Exam Code: CSC

Exam Name: Canadian Securities Course

Certification Provider: Canadian Securities Institute

Product Screenshots

Frequently Asked Questions

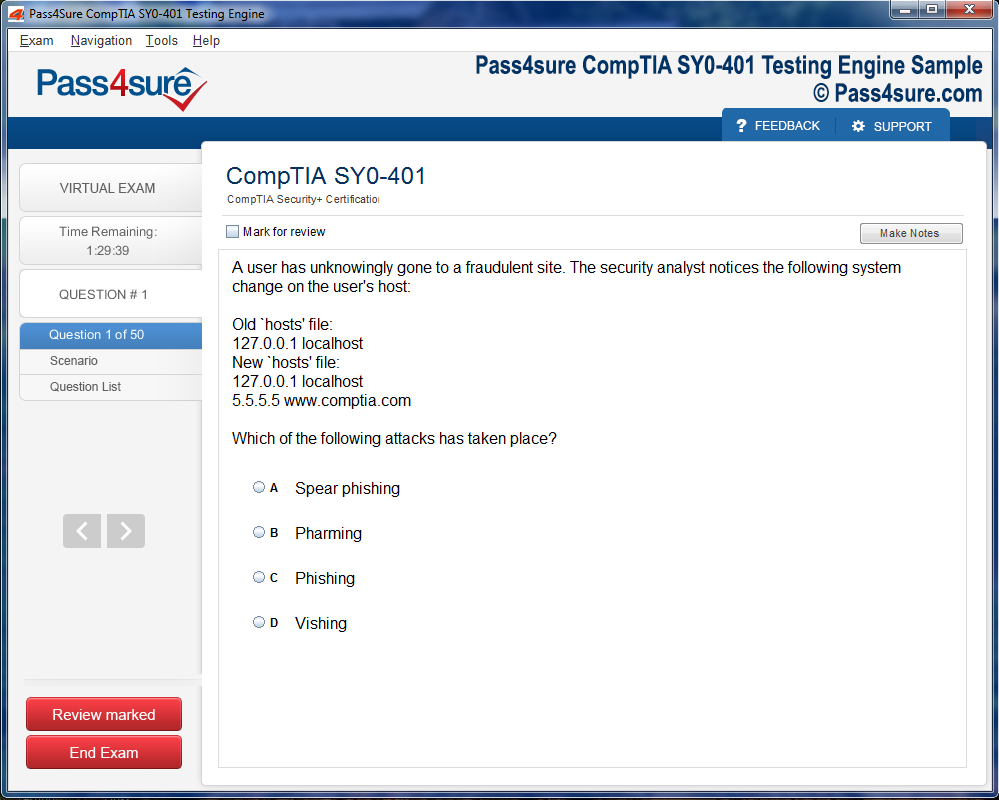

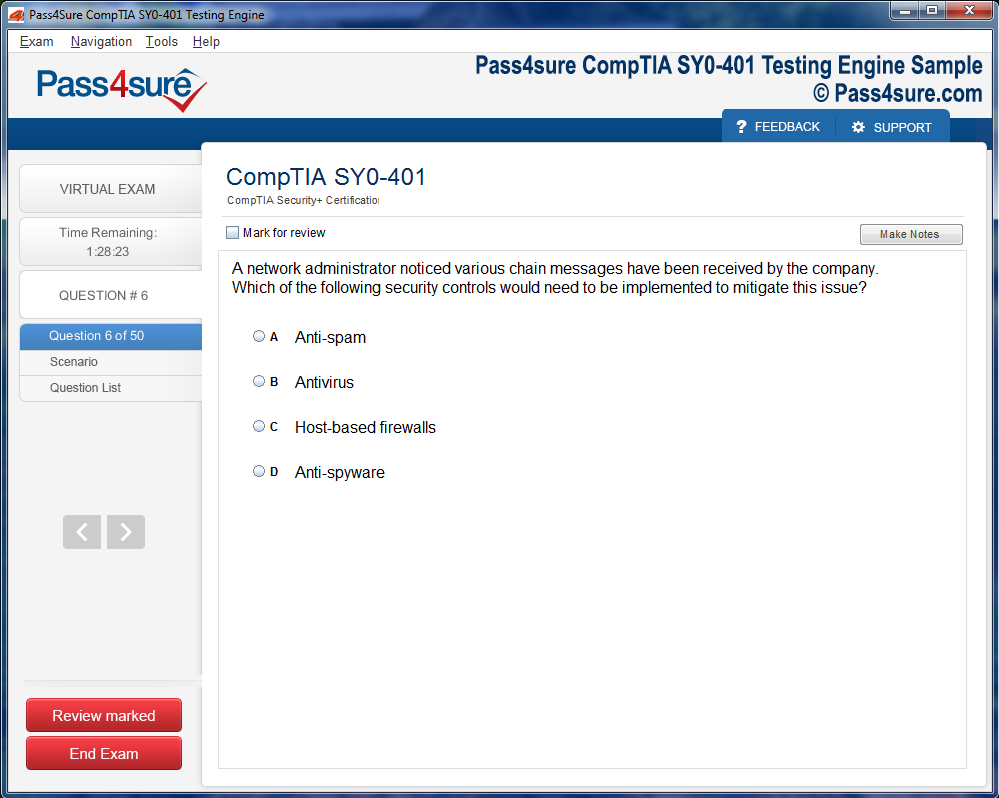

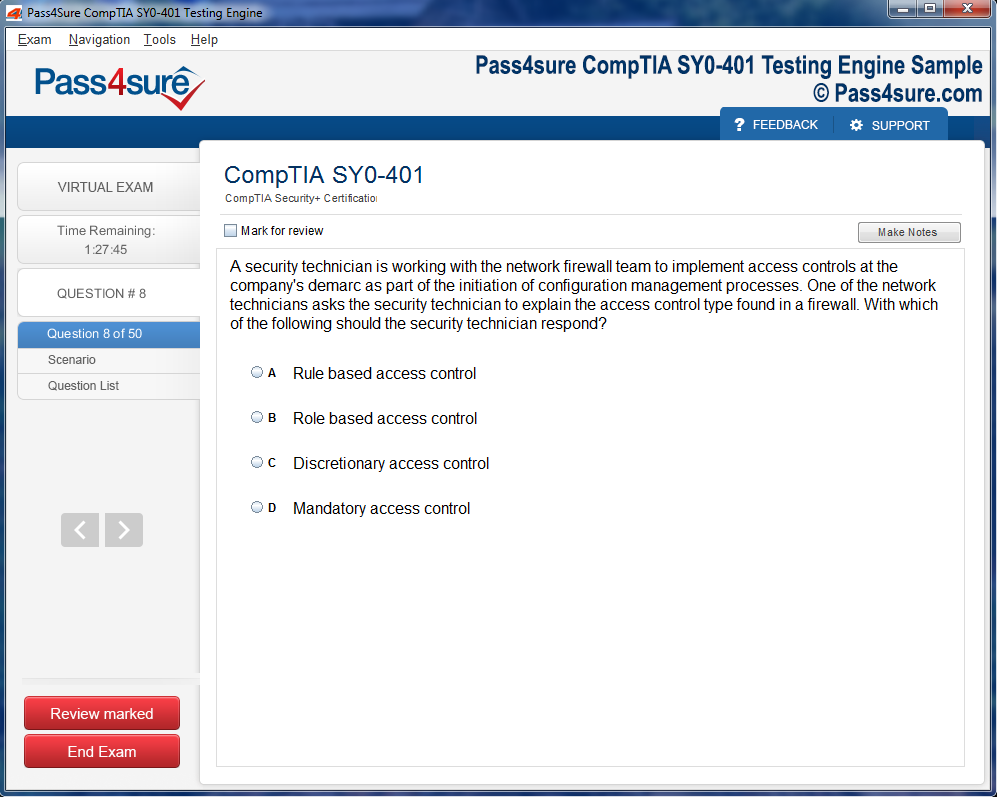

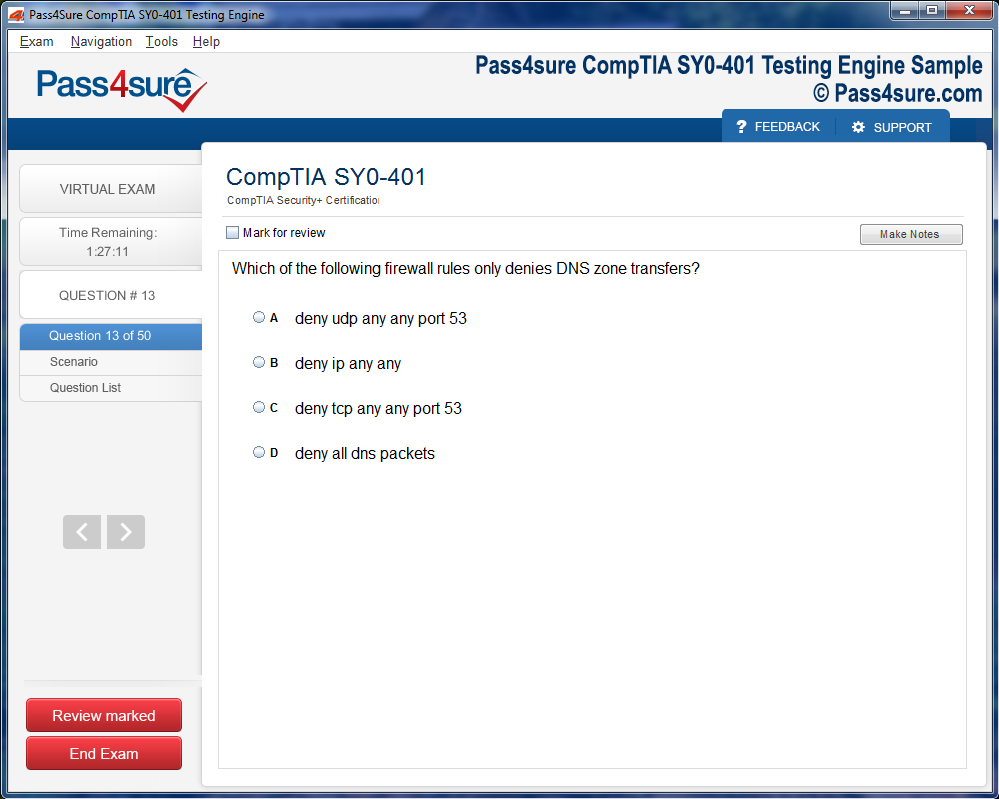

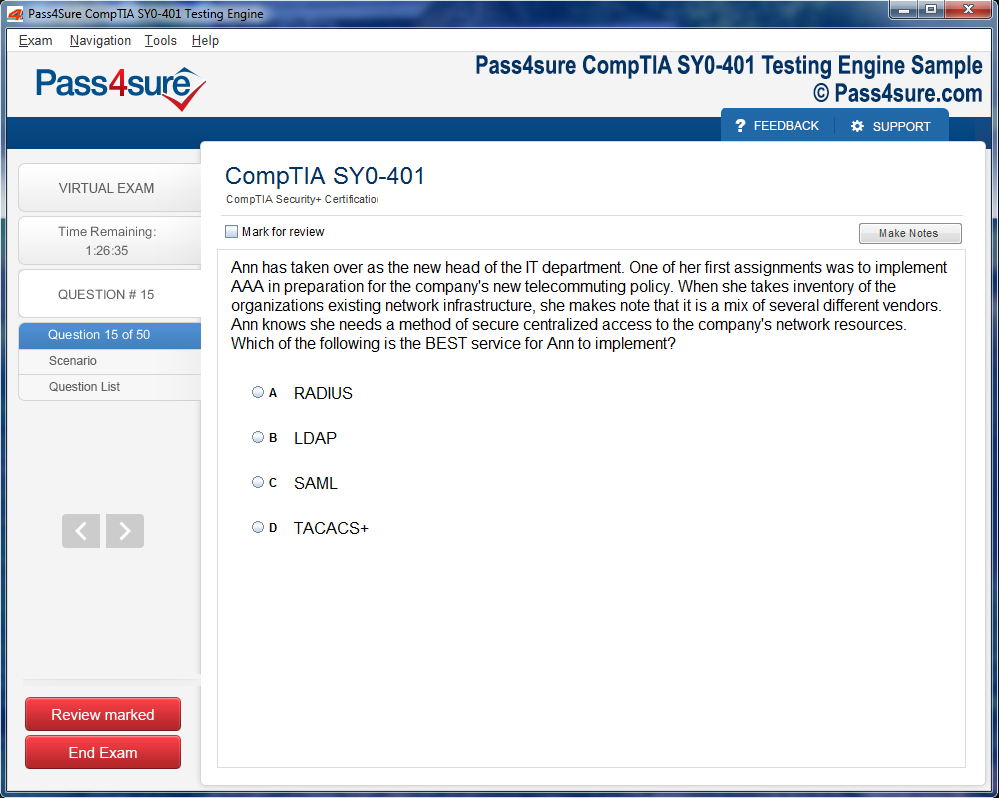

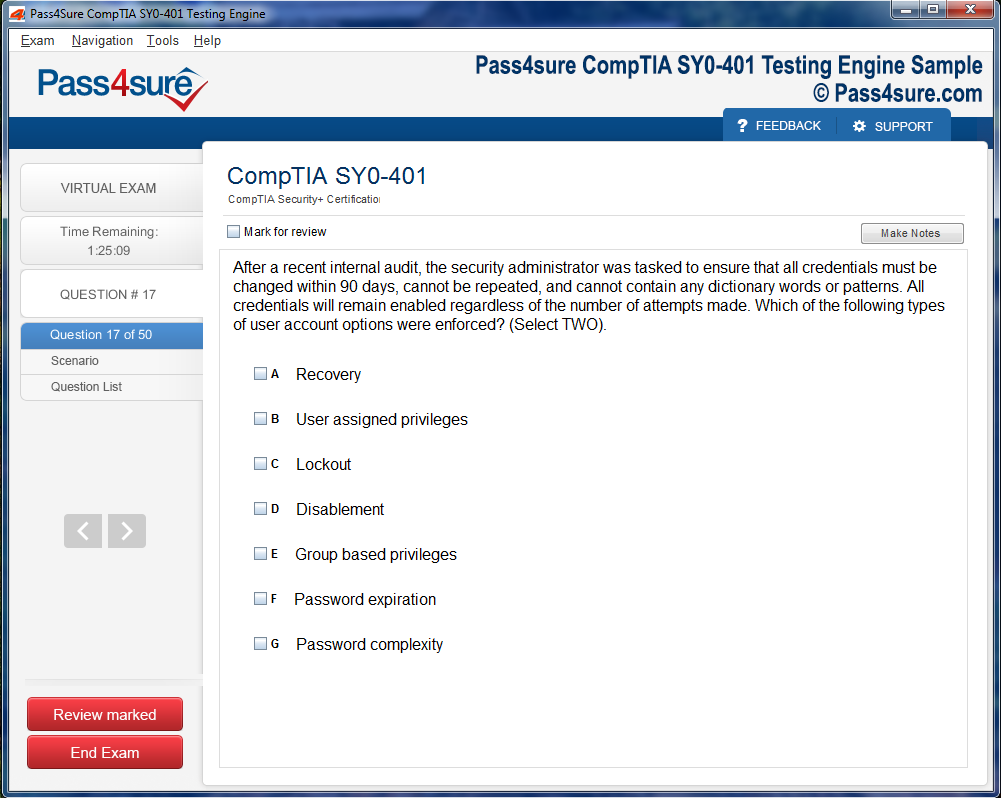

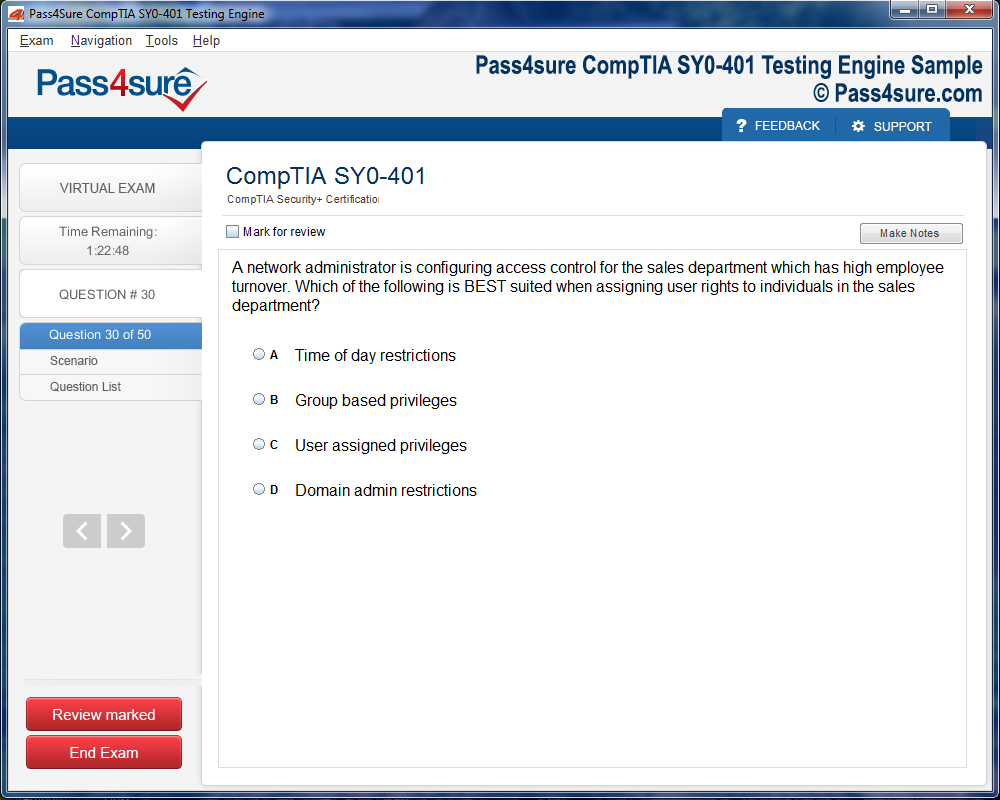

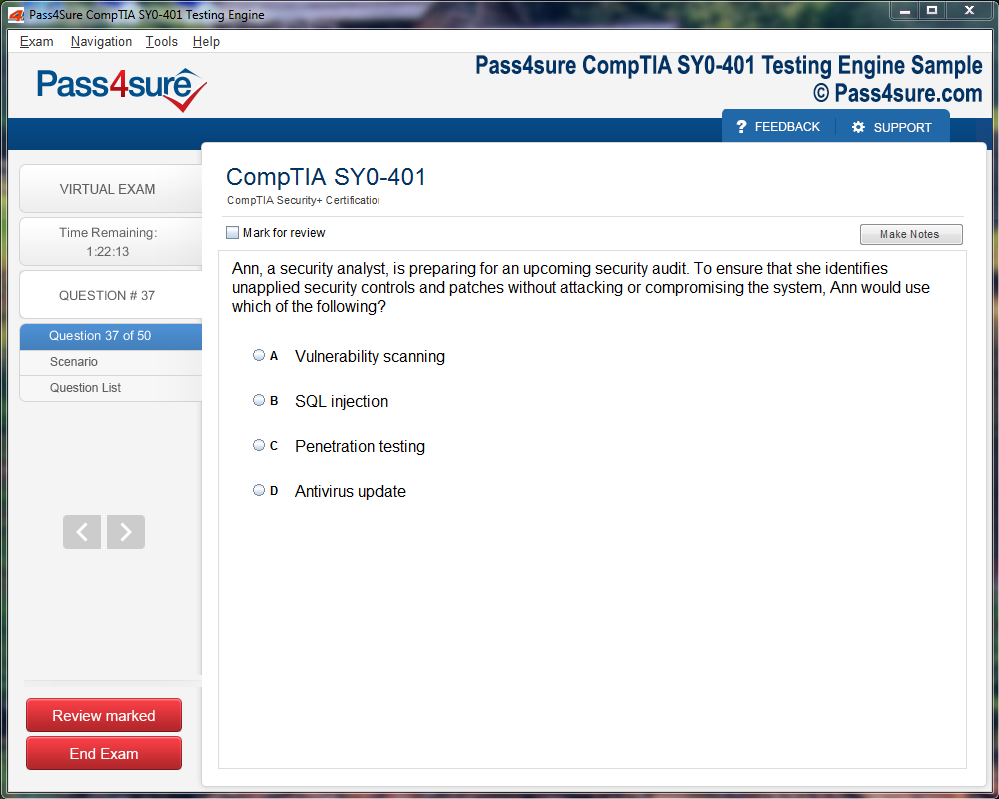

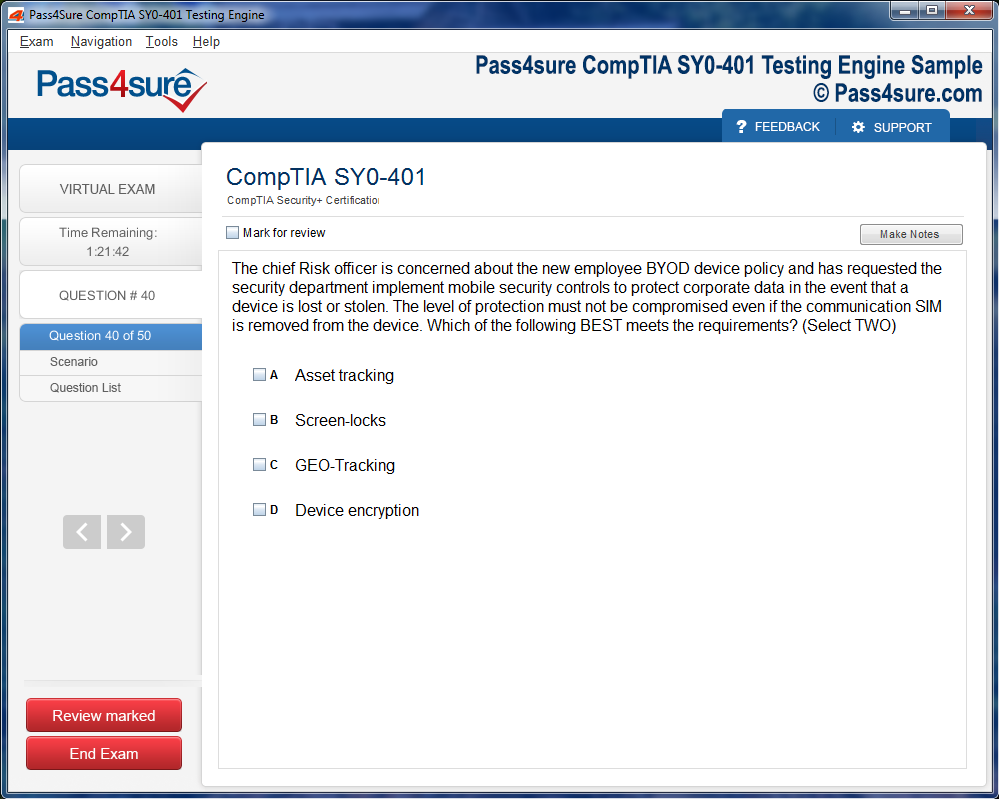

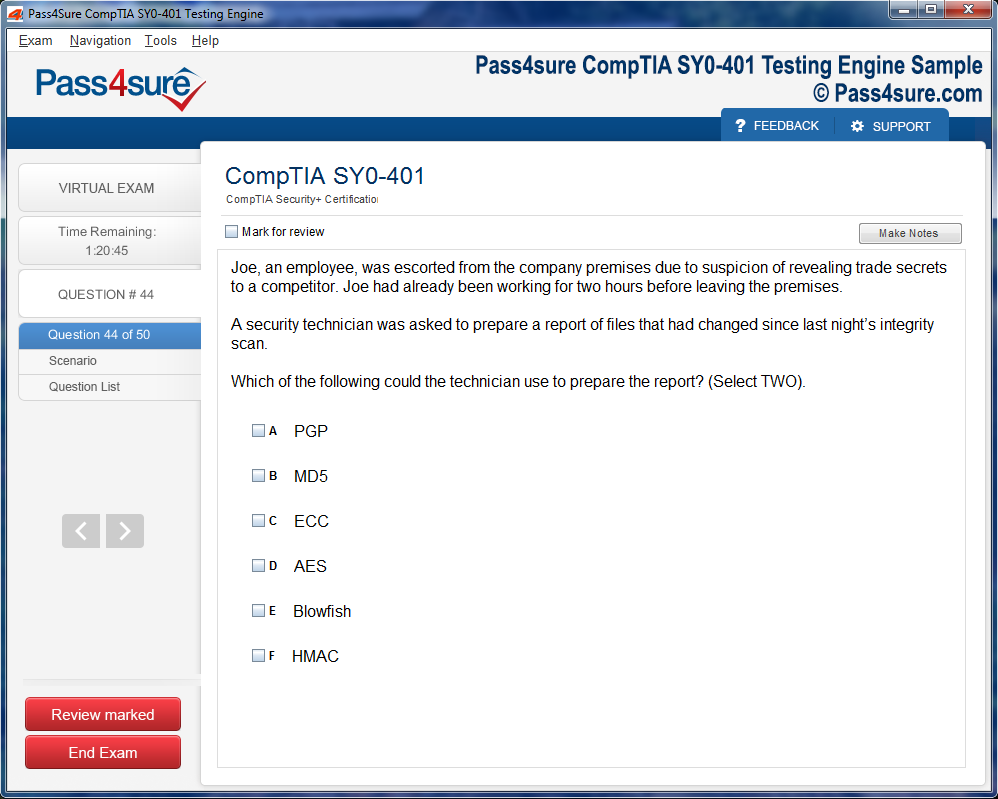

How does your testing engine works?

Once download and installed on your PC, you can practise test questions, review your questions & answers using two different options 'practice exam' and 'virtual exam'. Virtual Exam - test yourself with exam questions with a time limit, as if you are taking exams in the Prometric or VUE testing centre. Practice exam - review exam questions one by one, see correct answers and explanations.

How can I get the products after purchase?

All products are available for download immediately from your Member's Area. Once you have made the payment, you will be transferred to Member's Area where you can login and download the products you have purchased to your computer.

How long can I use my product? Will it be valid forever?

Pass4sure products have a validity of 90 days from the date of purchase. This means that any updates to the products, including but not limited to new questions, or updates and changes by our editing team, will be automatically downloaded on to computer to make sure that you get latest exam prep materials during those 90 days.

