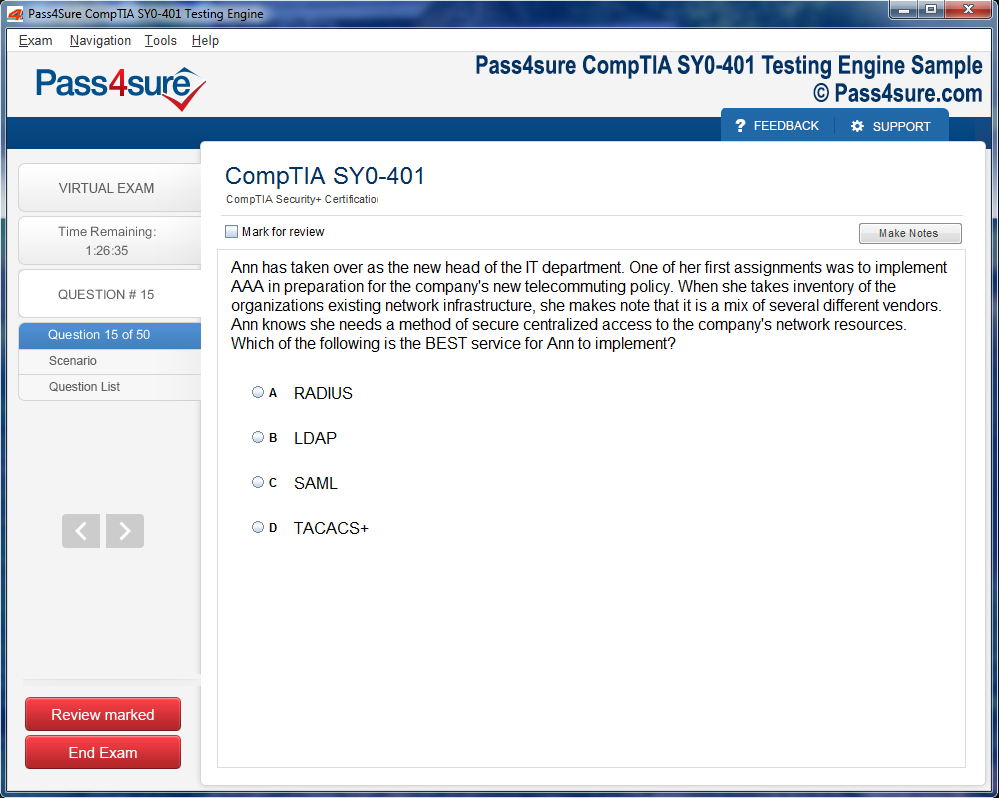

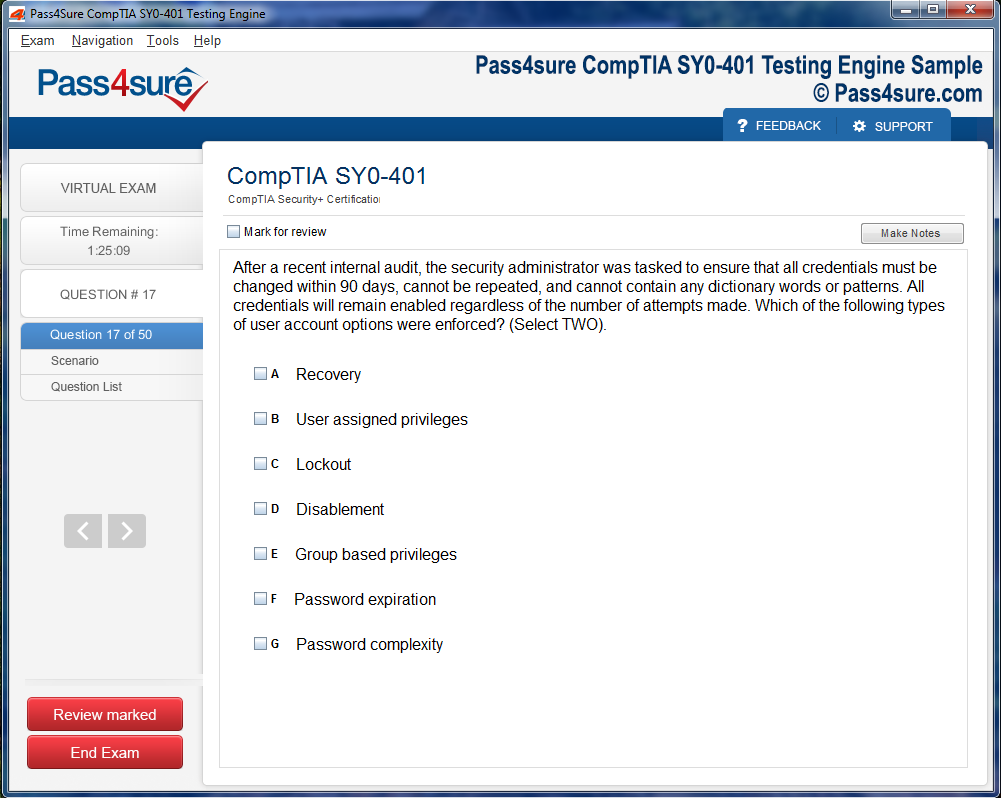

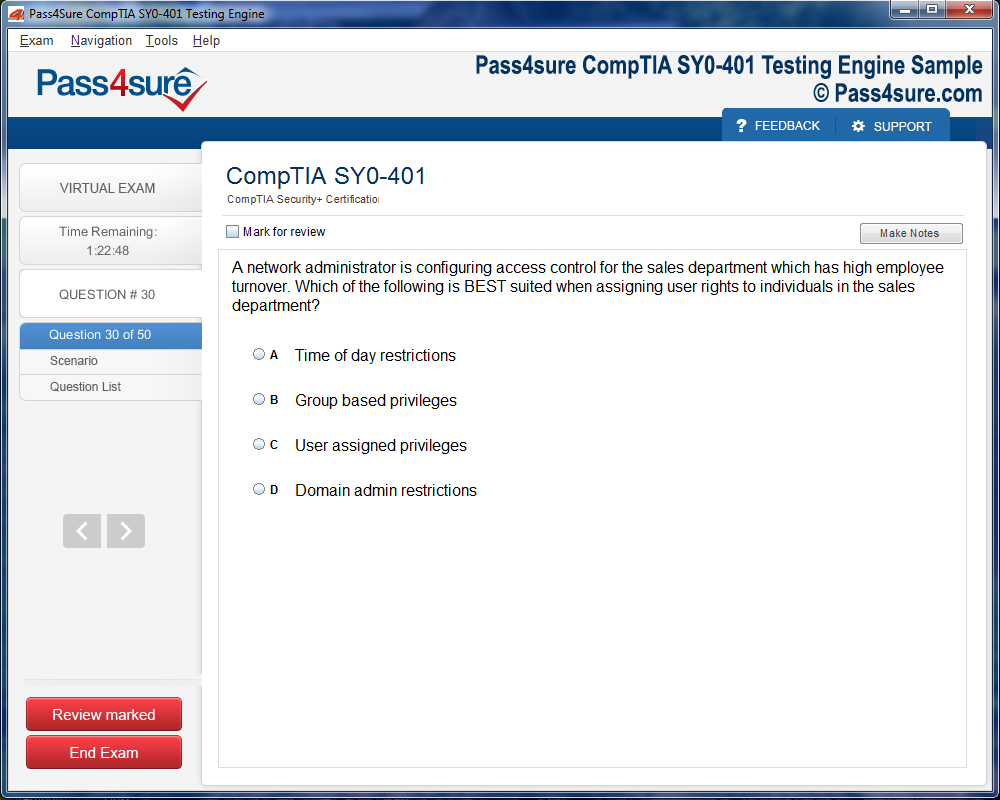

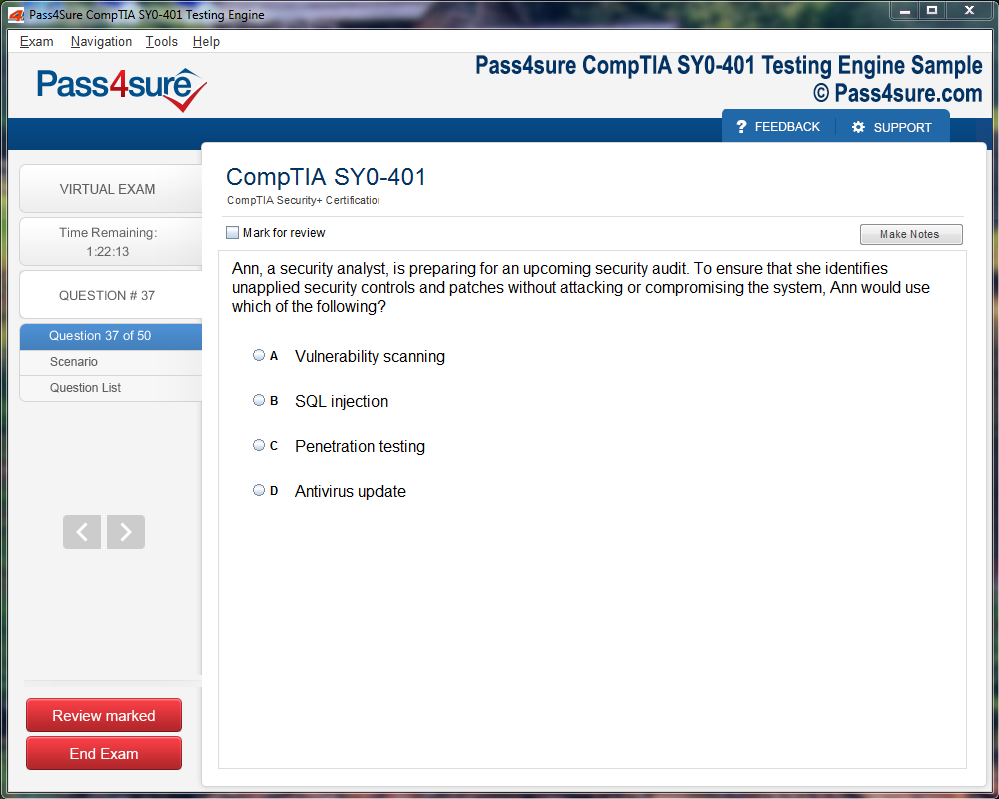

How does your testing engine works?

Once download and installed on your PC, you can practise test questions, review your questions & answers using two different options 'practice exam' and 'virtual exam'. Virtual Exam - test yourself with exam questions with a time limit, as if you are taking exams in the Prometric or VUE testing centre. Practice exam - review exam questions one by one, see correct answers and explanations).

How can I get the products after purchase?

All products are available for download immediately from your Member's Area. Once you have made the payment, you will be transferred to Member's Area where you can login and download the products you have purchased to your computer.

