Certification: CLSSGB

Certification Full Name: Certified Lean Six Sigma Green Belt

Certification Provider: GAQM

Exam Code: CLSSGB

Exam Name: Certified Lean Six Sigma Green Belt - GAQM

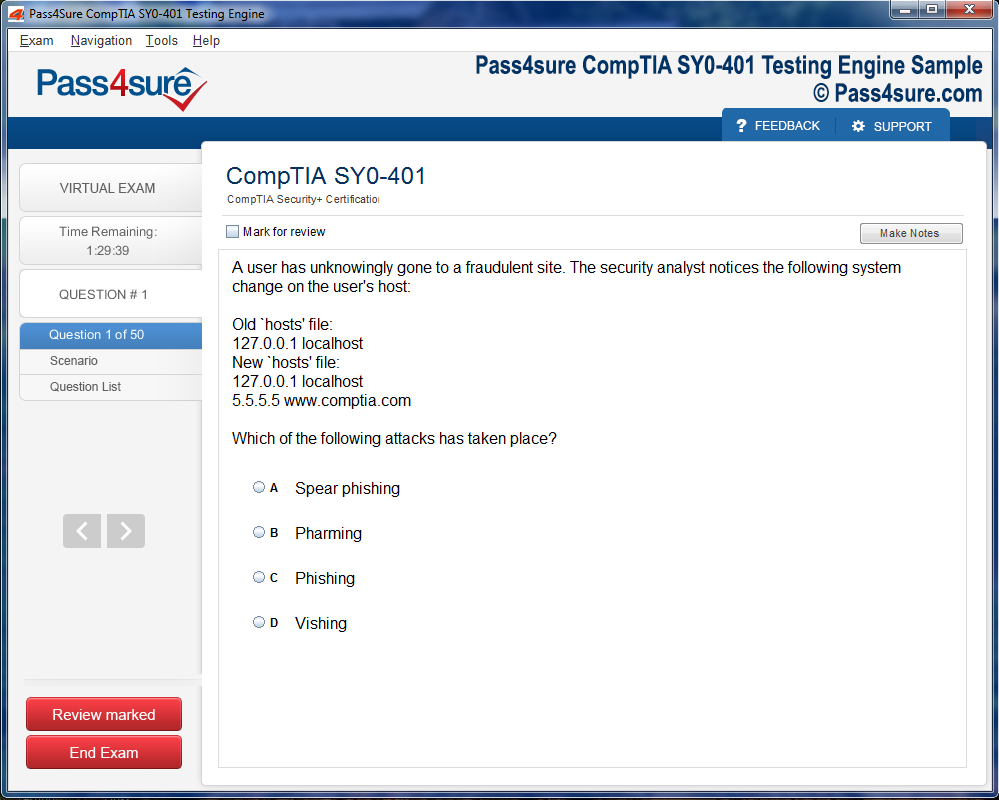

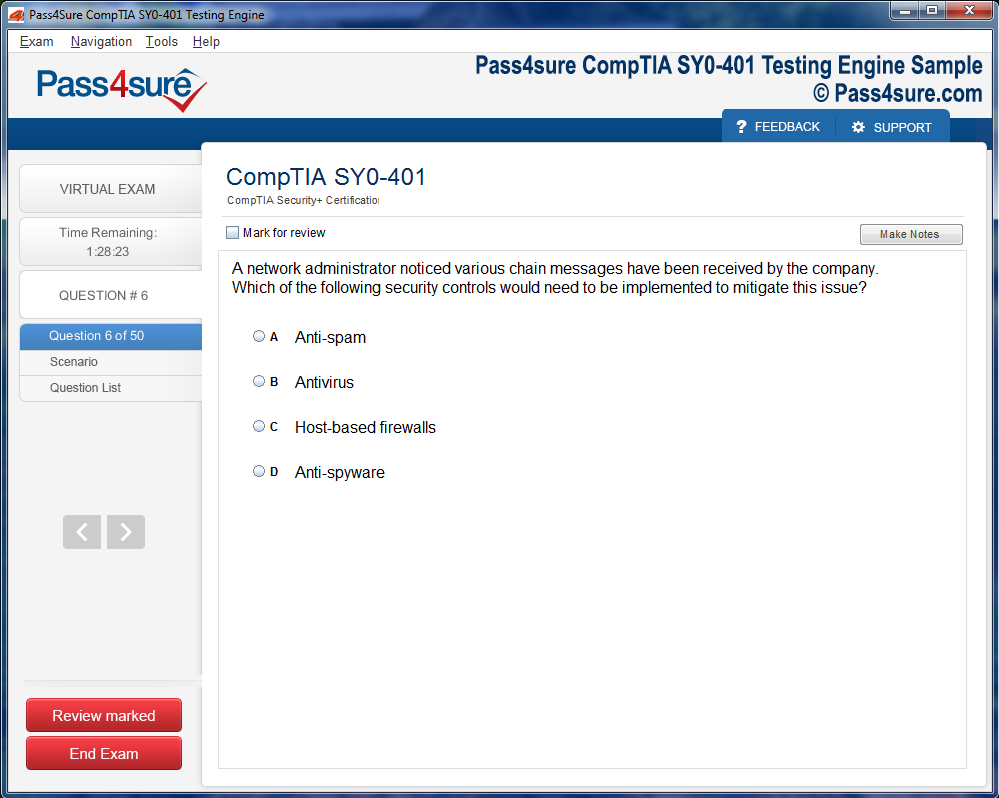

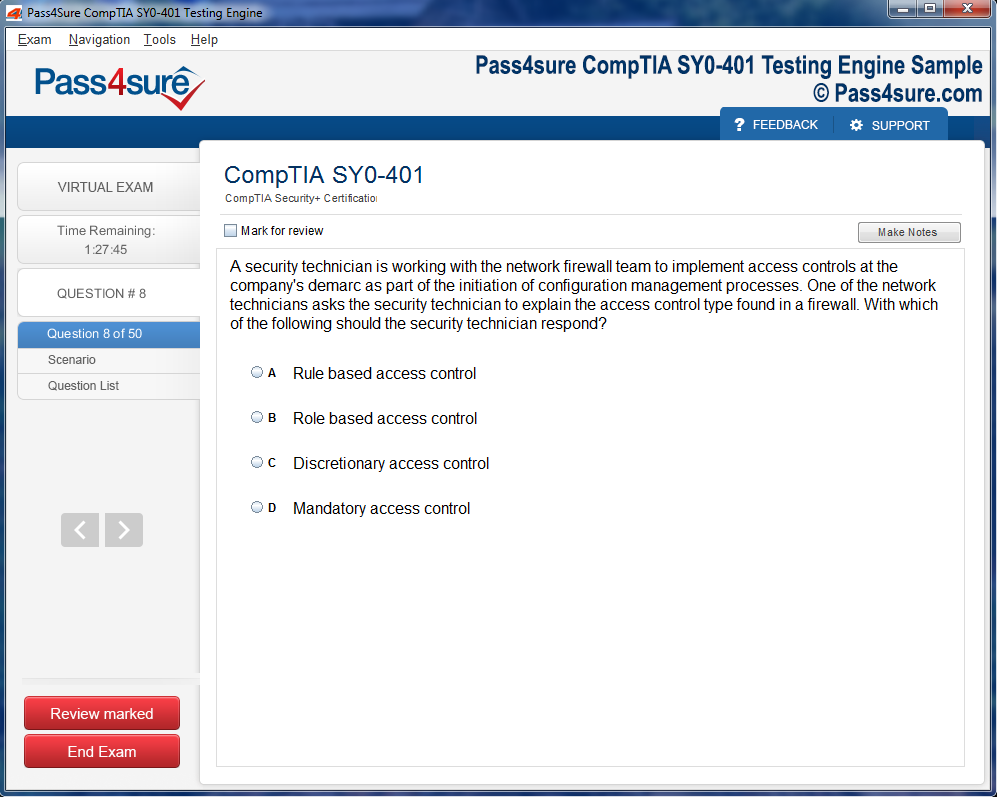

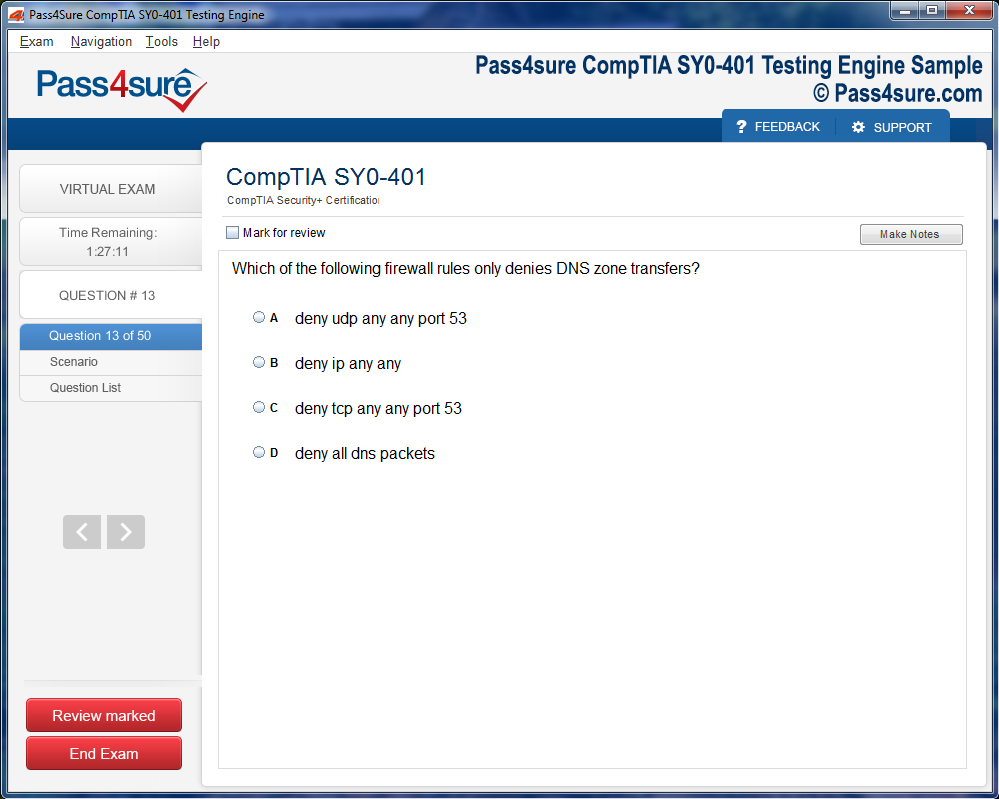

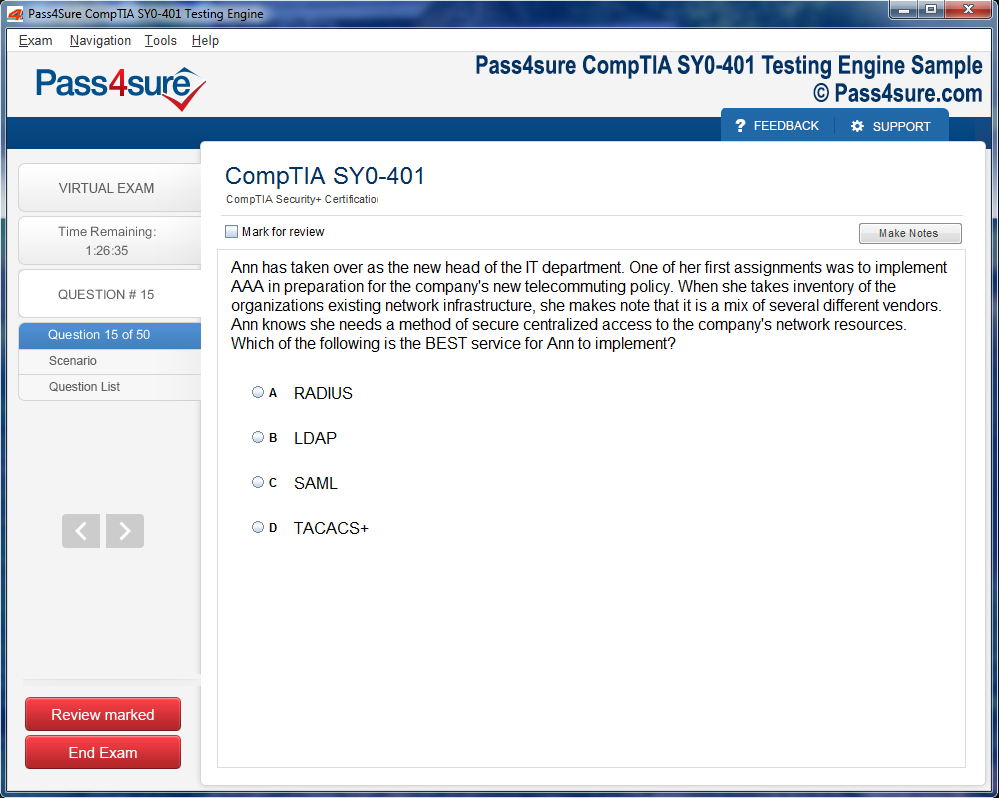

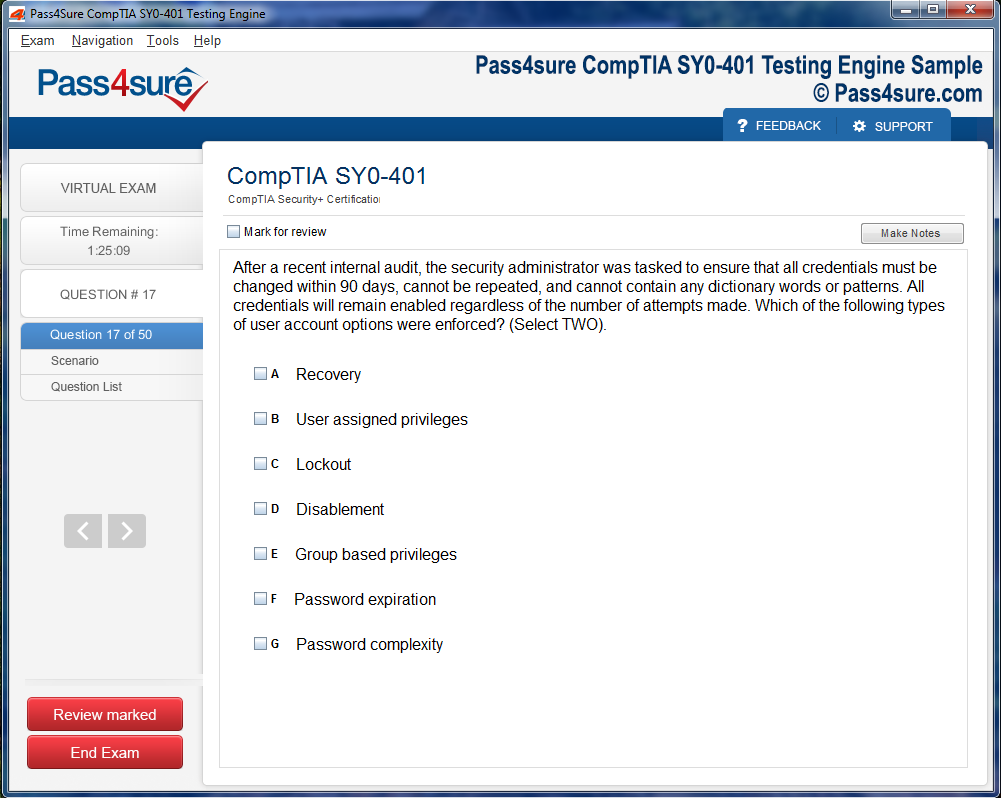

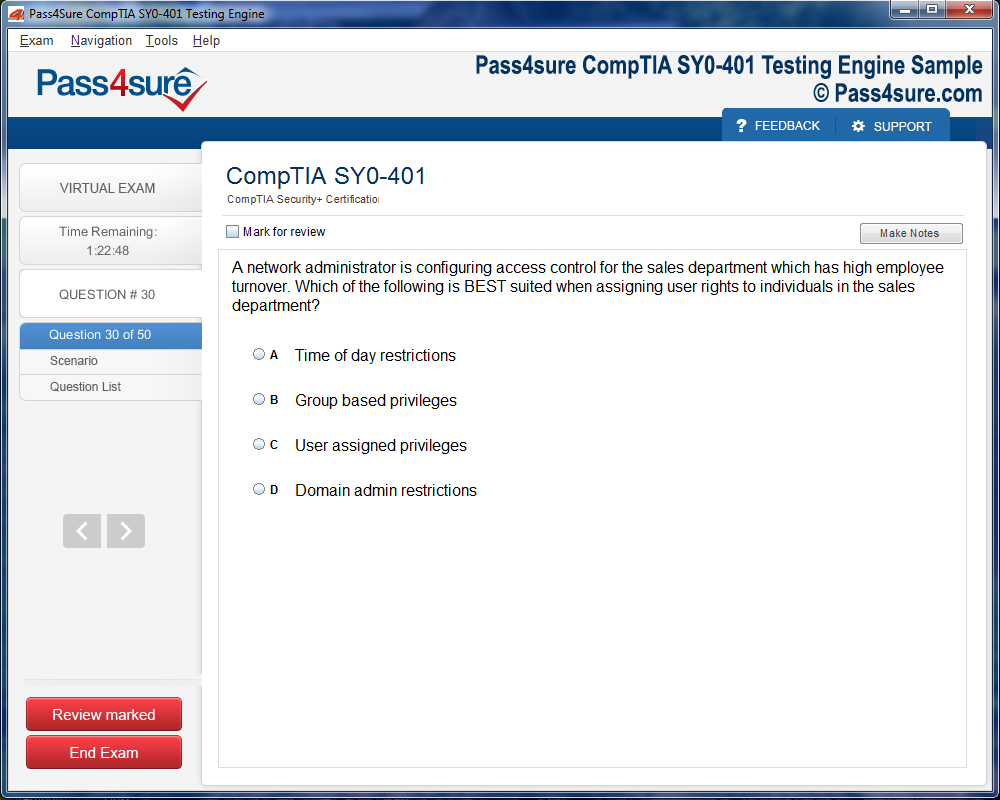

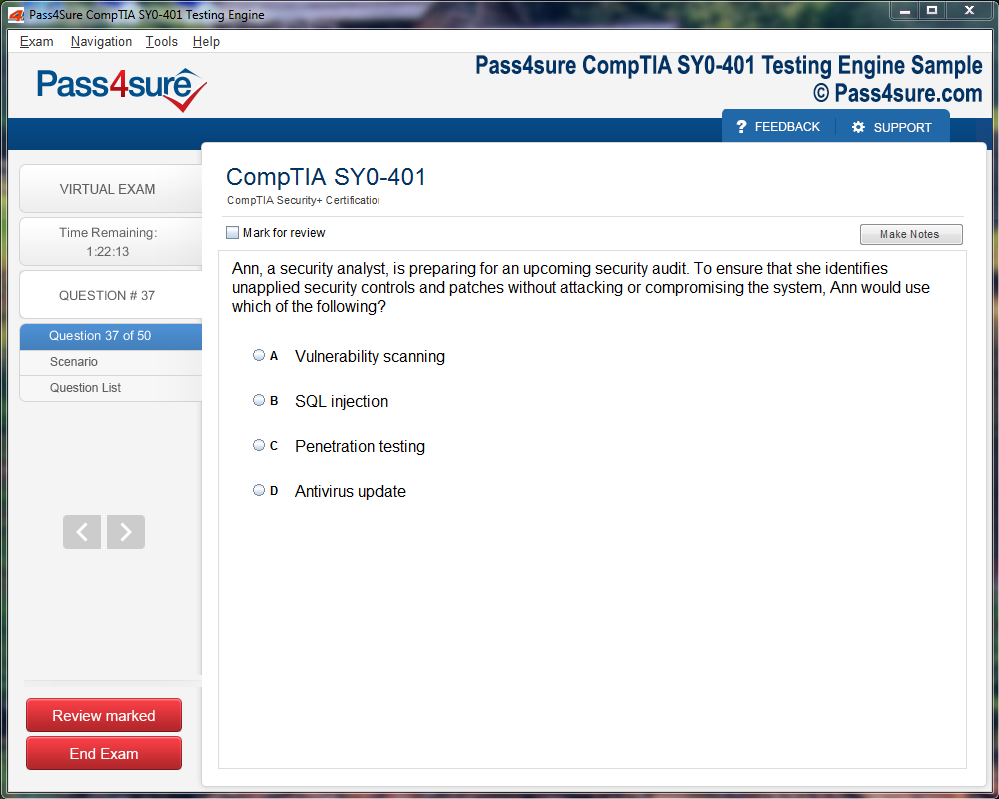

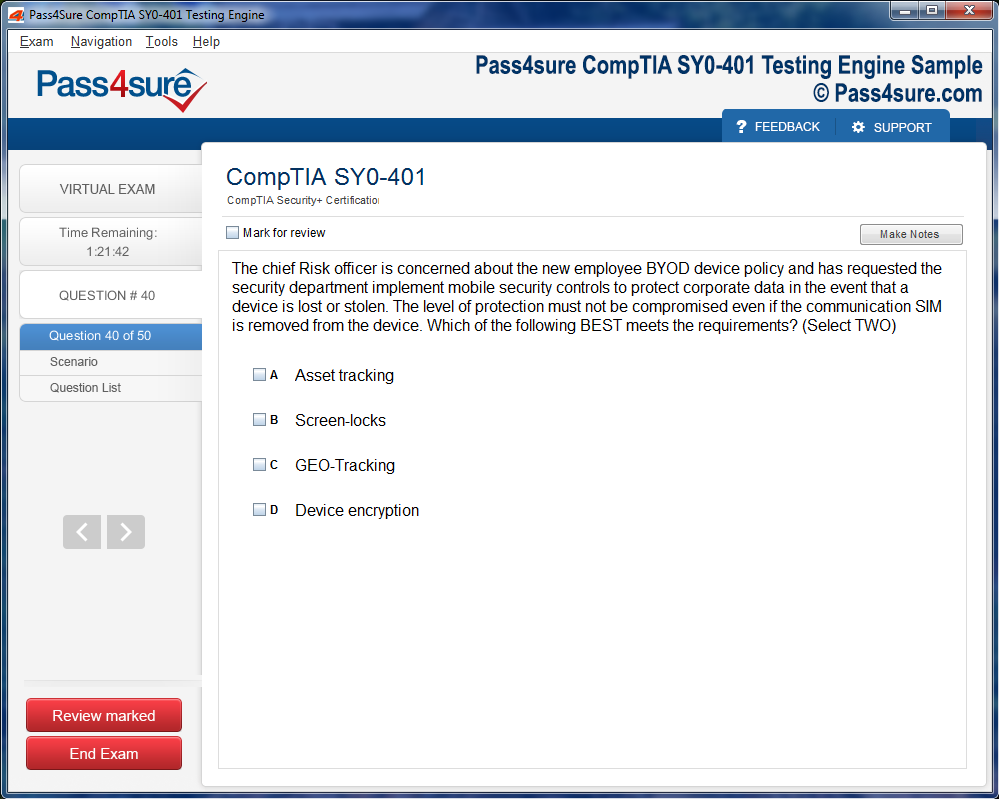

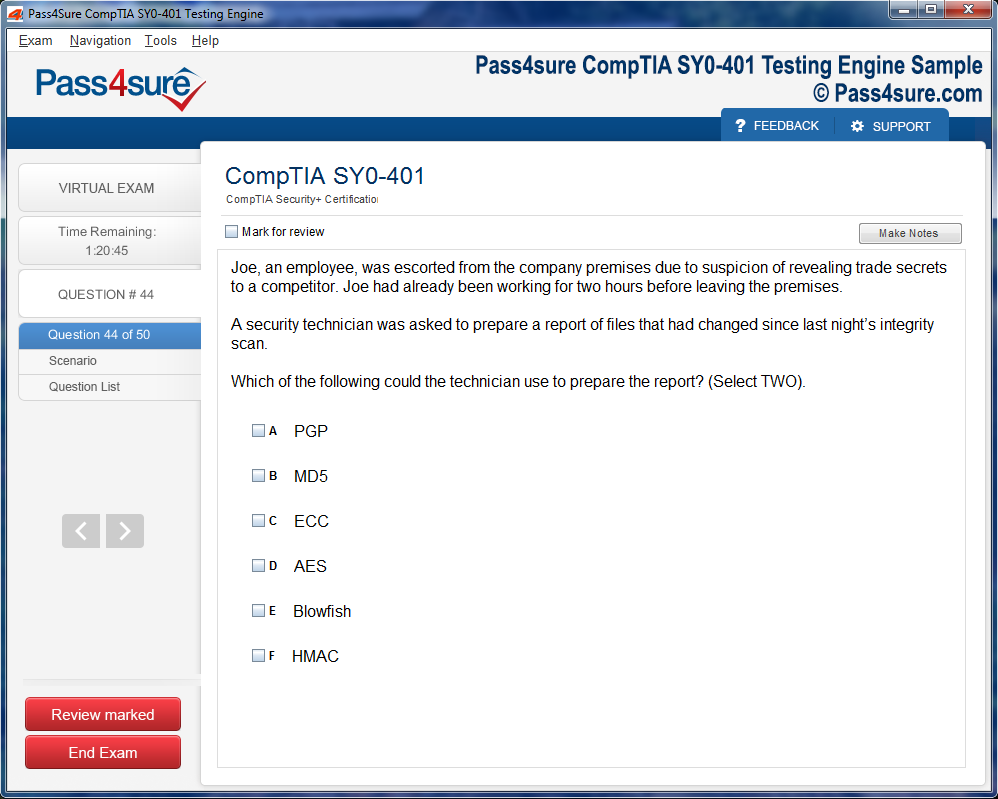

Product Screenshots

Lean Six Sigma CLSSGB Certification: How It Boosts Your Career

The contemporary professional world is characterized by rapid evolution, unprecedented competition, and a relentless quest for operational excellence. In this environment, Lean Six Sigma has emerged as a pivotal methodology that blends the efficiency-centric principles of Lean with the precision-oriented strategies of Six Sigma. This fusion creates a framework designed to optimize processes, minimize waste, and elevate overall organizational performance. Lean Six Sigma is not merely a set of techniques; it represents a mindset of continual refinement, a philosophy that instills discipline, analytical rigor, and a results-driven approach. Professionals who embrace this methodology often find themselves equipped with the tools to navigate increasingly complex business landscapes and to contribute meaningfully to sustained organizational growth.

Lean Six Sigma’s relevance transcends industry boundaries. From manufacturing floors to corporate offices, service-based enterprises, and healthcare institutions, the principles of process efficiency and quality assurance resonate across diverse operational domains. Organizations are progressively relying on Lean Six Sigma to address inefficiencies, enhance customer satisfaction, and maintain competitive advantage. For professionals, the ability to implement these strategies effectively is invaluable, positioning them as critical contributors to both immediate operational improvements and long-term strategic success.

The Significance of CLSSGB Certification

Attaining the Lean Six Sigma Green Belt (CLSSGB) certification is a profound milestone in a professional’s career trajectory. Unlike introductory certifications that offer superficial exposure, CLSSGB delves deeply into analytical tools, statistical analysis, process mapping, and quality management frameworks. This certification is meticulously structured to ensure candidates not only comprehend theoretical concepts but also acquire the capability to implement solutions in real-world scenarios. The journey toward certification equips professionals with the expertise to identify inefficiencies, drive measurable improvements, and lead teams in achieving operational excellence.