Can I renew my product if when it's expired?

Yes, when the 90 days of your product validity are over, you have the option of renewing your expired products with a 30% discount. This can be done in your Member's Area.

Please note that you will not be able to use the product after it has expired if you don't renew it.

How often are the questions updated?

We always try to provide the latest pool of questions, Updates in the questions depend on the changes in actual pool of questions by different vendors. As soon as we know about the change in the exam question pool we try our best to update the products as fast as possible.

How many computers I can download Pass4sure software on?

You can download the Pass4sure products on the maximum number of 2 (two) computers or devices. If you need to use the software on more than two machines, you can purchase this option separately. Please email sales@pass4sure.com if you need to use more than 5 (five) computers.

What are the system requirements?

Minimum System Requirements:

- Windows XP or newer operating system

- Java Version 8 or newer

- 1+ GHz processor

- 1 GB Ram

- 50 MB available hard disk typically (products may vary)

What operating systems are supported by your Testing Engine software?

Our testing engine is supported by Windows. Andriod and IOS software is currently under development.

Understanding the Canadian Securities Institute CSC Container Certification

Shipping containers are more than mere metal receptacles; they are linchpins of global commerce, enmeshed in a labyrinthine web of trade routes and logistical conduits. The Convention for Safe Containers, abbreviated as CSC, emerged in 1972 as a paramount regulatory milestone, promulgated by the International Maritime Organization. Its genesis was fueled by a pressing exigency: maritime and intermodal transport were burgeoning, yet container mishaps were proliferating, posing catastrophic threats to cargo, personnel, and vessels. CSC certification is the crystallized embodiment of a unified safety doctrine, meticulously engineered to harmonize international standards and obviate disparities across national jurisdictions.

Defining the Structural Imperative

The essence of CSC certification is anchored in structural veracity. Containers must be impervious to environmental vicissitudes, including torrential precipitation, salt-laden air, and drastic thermal fluxes. Inspections gauge wind and watertight integrity, evaluating whether rivets, welds, and corner fittings can endure protracted exposure to mechanical stress. The structural imperative transcends mere compliance—it is an existential bulwark against deformation, collapse, and catastrophic cargo loss. Through CSC certification, a container is rendered a resilient citadel, capable of enduring the formidable exigencies of intermodal transit.