How long can I use my product? Will it be valid forever?

Pass4sure products have a validity of 90 days from the date of purchase. This means that any updates to the products, including but not limited to new questions, or updates and changes by our editing team, will be automatically downloaded on to computer to make sure that you get latest exam prep materials during those 90 days.

Can I renew my product if when it's expired?

Yes, when the 90 days of your product validity are over, you have the option of renewing your expired products with a 30% discount. This can be done in your Member's Area.

Please note that you will not be able to use the product after it has expired if you don't renew it.

How often are the questions updated?

We always try to provide the latest pool of questions, Updates in the questions depend on the changes in actual pool of questions by different vendors. As soon as we know about the change in the exam question pool we try our best to update the products as fast as possible.

How many computers I can download Pass4sure software on?

You can download the Pass4sure products on the maximum number of 2 (two) computers or devices. If you need to use the software on more than two machines, you can purchase this option separately. Please email sales@pass4sure.com if you need to use more than 5 (five) computers.

What are the system requirements?

Minimum System Requirements:

- Windows XP or newer operating system

- Java Version 8 or newer

- 1+ GHz processor

- 1 GB Ram

- 50 MB available hard disk typically (products may vary)

What operating systems are supported by your Testing Engine software?

Our testing engine is supported by Windows. Andriod and IOS software is currently under development.