The CLSSGB credential conveys more than just technical knowledge. It signifies a professional’s commitment to continuous improvement, strategic thinking, and measurable impact. Green Belt holders are trained to approach problems systematically, relying on empirical data rather than intuition alone. This approach fosters credibility within organizations and cultivates a culture of accountability, where decisions are supported by concrete evidence. The ability to merge analytical prowess with practical leadership distinguishes CLSSGB professionals in competitive industries, enhancing their visibility and career advancement opportunities.

Data-Driven Decision Making as a Core Competency

A cornerstone of Lean Six Sigma is its emphasis on data-driven decision-making. Modern business environments demand that strategies are informed by objective metrics and rigorous analysis rather than conjecture or tradition. Certified Green Belts are proficient in employing statistical tools, hypothesis testing, regression analysis, and process control charts to diagnose inefficiencies, predict outcomes, and recommend optimized solutions. These competencies empower professionals to quantify deviations, monitor improvements, and sustain high levels of operational performance.

The analytical dimension of Lean Six Sigma encourages a culture where every process intervention is measurable, accountable, and aligned with organizational objectives. Professionals trained in these methods can anticipate potential pitfalls, mitigate risks, and implement proactive strategies that drive continuous improvement. For businesses, the presence of such data-oriented leaders reduces uncertainty, enhances decision-making precision, and fosters operational resilience in a competitive marketplace.

Cultivating Cross-Functional Collaboration

Lean Six Sigma transcends the realm of technical proficiency by emphasizing collaboration and communication. The CLSSGB curriculum trains professionals to lead project teams, engage stakeholders across departments, and navigate organizational complexities with finesse. Certified Green Belts serve as bridges between functional units, translating complex analytical insights into actionable strategies that resonate with diverse teams. This collaborative skill set ensures that process improvements are not confined to isolated areas but have a ripple effect throughout the organizational ecosystem.