Corner Fittings: The Unsung Sentinels

Among the most scrutinized components of a container are its corner fittings. These inconspicuous yet pivotal structures are the fulcrums upon which the entire integrity of container stacking and lifting hinges. During CSC inspection, surveyors subject corner fittings to tensile stress assays, verifying their capacity to sustain multifarious forces without yielding. A single compromised corner fitting can precipitate a cascade of structural failure, endangering crew, equipment, and the cargo itself. Thus, CSC certification enshrines the concept of preemptive fortification, rendering each container a paragon of engineered reliability.

Rigorous Load and Stress Testing

CSC-certified containers undergo exhaustive load and stress evaluations, simulating real-world adversities. Vertical stacking pressures, lateral torsion, and longitudinal bending are meticulously measured, ensuring that containers maintain equilibrium under multifaceted weight distributions. Additionally, dynamic impact tests emulate the shocks endured during crane handling and port loading. These evaluations transcend perfunctory inspection; they constitute a rigorous, quasi-forensic examination of a container’s mechanical endurance. Certification signifies that a container is battle-tested, capable of withstanding both quotidian stressors and anomalous strain events.

The Role of Continuous Examination Programs

A salient feature of CSC certification is its advocacy for continuous examination programs. Certification is not a static credential; it is a perpetually evolving validation. Containers enrolled in these programs undergo periodic re-inspections to confirm sustained structural soundness. This proactive vigilance mitigates latent vulnerabilities and forestalls degradation due to cumulative wear. In an era where shipping schedules are mercurial and cargo volumes immense, continuous examination programs ensure that container integrity remains invariant, fortifying the supply chain against unforeseen disruptions.

Safety Approval Plates: Codifying Transparency

A CSC-certified container bears a safety approval plate—a compact, yet information-rich, testament to its compliance. These plates encode pivotal data: manufacturer credentials, serial identification, permissible gross weight, stacking limits, and inspection chronology. This codification fosters transparency and traceability, rendering containers discernible across international transport networks. Operators, regulators, and insurers rely on this information to validate safety credentials, streamline logistical workflows, and mitigate liability exposure. Safety approval plates thus transform containers from anonymous metal units into fully accountable, auditable assets.

Surveyor Expertise: The Arbiter of Compliance

The acquisition of CSC certification mandates collaboration with accredited surveyors, who act as the arbiters of compliance. These professionals possess specialized acumen in metallurgical evaluation, structural engineering, and maritime logistics. Their assessments encompass weld quality, door functionality, floor integrity, and undercarriage robustness. Surveyors employ calibrated instrumentation and leverage sophisticated facilities—cranes, gantries, and load simulators—to conduct methodical inspections. Their expertise ensures that certification is not perfunctory but a rigorous affirmation of mechanical fidelity.

Legal Mandates and Regulatory Gravitas

CSC certification carries profound legal implications. International statutes often preclude uncertified containers from entering intermodal networks, rendering certification a prerequisite for operational legality. Regulatory agencies scrutinize CSC documentation to enforce compliance, safeguard port infrastructure, and maintain insurance eligibility. The absence of certification can result in logistical interdiction, financial penalties, and reputational damage. Consequently, CSC certification functions as both a technical standard and a juridical instrument, imbuing shipping operations with legitimacy and regulatory inviolability.

Cargo Security and Risk Mitigation

Beyond regulatory compliance, CSC certification enhances cargo security. Structurally sound containers mitigate the risk of deformation, leakage, or collapse during transit. Such fortification is critical for high-value or perishable goods, where even minor compromise can precipitate substantial financial loss. By adhering to CSC standards, shipping operators insulate their cargo from environmental hazards, mechanical mishaps, and human error. This risk mitigation extends to personnel, who rely on container reliability for safe handling, stacking, and transportation.

Operational Efficiency and Logistical Synergy

CSC certification contributes to operational efficiency by ensuring containers meet uniform, predictable standards. Standardized dimensions, weight limits, and structural tolerances facilitate seamless integration into port operations, container terminals, and intermodal transfer systems. Predictable performance reduces bottlenecks, minimizes equipment strain, and accelerates turnaround times. In essence, certification transforms containers from variable, unpredictable assets into standardized, synergistic components of a global logistical ecosystem.

Environmental Resilience and Sustainability

Containers with CSC certification exhibit enhanced environmental resilience. Wind- and watertight designs prevent ingress of water, salt, and particulate matter, preserving cargo quality and mitigating contamination risks. Robust construction also prolongs container lifespan, reducing the frequency of replacement and minimizing environmental impact. By incentivizing durable, sustainable engineering, CSC certification aligns operational pragmatism with ecological stewardship, underscoring the intersection of commerce and environmental responsibility.

Innovation and Technological Integration

CSC certification encourages the integration of innovative materials and technologies. Advanced composites, corrosion-resistant alloys, and reinforced structural frameworks are increasingly incorporated to meet evolving safety standards. Surveyors evaluate these innovations to ensure they conform to CSC protocols, creating a feedback loop that fosters continual improvement in container engineering. This symbiosis between regulatory rigor and technological advancement ensures that the shipping industry evolves without compromising safety.

Global Trade Harmonization

The international nature of CSC certification fosters global trade harmonization. By establishing a universally recognized safety benchmark, CSC reduces friction between disparate national regulatory frameworks. Containers certified under this system can traverse oceans, railways, and highways with minimal bureaucratic impediments. This harmonization accelerates trade, reduces transactional uncertainty, and strengthens supply chain reliability, reinforcing the foundational role of CSC certification in facilitating cross-border commerce.

Economic Implications for Shipping Companies

Investing in CSC-certified containers yields long-term economic benefits. While the upfront cost of inspection and certification may be significant, it is dwarfed by the potential costs of cargo damage, port fines, or insurance complications. Certified containers enhance customer confidence, streamline logistical operations, and reduce unplanned maintenance or replacement expenses. In aggregate, certification acts as a form of risk-adjusted capital investment, optimizing operational expenditures while safeguarding revenue streams.

CSC Certification and Insurance Compliance

Insurance providers frequently mandate CSC certification as a condition for coverage. Certified containers reduce the likelihood of claims related to structural failure or cargo loss, creating a mutually beneficial framework for insurers and shipping operators. Documentation provided through safety approval plates and surveyor reports enables precise risk assessment, facilitating underwriting accuracy and premium optimization. Consequently, certification functions as both a protective measure and a financial instrument within the maritime insurance ecosystem.

Intermodal Transport Synergy

The significance of CSC certification is particularly pronounced in intermodal transport. Containers transition seamlessly from ship to rail to truck, often crossing multiple jurisdictions and regulatory environments. Certification guarantees that structural standards, stacking tolerances, and load capacities remain consistent, irrespective of mode of transport. This interoperability enhances operational fluidity, minimizes transfer delays, and mitigates the risk of structural compromise during handling or transit.

CSC Certification as a Benchmark of Trust

Ultimately, CSC certification functions as a universal benchmark of trust. It signals to stakeholders—from shipping companies to port authorities, freight forwarders to insurers—that containers have been meticulously evaluated, structurally fortified, and continuously monitored. In a world where supply chains are intricate and cargo volumes are immense, this trust is indispensable, underpinning both operational efficacy and reputational integrity.

Future Trajectories of Container Safety

Looking forward, CSC certification is poised to evolve alongside emerging technologies and trade paradigms. Smart sensors, digital inspection protocols, and blockchain-based traceability systems may augment traditional certification, creating an even more robust safety ecosystem. These innovations will further reinforce the fundamental objectives of CSC: ensuring structural integrity, operational safety, and regulatory compliance in a dynamic global trade environment.

The Indispensable Role of CSC Certification

In summation, CSC certification transcends regulatory formality; it is an essential instrument for safeguarding global commerce. By guaranteeing structural soundness, legal compliance, operational efficiency, and cargo security, CSC-certified containers underpin the intricate lattice of international trade. As markets expand and intermodal transport intensifies, the role of CSC certification becomes ever more critical, ensuring that containers remain resilient sentinels of safety, reliability, and trust. Its enduring relevance is a testament to the foresight of international maritime governance and the continual pursuit of excellence in container engineering.

Structural Integrity and Its Imperative Role

The foundational cornerstone of CSC certification is the unequivocal structural integrity of the container. A container’s frame must exhibit resilience against perturbations that could jeopardize its wind and watertight capabilities. Even infinitesimal fissures or micro-fractures within the metal skin can serve as conduits for moisture infiltration, resulting in cargo deterioration or hazardous conditions during transit. Detailed non-destructive examinations, including ultrasonic thickness gauging and visual scrutiny, ensure that all surfaces—from roofs to floors—are impervious to deleterious forces. The precision of these inspections safeguards against latent structural vulnerabilities that might manifest under prolonged logistical strain. Robust structural composition guarantees that the container withstands not merely quotidian handling but also anomalous pressures exerted during intermodal transport, thereby obviating latent hazards.

Strength Testing and Load Resilience

The crucible of strength testing evaluates a container’s fortitude under dynamic loading conditions. Maritime transport routinely imposes multifarious pressures, with containers stacked in towering arrays, sometimes extending beyond six layers. The distribution of weight, if uneven, can catalyze structural fatigue or catastrophic deformation. Inspectors deploy meticulously calibrated load simulations to the container’s extremities, including corner posts and longitudinal walls, to ascertain stability under maximum payload thresholds. The testing regimen encompasses torsional stress, vertical compression, and lateral shear assessments, each designed to illuminate potential structural deficiencies. A container’s ability to resist these forces without discernible deflection or compromise is indicative of compliance. Such rigorous evaluation mitigates the risk of accidents, ensures cargo integrity, and reinforces environmental safety during maritime voyages.

Corner Fittings and Lashing Point Assessment

Corner castings and lashing points serve as the interface between human handling and mechanical orchestration. Their tensile strength and structural alignment are pivotal for secure lifting, stacking, and transportation. Surveyors employ calibrated instrumentation to measure the resistance of these components to bending, twisting, and torsional forces, verifying their adequacy for sustained operational demands. Lashing points are examined for material fatigue, weld integrity, and corrosion resistance, given that deficiencies in these areas can precipitate mishandling or catastrophic detachment during transit. Precision in these fittings is non-negotiable, as even minor anomalies could compromise intermodal safety. The assessment guarantees that every container, whether deployed in port yards or aboard vessels, performs consistently under rigorous operational exigencies.

Wind and Watertightness Verification

Ensuring hermetic sealing is a sine qua non for CSC certification. Containers must demonstrate impermeability to environmental ingress, particularly water and particulate matter. Doors, seals, and panels undergo stringent testing under differential pressure conditions to ascertain the continuity of their seal. Water intrusion trials, often conducted under controlled spray and submersion scenarios, simulate real-world maritime exposure, revealing micro-leaks or gasket deficiencies. Such meticulous scrutiny safeguards not only the cargo but also personnel working in proximity, as moisture accumulation can induce slippery surfaces and electrical hazards. A container that fails wind and watertightness testing is deemed unsuitable for intermodal transport, underscoring the criticality of airtight construction and diligent maintenance.

Accurate Labeling Through CSC Plates

The CSC plate is more than a mere identifier; it is a testament to the container’s regulatory compliance and operational provenance. Each plate must display essential parameters, including manufacturer details, serial numbers, maximum gross weight, and approved stacking limits. Additionally, plates chronicle the container’s inspection history and its inclusion in continuous examination programs, providing a transparent audit trail. The plates must be fabricated from fire-resistant, corrosion-tolerant materials to ensure legibility under extreme conditions. Accurate labeling facilitates rapid verification by inspectors, port authorities, and logistics personnel, allowing for seamless integration into global shipping networks. Failure to maintain precise and durable labeling can impede operational efficiency and render a container non-compliant with CSC protocols.

Material Composition and Metallurgical Standards

The intrinsic material composition of containers is subjected to rigorous scrutiny. High-tensile steel or corrosion-resistant alloys are mandated to endure maritime environmental challenges, including saline exposure, temperature flux, and mechanical abrasion. Metallurgical analysis, encompassing tensile testing, hardness measurement, and fatigue evaluation, ensures the selected materials exhibit optimal resilience. The welding processes used in container fabrication are also assessed for consistency and structural soundness, as substandard joins can propagate cracks under cyclic stress. Adherence to these metallurgical standards is paramount for containers to maintain operational integrity across prolonged service lifespans, preventing structural compromise and safeguarding the cargo entrusted to their containment.

Door Mechanisms and Operational Efficacy

Functionality of container doors is a pivotal facet of CSC certification. Hinges, locking rods, and gasket alignments are scrutinized to ensure smooth operation under varying loads and environmental conditions. Mechanical examinations assess torque resistance and alignment precision, ensuring that doors remain operable even under lateral stress or minor deformation. Proper door functionality mitigates risk during loading and unloading, prevents inadvertent cargo exposure, and ensures that sealing integrity is preserved. Containers exhibiting door malfunctions or misalignments are flagged for remedial action, reinforcing the emphasis on operational reliability as a cornerstone of safety compliance.

Thermal Resistance and Environmental Adaptability

Containers frequently traverse regions with extreme climatic conditions, necessitating robust thermal resistance. Thermal expansion, contraction, and stress concentrations are evaluated to predict long-term durability. Inspections may incorporate heat cycling, cold chamber testing, and humidity exposure simulations to gauge container performance across temperature extremes. Environmental adaptability ensures that containers maintain structural coherence and seal integrity despite fluctuating external conditions. This aspect of certification is particularly critical for temperature-sensitive cargo, where deviations in insulation or thermal response can lead to spoilage or hazardous chemical reactions.

Continuous Examination and Periodic Audits

CSC certification is contingent not merely on a singular evaluation but on continuous examination protocols. Containers must participate in regular inspections to validate ongoing compliance with technical standards. Periodic audits encompass visual inspections, structural assessments, and load tests to identify emerging vulnerabilities due to wear, corrosion, or mechanical fatigue. Continuous examination fosters a culture of proactive maintenance and accountability, ensuring containers remain fit for intermodal deployment. Operators benefit from early detection of deficiencies, reducing the likelihood of accidents and optimizing logistical reliability.

Documentation, Traceability, and Compliance Assurance

Comprehensive documentation underpins the CSC certification framework. Inspection reports, maintenance logs, and repair records establish traceability and facilitate regulatory oversight. Accurate record-keeping ensures that any anomalies or corrective actions are verifiable and auditable. Compliance assurance is further reinforced through digital tracking systems, enabling stakeholders to monitor container status in real-time. This meticulous attention to documentation elevates operational transparency, fortifies safety standards, and engenders trust among shippers, carriers, and authorities.

Innovations in Container Design and Certification

Advancements in container engineering have introduced novel materials, design optimizations, and smart monitoring systems. High-performance composites and reinforced alloys enhance structural resilience while reducing weight. Modular designs improve load distribution and stacking efficiency, mitigating stress concentrations. Emerging technologies, such as IoT-enabled sensors, provide continuous feedback on structural health, temperature fluctuations, and humidity levels, allowing for predictive maintenance and proactive compliance management. Incorporating these innovations within the CSC certification paradigm ensures that modern containers meet evolving safety, operational, and environmental requirements.

Corrosion Protection and Longevity Enhancement

Corrosion is a persistent adversary in maritime logistics, compromising container integrity over time. Protective coatings, galvanization, and cathodic treatments are deployed to resist chemical degradation from saltwater, humidity, and pollutants. Regular inspections evaluate coating adherence, corrosion progression, and potential metal fatigue. Longevity enhancement strategies, including preventive maintenance and surface treatments, are integral to sustaining compliance and operational reliability. Containers that exhibit robust corrosion resistance reduce maintenance costs, extend service life, and ensure the safe conveyance of cargo under diverse environmental conditions.

Load Distribution and Weight Management

Proper weight management is crucial for CSC compliance. Containers are evaluated for uniform load distribution, with particular attention to stacking limits and floor load capacity. Imbalanced or overloaded containers pose significant hazards, including tipping, structural deformation, or floor collapse. Inspectors assess the floor panels, cross-members, and corner posts to ensure load-bearing adequacy. Weight management protocols also include adherence to maximum gross weight specifications, which are clearly indicated on CSC plates. These measures collectively safeguard cargo integrity and contribute to the overarching stability of intermodal transport systems.

Human Factors and Ergonomic Considerations

Human interaction with containers encompasses handling, inspection, and maintenance activities. Ergonomic considerations, such as ease of door operation, accessibility of lashing points, and maneuverability, are incorporated into certification assessments. Reducing human strain and enhancing operational ergonomics minimizes accidents, facilitates rapid handling, and ensures consistent adherence to safety protocols. Human-centric design features, while secondary to structural integrity, contribute significantly to the overall efficacy and reliability of container operations in high-intensity logistics environments.

Risk Mitigation and Safety Assurance

CSC certification is fundamentally a risk mitigation instrument. By enforcing rigorous technical standards, the certification process minimizes the probability of structural failures, cargo loss, and environmental hazards. Containers that comply with these standards provide a predictable, safe framework for global logistics, enabling operators to manage risks effectively. Safety assurance is reinforced through integrated testing, continuous monitoring, and adherence to comprehensive operational protocols. The resultant risk reduction fosters confidence among supply chain stakeholders and underpins the seamless functioning of international transport networks.

Regulatory Synergy and International Standards

CSC certification aligns containers with global regulatory frameworks, ensuring interoperability across international transport systems. Compliance with technical requirements guarantees that containers are legally recognized for maritime, rail, and road transit, eliminating bureaucratic impediments and enhancing operational fluidity. Harmonization with international standards also facilitates cross-border logistics, simplifies customs procedures, and promotes uniform safety practices. This regulatory synergy underscores the pivotal role of CSC certification in sustaining a cohesive, secure, and efficient global supply chain ecosystem.

Economic Implications of Compliance

Adhering to CSC technical requirements is not merely a safety imperative; it carries significant economic ramifications. Certified containers reduce the incidence of cargo damage, operational downtime, and accident-related liabilities, thereby enhancing cost-efficiency. The long-term financial benefits of compliance include lower insurance premiums, extended container lifespan, and reduced maintenance expenditures. Investment in compliant containers translates into tangible operational savings, improved reliability, and strengthened competitiveness within the logistics sector. Economic prudence is thus intrinsically linked to technical conformity with CSC standards.

Sustainability and Environmental Stewardship

Modern container certification increasingly emphasizes sustainability. Durable, corrosion-resistant materials reduce resource consumption by extending container service life. Efficient load distribution and optimized design minimize fuel consumption and carbon emissions during transportation. Continuous monitoring technologies enable proactive maintenance, preventing environmental contamination due to cargo spillage or structural failure. By aligning technical compliance with environmental stewardship, CSC certification contributes to sustainable logistics practices and reinforces corporate responsibility within the shipping industry.

Future Trends in Container Safety and Certification

The future of CSC certification will likely be influenced by technological innovation and evolving safety paradigms. Smart sensors, AI-driven predictive maintenance, and advanced materials will enhance container monitoring, structural resilience, and operational efficiency. Certification protocols may adapt to include real-time performance data, remote inspections, and automated compliance verification, further reducing human error and improving global logistics safety. Anticipating these trends ensures that stakeholders remain ahead of regulatory developments, technological advancements, and emergent operational risks, sustaining the integrity of intermodal transport systems.