Cross-functional collaboration also amplifies the visibility and influence of certified professionals. By facilitating cohesive teamwork and aligning efforts toward common goals, Green Belts enhance organizational synergy and foster a culture of mutual accountability. Professionals adept in collaboration are frequently entrusted with transformational projects, and their ability to harmonize diverse perspectives positions them as indispensable assets in both operational and strategic contexts.

Fostering a Mindset of Continuous Improvement

Beyond technical expertise and collaborative acumen, Lean Six Sigma cultivates a mindset centered on curiosity, experimentation, and iterative refinement. Certified Green Belts are encouraged to challenge established norms, explore alternative methodologies, and embrace a philosophy of perpetual learning. This mindset equips professionals to respond adeptly to ambiguity, adapt strategies based on evolving circumstances, and identify opportunities for sustained improvement.

The value of this mindset is profound in dynamic industries where traditional approaches are often insufficient. Lean Six Sigma practitioners demonstrate resilience in problem-solving, creativity in optimizing workflows, and diligence in maintaining high standards of quality. The CLSSGB certification, therefore, represents not only mastery of statistical and process improvement tools but also a commitment to professional growth, intellectual agility, and adaptive leadership.

Strategic Career Advancement Through Lean Six Sigma

The impact of Lean Six Sigma certification on career progression is both significant and multifaceted. Professionals who hold the CLSSGB credential frequently find themselves positioned for leadership roles due to their demonstrated capability in managing complex projects, assessing risks, and driving performance improvements. Green Belts are entrusted with responsibilities that extend beyond immediate project execution to include strategic planning, organizational analysis, and quality assurance initiatives. These competencies enhance employability, increase compensation potential, and pave the way for roles that influence overarching business strategies.

The strategic value of Lean Six Sigma also lies in its ability to differentiate professionals within competitive labor markets. Organizations increasingly seek individuals who combine analytical insight with operational acumen, who can lead transformative initiatives while fostering collaboration, and who maintain a relentless focus on measurable outcomes. Possession of the CLSSGB certification signals to employers that the professional is capable of contributing both tactical and strategic value, making them an integral part of organizational growth and long-term success.

Elevating Organizational Performance and Influence

Lean Six Sigma Green Belts are instrumental in elevating organizational performance. Through meticulous process mapping, waste reduction, and quality enhancement initiatives, these professionals contribute to operational excellence that transcends department boundaries. Their work ensures that organizations function efficiently, respond swiftly to challenges, and maintain the highest standards of service or production quality. The influence of Green Belts extends to mentoring colleagues, instilling data-driven practices, and shaping a culture that values continuous improvement and innovation.

Moreover, the adoption of Lean Six Sigma methodologies promotes sustainability and long-term operational resilience. Organizations benefit from improved resource utilization, reduced errors, and enhanced customer satisfaction. Professionals with CLSSGB certification not only drive these outcomes but also embody a leadership paradigm rooted in diligence, strategic insight, and analytical precision. The combination of technical expertise, collaborative aptitude, and forward-looking problem-solving empowers certified individuals to become catalysts for transformation within their organizations, reinforcing both professional credibility and organizational competitiveness.

Integrating Lean Six Sigma Into Everyday Practices

The true power of Lean Six Sigma lies in its practical application. Certified professionals integrate its principles into daily operations, continuously seeking opportunities for enhancement. Whether analyzing supply chains, optimizing service workflows, or improving internal communication processes, Green Belts apply methodologies that yield tangible, measurable results. The iterative nature of Lean Six Sigma ensures that improvements are sustained over time, creating a dynamic environment where learning and adaptation are constant.

Every project undertaken by a Green Belt becomes a learning experience that contributes to professional refinement. The process of identifying root causes, implementing corrective actions, and verifying results reinforces a cycle of perpetual development. This hands-on approach not only enhances organizational efficiency but also reinforces the professional’s capacity to lead, innovate, and influence operational strategies effectively.