The Holistic Imperative of CSC Certification

Ultimately, CSC certification represents a holistic synthesis of structural engineering, operational safety, and regulatory compliance. Every technical requirement—from structural integrity and load resilience to corrosion protection and labeling accuracy—serves a unified purpose: safeguarding cargo, personnel, and the environment while facilitating seamless global logistics. By embracing these rigorous standards, operators fortify operational reliability, mitigate risks, and engender trust among shippers, carriers, and regulatory authorities. CSC certification is thus both a technical mandate and a strategic enabler, integral to the modern logistics ecosystem.

The Imperative Significance of CSC Plates in Modern Logistics

Container Safety Convention (CSC) plates are an often-overlooked yet quintessential facet of intermodal transportation infrastructure. These plates, affixed indelibly to shipping containers, serve as both a regulatory hallmark and an operational sentinel. Far beyond mere metallic tags, they encapsulate a repository of vital data, rendering them indispensable in safeguarding cargo, personnel, and infrastructural assets across global transport corridors. Their existence underscores a meticulously orchestrated symbiosis between engineering precision, legal compliance, and logistical orchestration.

Historical Evolution and Regulatory Genesis

The genesis of CSC plates traces back to the mid-20th century, when burgeoning maritime trade exposed the vulnerabilities inherent in standardized containerization. Early shipping containers, though revolutionary in their ability to streamline cargo transfer, lacked a uniform mechanism for verifying structural integrity. Catastrophic incidents at sea highlighted the necessity of a globally recognized standard. Consequently, international regulatory bodies instituted CSC protocols, mandating conspicuous and indelible plate affixation. This regulatory crucible transformed CSC plates from optional markers into compulsory artifacts of maritime jurisprudence.

Material Composition and Durability Mandates

CSC plates are engineered with an emphasis on permanence and resilience. Typically fabricated from corrosion-resistant alloys or fireproof composites, these plates are designed to withstand prolonged exposure to saline atmospheres, ultraviolet radiation, and extreme mechanical stress. Embossed or stamped lettering ensures legibility across decades of usage, while advanced protective coatings mitigate the deleterious effects of oxidation. This meticulous attention to material science exemplifies the confluence of metallurgical innovation and regulatory foresight, ensuring that plates remain decipherable under the harshest operational conditions.

Metadata Encapsulation and Information Hierarchy

A CSC plate is more than a mere tag; it is a codified compendium of metadata, systematically arranged to facilitate rapid verification. The manufacturer’s identity and production date are prominently displayed, providing traceability in instances of structural anomaly or defect. Unique container identification numbers imbue each unit with an immutable digital fingerprint, pivotal for record-keeping, audit compliance, and cargo tracking. Beyond these identifiers, plates enumerate maximum gross weight, stacking weight thresholds, and racking test load parameters, collectively delineating operational limitations to prevent catastrophic failure during handling and transit.

Weight Parameters and Structural Integrity

The weight parameters inscribed on CSC plates are not arbitrary—they constitute the bulwark of structural safety. Maximum gross weight dictates the upper boundary of permissible cargo mass, while stacking weight parameters govern the sequential placement of containers in intermodal stacks. Racking test load values, derived from rigorous engineering assessments, predict the container’s capacity to withstand lateral forces during transit. Failure to adhere to these specifications can precipitate structural deformation, tipping hazards, and potentially devastating maritime incidents. CSC plates thus function as both guardians and informants of mechanical prudence.

Inspection Protocols and Lifecycle Monitoring

Inspection dates etched upon CSC plates provide an operational chronicle of a container’s life cycle. Under the Periodic Examination Scheme, forthcoming evaluation dates signal impending re-certification requirements. Continuous examination frameworks, such as ACEP, document containers enrolled in ongoing scrutiny programs, facilitating persistent compliance monitoring. This temporal indexing allows port authorities, shipping lines, and customs officials to assess safety credentials instantaneously, reducing bureaucratic friction while elevating the assurance of cargo integrity.

Standardization and Legibility Imperatives

Legibility is a non-negotiable attribute of CSC plates. International conventions stipulate that all information be permanently inscribed and resistant to environmental degradation. The positioning of plates—typically affixed to the container’s left door—ensures immediate visibility for inspectors, preventing ambiguity during rapid operational evaluations. By enforcing these standards, regulatory bodies minimize interpretative errors, fostering a universal lingua franca for container certification. In essence, CSC plates are engineered to speak an unambiguous, globally intelligible dialect of safety.

Operational Repercussions of Non-Compliance

Containers lacking valid CSC plates face immediate operational ramifications. Intermodal terminals may deny access, disrupting cargo flows and impinging upon trade efficiency. Legal implications may extend to fines or suspension of operational privileges, underscoring the non-triviality of these plates in global commerce. Beyond regulatory compliance, maintaining accurate and current CSC plates is a proactive measure against infrastructural strain, accident liability, and reputational risk for shipping consortia.

The Semiotic Role of CSC Plates

Beyond their physical and operational attributes, CSC plates serve a semiotic function within the logistics ecosystem. They communicate authority, certification, and reliability in a manner that transcends language barriers. In effect, a CSC plate is a visual affirmation that a container has undergone rigorous scrutiny and conforms to internationally codified standards. This semiotic potency reinforces confidence among stakeholders, from port operators to multinational shippers, fostering an environment of trust and operational predictability.

Technological Integration and Data Digitization

Modern logistics increasingly integrates CSC plate data into digital tracking systems, enabling real-time monitoring and analytics. Optical character recognition and RFID integration allow plates to interface with automated inventory management and port handling software. This evolution transforms static plates into dynamic data nodes, bridging the gap between analog verification and digital logistics intelligence. Consequently, CSC plates are no longer mere markers; they are integral nodes within a sophisticated, data-driven supply chain matrix.

Corrosion Resistance and Environmental Adaptation

The environmental resilience of CSC plates warrants emphasis. Containers traverse oceans, deserts, and arctic climes, confronting moisture, salt, thermal flux, and mechanical abrasion. Plates must retain clarity and legibility despite these adversities. Innovations in surface metallurgy, polymer coatings, and embossed lettering mitigate degradation, ensuring long-term durability. This adaptation to environmental exigencies exemplifies how material science intersects with regulatory imperatives, maintaining functional integrity over protracted operational horizons.

Legal Implications and International Trade Compliance

CSC plates carry substantial legal weight within international trade frameworks. They are tangible evidence of compliance with the International Convention for Safe Containers, a treaty ratified by the majority of maritime nations. Non-conformity can provoke trade disputes, customs clearance delays, and insurance repudiation. In this legal context, CSC plates operate as both a protective measure for stakeholders and a codified guarantor of contractual and statutory adherence, underscoring their multifaceted significance.

Lifecycle Management and Maintenance Protocols

Effective lifecycle management of CSC plates entails regular inspection, cleaning, and, when necessary, replacement. Containers undergo periodic re-certification, and plate maintenance ensures continued compliance with evolving standards. This process requires coordination between container owners, inspection agencies, and regulatory authorities. Neglecting this upkeep compromises structural assurance and operational legality, highlighting the plate’s integral role in container stewardship.

Strategic Placement and Ergonomic Considerations

The strategic placement of CSC plates on the container’s left door is not arbitrary. Ergonomic principles dictate visibility, accessibility, and inspection efficiency. Placement ensures that inspectors, crane operators, and port personnel can rapidly authenticate container credentials without obstructing operational workflows. This seemingly minor detail reflects a broader design philosophy: optimizing the interface between human operators and regulatory artifacts to enhance efficiency and reduce error.

Semi-Permanent Identification and Traceability

Unique identification numbers on CSC plates are semi-permanent markers of traceability. These alphanumeric codes enable meticulous tracking through global logistics networks, facilitating auditing, maintenance logging, and incident investigation. Traceability is particularly critical when addressing cargo discrepancies, container damage, or insurance claims. Each CSC plate thus functions as a persistent node within a vast information lattice, underpinning operational transparency and accountability.

Risk Mitigation and Safety Assurance

By codifying weight limits, structural capacities, and inspection intervals, CSC plates actively mitigate risk. They reduce the probability of mechanical failure, tipping accidents, and structural compromise. From a safety engineering perspective, these plates embody a preventive strategy: communicating constraints to human operators and mechanized handling systems alike. In doing so, they protect not only cargo but also human life and infrastructural assets, embodying a philosophy of proactive hazard management.

Intermodal Passport Functionality

CSC plates operate metaphorically as passports for containers. They authorize passage across ports, borders, and intermodal nodes, signaling compliance with international safety statutes. Without this “passport,” containers are effectively barred from global trade circulation, illustrating how a small metallic artifact can wield outsized influence over commerce and logistics. In this context, the plate transcends its physicality, assuming a role of regulatory and operational sovereignty.

Future Trends and Technological Innovations

Emerging trends suggest an evolution in CSC plate functionality. Smart plates incorporating blockchain verification, embedded sensors for real-time stress monitoring, and augmented reality interfaces for inspectors are on the horizon. These innovations promise to enhance traceability, reduce manual errors, and integrate plates more deeply into digital logistics ecosystems. As containers become increasingly intelligent, CSC plates are poised to evolve from static markers into dynamic instruments of operational intelligence.

Convergence of Safety, Compliance, and Efficiency

The essence of CSC plates lies in their confluence of safety, regulatory compliance, and operational efficiency. They embody an elegant synthesis of material science, engineering precision, legal rigor, and logistical pragmatism. By ensuring containers meet defined structural thresholds, providing traceable identification, and communicating inspection history, CSC plates enable seamless, secure, and predictable global trade. Their ubiquity belies their criticality, serving as silent sentinels of an intricate and interdependent transportation ecosystem.