The Broader Influence of Lean Six Sigma Certification

Lean Six Sigma certification carries a profound influence beyond individual projects and organizational boundaries. Professionals equipped with CLSSGB credentials contribute to shaping industry standards, fostering innovation, and promoting best practices. Their insights influence decision-making at strategic levels, and their ability to transform complex challenges into structured, actionable solutions sets them apart in highly competitive fields.

In addition, the credibility and recognition associated with Lean Six Sigma certification foster trust among colleagues, stakeholders, and clients. Certified Green Belts exemplify professionalism, analytical rigor, and a commitment to excellence, qualities that resonate across business ecosystems. Their role often extends to mentoring, training, and inspiring teams, thereby multiplying the impact of their expertise throughout the organization.

Continuous Learning and Lifelong Value

One of the most compelling aspects of Lean Six Sigma Green Belt certification is its emphasis on lifelong learning. The principles, methodologies, and analytical tools acquired through the certification process equip professionals with skills that remain relevant regardless of industry shifts or technological changes. Certified Green Belts are empowered to continuously refine their approach, adopt emerging best practices, and respond proactively to evolving organizational needs.

This continuous learning ethos fosters adaptability, ensuring that professionals remain valuable assets to their organizations. The ability to navigate complex processes, implement improvements, and lead diverse teams underpins sustained professional relevance. For those seeking to cultivate a distinctive professional identity, the CLSSGB certification offers not only immediate operational competence but also enduring strategic and intellectual capital.

Understanding the Value of CLSSGB Certification

In today’s competitive professional world, standing out requires more than ordinary skills. Lean Six Sigma Green Belt certification represents a confluence of technical expertise and strategic insight. Professionals who achieve this credential are recognized as individuals capable of not only performing tasks efficiently but also improving entire systems. The value of CLSSGB certification lies in its dual promise: the ability to manage processes effectively and to influence organizational outcomes positively. Companies increasingly seek individuals who can identify hidden inefficiencies, propose data-driven solutions, and execute process improvements with measurable results. This recognition empowers certified Green Belts to occupy strategic roles and positions them as critical contributors to business success.

Certification serves as a formal acknowledgment of proficiency. It validates the knowledge of process improvement principles, statistical tools, and project management techniques. More importantly, it signals to employers and peers that the professional is committed to excellence and continuous learning. In sectors where competition is fierce and operational efficiency is paramount, such credentials differentiate candidates who possess theoretical knowledge from those who can translate that knowledge into tangible organizational improvements. This distinction often leads to immediate professional credibility and long-term career growth.

Enhancing Operational Excellence

One of the primary advantages of Lean Six Sigma Green Belt certification is the enhancement of operational effectiveness. Certified professionals are trained to analyze processes systematically, uncover inefficiencies, and design improvements that optimize performance. Their contributions often result in significant cost savings, better quality control, and faster delivery times. The ability to approach challenges analytically ensures that every action taken is informed by data and empirical evidence rather than intuition alone.

Green Belts often take the lead on projects that impact key performance indicators directly. They employ tools such as process mapping, root cause analysis, and statistical measurement to diagnose problems accurately. This structured approach enables organizations to reduce errors, eliminate waste, and improve customer satisfaction. Over time, the cumulative effect of these improvements translates into stronger financial results, better reputation, and a more resilient operational framework. Professionals who can consistently demonstrate such value become indispensable assets within their organizations.

Expanding Career Versatility

Another compelling advantage of CLSSGB certification is the versatility it provides across industries. Lean Six Sigma principles are not confined to a single sector; they apply equally to manufacturing, healthcare, technology, finance, and service-based businesses. This adaptability allows certified professionals to transition seamlessly between different organizational contexts, bringing valuable insights wherever they go. Their ability to apply analytical techniques, manage projects, and foster continuous improvement makes them highly sought after in diverse work environments.

Versatility also increases employability in uncertain job markets. Companies value professionals who can step into various roles and drive positive change. A Green Belt’s knowledge enables them to understand operational dynamics quickly, identify opportunities for improvement, and implement solutions effectively. This skill set ensures that certified professionals remain relevant and in demand even as industries evolve. The capacity to adapt Lean Six Sigma methodologies to different contexts reflects a level of strategic thinking and operational acumen that few other certifications offer.

Amplifying Professional Influence

Lean Six Sigma Green Belts do more than improve processes; they enhance organizational influence. Certified individuals often act as internal consultants, guiding teams and leadership through improvement initiatives. Their decisions are grounded in data, analysis, and best practices, which fosters trust and respect among colleagues. This professional influence extends beyond project teams, as Green Belts frequently contribute to shaping organizational culture and promoting a mindset of continuous improvement.

Influence also manifests in mentorship and collaboration. Certified professionals are well-positioned to teach others about efficiency techniques, effective problem-solving, and quality management. Their guidance elevates the performance of entire departments and encourages a culture where employees value innovation and strategic thinking. The combination of technical expertise and interpersonal effectiveness ensures that Green Belts become central figures within organizations, capable of driving initiatives that extend far beyond the immediate scope of a single project.

Strengthening Decision-Making and Risk Management

CLSSGB certification equips professionals with the ability to make better decisions and manage risks more effectively. Lean Six Sigma emphasizes the importance of analyzing processes, identifying potential obstacles, and understanding variability within systems. Certified professionals develop the insight to anticipate challenges, evaluate consequences, and implement improvements that minimize risk. This analytical approach ensures that decisions are not only informed but also optimized for long-term outcomes.

The capacity to manage risk is critical in environments where errors can be costly or damaging. Green Belts use structured methodologies to determine root causes, evaluate alternatives, and measure the impact of changes. This structured decision-making process strengthens the organization’s resilience and enhances its capacity to adapt to changing circumstances. Professionals who can combine operational knowledge with risk awareness contribute to both the efficiency and stability of their organizations, increasing their strategic importance in ways that are easily recognized by leadership.

Financial and Career Growth Benefits

The financial implications of CLSSGB certification are significant. Professionals with Lean Six Sigma credentials often enjoy higher salaries, better promotion prospects, and increased negotiating power. Employers recognize the value of individuals capable of implementing efficiency-driven projects that generate measurable results. Certification indicates a commitment to professional development, readiness to take on higher responsibilities, and the ability to influence organizational outcomes positively.

Career growth is equally compelling. Green Belts frequently find themselves positioned for leadership roles, special assignments, and cross-functional opportunities. Their unique combination of technical, analytical, and strategic skills makes them ideal candidates for management positions or roles that require problem-solving expertise at a system-wide level. Over time, this career trajectory can lead to positions of significant authority and responsibility, providing both financial rewards and personal fulfillment.

Personal Growth and Long-Term Impact

Beyond professional and financial advantages, Lean Six Sigma Green Belt certification contributes profoundly to personal development. The rigorous training and real-world problem-solving challenges enhance critical thinking, resilience, and communication skills. Professionals learn to navigate complex environments, work collaboratively, and approach problems with both creativity and analytical rigor. These skills translate into long-term value, equipping individuals to handle challenges effectively and make meaningful contributions throughout their careers.

The combination of personal and professional growth makes the CLSSGB credential transformative. Certified Green Belts emerge as well-rounded professionals capable of driving organizational excellence while cultivating a mindset of continuous learning. The holistic development achieved through certification strengthens their confidence, adaptability, and strategic perspective, ensuring they remain vital contributors in any setting. This ongoing impact reinforces the enduring value of Lean Six Sigma principles, creating professionals who are not only skilled in process improvement but also empowered to shape organizational futures.

Skills Developed Through CLSSGB Training

The journey toward Lean Six Sigma Green Belt certification is a profound odyssey that transcends mere technical mastery. It shapes professionals into versatile problem-solvers who navigate complexity with agility and precision. The CLSSGB curriculum instills a multidimensional skill set that extends far beyond process improvement, encompassing analytical rigor, project leadership, interpersonal acumen, and data-driven insight. Professionals emerging from this training exhibit a keen capacity for systematic thinking, an attribute that empowers them to deconstruct intricate workflows and unveil opportunities for tangible enhancement.