The Indispensable Role of CSC Plates

CSC plates are not merely regulatory ornaments; they are central to the structural integrity, operational safety, and legal compliance of intermodal containers. Their meticulous design, strategic placement, and comprehensive information encapsulation confer upon them a status that is simultaneously practical, semiotic, and juridical. In the intricate ballet of global logistics, CSC plates serve as both guardians and guides, ensuring containers navigate intermodal networks safely, efficiently, and in full adherence to international standards. Maintaining these plates is thus an imperative not only for legal conformity but also for the safeguarding of human life, cargo, and the broader apparatus of global commerce.

Understanding the Intricacies of CSC Certification

Obtaining a CSC (Convention for Safe Containers) certification is an intricate endeavor that transcends the mere completion of paperwork. It demands a comprehensive evaluation of each container by certified surveyors, whose expertise ensures conformity with stringent international safety standards. Container proprietors who grasp the nuances of this process can navigate it with alacrity, minimizing delays and maximizing operational efficiency. The certification is not merely bureaucratic—it serves as a safeguard, guaranteeing structural resilience and intermodal transport readiness.

The Role of Certified Surveyors in Container Evaluation

Certified surveyors are the linchpins of the CSC certification process. Their proficiency encompasses more than visual inspection; it involves the meticulous appraisal of structural fortitude, wind- and watertightness, and load-bearing capacities. Surveyors operate within specialized facilities, often equipped with mechanized cranes, forklifts, and auxiliary lifting contrivances. These tools enable them to access every corner, including the undersides and recesses of containers, which are otherwise inaccessible. This level of scrutiny ensures that containers can endure the rigors of transport without compromise.

Identifying an Approved Surveyor

The preliminary phase of certification necessitates the identification of an approved surveyor. Only surveyors accredited under CSC regulations are authorized to execute inspections and issue certifications. This verification process is crucial, as unaccredited personnel cannot legally validate containers for intermodal transport. Surveyors typically maintain affiliations with facilities designed to accommodate the logistical demands of container handling, further ensuring that evaluations are both accurate and exhaustive.

Meticulous Structural Assessment

The inspection process itself is rigorous and multifaceted. Surveyors conduct structural assessments, meticulously examining walls, floors, ceilings, and corner castings. These inspections ascertain whether the container retains its original strength and integrity, as well as its capacity to withstand environmental and mechanical stress. The process involves evaluating welds, panels, and structural reinforcements to identify potential vulnerabilities that could jeopardize safety during transport.

Wind and Watertightness Verification

Equally critical is the assessment of wind- and watertightness. Surveyors meticulously inspect door seals, gaskets, and panel interfaces, verifying that they form a hermetic seal. Imperfections in sealing could compromise cargo, resulting in damage or contamination. These checks simulate the container’s exposure to extreme weather conditions, including rain, snow, and high winds, ensuring the container can safeguard its contents during transit.

Load-Bearing and Tensile Strength Evaluations

CSC inspections involve rigorous testing of a container’s load-bearing and tensile strengths. Corner castings, lashing points, and floor structures are subjected to stress simulations to ascertain their capacity to endure the forces encountered during stacking, lifting, and transport. These tests replicate real-world conditions, from the tension experienced when lifted by cranes to the compression exerted by stacked containers in a shipping yard. The results dictate whether a container meets the exacting standards required for certification.

Issuance of the CSC Certificate

Upon successful completion of all evaluations, a CSC certificate is issued. This document attests to the container’s compliance with international safety standards and is accompanied by the affixation of safety approval plates. These plates serve as a visible confirmation of compliance, permitting legal participation in intermodal transport networks. Containers devoid of certification cannot be transported via international routes, although they may still serve secondary purposes, such as storage, until remediation and re-certification are conducted.

The Consequences of Non-Compliance

Containers that fail to meet CSC standards face operational limitations. Non-compliant containers cannot be transported internationally, which could disrupt supply chains and precipitate financial losses. Moreover, using substandard containers risks cargo damage, accidents, and legal penalties. This underscores the importance of thorough inspections and the need for owners to collaborate with experienced surveyors who can identify deficiencies before they escalate into logistical crises.

Specialized Facilities and Streamlined Processes

Facilities dedicated to CSC certification provide a controlled environment for meticulous inspections. Equipped with state-of-the-art lifting mechanisms, specialized tools, and trained personnel, these centers facilitate efficient evaluations while ensuring thorough compliance. Streamlined processes reduce operational downtime and minimize costs, benefiting container owners who require swift certification to maintain supply chain fluidity. The integration of advanced diagnostics and testing equipment allows for precise structural assessments, reinforcing the reliability of issued certificates.

Regional Availability and Accessibility of Surveyors

Geographic accessibility of accredited surveyors enhances operational efficiency. In many regions, networks of certified surveyors enable container owners to obtain CSC certification without incurring extensive logistical burdens. Localized facilities reduce transport time to inspection sites and provide timely certification, ensuring that containers are swiftly ready for deployment. This accessibility is particularly beneficial for businesses operating across multiple ports or transport hubs, where timing is critical to maintaining supply chain continuity.

Navigating the Certification Process Efficiently

Effective navigation of the CSC certification process requires proactive planning. Container owners should maintain accurate records of previous inspections, repairs, and structural modifications. Such documentation aids surveyors in conducting thorough evaluations while streamlining the process. Early engagement with accredited surveyors also allows owners to anticipate potential deficiencies and implement corrective measures before formal inspection, minimizing the risk of failure and ensuring timely certification.

The Economic Implications of CSC Certification

Beyond safety considerations, CSC certification bears significant economic implications. Certified containers facilitate seamless participation in global trade, unlocking intermodal transport opportunities and expanding logistical flexibility. Conversely, uncertified containers face restrictions that may necessitate alternative transport arrangements or incur additional storage costs. By investing in certification and preventive maintenance, container owners mitigate financial risk while enhancing operational reliability, underscoring the strategic value of CSC compliance.

Safety Assurance and Risk Mitigation

The paramount advantage of CSC certification lies in safety assurance. Containers evaluated under rigorous standards protect both cargo and personnel, mitigating the risk of accidents during handling, transport, and storage. Structural weaknesses, if undetected, could result in catastrophic failure, jeopardizing lives and cargo alike. By ensuring compliance with international standards, certification acts as a proactive measure against preventable incidents, reinforcing the resilience of global supply chains.

Technological Integration in Surveying

Modern surveyors increasingly integrate technology into the CSC inspection process. Non-destructive testing tools, digital measurement systems, and imaging devices enhance accuracy and efficiency. These innovations allow surveyors to detect micro-fractures, corrosion, and structural anomalies that might elude conventional visual inspection. The integration of technology not only accelerates certification but also ensures a higher degree of confidence in the structural soundness of evaluated containers.

Maintenance and Periodic Recertification

CSC certification is not a one-time event; containers require periodic reassessment to maintain validity. Routine inspections verify that structural integrity and safety standards remain intact over time. Maintenance activities, including repairs, repainting, and gasket replacement, are integral to prolonging a container’s operational lifespan and sustaining certification. Proactive upkeep minimizes the likelihood of failures and facilitates continuous compliance, supporting uninterrupted participation in international transport networks.

Collaboration Between Owners and Surveyors

Effective collaboration between container owners and surveyors enhances the efficiency and reliability of the certification process. Transparent communication regarding container history, modifications, and intended usage enables surveyors to tailor evaluations appropriately. Owners benefit from expert guidance on maintenance and corrective measures, while surveyors ensure compliance with stringent standards. This symbiotic relationship fosters trust, operational clarity, and seamless certification outcomes.

Legal and Regulatory Compliance

CSC certification serves as a tangible marker of legal and regulatory compliance. International shipping regulations mandate adherence to these standards, and failure to comply can result in penalties, confiscation of containers, or denial of port entry. By securing certification, container owners demonstrate conformity with international law, avoiding legal entanglements and ensuring uninterrupted access to global trade routes. This regulatory alignment reinforces credibility and facilitates long-term operational sustainability.

Environmental Considerations in Container Certification

Environmental sustainability increasingly intersects with container certification. Inspectors evaluate not only structural integrity but also conditions that may affect environmental safety, such as chemical contamination or hazardous materials storage. Proper sealing and maintenance prevent leaks and contamination, protecting ecosystems and human health. CSC certification thus aligns with broader environmental stewardship initiatives, underscoring the multifaceted value of rigorous container assessment.

Strategic Advantages for Global Supply Chains

Containers with CSC certification confer strategic advantages within global supply chains. Certified containers are versatile, compatible with intermodal transport, and reliable under varied logistical conditions. Their predictable performance minimizes delays, reduces damage claims, and enhances the efficiency of transport operations. For businesses operating across diverse geographic regions, certified containers provide operational continuity, fostering resilience against disruptions and optimizing overall supply chain performance.

The Imperative of CSC Certification

The journey to CSC certification is both intricate and indispensable. It encompasses meticulous inspections, structural evaluations, and compliance with rigorous international standards. Working with approved surveyors ensures that containers are safe, reliable, and legally transportable. Beyond regulatory adherence, certification fortifies global supply chains, mitigates risks, and underpins economic efficiency. For container owners and operators, investing in CSC certification is not merely a legal obligation—it is a strategic imperative that safeguards assets, personnel, and commercial operations alike.

Understanding the Essence of CSC Certification Renewal

CSC certification is not merely a bureaucratic formality; it embodies a sentinel of intermodal safety and operational fidelity. Once a container attains this certification, the responsibility does not dissipate—it metamorphoses into a continuous guardianship of structural integrity and regulatory compliance. Neglecting renewal obligations can precipitate multifarious consequences, from operational suspensions to potential legal ramifications, underscoring the primacy of understanding available renewal options.

The renewal process functions as a pivotal nexus between regulatory compliance and pragmatic container management. Container operators must assimilate the intricate mechanisms by which CSC certification is perpetuated. By elucidating the two primary renewal paradigms—the Periodic Examination Scheme (PES) and the Approved Continuous Examination Program (ACEP)—operators gain the perspicacity necessary to harmonize safety with operational efficiency.

Periodic Examination Scheme: Structured Oversight

The Periodic Examination Scheme epitomizes a regimented, temporally delineated framework for container inspections. Under this paradigm, a nascent container is mandated to undergo its inaugural inspection within a quintennial period following manufacture. Subsequent inspections adhere to a triennial cadence, with intervals never exceeding thirty months. The subsequent examination date, emblazoned upon the CSC plate, functions as an immutable lodestar for compliance, offering transparency and logistical predictability.

PES’s structured approach ensures that containers are periodically scrutinized for latent structural vulnerabilities, corrosion anomalies, and potential fatigue in load-bearing elements. The methodical schedule of PES fosters a predictable operational rhythm, allowing operators to allocate maintenance resources judiciously while mitigating unforeseen downtime. The framework’s temporal clarity is particularly beneficial for smaller operators who lack extensive surveillance infrastructures yet seek to maintain rigorous safety adherence.

Approved Continuous Examination Program: Dynamic Surveillance

The Approved Continuous Examination Program introduces a paradigm of perpetual vigilance, juxtaposing PES’s fixed inspections with an agile, real-time monitoring ethos. Containers enrolled in ACEP are inspected with each ingress into repair facilities or during routine maintenance. This dynamic oversight ensures that containers are perpetually evaluated for structural soundness, permitting immediate remediation of anomalies before they escalate into critical failures.

The ACEP scheme number inscribed upon the CSC plate signals that the container is integrated within a continuous oversight matrix. This transparency fosters trust among shippers, carriers, and regulatory entities, as the container’s safety trajectory is meticulously documented and readily verifiable. ACEP’s adaptive nature is especially propitious for large-scale operators and leasing consortia, where fleet-wide coherence and instantaneous data aggregation are imperative.

Repair Obligations and Structural Integrity

Irrespective of the renewal method, the cornerstone of CSC maintenance lies in rectifying structural compromises. Any damage that attenuates the container’s integrity—be it denting, corrosion, perforation, or compromised welds—necessitates prompt repair. These reparations are not perfunctory; they demand subsequent CSC inspection to certify that remedial interventions restore compliance with rigorous safety parameters.

Neglecting these obligations is fraught with peril. Containers exhibiting unremediated damage may be refused at intermodal terminals, exposing operators to logistical bottlenecks and contractual liabilities. Legal enforcement mechanisms can impose fines or operational sanctions, making diligent adherence not merely advisable but imperative. Thus, the confluence of repair protocols and inspection schedules serves as a sentinel safeguarding both cargo and human operators.

Scheduling Inspections and Operational Fluidity

Renewal processes are most efficacious when synchronized with specialized inspection facilities. These centers provide streamlined pathways for CSC evaluations, integrating technical expertise with logistical expedience. Operators often cultivate enduring partnerships with accredited surveyors to ensure inspections occur punctually, reducing the likelihood of unscheduled downtime that can disrupt supply chains.

The confluence of proactive planning and professional oversight engenders operational fluidity. By strategically scheduling inspections in alignment with transport cycles and maintenance routines, operators minimize disruptions while maintaining regulatory fidelity. This orchestration of timing, expertise, and procedural adherence epitomizes the strategic dimension of CSC renewal.

Regulatory Compliance and Operational Prudence

Maintaining CSC certification transcends mere adherence to international codes; it epitomizes operational prudence and a culture of safety. Containers that consistently meet PES or ACEP requirements are emblematic of organizations that prioritize long-term operational viability over ephemeral cost-cutting. Regulatory bodies interpret sustained certification as an indicator of organizational competence, reinforcing the operator’s reputation and credibility in the global shipping arena.

Moreover, the demonstration of compliance instills confidence among stakeholders. Shippers entrust their cargo to containers whose integrity is systematically validated, while insurers recognize the mitigated risk inherent in rigorously maintained equipment. The nexus between compliance and commercial trust underscores why CSC maintenance is not a perfunctory obligation but a strategic imperative.

Strategic Benefits of Continuous Oversight

Continuous oversight, whether via PES or ACEP, confers a multitude of strategic advantages. Beyond regulatory compliance, the practice functions as a sentinel against latent structural anomalies, corrosion propagation, and operational disruptions. Containers subjected to consistent scrutiny exhibit prolonged service life, diminished repair costs, and enhanced reliability in intermodal operations.

From a fleet management perspective, continuous oversight permits the aggregation of predictive maintenance data, fostering analytics-driven decision-making. Operators can preemptively identify containers prone to recurrent faults, optimize repair schedules, and allocate resources more efficiently. The synthesis of regulatory compliance with strategic foresight exemplifies the multidimensional utility of meticulous CSC maintenance.

Documentation and CSC Plate Fidelity

The CSC plate serves as both a certification artifact and a navigational instrument for operational compliance. Accurate recording of renewal dates, ACEP enrollment, and inspection histories on the plate ensures that regulatory verification is straightforward and unambiguous. Inaccuracies or omissions can provoke scrutiny, delays, and potential denial of container usage, emphasizing the need for meticulous documentation.

Operators are advised to integrate CSC plate data with digital maintenance records, enabling real-time tracking of compliance status across extensive fleets. Such integration enhances transparency, facilitates audits, and strengthens the operator’s defensibility in regulatory contexts. In essence, the CSC plate transcends its nominal role to become a keystone of operational and compliance management.

Minimizing Operational Downtime

One of the most palpable challenges in container management is mitigating downtime associated with inspections and repairs. Proactive scheduling, fortified by robust relationships with surveyors, is instrumental in maintaining continuity. Operators who anticipate inspection intervals and coordinate maintenance activities around cargo cycles can substantially reduce operational interruptions.

Moreover, ACEP’s dynamic inspection paradigm inherently diminishes unanticipated downtime by embedding inspections within routine maintenance workflows. Containers are continuously vetted, allowing operators to address deficiencies opportunistically rather than reactively. This strategic alignment of inspection, repair, and operational cadence exemplifies efficiency in action.

Risk Mitigation and Cargo Protection

CSC certification renewal functions as a bulwark against operational risk. Containers that meet regulatory inspection standards are less susceptible to catastrophic failures that could compromise cargo integrity. In this sense, certification is not merely procedural but a tangible mechanism for asset protection and risk mitigation.

For high-value or sensitive shipments, consistent compliance serves as an assurance of reliability. Shippers gain confidence that containers will withstand intermodal stresses, environmental exposure, and handling variations. The preservation of cargo fidelity directly correlates with an operator’s reputation and commercial viability, reinforcing the economic rationale for rigorous certification maintenance.

Integrating Renewal Practices into Fleet Strategy

The orchestration of renewal practices must be seamlessly integrated into overarching fleet management strategies. Operators benefit from centralized scheduling systems that consolidate PES and ACEP obligations, allowing for predictive maintenance planning and resource optimization. Such integration ensures that compliance is not a siloed activity but a cohesive component of operational governance.

Furthermore, embedding renewal protocols within fleet management software enhances traceability, facilitates regulatory reporting, and supports data-driven decision-making. This harmonization of compliance and operational intelligence exemplifies the modern paradigm of intermodal container management, where regulatory adherence is symbiotic with strategic efficiency.

Future Trends in CSC Renewal Oversight

As global shipping networks expand and technological innovations proliferate, CSC certification renewal is poised to evolve. Emerging digital inspection modalities, predictive maintenance analytics, and blockchain-based compliance tracking are likely to augment traditional PES and ACEP frameworks. These innovations promise heightened transparency, expedited verification, and more precise predictive capabilities.

Operators who adopt these advancements proactively will gain competitive advantages, including enhanced fleet reliability, lower unplanned maintenance costs, and strengthened stakeholder confidence. The evolution of renewal practices reflects a broader trend in logistics: the convergence of safety, efficiency, and technological sophistication.

Fostering a Culture of Safety and Compliance

At its core, CSC certification renewal embodies a cultural commitment to safety and compliance. Organizations that prioritize inspection, repair, and continuous oversight cultivate a workforce attuned to structural integrity, operational prudence, and regulatory diligence. This culture permeates beyond compliance metrics, influencing daily operational decisions, cargo handling practices, and maintenance ethos.

The perpetuation of such a culture ensures that containers remain robust, cargo is safeguarded, and intermodal operations proceed without interruption. CSC renewal thus transcends its administrative veneer to become a living testament to organizational values and operational excellence.

Conclusion

Maintaining CSC certification is not a perfunctory bureaucratic exercise but a dynamic interplay of inspection, repair, documentation, and strategic foresight. Through PES or ACEP, operators ensure that containers remain structurally sound, compliant with international standards, and operationally reliable. The meticulous orchestration of inspections, repair protocols, and fleet-wide monitoring cultivates a culture of safety, mitigates risk, and fortifies stakeholder confidence.

In essence, CSC renewal is the fulcrum upon which intermodal operational excellence balances. It safeguards assets, ensures continuity, and sustains the integrity of global supply chains. By embracing proactive maintenance, continuous oversight, and strategic integration, container operators affirm their commitment to safety, efficiency, and enduring compliance.