The development of analytical abilities is central to the CLSSGB experience. Trainees learn to employ a rich array of tools and methodologies that dissect processes with surgical precision. Process mapping allows individuals to visualize operations, identify inefficiencies, and document workflows in a coherent manner. Root cause analysis enables them to probe underlying issues rather than addressing mere symptoms, promoting solutions that endure. Statistical process control and hypothesis testing add quantitative depth, allowing professionals to validate improvements and anticipate variations. The cultivation of these competencies fosters a mindset that balances rigor with creativity, empowering professionals to engineer solutions that are both innovative and robust.

Cultivating Critical Thinking and Problem-Solving

Critical thinking forms the cornerstone of Lean Six Sigma philosophy. Green Belts are trained to question prevailing assumptions, scrutinize procedures from multiple vantage points, and challenge conventional practices that may obstruct progress. This discipline nurtures a mindset that blends intellectual curiosity with operational pragmatism. Professionals are encouraged to explore unconventional avenues, weighing risks and rewards with discernment. The resultant solutions are often unexpected yet practical, delivering measurable value to organizations.

Problem-solving under the CLSSGB framework is deliberate and structured. Individuals learn to approach challenges through a sequence of methodical steps that ensure thoroughness and accuracy. They develop the ability to anticipate consequences, balance competing priorities, and refine processes iteratively. Such a mindset is transformative not only for organizational efficiency but also for personal confidence. Professionals gain the assurance to make informed decisions, lead initiatives, and influence outcomes with clarity and authority.

Mastering Project Management

Project management is seamlessly integrated into Lean Six Sigma training, reinforcing the link between analysis and action. Green Belts acquire the aptitude to plan, execute, and monitor initiatives while adhering to defined timelines and resource constraints. This skill set extends beyond traditional project oversight; it involves designing improvement initiatives that align with strategic organizational goals and measurable outcomes.

Green Belts develop expertise in setting realistic objectives, establishing key performance indicators, and ensuring accountability throughout the project lifecycle. They learn to anticipate roadblocks, adapt strategies dynamically, and maintain communication with stakeholders to guarantee project alignment. The ability to orchestrate complex projects enhances professional credibility and opens doors to leadership roles. Organizations benefit from these competencies through streamlined operations, cost efficiencies, and the consistent realization of strategic objectives.

Interpersonal and Leadership Competencies

Interpersonal intelligence and leadership acumen are deeply emphasized in CLSSGB training. Green Belts often function as catalysts for change, requiring the ability to inspire, influence, and collaborate across hierarchical and departmental boundaries. Training fosters effective communication, equipping professionals to articulate ideas persuasively, resolve conflicts with tact, and cultivate stakeholder trust.

The development of leadership skills is intertwined with the principle of continuous improvement. Green Belts learn to motivate teams, manage resistance, and foster a culture where process enhancements are embraced rather than resisted. They are prepared to act as mentors and facilitators, encouraging colleagues to adopt systematic approaches to problem-solving. The integration of leadership and technical expertise ensures that professionals are not only capable of designing improvements but also of sustaining them within organizational culture.

Enhancing Data Literacy

Data literacy is a pivotal component of Lean Six Sigma proficiency. Green Belts are trained to collect, interpret, and leverage data effectively, transforming raw information into actionable insights. Statistical fluency enables professionals to discern trends, measure performance accurately, and validate interventions quantitatively. This rigorous approach ensures that process improvements are grounded in evidence rather than intuition, enhancing reliability and accountability.

Beyond technical data skills, professionals develop an appreciation for data as a strategic asset. They learn to align analytical findings with business objectives, communicate results effectively, and guide decision-making processes. Organizations gain from this expertise through enhanced operational efficiency, predictive insight, and a culture that prioritizes evidence-based strategies. Professionals gain a rare combination of analytical depth and business relevance, which elevates their influence and impact within the organization.

Building Multifaceted Professional Competence

The confluence of analytical, project management, leadership, and data skills cultivated through CLSSGB training produces a comprehensive professional profile. Individuals emerge as versatile contributors capable of delivering measurable results, navigating complexity, and inspiring organizational transformation. This multifaceted competence enhances employability and positions Green Belts for a broad spectrum of career opportunities.

Professionals equipped with these capabilities demonstrate resilience in the face of evolving organizational demands. They are adept at identifying inefficiencies, implementing effective solutions, and sustaining improvements over time. The ability to integrate technical knowledge with interpersonal influence and strategic insight distinguishes them in competitive professional landscapes. Their presence elevates organizational performance, reduces operational waste, and fosters a culture of innovation and continuous improvement.

Real-World Application and Career Advancement

The skills honed through CLSSGB training have far-reaching implications for career development and professional recognition. Green Belts are often entrusted with high-visibility projects that demand both technical acumen and leadership presence. Their ability to deliver tangible results bolsters credibility, enhances reputation, and positions them as indispensable contributors within their organizations.

The practical application of Lean Six Sigma principles transforms day-to-day operations into arenas for measurable impact. Green Belts contribute to cost reduction, quality enhancement, and customer satisfaction through meticulously designed process improvements. The cumulative effect of these contributions extends to organizational growth, competitive advantage, and sustained operational excellence. On a personal level, mastery of Lean Six Sigma methodologies cultivates confidence, strategic thinking, and a sense of professional fulfillment, creating a virtuous cycle of growth and opportunity.

Sustaining Continuous Improvement

CLSSGB training instills a mindset that values ongoing learning, experimentation, and refinement. Green Belts recognize that process improvement is not a one-time initiative but a continuous journey. They develop the discipline to monitor performance metrics, reassess interventions, and adapt strategies proactively. This commitment to perpetual enhancement ensures that improvements are durable, scalable, and aligned with evolving business objectives.

The philosophy of continuous improvement also nurtures resilience and adaptability. Professionals learn to embrace change, navigate uncertainty, and leverage challenges as opportunities for growth. The integration of analytical, leadership, and interpersonal competencies empowers Green Belts to sustain organizational improvements and foster a culture where innovation and efficiency are embedded in everyday practices. Over time, this approach contributes to long-term operational excellence and establishes professionals as trusted agents of transformation within their enterprises.

Lean Six Sigma Green Belt Fundamentals

Lean Six Sigma Green Belt certification equips professionals with a robust toolkit for process improvement, blending the principles of lean management and statistical analysis. The core philosophy emphasizes the elimination of inefficiencies while sustaining quality standards. Green Belts possess the expertise to evaluate workflows, identify bottlenecks, and implement data-driven solutions that yield tangible results. They utilize a range of analytical instruments, including process mapping, cause-and-effect diagrams, and control charts, ensuring interventions are both precise and impactful. Unlike superficial operational adjustments, these strategies cultivate long-term resilience and adaptability across organizational systems.

The methodology instills a disciplined mindset focused on measurable outcomes. Lean principles highlight the importance of minimizing waste in all forms, whether time, material, or labor, while Six Sigma frameworks provide statistical rigor to guarantee quality consistency. Professionals trained in CLSSGB techniques approach problems systematically, examining every facet of a process before suggesting improvements. This rigorous approach distinguishes Green Belts from casual problem-solvers, as it emphasizes root cause analysis over temporary fixes. Consequently, organizations benefit from sustainable performance enhancements that extend beyond immediate gains.

Operational Excellence in Manufacturing

Manufacturing environments present abundant opportunities for Lean Six Sigma Green Belts to create value. Production lines often operate under complex constraints, where even minor inefficiencies can amplify costs and delay delivery schedules. Green Belts analyze these operations with meticulous attention, employing statistical process control to detect variations and deviations from standards. By streamlining procedures, eliminating redundant steps, and optimizing material flow, they significantly reduce defect rates. This leads to higher product quality, decreased rework, and enhanced profitability.

Moreover, Green Belts facilitate cross-functional collaboration within manufacturing teams. They coordinate between production, quality assurance, and supply chain departments to ensure that improvements align with overarching organizational objectives. Their interventions often extend to inventory management, equipment utilization, and scheduling practices, yielding comprehensive operational gains. The application of Lean Six Sigma in manufacturing exemplifies how analytical rigor, combined with practical problem-solving, transforms operational landscapes and elevates organizational performance.

Service Industry Transformation

Service-based sectors experience remarkable benefits from Lean Six Sigma Green Belt interventions. Customer-facing workflows, whether in finance, hospitality, or telecommunications, often involve repetitive tasks that are prone to delays or errors. Certified professionals dissect these processes to uncover inefficiencies and bottlenecks that impede service delivery. By reengineering procedures, they reduce processing times, streamline communication, and enhance service consistency. The impact on customer satisfaction is immediate and measurable, reinforcing brand loyalty and reputation.

In addition, Green Belts introduce standardization in service operations. Documentation, procedural guidelines, and workflow templates are refined to minimize variability and ensure reliability. This reduces dependence on individual expertise, allowing teams to maintain high performance despite personnel changes. Furthermore, service organizations benefit from improved reporting mechanisms, enabling management to track performance metrics and adjust strategies proactively. Lean Six Sigma Green Belts thus infuse structure, accountability, and agility into service ecosystems, promoting efficiency without compromising quality.

Enhancing Healthcare Processes

Healthcare is a sector where operational inefficiencies can have profound consequences. Lean Six Sigma Green Belts contribute by applying methodical process improvement techniques to enhance patient safety, reduce errors, and optimize resource allocation. Hospital operations, including patient admissions, medication administration, and diagnostic workflows, are systematically analyzed to identify delays and inconsistencies. The resulting interventions often involve restructuring procedural steps, implementing checklists, and standardizing critical functions to minimize human error.

Green Belts in healthcare also facilitate interdisciplinary collaboration. They work closely with clinicians, administrators, and support staff to design solutions that balance efficiency with patient-centric care. Statistical tools such as control charts and failure mode effect analysis are used to monitor outcomes and ensure continuous improvement. The strategic application of Lean Six Sigma principles within healthcare settings not only elevates operational performance but also enhances patient experiences, improves safety standards, and supports sustainable resource utilization.

Corporate and Administrative Efficiency

Beyond manufacturing and services, Lean Six Sigma Green Belts have profound applications in corporate and administrative functions. Finance, human resources, procurement, and logistics benefit from structured process analysis aimed at reducing errors and streamlining workflows. Green Belts apply tools like process audits, variance analysis, and performance tracking to identify inefficiencies and recommend actionable improvements. These interventions often result in faster transaction cycles, improved data accuracy, and enhanced collaboration across departments.

Administrative projects frequently involve repetitive tasks, complex approvals, or multi-step procedures. Green Belts scrutinize these processes to minimize delays, automate manual functions, and standardize documentation practices. Their insights allow management to allocate resources more effectively, reduce operational costs, and maintain high compliance standards. In essence, Lean Six Sigma Green Belts transform mundane administrative tasks into streamlined, reliable, and measurable processes that contribute to organizational agility and strategic success.

Project Management and Cross-Functional Leadership

Green Belts often serve pivotal roles in project-based environments where coordination across multiple departments is essential. They bring analytical rigor and structured problem-solving to project management, ensuring that initiatives are executed efficiently and achieve intended outcomes. By applying Lean Six Sigma methodologies, Green Belts identify potential risks, anticipate challenges, and implement corrective measures proactively. Their expertise in process mapping, root cause analysis, and data interpretation ensures that projects progress smoothly while maintaining quality and resource efficiency.

Moreover, Green Belts act as internal consultants and change agents, guiding teams through transformation initiatives. They facilitate workshops, mentor colleagues, and embed continuous improvement practices throughout the organization. This leadership extends beyond isolated projects, fostering a culture where teams are empowered to monitor processes, identify improvement opportunities, and implement sustainable solutions. Their influence enhances organizational cohesion, accelerates project delivery, and strengthens the overall capacity for innovation and adaptability in dynamic environments.

Strategic Value and Career Advancement

The strategic value of Lean Six Sigma Green Belts extends beyond immediate operational improvements. Professionals with CLSSGB credentials are recognized as catalysts for efficiency, quality, and innovation within their organizations. Their ability to combine analytical insight with practical application positions them as indispensable contributors to strategic planning and performance optimization. Organizations gain measurable advantages, from cost reductions to enhanced customer experiences, while individuals benefit from elevated career prospects and recognition as process improvement leaders.

Furthermore, Green Belts cultivate a mindset oriented toward continuous learning and adaptability. The analytical frameworks, problem-solving techniques, and collaborative skills acquired through certification prepare professionals to address complex challenges across diverse industries. Whether implementing new workflows, refining service delivery, or leading transformation initiatives, certified Green Belts consistently demonstrate the capacity to translate technical expertise into meaningful organizational impact. Their contributions enhance not only operational efficiency but also the resilience, competitiveness, and long-term sustainability of the organizations they serve.

Lean Six Sigma Green Belt: A Gateway to Strategic Excellence

Lean Six Sigma Green Belt certification represents more than a credential; it is a transformative pathway that empowers professionals to shape the trajectory of their careers. Possessing CLSSGB credentials demonstrates mastery in process optimization, statistical analysis, and project leadership, providing a foundation for individuals to contribute significantly to organizational growth. Unlike other certifications that merely validate knowledge, Lean Six Sigma emphasizes actionable skills that produce tangible results, ensuring that certified individuals are consistently recognized as valuable assets.

The methodology ingrained in Green Belt training equips professionals with the ability to identify inefficiencies, uncover hidden patterns in data, and implement systematic improvements. This skill set transcends routine problem-solving, fostering a mindset of critical thinking and innovation. Professionals learn not only to execute projects effectively but also to understand the strategic implications of their work. They can anticipate challenges, predict outcomes, and design solutions that align with organizational objectives. Such capabilities elevate their professional persona, positioning them as integral contributors to long-term success.

Certified Green Belts also gain a holistic understanding of organizational dynamics. Lean Six Sigma principles encourage collaboration across departments, emphasizing cross-functional teamwork and communication. Individuals become adept at engaging stakeholders, negotiating priorities, and aligning diverse perspectives toward common goals. This comprehensive approach enhances leadership presence, making certified professionals influential in decision-making processes and strategic initiatives. Their insights are often sought after by senior management, reinforcing the credibility and visibility associated with the Green Belt designation.

Operational Efficiency and Measurable Impact

At the heart of Lean Six Sigma Green Belt expertise lies the ability to drive operational efficiency. By leveraging statistical tools and structured methodologies, professionals can identify bottlenecks, reduce waste, and streamline processes in ways that yield measurable results. This focus on practical, data-driven improvement ensures that the contributions of certified individuals are immediately visible and quantifiable, enhancing both organizational performance and personal professional standing.

The systematic approach embedded in Lean Six Sigma involves meticulous data collection, process mapping, and root cause analysis. Certified Green Belts become skilled in dissecting complex workflows, recognizing patterns, and proposing sustainable solutions. This proficiency not only accelerates project completion but also cultivates a culture of continuous improvement within organizations. Colleagues and leadership recognize the tangible benefits, leading to enhanced trust and a reputation for reliability and expertise.

Furthermore, Lean Six Sigma encourages proactive problem prevention rather than reactive intervention. Green Belts are trained to anticipate potential issues, design robust solutions, and monitor key performance indicators consistently. This anticipatory capability reduces errors, mitigates risks, and ensures that improvements are enduring. Professionals who apply these methods gain a distinct advantage, as they are capable of delivering results that extend beyond the immediate scope of projects and influence long-term organizational efficiency.

The economic ramifications of these improvements are significant. Streamlined processes reduce operational costs, minimize resource wastage, and optimize productivity. Organizations frequently recognize this value through enhanced compensation, performance incentives, and promotion opportunities for certified Green Belts. Thus, Lean Six Sigma certification not only enriches professional expertise but also generates tangible financial benefits, reinforcing the importance of strategic operational contributions.

Career Mobility and Versatility

One of the most compelling aspects of Lean Six Sigma Green Belt certification is its versatility across industries and roles. Unlike technical certifications confined to a specific domain, CLSSGB credentials offer a transferable skill set applicable in manufacturing, healthcare, finance, information technology, logistics, and beyond. This flexibility empowers professionals to navigate diverse career pathways and adapt to evolving market demands with confidence.

Certified Green Belts often discover opportunities to pivot into roles such as operations management, business analysis, quality assurance, process consulting, and project leadership. The skill set acquired through training equips them to manage teams, lead improvement projects, and contribute to strategic planning regardless of organizational sector. This mobility fosters professional resilience, enabling individuals to pursue roles that align with personal interests, career ambitions, and geographic preferences.

The adaptability inherent in Lean Six Sigma also enhances employability. Organizations increasingly seek professionals who can implement systemic improvements, reduce inefficiencies, and provide actionable insights. A Green Belt certification signals the presence of these capabilities, elevating candidates above peers who lack formal training. In a competitive labor market, this distinction is crucial, granting certified professionals access to higher-level roles, leadership tracks, and cross-functional assignments.

Moreover, the global applicability of Lean Six Sigma principles extends career potential internationally. Professionals familiar with standardized methodologies can collaborate across borders, implement best practices in multinational organizations, and participate in global projects. This dimension of career mobility underscores the enduring relevance of Green Belt credentials and positions individuals to seize opportunities that transcend geographic limitations.

Analytical Proficiency and Data-Driven Decision Making

Lean Six Sigma Green Belt certification places a strong emphasis on analytical rigor and data-driven decision-making. Professionals are trained to employ a variety of statistical tools, process metrics, and performance indicators to identify inefficiencies and drive improvements. This emphasis on quantifiable evidence ensures that solutions are objective, reliable, and sustainable, establishing a foundation for credible and influential professional contributions.

Green Belts develop expertise in techniques such as root cause analysis, process mapping, control charts, and hypothesis testing. These tools allow for detailed examination of workflows, accurate measurement of performance, and identification of areas requiring intervention. The ability to transform raw data into actionable insights distinguishes certified individuals as proficient problem solvers who rely on empirical evidence rather than intuition or guesswork.

The application of analytical skills also strengthens strategic thinking. Professionals can assess potential risks, forecast outcomes, and design processes that align with long-term organizational goals. Their recommendations carry weight because they are backed by measurable evidence, enhancing confidence among stakeholders and reinforcing credibility. This analytical approach cultivates a reputation for precision, reliability, and insight, traits highly valued in managerial and executive roles.

Data-driven decision-making further promotes a culture of continuous improvement. By monitoring results and tracking trends over time, Green Belts can refine processes, implement incremental enhancements, and sustain operational excellence. This iterative approach demonstrates not only technical competence but also a commitment to ongoing learning and adaptability, key factors in long-term career growth.

Leadership Development and Influence

Beyond technical skills, Lean Six Sigma Green Belt certification fosters leadership development. Professionals are trained to lead cross-functional teams, manage projects, and influence organizational culture. This aspect of the certification underscores the interplay between process improvement and strategic leadership, highlighting the capacity of Green Belts to shape organizational outcomes beyond individual tasks.

Certified Green Belts learn to communicate effectively with diverse teams, navigate complex organizational dynamics, and motivate colleagues toward shared objectives. They are equipped to translate technical findings into practical recommendations that resonate with both operational staff and executive leadership. This dual capability—technical acumen combined with persuasive communication—enhances influence and positions Green Belts as integral contributors to organizational success.

The leadership component of Lean Six Sigma also involves fostering accountability and ownership. Professionals guide teams through structured problem-solving, establish clear goals, and ensure that improvements are measurable and sustainable. This approach cultivates respect, credibility, and trust, qualities that naturally lead to expanded responsibilities and opportunities for advancement. Leadership, in this context, is both a skill set and a professional identity that amplifies the impact of Green Belt certification.

Strategic leadership extends beyond immediate project management. Certified individuals often advise senior management on operational strategies, resource allocation, and risk mitigation. Their insights help shape policies and processes that drive long-term success, demonstrating the value of combining analytical proficiency with leadership capabilities. The Green Belt thus serves as a bridge between operational execution and organizational strategy, enhancing both professional visibility and influence.

Lifelong Learning and Professional Growth

Lean Six Sigma Green Belt certification instills a commitment to lifelong learning and professional growth. The methodologies taught encourage continuous engagement with process improvement initiatives, ongoing education, and adaptation to emerging industry trends. This mindset nurtures professional resilience and ensures that certified individuals remain relevant in dynamic work environments.

Green Belts are encouraged to pursue advanced certification levels, explore new analytical tools, and apply innovative solutions to evolving challenges. This proactive approach to professional development fosters adaptability, creativity, and problem-solving expertise. Organizations recognize the value of employees who demonstrate both technical proficiency and a dedication to personal growth, often providing additional opportunities, mentorship roles, and career advancement as a result.

The culture of continuous learning also extends to soft skills, including communication, collaboration, and strategic thinking. Professionals who integrate these skills with technical capabilities become well-rounded contributors capable of navigating complex organizational landscapes. This combination enhances employability, professional credibility, and long-term career sustainability.

In addition, the personal satisfaction derived from mastering Lean Six Sigma principles reinforces motivation and engagement. Green Belts experience a sense of accomplishment as they implement effective solutions, witness measurable improvements, and contribute to organizational success. This intrinsic reward strengthens commitment, nurtures confidence, and sustains enthusiasm for ongoing professional challenges.

Financial and Strategic Advantages

Obtaining a Lean Six Sigma Green Belt yields significant financial and strategic benefits. Certified professionals frequently experience enhanced earning potential, including higher salaries, performance bonuses, and career advancement incentives. Organizations recognize the measurable value of process improvements, quality enhancements, and efficiency gains facilitated by Green Belts, translating these contributions into tangible rewards.

The strategic advantages of certification are equally compelling. Certified individuals are often positioned to influence decision-making, optimize resource utilization, and contribute to the development of organizational policies. Their ability to implement systemic improvements with measurable impact strengthens both operational and strategic performance. This dual contribution reinforces the professional reputation of Green Belts as indispensable members of the workforce.

Moreover, the financial and strategic benefits are interrelated. Organizations that leverage Lean Six Sigma expertise gain a competitive edge through cost reduction, improved quality, and enhanced customer satisfaction. Professionals who deliver these outcomes are recognized and rewarded, creating a virtuous cycle of career growth, financial gain, and organizational improvement. The investment in certification is thus reciprocated through both tangible and intangible returns, solidifying its value as a career-defining credential.

Conclusion

Lean Six Sigma Green Belt certification is more than a professional credential; it is a gateway to transformative career growth and organizational impact. By equipping professionals with analytical rigor, process optimization skills, and leadership capabilities, CLSSGB empowers individuals to deliver measurable improvements and drive strategic initiatives. The certification enhances employability, broadens career opportunities, and cultivates a mindset of continuous improvement that is invaluable in today’s competitive landscape.

Professionals who attain this certification gain a distinctive edge, demonstrating the ability to navigate complex challenges, foster collaboration, and influence organizational success. Beyond technical expertise, Green Belts develop critical thinking, effective communication, and project management skills, positioning them for long-term advancement and leadership roles.

In essence, Lean Six Sigma Green Belt certification bridges the gap between knowledge and practical impact. It enables professionals to contribute meaningfully to their organizations while accelerating personal career trajectories. For anyone seeking to stand out, achieve operational excellence, and embrace a path of continuous growth, CLSSGB certification serves as a strategic, empowering, and career-defining milestone.

Frequently Asked Questions

How does your testing engine works?

Once download and installed on your PC, you can practise test questions, review your questions & answers using two different options 'practice exam' and 'virtual exam'. Virtual Exam - test yourself with exam questions with a time limit, as if you are taking exams in the Prometric or VUE testing centre. Practice exam - review exam questions one by one, see correct answers and explanations).

How can I get the products after purchase?

All products are available for download immediately from your Member's Area. Once you have made the payment, you will be transferred to Member's Area where you can login and download the products you have purchased to your computer.

How long can I use my product? Will it be valid forever?

Pass4sure products have a validity of 90 days from the date of purchase. This means that any updates to the products, including but not limited to new questions, or updates and changes by our editing team, will be automatically downloaded on to computer to make sure that you get latest exam prep materials during those 90 days.

Can I renew my product if when it's expired?

Yes, when the 90 days of your product validity are over, you have the option of renewing your expired products with a 30% discount. This can be done in your Member's Area.

Please note that you will not be able to use the product after it has expired if you don't renew it.

How often are the questions updated?

We always try to provide the latest pool of questions, Updates in the questions depend on the changes in actual pool of questions by different vendors. As soon as we know about the change in the exam question pool we try our best to update the products as fast as possible.

How many computers I can download Pass4sure software on?

You can download the Pass4sure products on the maximum number of 2 (two) computers or devices. If you need to use the software on more than two machines, you can purchase this option separately. Please email sales@pass4sure.com if you need to use more than 5 (five) computers.

What are the system requirements?

Minimum System Requirements:

- Windows XP or newer operating system

- Java Version 8 or newer

- 1+ GHz processor

- 1 GB Ram

- 50 MB available hard disk typically (products may vary)

What operating systems are supported by your Testing Engine software?

Our testing engine is supported by Windows. Andriod and IOS software is currently under development.